Introduction

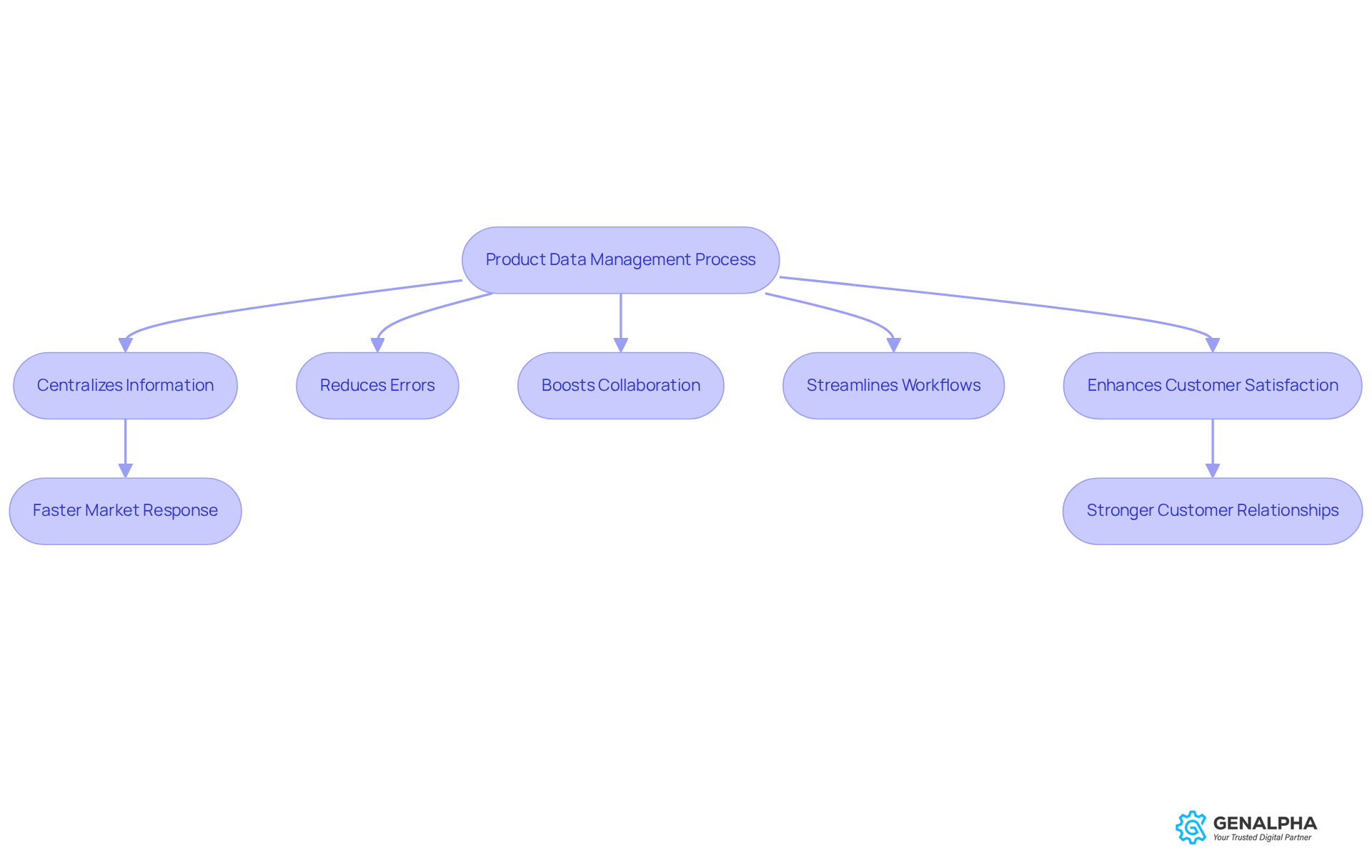

Mastering the product data management (PDM) process is crucial for equipment manufacturers who want to stand out in a competitive market. Imagine being able to centralize all your product information - sounds great, right? By doing this, manufacturers can cut down on errors, boost collaboration, and speed up time-to-market. All of this leads to happier customers!

But let’s be real: implementing a solid PDM system isn’t a walk in the park. There are plenty of hurdles to jump over, from pesky information silos to getting users on board. So, how can manufacturers tackle these challenges and truly harness the power of their product data management processes?

Let’s dive in and explore some strategies together!

Define Product Data Management (PDM) and Its Importance

Have you ever thought about how product information flows from design to production and beyond? That’s where Product Information Management (PIM) comes in. It’s a structured way to manage all that product-related info throughout its lifecycle in the product data management process. For equipment manufacturers, a solid product data management process is crucial. It centralizes all item information, making sure everything is accurate and easy to access.

Imagine reducing errors and boosting collaboration across departments - sounds great, right? That’s exactly what a robust product data management process can accomplish. It streamlines workflows and automates the product data management process, allowing you to get new products to market faster. And let’s be honest, in today’s fast-paced world, being able to react quickly to market needs is a game changer.

But it doesn’t stop there. This centralized approach not only makes your internal product data management process more efficient but also enhances customer satisfaction. When customers have access to accurate product information, their purchasing experience becomes much smoother. As industry leaders often point out, organizations that effectively utilize the product data management process can significantly reduce risks associated with incorrect information. This ultimately leads to stronger customer relationships and promotes growth.

So, why not consider how PDM could transform your operations? It might just be the key to unlocking your business’s potential!

Identify Key Components of an Effective PDM System

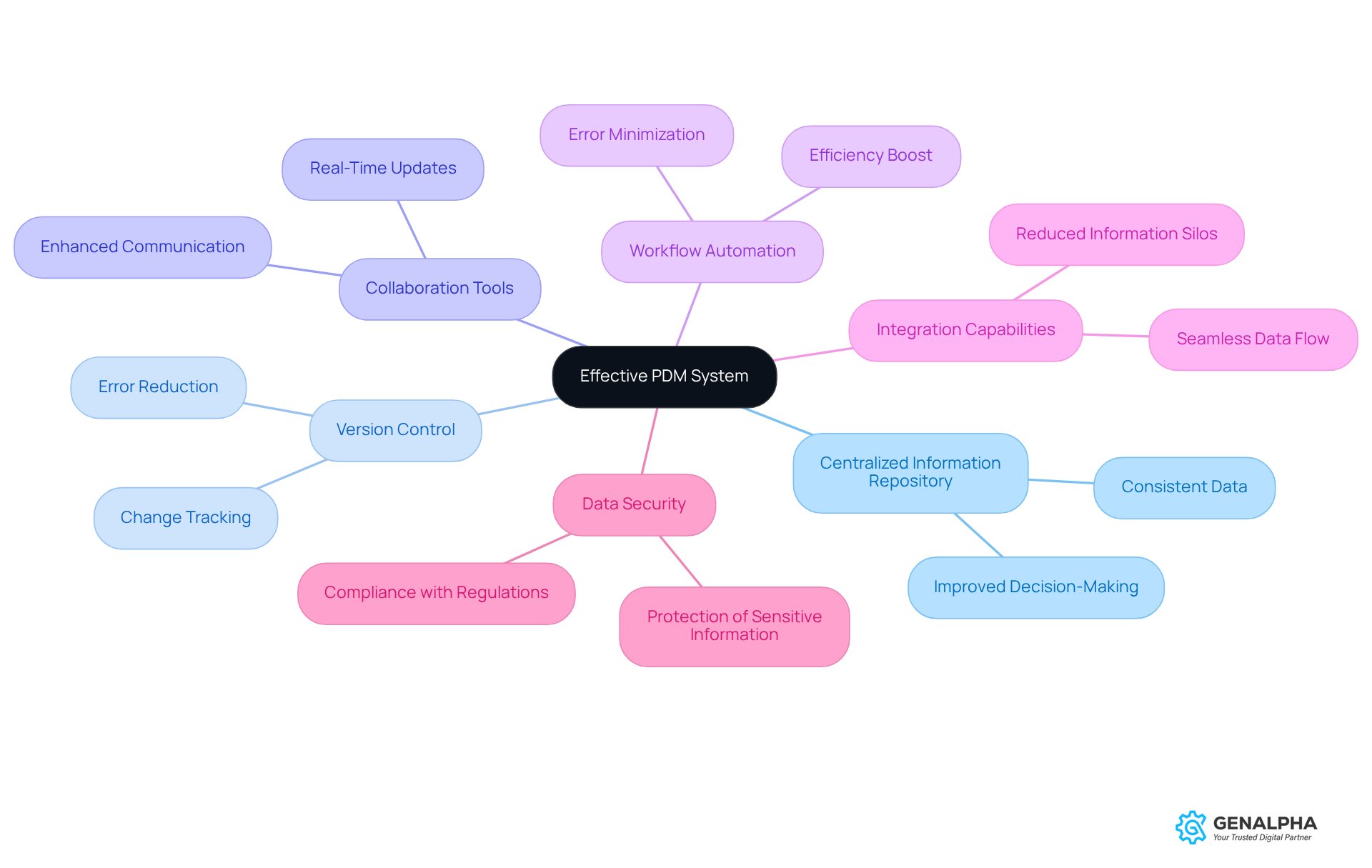

An effective product data management process includes key components that significantly enhance operational efficiency and data accuracy. Let’s break it down:

-

Centralized Information Repository: Think of this as your go-to source for all product-related details. It keeps everything consistent and accurate across departments, which means fewer mistakes and better decision-making. When everyone’s on the same page, it’s easier to get a clear view of your information.

-

Version Control: This feature is like a safety net for your data. It tracks changes and keeps a detailed history of item data. By preventing confusion, version control ensures that all teams are working with the latest information, which is crucial for maintaining quality.

-

Collaboration Tools: Integrated collaboration tools make it easy for teams to communicate. Real-time updates and feedback speed up the development cycle, allowing departments to share insights and tackle issues quickly. Who doesn’t love a smoother workflow?

-

Workflow Automation: Automating routine tasks not only boosts efficiency but also cuts down on manual errors. By streamlining processes, manufacturers can focus on what really matters - strategic initiatives - rather than getting bogged down by repetitive tasks.

-

Integration Capabilities: Being able to connect seamlessly with existing ERP systems and other software is a game-changer. This integration ensures that item information flows smoothly across platforms, reducing the risk of information silos and enhancing overall productivity.

-

Data Security: Let’s not forget about security! Strong measures are essential to protect sensitive product information from unauthorized access. By establishing solid governance policies, you can maintain information integrity and comply with industry regulations.

Before jumping into a central information repository, it’s crucial for manufacturers to outline specific business goals and information needs. This alignment with organizational objectives is key. By ensuring these components are in place, manufacturers can really optimize their product data management process, which leads to better accuracy and efficiency.

For instance, companies like Procter & Gamble have leveraged centralized information management to enhance item information precision, enabling them to respond quickly to market trends and consumer preferences. Did you know that flawed information can cost companies a staggering $12.9 million annually, according to Gartner? That’s a hefty price for poor information management! As manufacturing continues to evolve, adopting a comprehensive product data management process will be vital for maintaining competitiveness. So, are you ready to take the plunge?

Implement Best Practices for Streamlining PDM

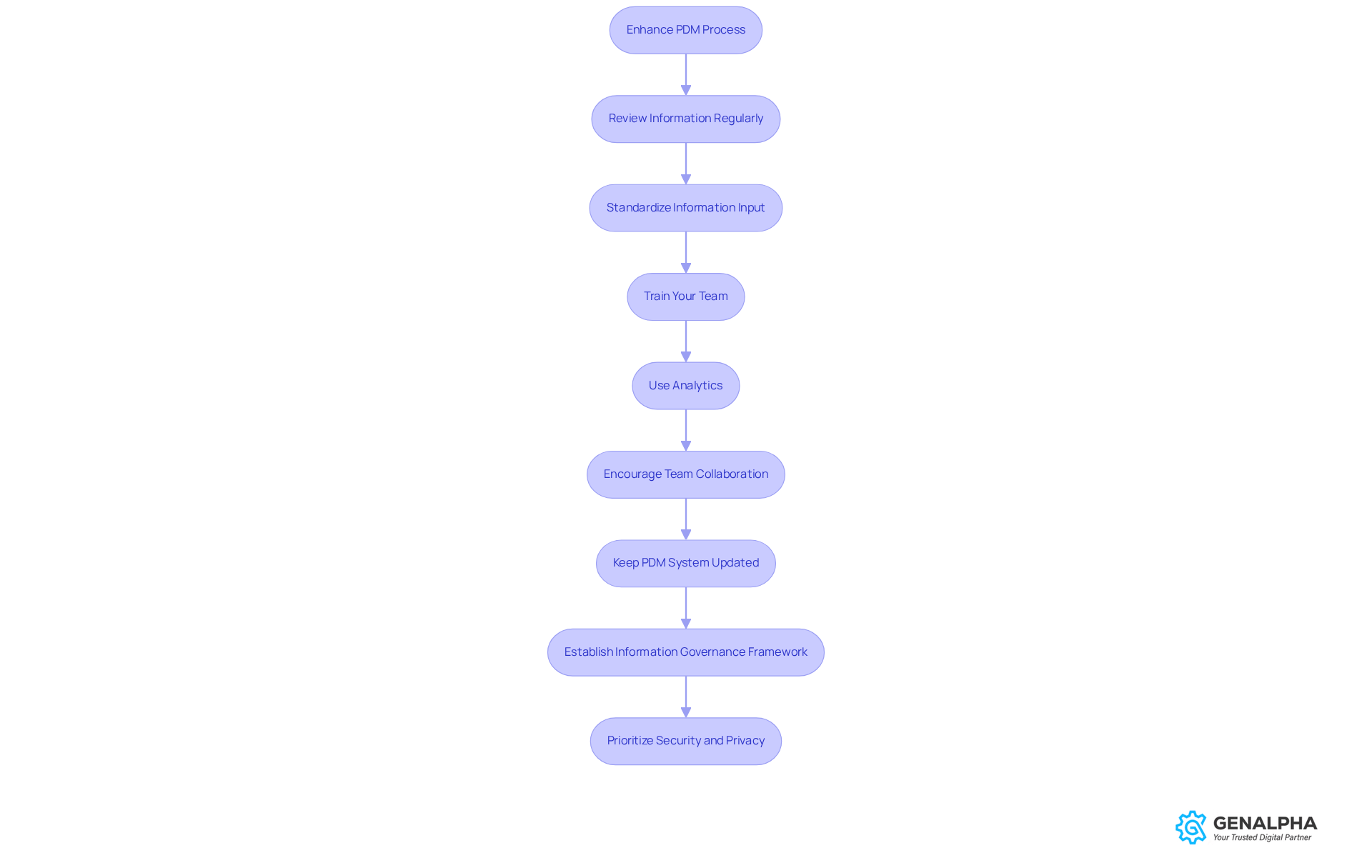

To enhance the Product Data Management (PDM) process, manufacturers can really benefit from implementing some straightforward practices:

-

Review Your Information Regularly: Think about it-how often do you check your product details? Regularly examining and cleaning up merchandise information is key to keeping things accurate and relevant. Research shows that companies that conduct regular audits can cut down on mistakes by as much as 30%. That means more reliable product info for everyone!

-

Standardize Information Input: Ever noticed how inconsistent data can lead to chaos? Establishing clear guidelines for information entry helps minimize discrepancies and errors. This standardization is super important because mixed-up information can create major operational headaches and leave customers feeling frustrated.

-

Train Your Team: Investing in comprehensive training on PDM tools and processes can really pay off. When employees know what they’re doing, they’re more likely to adopt these tools effectively. Companies that prioritize training often see a 25% boost in productivity as staff become more adept at managing product information.

-

Use Analytics: Let’s talk about the power of data! Harnessing analytics gives you insights into product performance and customer preferences, which can help you make smarter decisions. Plus, effective analytics can speed up your time-to-market by automating the flow of information between development and eCommerce platforms, making you more responsive to market demands.

-

Encourage Team Collaboration: Building a culture of teamwork across departments ensures everyone is on the same page and aware of any changes in product information. This collaboration can significantly improve data accuracy and operational efficiency. In fact, case studies show that integrated teams can shorten product launch times by 20%!

-

Keep Your PDM System Updated: Staying on top of PDM software updates means you can take advantage of new features and improvements. Regular updates can lead to better system performance and lower maintenance costs over time-who doesn’t want that?

-

Establish an Information Governance Framework: Creating a solid information governance framework is essential for effective data management. This framework helps ensure consistent handling of information, compliance with regulations, and protection against breaches, which are all critical for maintaining integrity and security.

-

Prioritize Security and Privacy: Protecting sensitive information is a must! Manufacturers need to implement strong security measures to comply with regulations like GDPR and CCPA. This includes regular security evaluations and training employees on best practices for information protection.

By putting these practices into action, manufacturers can significantly enhance their product data management process, leading to improved operational efficiency and better business outcomes. So, what are you waiting for? Let’s get started!

Address Common Challenges and Troubleshoot PDM Implementation

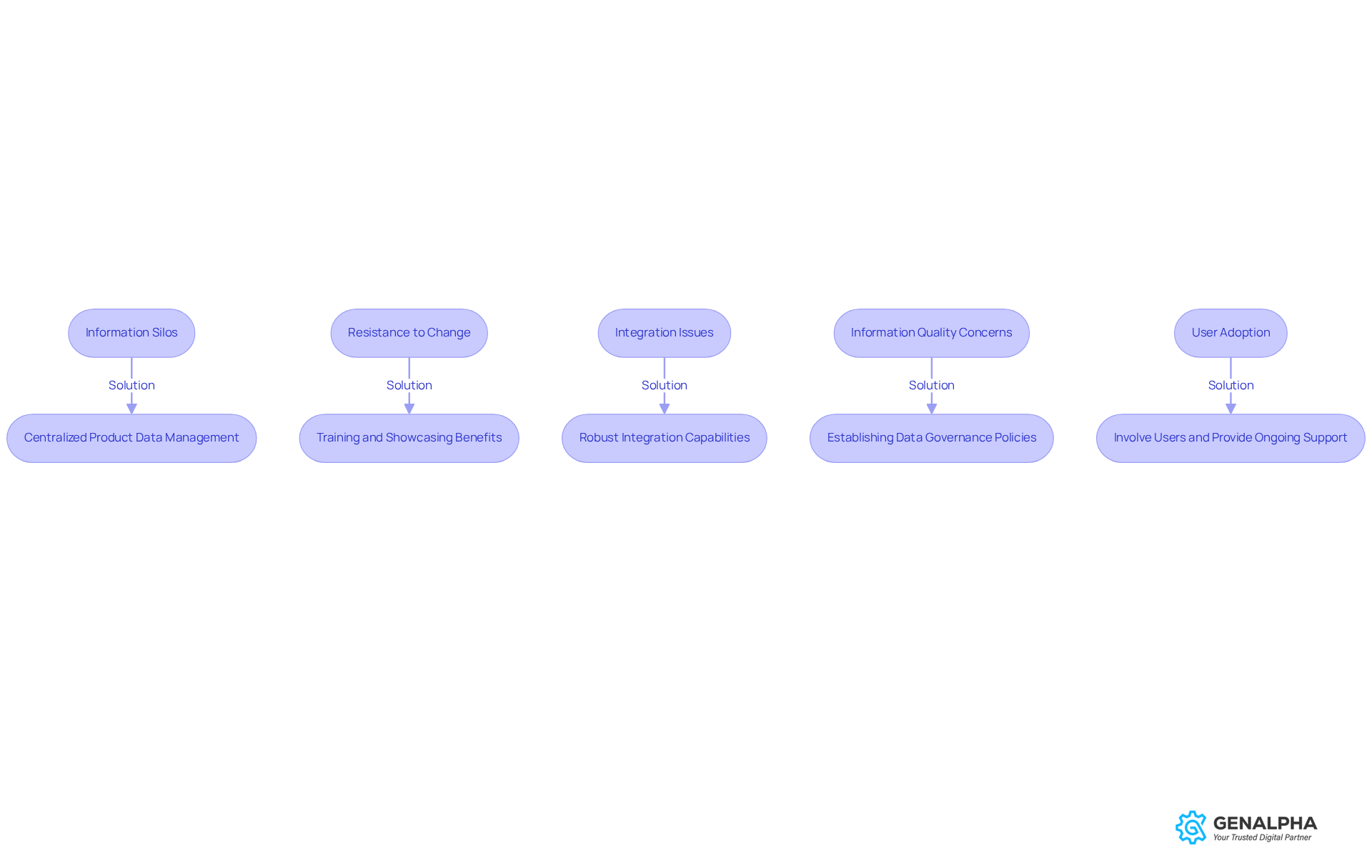

Implementing a PDM system can be a bit tricky, right? Let’s dive into some common challenges you might face and how to tackle them:

-

Information Silos: Ever notice how product information often gets scattered across different departments? It can be a real headache! The solution? A centralized product data management process can help unify access to all that crucial information.

-

Resistance to Change: Change can be tough, especially when it comes to new systems. Employees might hesitate to jump on board. So, what’s the fix? Offering thorough training and showcasing the benefits of the product data management process can really help encourage everyone to get on board.

-

Integration Issues: Integrating PDM with your existing systems can sometimes feel like trying to fit a square peg in a round hole. To avoid this, choose a product data management process solution that boasts robust integration capabilities and collaborate closely with your IT team during the rollout.

-

Information Quality Concerns: We all know that incorrect or outdated information can lead to poor decisions. To keep things on track, establishing data governance policies is key to maintaining the product data management process and ensuring data integrity.

-

User Adoption: If users aren’t engaging with the PDM system, its effectiveness can really take a hit. The solution? Involve users in the selection process and provide ongoing support to keep them engaged.

By proactively addressing these challenges, manufacturers can set themselves up for a successful product data management process implementation that enhances operational efficiency. So, what do you think? Ready to tackle these issues head-on?

Conclusion

Embracing a solid Product Data Management (PDM) process is crucial for equipment manufacturers looking to boost their operational efficiency and keep customers happy. By centralizing product information, manufacturers can ensure accuracy, streamline workflows, and respond quickly to market demands. The importance of effective PDM is huge - it not only reduces risks tied to incorrect data but also helps build stronger relationships with customers.

In this guide, we’ve highlighted key components like:

- A centralized information repository

- Version control

- Collaboration tools

- Workflow automation

as must-haves for a successful PDM system. Plus, best practices such as:

- Regular information reviews

- Standardized data input

- A solid governance framework

are vital for keeping data integrity and security intact. Tackling common challenges like information silos and resistance to change can make the implementation process smoother.

Ultimately, manufacturers that invest in mastering the PDM process set themselves up for greater competitiveness and growth. Taking proactive steps toward effective product data management isn’t just a suggestion; it’s a strategic necessity for thriving in today’s fast-paced manufacturing landscape. So, why wait? It’s time to transform your PDM approach and tap into the full potential of your operations!

Frequently Asked Questions

What is Product Data Management (PDM)?

Product Data Management (PDM) is a structured process that manages all product-related information throughout its lifecycle, from design to production and beyond.

Why is PDM important for equipment manufacturers?

PDM is crucial for equipment manufacturers as it centralizes all item information, ensuring accuracy and easy access, which reduces errors and boosts collaboration across departments.

How does PDM improve workflows?

PDM streamlines workflows and automates the product data management process, allowing companies to bring new products to market faster and respond quickly to market needs.

What impact does PDM have on customer satisfaction?

PDM enhances customer satisfaction by providing accurate product information, which leads to a smoother purchasing experience for customers.

How does effective PDM reduce risks for organizations?

Organizations that effectively utilize PDM can significantly reduce risks associated with incorrect information, leading to stronger customer relationships and promoting growth.

What potential benefits can PDM offer businesses?

PDM can transform operations by improving efficiency, reducing errors, enhancing customer satisfaction, and ultimately unlocking a business's potential.