Introduction

Maximizing efficiency in the equipment manufacturing sector is super important, right? Well, proposal CPQ (Configure, Price, Quote) solutions are stepping up as game-changers in this space. These systems not only make the quoting process smoother but also boost accuracy and customer satisfaction. This means manufacturers can respond quickly to what the market needs. But here’s the kicker: implementing CPQ solutions comes with its own challenges.

So, how can manufacturers make sure they’re using these tools effectively to ramp up productivity and stay ahead of the competition?

Understand CPQ Systems and Their Role in Equipment Manufacturing

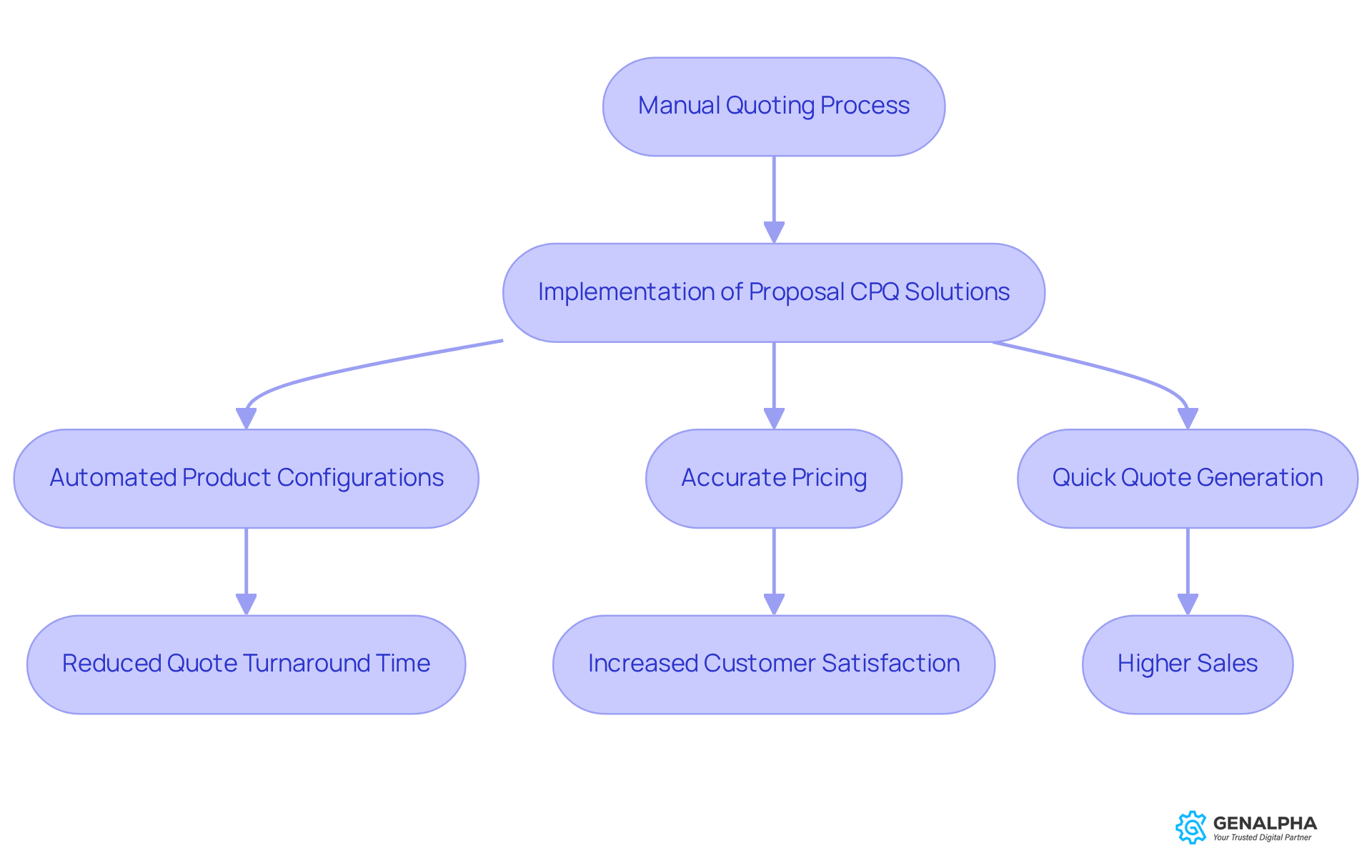

Have you ever found yourself bogged down in the quoting process? Well, that’s where proposal CPQ solutions come into play! These tools are game-changers for equipment producers, designed to streamline the quoting process with the proposal CPQ by automating everything from product configurations to pricing and quote generation.

Imagine cutting down the time spent on manual quoting, which often leads to mistakes and inefficiencies. With proposal CPQ solutions, sales teams can quickly create accurate quotes tailored to customer needs, while adhering to pricing guidelines and product configurations. This not only speeds up the sales cycle - shortening it by about a third, from 4.68 months to 3.42 months - but also boosts customer satisfaction by delivering timely and precise quotes.

For instance, one producer that embraced a proposal CPQ solution experienced a remarkable 30% reduction in quote turnaround time. That’s right - higher sales and better customer relationships all thanks to quicker quotes! Plus, companies using proposal CPQ generate 49% more offers compared to those that don’t, showcasing just how effective these solutions are at creating more opportunities.

Looking ahead to 2025, the integration of AI into proposal CPQ systems is set to elevate quoting processes, allowing producers to respond to customer needs faster and more accurately than ever. But here’s a heads-up: implementing CPQ isn’t without its challenges, so careful planning is key to ensuring success.

The proposal CPQ market is experiencing growth, with projections suggesting it could reach or even exceed the $7 billion mark by 2030. This growth reflects the increasing reliance on these solutions in business operations. So, are you ready to explore how CPQ can transform your quoting process?

Implement Proposal Automation to Enhance Efficiency and Accuracy

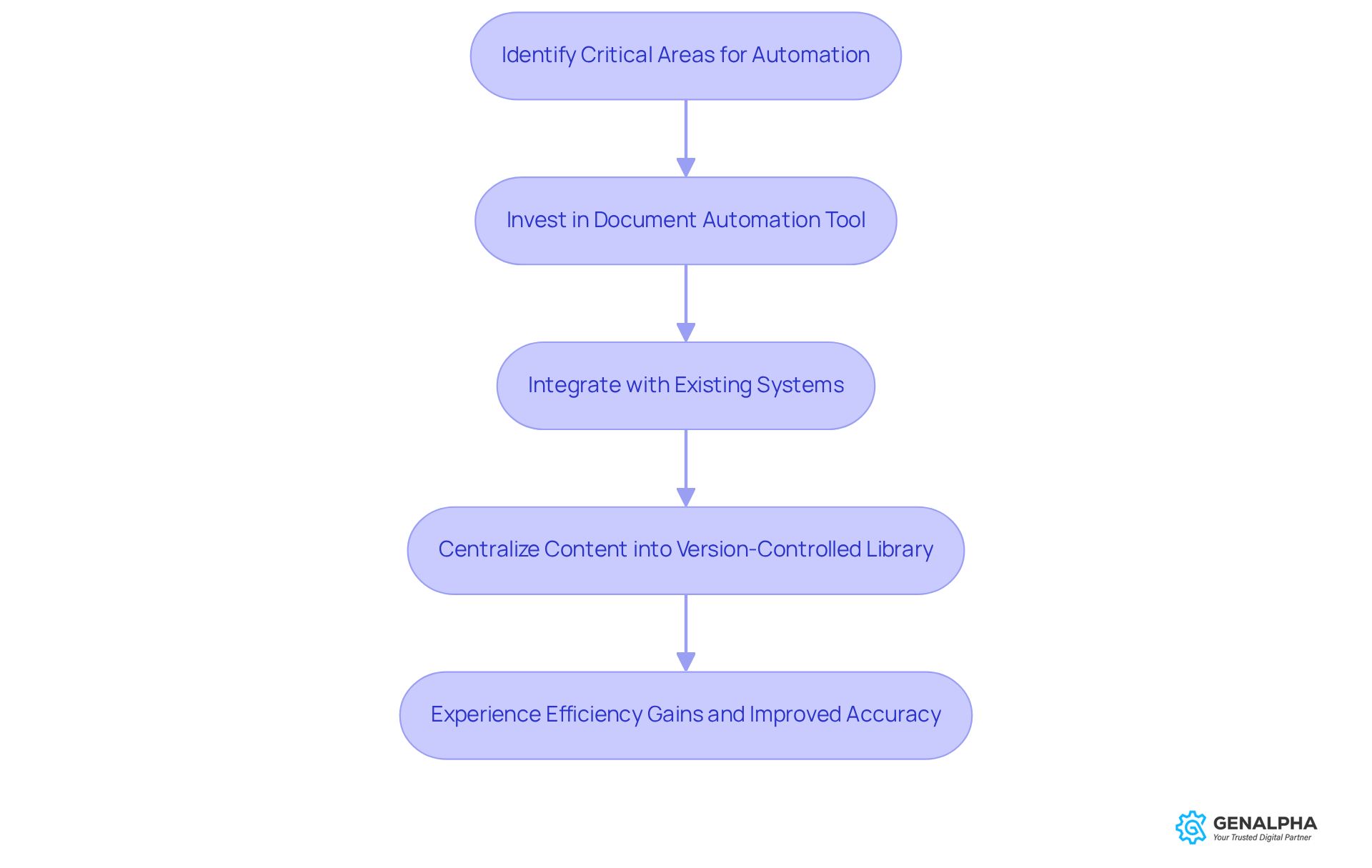

Have you ever thought about how automation could change the game for equipment producers? Imagine cutting down the time it takes to handle quotes and submissions by utilizing a proposal cpq. By using software that automates those repetitive tasks - like data entry and formatting - producers can really speed things up. For instance, one well-known equipment producer managed to slash their preparation time for submissions by an impressive 50% after they embraced automation.

Most companies notice some solid time savings within just the first month of using automation for proposal cpq. This means their sales teams can shift their focus to strategic selling, all while boosting accuracy and reducing human error. So, how do you get started with automating submissions? First off, manufacturers should pinpoint those critical areas in their current processes that tend to be both time-consuming and prone to mistakes.

Investing in a robust document automation tool that fits seamlessly with existing systems can lead to some serious efficiency gains and happier customers. Plus, companies that centralize their content into a version-controlled library often report quicker turnaround times and better brand consistency. This really shows how automation can enhance overall operational effectiveness. As Mearas puts it, 'Integrated proposal cpq software ensures branded, customized documents are generated instantly, enhancing the customer’s journey.'

So, are you ready to explore how automation can transform your quoting process?

Integrate CPQ with ERP Systems for Streamlined Operations

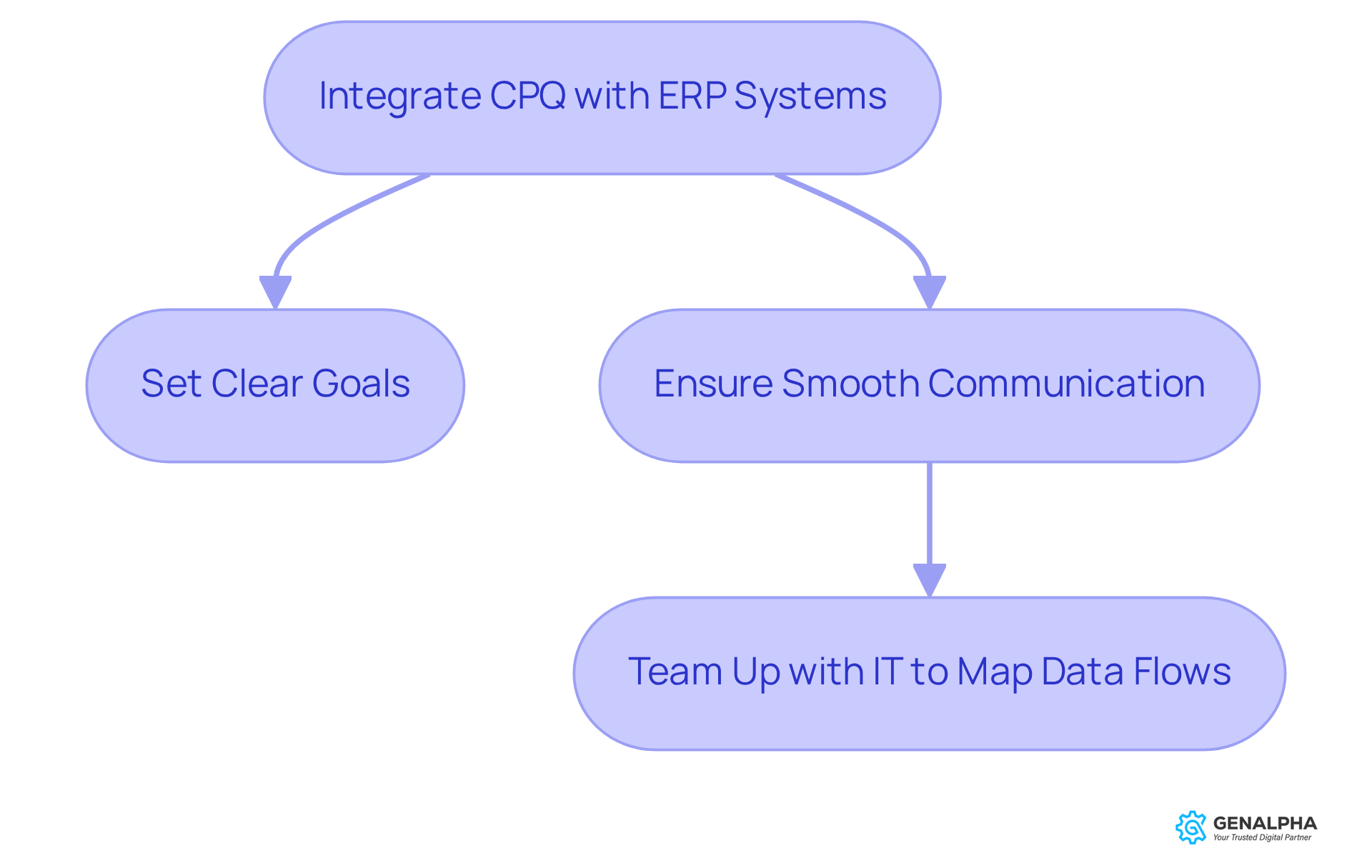

Are we combining ERP solutions with proposal CPQ platforms? That’s a smart move for equipment producers looking to boost their operational efficiency! Imagine this: real-time data syncing between sales and production, making sure all product configurations and pricing are spot on across the board. For instance, one producer that linked its CPQ with its ERP saw a 20% jump in order accuracy and a significant drop in order processing times.

So, how can you achieve this effective integration? Start by:

- Setting clear goals

- Ensuring both systems can communicate smoothly

This might mean teaming up with your IT folks to map out data flows and set up protocols for data updates. By tapping into the strengths of both CPQ and ERP systems, the proposal CPQ can help you build a more cohesive and efficient operational framework. Ready to take the plunge?

Leverage Analytics for Data-Driven Proposal Optimization

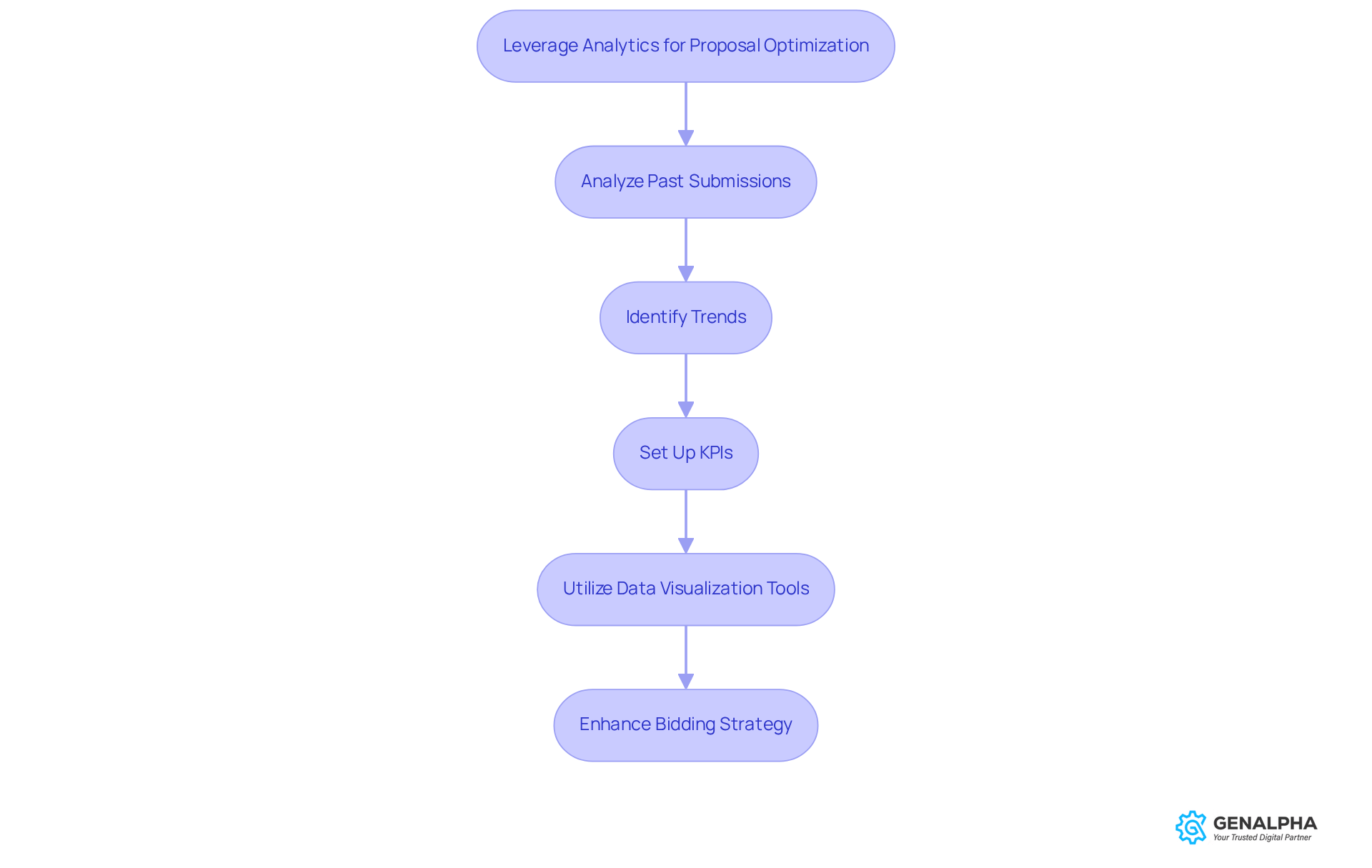

Using analytics in the bidding process can really help equipment producers make smarter choices that boost their bid effectiveness. Have you ever thought about how looking back at past submissions could reveal trends in what customers prefer? By analyzing this data, producers can spot pricing strategies and key components that work well. For example, one producer who embraced analytics found that bids featuring specific product features had a whopping 40% higher success rate!

So, how can producers tap into the power of analytics? First off, it’s crucial to set up key performance indicators (KPIs) to keep track of how submissions are doing. And don’t forget about data visualization tools - they can provide valuable insights into submission performance. Regularly checking this data can really help manufacturers fine-tune their proposal CPQ strategies, keeping them competitive in a fast-changing market.

What do you think? Are you ready to start leveraging analytics to enhance your bidding process?

Conclusion

Embracing proposal CPQ solutions is a game-changer for equipment manufacturers who want to level up their quoting processes and boost operational efficiency. Imagine automating those tedious quoting tasks, seamlessly integrating with ERP systems, and tapping into analytics. Sounds great, right? This approach can really enhance accuracy, cut down turnaround times, and ultimately make your customers happier. The magic of CPQ lies in its ability to streamline operations and open up new avenues for sales growth.

Throughout this article, we’ve highlighted some key practices that can help you maximize the potential of proposal CPQ:

- Understanding CPQ systems

- Implementing proposal automation

- Integrating CPQ with ERP

- Utilizing analytics

Each of these practices contributes to a smoother workflow, allowing manufacturers to respond quickly to customer needs while keeping errors at bay. The stats we shared show just how beneficial these strategies can be, like reducing quote preparation time and boosting bid success rates.

As the equipment manufacturing landscape keeps evolving, adopting these best practices is crucial for staying ahead of the competition. So, what are you waiting for? It’s time for equipment manufacturers to take proactive steps toward integrating CPQ solutions into their operations. By doing this, you’re not just enhancing your quoting processes; you’re also setting yourself up for sustainable growth in an increasingly data-driven market. Let’s get started!

Frequently Asked Questions

What is a CPQ system and its purpose in equipment manufacturing?

A CPQ (Configure, Price, Quote) system is a tool designed to streamline the quoting process for equipment manufacturers by automating product configurations, pricing, and quote generation.

How does a proposal CPQ solution improve the quoting process?

Proposal CPQ solutions reduce the time spent on manual quoting, minimize mistakes, and improve efficiency, allowing sales teams to create accurate quotes tailored to customer needs quickly.

What impact does using a proposal CPQ solution have on the sales cycle?

Implementing a proposal CPQ solution can shorten the sales cycle by about a third, reducing the average time from 4.68 months to 3.42 months.

Can you provide an example of the benefits of a proposal CPQ solution?

One producer that adopted a proposal CPQ solution saw a 30% reduction in quote turnaround time, leading to higher sales and improved customer relationships.

How does the use of proposal CPQ solutions affect the number of offers generated?

Companies using proposal CPQ solutions generate 49% more offers compared to those that do not use these systems, indicating their effectiveness in creating more business opportunities.

What future developments are expected in proposal CPQ systems?

By 2025, the integration of AI into proposal CPQ systems is anticipated to enhance quoting processes, enabling producers to respond to customer needs more quickly and accurately.

What challenges might companies face when implementing CPQ systems?

Implementing CPQ systems can come with challenges, making careful planning essential for ensuring successful integration and operation.

What is the projected growth of the proposal CPQ market?

The proposal CPQ market is expected to grow significantly, with projections suggesting it could reach or exceed $7 billion by 2030, reflecting its increasing importance in business operations.