Introduction

The manufacturing world today is a bit of a puzzle, isn’t it? With so many customizable options for products, it can feel overwhelming. That’s where Configure, Price, Quote (CPQ) software comes into play. Think of it as your trusty sidekick, helping to streamline product configuration, ensure pricing accuracy, and generate quotes efficiently. By using CPQ solutions, manufacturers can really boost their sales efficiency and keep customers happy.

But here’s the kicker: implementing CPQ isn’t always a walk in the park. How can manufacturers make sure they choose and integrate the right solution to truly reap the rewards?

Let’s dive into this together!

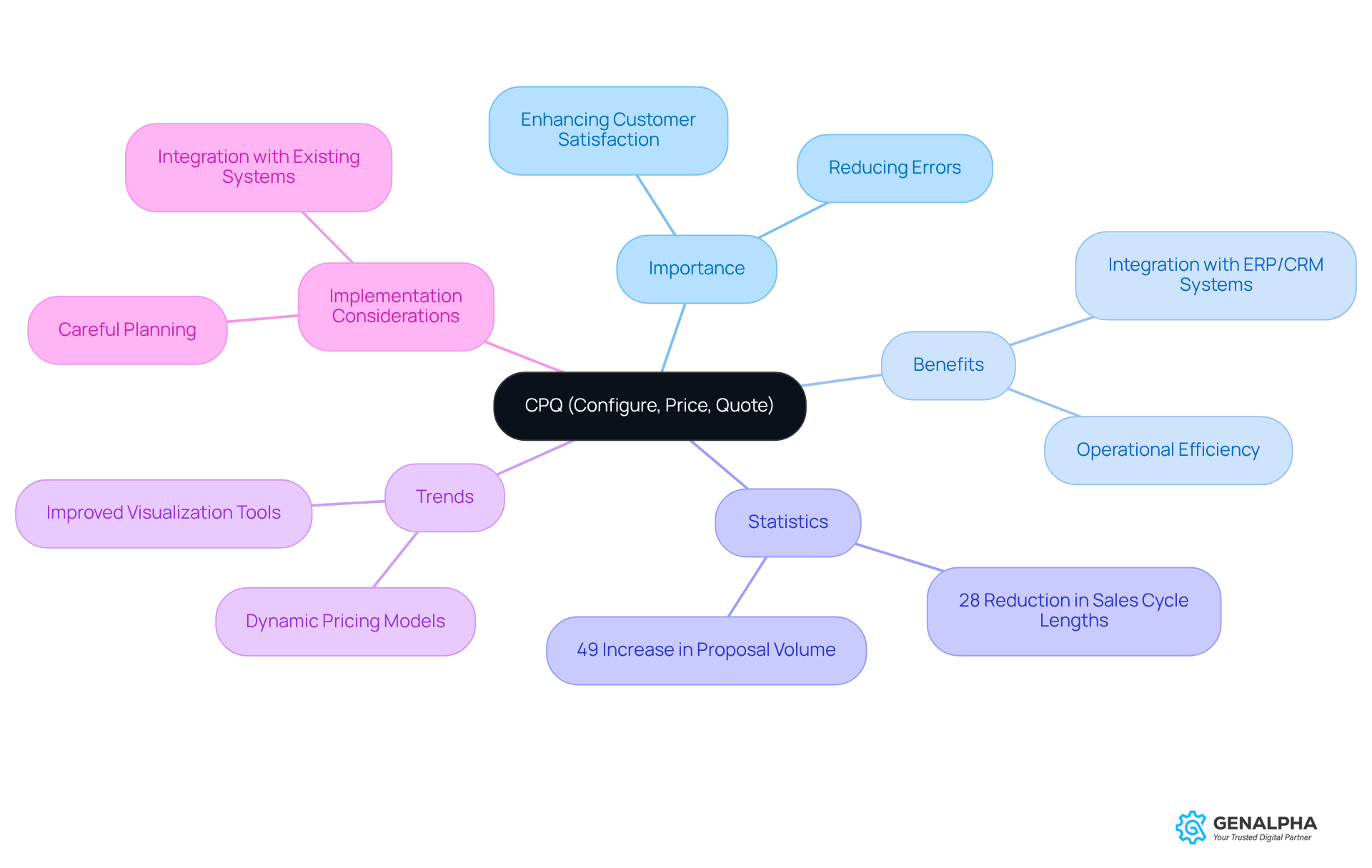

Define CPQ and Its Importance for Complex Products

Have you ever felt overwhelmed by the complexity of configuring products? That’s where CPQ, or Configure, Price, Quote, comes into play! It’s a game-changer for manufacturers, allowing them to use CPQ for complex products, which makes it easier to configure intricate products, set accurate pricing, and generate quotes quickly and efficiently. In the manufacturing world, where products often come with a ton of customizable options, CPQ tools are vital. They empower sales teams to meet client needs swiftly and accurately.

By automating these processes, CPQ helps reduce the errors that often come with manual quoting methods. This not only boosts customer satisfaction but also builds trust. Plus, CPQ solutions seamlessly integrate with existing ERP and CRM systems, providing real-time data that supports informed decision-making and enhances operational efficiency.

Did you know that organizations using CPQ solutions see a 28% reduction in sales cycle lengths and a whopping 49% increase in proposal volume per representative? That’s according to the Aberdeen Group, and it really highlights how CPQ for complex products can enhance sales efficiency in manufacturing.

As the manufacturing landscape evolves, the latest trends in CPQ for complex products emphasize dynamic pricing models and improved visualization tools. These innovations make the quoting process even simpler and enhance client engagement. However, it’s crucial for manufacturers to be mindful of potential pitfalls when implementing CPQ. Careful planning and integration with existing systems are key to avoiding operational hiccups.

So, are you ready to explore how CPQ can streamline your sales process? Let’s dive in!

Identify Key Benefits of CPQ for Manufacturing Efficiency

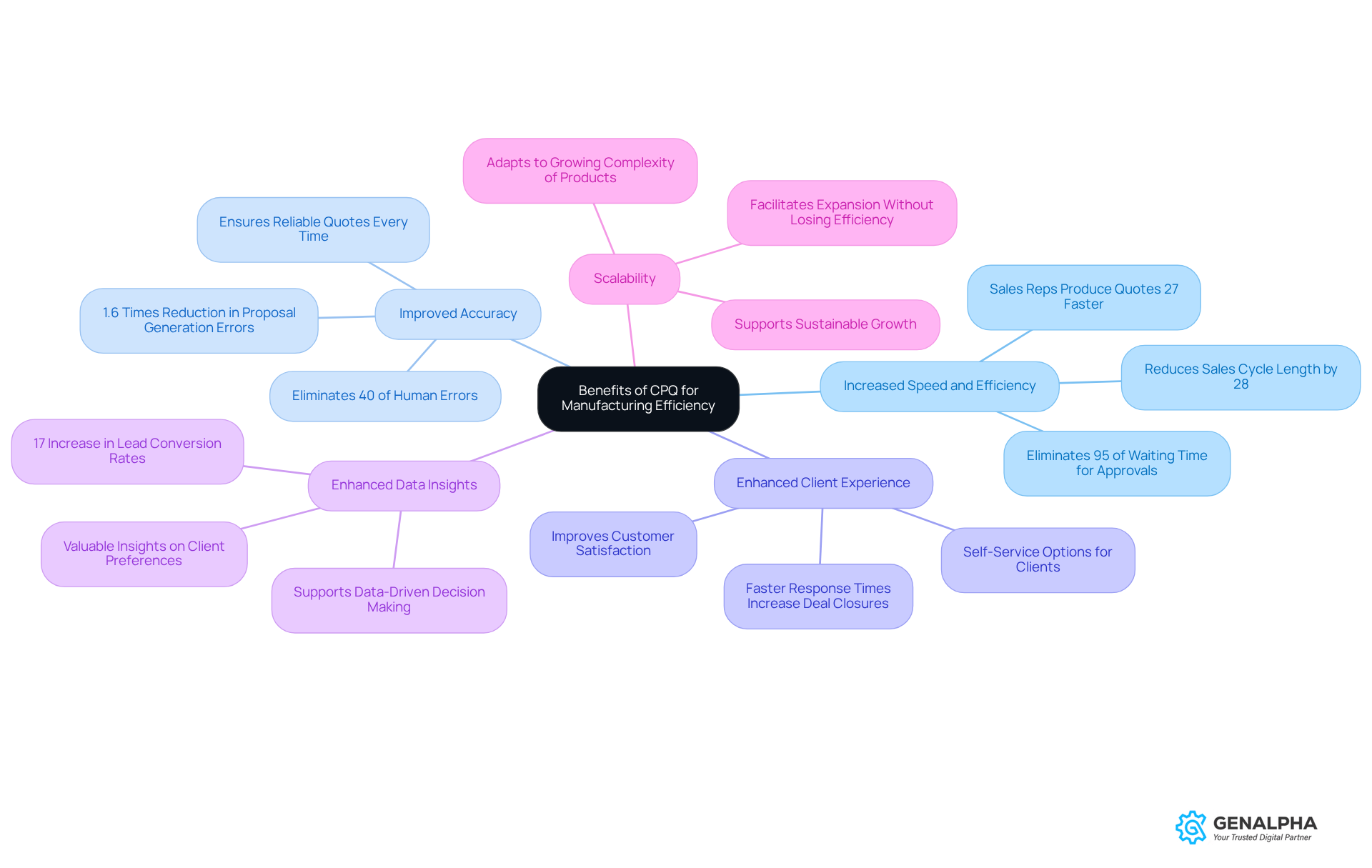

Implementing a CPQ solution brings a bunch of great benefits for manufacturers. Let’s dive into a few of them:

-

Increased Speed and Efficiency: Imagine being able to whip up quotes in no time! CPQ automates the quoting process, which means sales teams can respond to client inquiries faster. This boost in speed not only helps close deals quicker but also keeps clients happy. In fact, CPQ software has been shown to cut cycle times by an impressive 28%!

-

Improved Accuracy: Nobody likes mistakes, especially when it comes to pricing. By automating pricing and configuration, CPQ helps reduce those pesky human errors that can lead to costly blunders. Accurate quotes mean clients get the right pricing and product specs, building trust along the way. As Kristina Parren puts it, "CPQ is designed to remove human error from the equation by delivering accurate quotes you can rely on every time." Plus, it can eliminate up to 40% of human errors, which is a game-changer for sales outcomes.

-

Enhanced Client Experience: Who doesn’t want a smoother purchasing process? With quicker and more accurate quotes, clients can enjoy a hassle-free experience. CPQ solutions even offer self-service options, letting clients configure products and get quotes on their own. This is a big win, especially with the growing demand for instant service these days.

-

Enhanced Data Insights: CPQ systems are like treasure troves of information! They gather valuable insights on client preferences and transaction trends, helping manufacturers make smart, data-driven decisions. Businesses using CPQ software see a 17% boost in lead conversion rates, which is crucial for adapting to changing market needs and refining sales strategies.

-

Scalability: As your business grows, you want solutions that can keep up, right? CPQ for complex products easily adapts to the growing complexity of product offerings and customer demands. This scalability means manufacturers can expand operations without losing efficiency, making CPQ for complex products an essential tool for sustainable growth.

So, are you ready to explore how a CPQ solution can transform your business? Let’s chat!

Select and Integrate the Right CPQ Solution

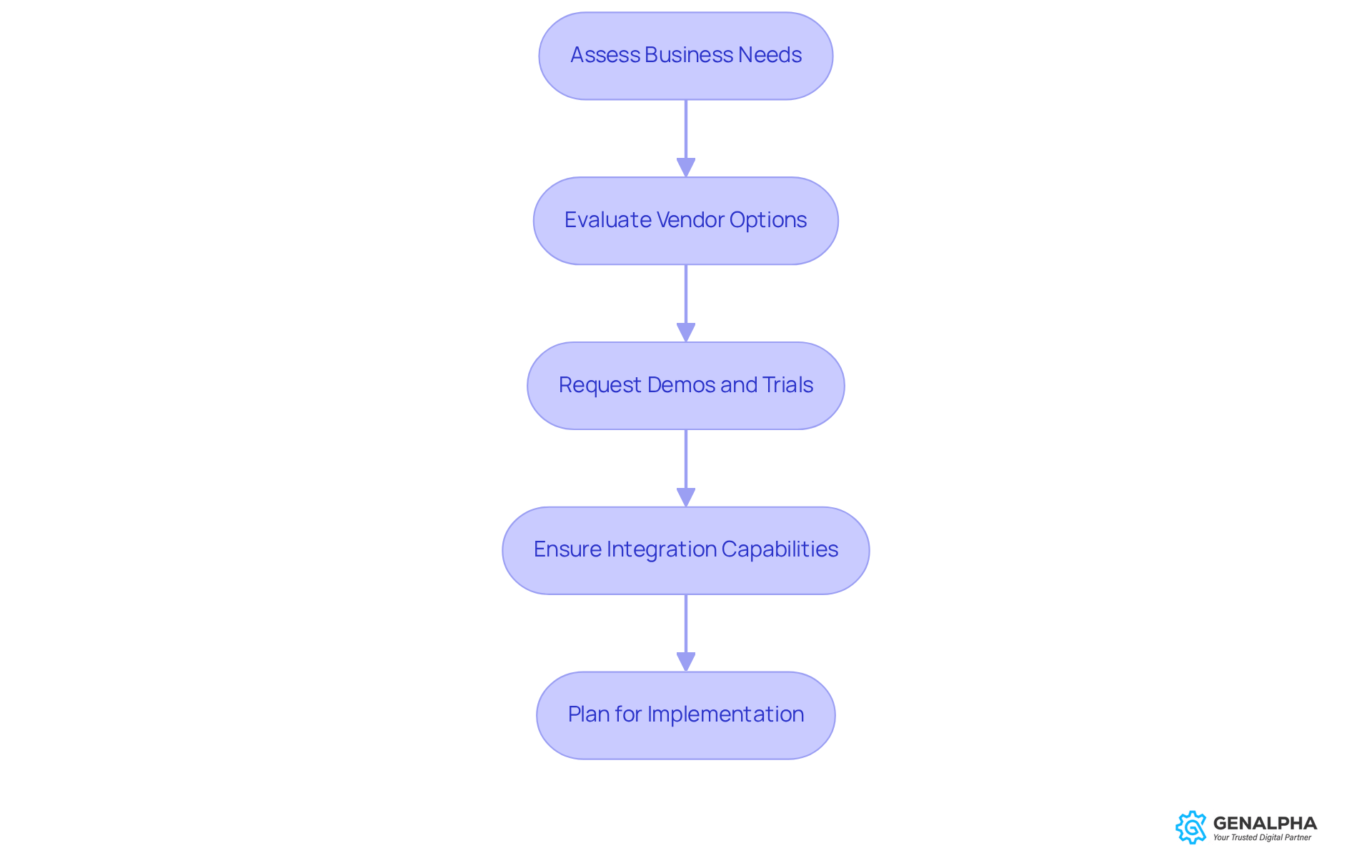

When you're on the hunt for a CPQ solution, there are a few steps you might want to keep in mind:

-

Assess Business Needs: First off, think about the specific challenges and requirements of your sales process. What’s the product complexity like? What pricing models do you have? And how does it all fit with your current systems?

-

Evaluate Vendor Options: Next, do a little research on various CPQ vendors and what they offer. Look for those with a solid track record in the manufacturing sector and CPQ for complex products that truly resonate with your business needs.

-

Request Demos and Trials: Before you make any decisions, why not ask for some demos and trial periods from potential vendors? Getting hands-on experience can really help you gauge how user-friendly and functional the CPQ platform is.

-

Ensure Integration Capabilities: It’s also super important to check that the CPQ solution can connect with your existing ERP and CRM platforms. Seamless integration is key to keeping your data consistent and your operations running smoothly.

-

Plan for Implementation: Finally, take the time to develop a clear implementation plan. This should include timelines, resource allocation, and training for your staff. A well-structured rollout can make all the difference in ensuring a smooth adoption and minimizing disruptions to your ongoing operations.

Implement Training and Change Management Strategies

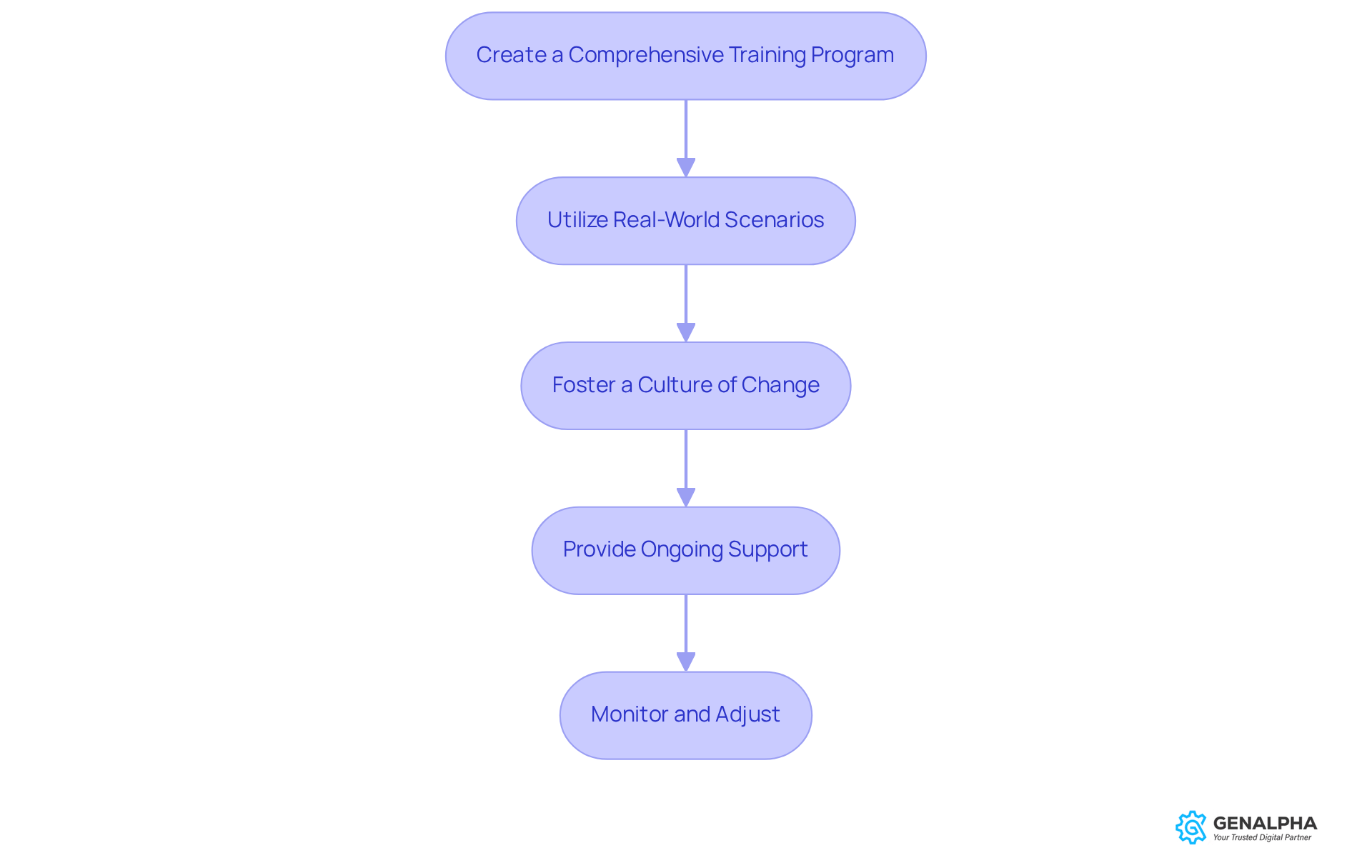

To make sure everyone gets on board with a CPQ solution, manufacturers should think about these training and change management strategies:

-

Create a Comprehensive Training Program: Start by designing a training curriculum that meets the unique needs of different user roles - think representatives, pricing analysts, and administrators. When training is tailored, it boosts user confidence and skills, leading to a more effective use of CPQ for complex products and better sales efficiency.

-

Utilize Real-World Scenarios: Why not spice up training sessions with real-world examples? This helps users see how the CPQ tool fits into their daily tasks. A hands-on approach not only makes the information stick but also prepares users for the challenges they’ll face in real life.

-

Foster a Culture of Change: It’s important to keep the lines of communication open about the benefits of CPQ for complex products. Address any worries or pushback from employees - like fears of job loss or increased workload. Involving key stakeholders in the change management process can really help generate enthusiasm and encourage broader acceptance of the new approach.

-

Provide Ongoing Support: After implementation, set up a solid support system for users. This could mean access to help desks, online resources, and regular check-ins to tackle challenges as they pop up. It’s all about making sure users feel supported throughout their transition.

-

Monitor and Adjust: Keep an eye on how the adoption process is going and gather feedback from users. Be ready to tweak training and support strategies based on what users experience and need as things evolve. This way, the implementation of CPQ for complex products remains effective and aligned with your organizational goals.

Conclusion

Maximizing efficiency in manufacturing with CPQ (Configure, Price, Quote) solutions isn’t just a trend; it’s a must for businesses handling complex products. Think about it: automating the quoting process means smoother operations, fewer errors, and a better experience for customers. This tech gives sales teams the power to deliver accurate and timely quotes, which builds trust and satisfaction with clients.

Let’s dive into some key benefits of CPQ. You’ll find:

- Increased speed and efficiency

- Improved accuracy

- Enhanced client experiences

- Valuable data insights

- Scalability

Each of these perks is crucial for transforming how manufacturers work, helping them keep up with market demands while maintaining top-notch service. Plus, the steps for choosing and integrating the right CPQ solution, along with effective training and change management strategies, really highlight how important thoughtful implementation is.

As the manufacturing landscape keeps changing, embracing CPQ solutions is essential to stay competitive. By investing in the right tools and training, manufacturers can not only streamline their internal processes but also deliver exceptional value to their clients. So, why wait? Now’s the time to leverage CPQ technology for significant advancements in efficiency and customer satisfaction, paving the way for sustainable growth in the future.

Frequently Asked Questions

What does CPQ stand for and what is its purpose?

CPQ stands for Configure, Price, Quote. Its purpose is to help manufacturers configure complex products, set accurate pricing, and generate quotes quickly and efficiently.

Why is CPQ important for manufacturers?

CPQ is important for manufacturers because it simplifies the process of configuring intricate products, reduces errors associated with manual quoting, and enhances customer satisfaction by allowing sales teams to meet client needs swiftly and accurately.

How does CPQ improve operational efficiency?

CPQ improves operational efficiency by automating the quoting process and integrating seamlessly with existing ERP and CRM systems, providing real-time data that supports informed decision-making.

What are the benefits of using CPQ solutions according to the Aberdeen Group?

Organizations using CPQ solutions experience a 28% reduction in sales cycle lengths and a 49% increase in proposal volume per representative, highlighting enhanced sales efficiency in manufacturing.

What are the latest trends in CPQ for complex products?

The latest trends in CPQ for complex products emphasize dynamic pricing models and improved visualization tools, making the quoting process simpler and enhancing client engagement.

What should manufacturers consider when implementing CPQ?

Manufacturers should be mindful of potential pitfalls when implementing CPQ and ensure careful planning and integration with existing systems to avoid operational hiccups.