Introduction

Real-time integration is shaking up the manufacturing world, creating a web of connectivity that boosts efficiency and responsiveness. As we look ahead to the challenges of 2026, having access to real-time data on production and supply chain dynamics isn’t just a nice-to-have; it’s a must. But here’s the big question: how can manufacturers put these integration strategies into action to not just keep up, but really thrive in a competitive landscape?

Think about it. Imagine being able to see exactly what’s happening on the production floor or in the supply chain at any moment. That kind of insight can make all the difference. It’s not just about staying afloat; it’s about sailing ahead of the competition. So, what steps can we take to make this a reality? Let's dive into some strategies that can help manufacturers harness the power of real-time integration.

Understand Real-Time Integration in Manufacturing

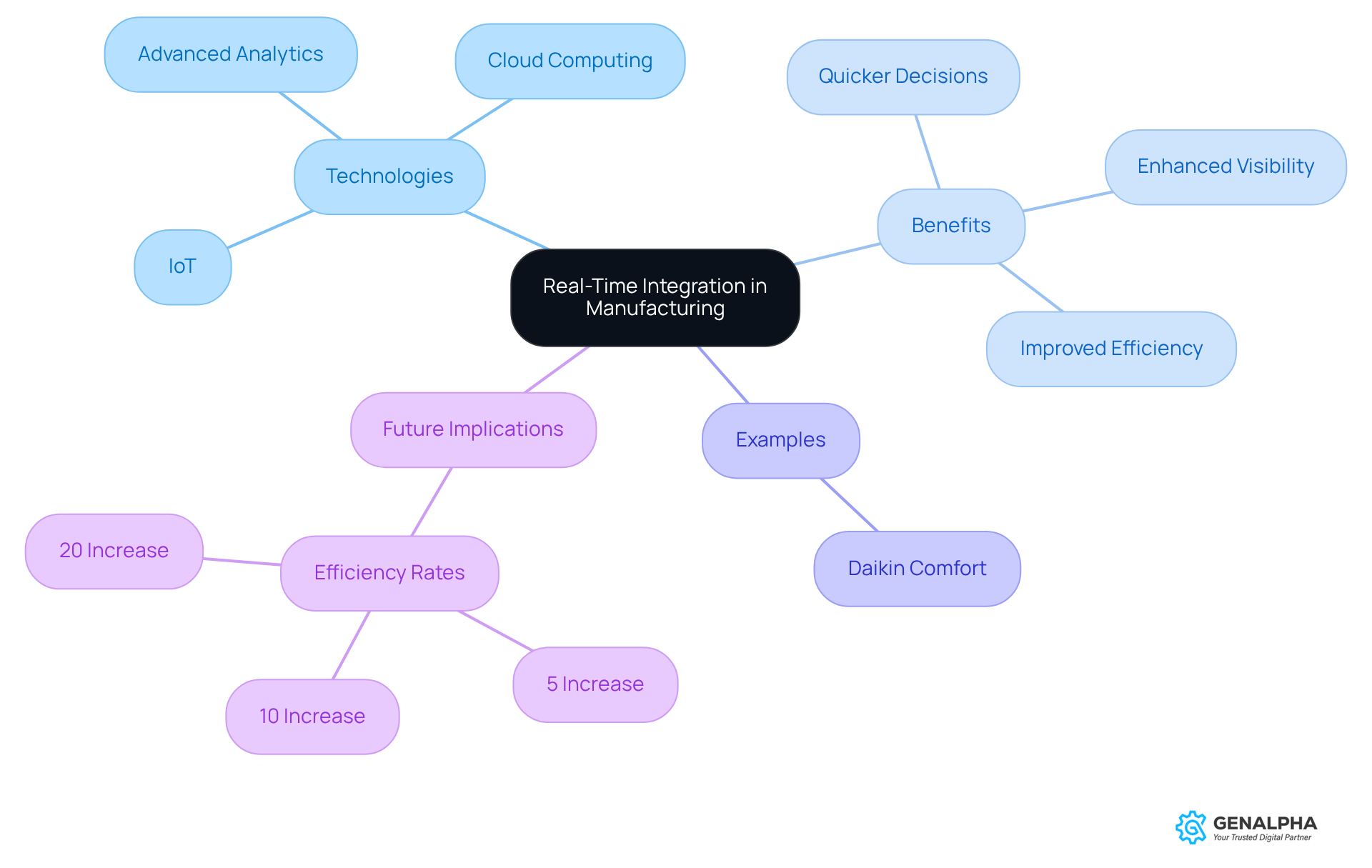

Let’s discuss real time integration regarding connections in manufacturing. Imagine a world where all your systems, applications, and information sources are seamlessly linked and synchronized. This means you can access up-to-the-minute info on production, inventory, and supply chain dynamics. Pretty cool, right? Real time integration enables manufacturers to make quicker decisions and respond better to market demands. By leveraging technologies like IoT, cloud computing, and advanced analytics, companies can achieve real time integration, allowing for a unified ecosystem where information flows freely and is constantly updated across platforms. This not only streamlines operations but also boosts visibility into processes, leading to greater efficiency and happier customers.

Now, think about the impact of real time integration of instant data flow on manufacturing efficiency, especially as we approach 2026. Companies that master real time integration could see efficiency rates soar by 5%, 10%, or even 20%! That’s not just a guess; industry experts are backing this up. Take Daikin Comfort, for example. They’ve quickly adapted to real-time market changes by redesigning their critical planning functions. As Don Rogers points out, the challenge for producers isn’t just about going digital; it’s a systemic and cultural shift. It calls for a comprehensive strategy to weave data into every function. This shift is all about positioning manufacturers to chase both value and resilience, turning long-held ideals into competitive advantages.

So, what do you think? Are you ready to embrace this change and see how it can transform your operations?

Identify Benefits of Real-Time Integration

Have you ever thought about how real time integration in manufacturing can really change the game? Let’s dive into some of the perks!

-

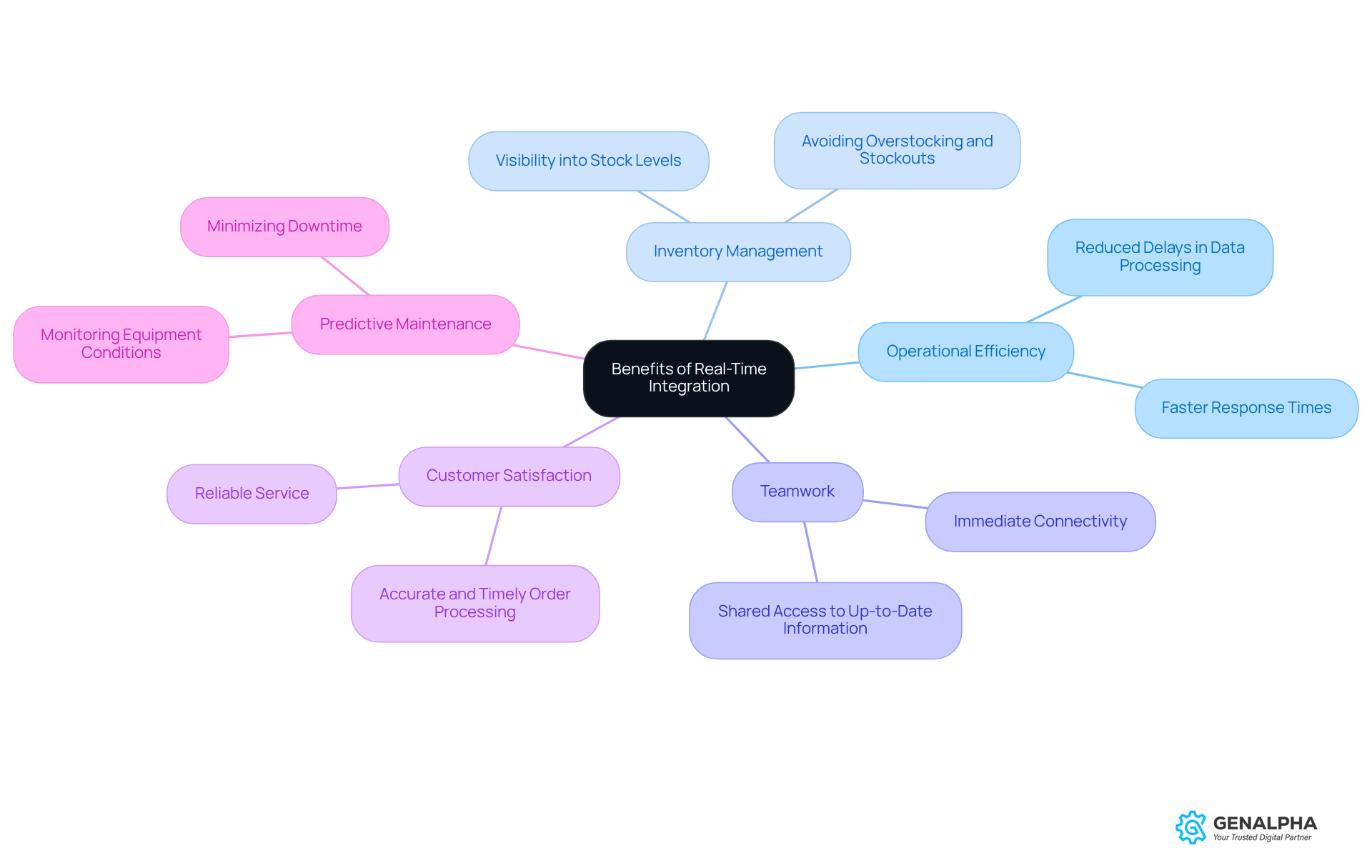

First off, it boosts operational efficiency. Imagine how real time integration can help cut down on those annoying delays in data processing. With faster response times to production hiccups, things just flow better.

-

Then there’s inventory management. With real time integration, you gain visibility into stock levels, helping you avoid the dreaded overstocking or stockouts. No one likes running out of essential supplies, right?

-

And let’s not forget about teamwork! Immediate connectivity through real time integration means everyone’s on the same page. When departments can access the same up-to-date info via real time integration, decision-making becomes a breeze.

-

Plus, customer satisfaction gets a nice boost. Orders are processed accurately and on time, which keeps customers coming back for more. Who doesn’t love a reliable service?

-

Finally, think about predictive maintenance. Instant coordination allows producers to keep an eye on equipment conditions, which helps minimize downtime and cut maintenance costs.

So, what do you think? Isn’t it time to consider how immediate integration could transform your manufacturing process?

Implement Strategies for Successful Integration

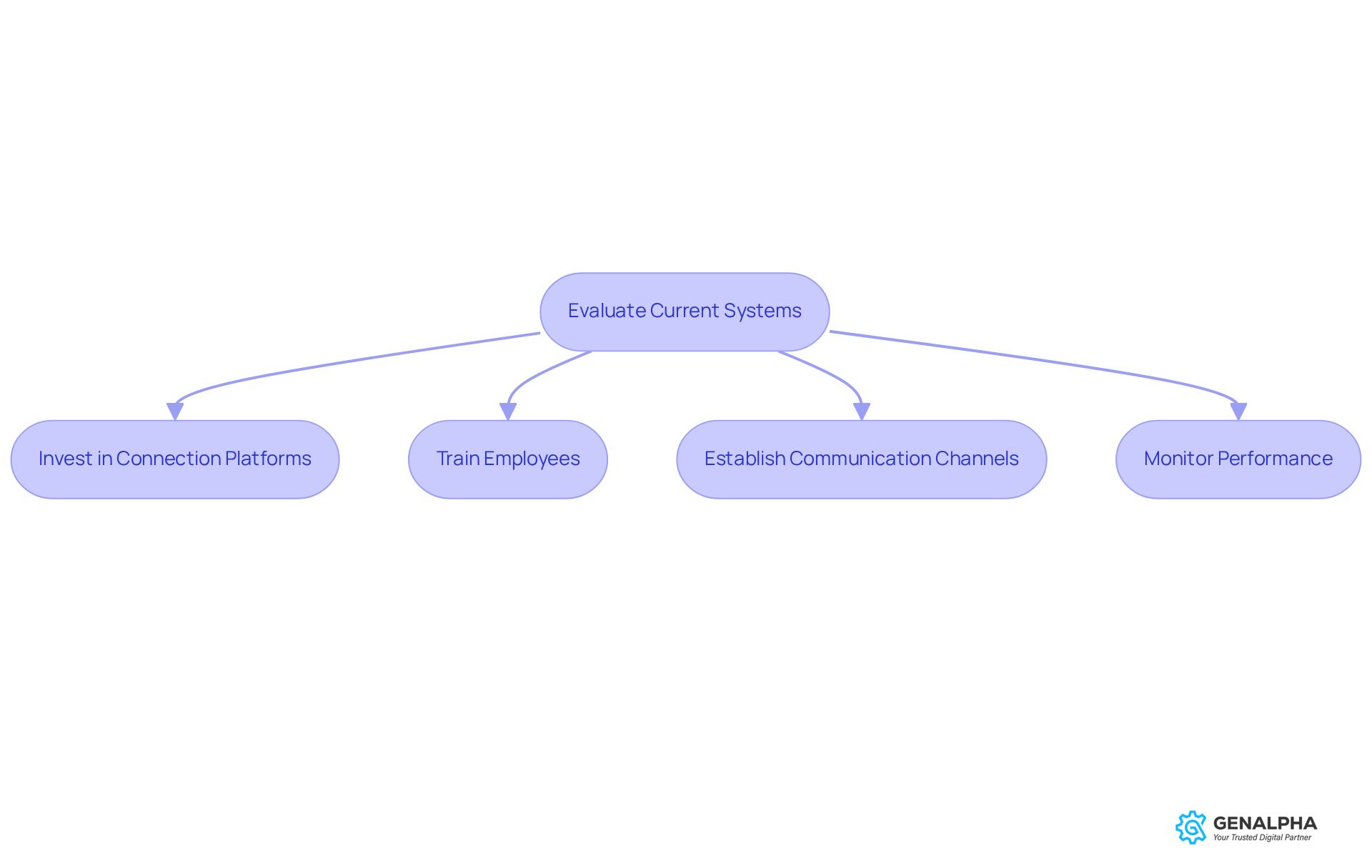

To truly achieve real time integration, manufacturers need to take a few strategic steps. First off, it’s crucial to take a good look at your current systems to spot any connection gaps. This means evaluating your software, hardware, and information management practices to see where improvements are needed. Investing in robust connection platforms that enable real time integration for information exchange is key; these platforms should work seamlessly with your existing ERP systems and be able to handle large amounts of data.

And let’s not forget about training your employees! Ensuring that your staff can effectively use new technologies is vital for boosting overall operational efficiency. Establishing clear communication channels between departments is also essential for fostering collaboration and smooth data sharing. Plus, keeping an eye on performance lets manufacturers make necessary tweaks, improving processes over time.

For example, companies that have set up continuous monitoring systems have been able to catch compliance issues early, preventing potential violations before they become a problem. By following these best practices, manufacturers can enhance their unification strategies, driving operational excellence and staying compliant with changing regulations.

It’s also worth noting that combined spending tends to rise 15-20% faster than total IT budgets, which underscores the need to invest in solid platforms. Case studies show that centralized control and visibility can bring real benefits when it comes to modern system unification. Just be aware of common challenges, like the connectivity gap that affects 95% of IT leaders, which can slow progress if left unaddressed. So, what steps will you take to bridge those gaps?

Monitor and Optimize Integration Performance

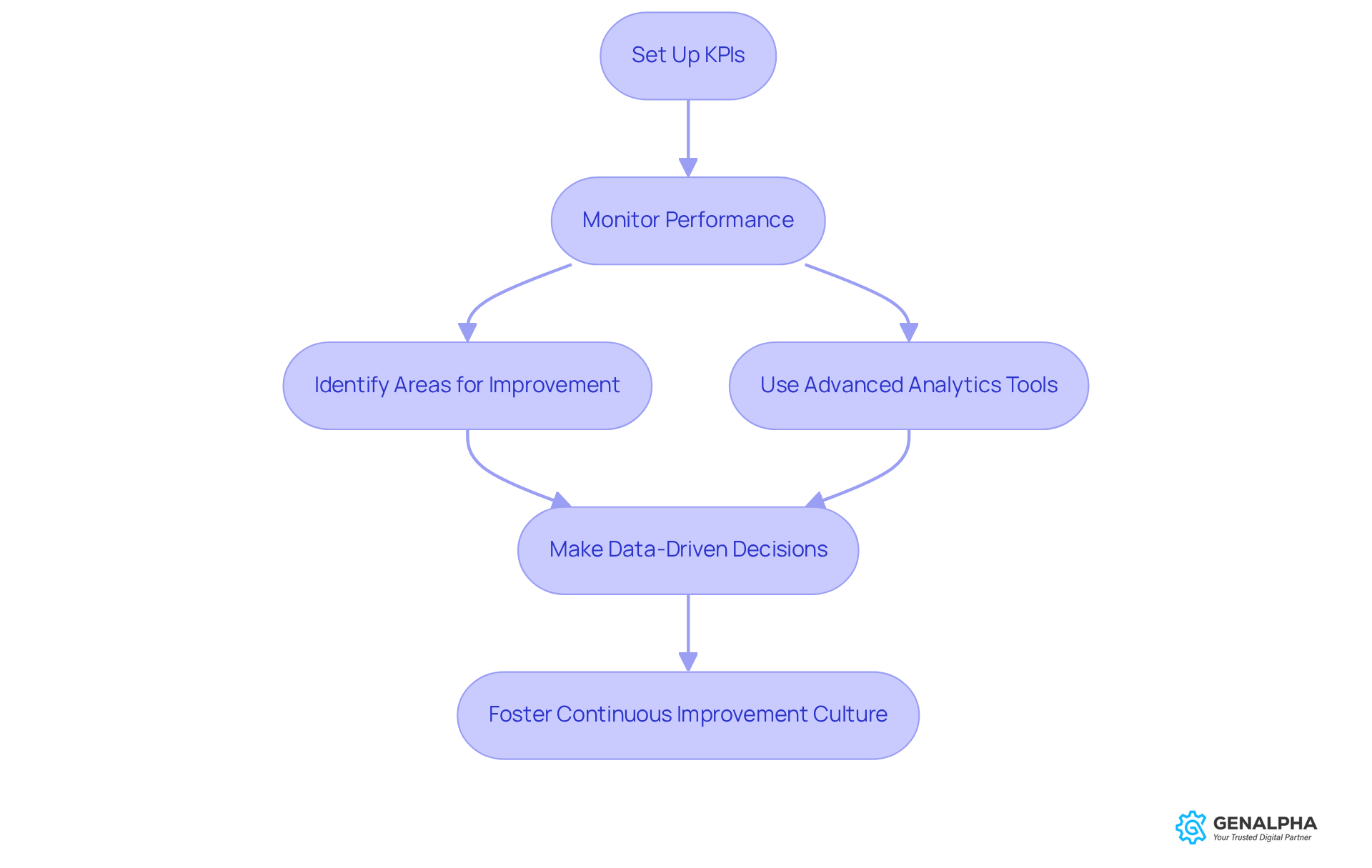

To keep an eye on how well the system is performing and to make improvements, manufacturers really need to set up key performance indicators (KPIs) that match their strategic goals. Think about metrics like Overall Equipment Effectiveness (OEE), Cycle Time, information accuracy, processing speed, and system uptime. These metrics work together to give a clear picture of how successful implementation efforts are. For instance, companies that use real-time information monitoring often notice big boosts in processing speed - some even report improvements of up to 30%! That’s something recent industry research has highlighted.

Regular check-ins and feedback loops are crucial for spotting areas that need a little TLC. This way, producers can make smart, data-driven decisions that enhance their processes. Plus, using advanced analytics tools can help identify operational bottlenecks and inefficiencies. This means manufacturers can make proactive tweaks to streamline workflows.

Success stories from leading producers show that those who focus on KPI monitoring and real-time integration not only enhance operational efficiency but also improve customer satisfaction. As Adeline de Oliveira points out, picking the right KPIs and weaving them into a continuous improvement process is key to nurturing a culture that adapts to changing business needs. By fostering this kind of culture, manufacturers can ensure their integration systems grow alongside their business needs, ultimately leading to greater efficiency and a competitive edge.

Conclusion

Real-time integration in manufacturing isn’t just a tech upgrade; it’s a game changer that can redefine how we operate and respond. Imagine being able to connect all your systems and applications seamlessly. This means you get immediate access to crucial data, which helps you make quicker decisions and adapt to market demands like a pro. It’s all about creating a unified ecosystem where information flows freely, leading to better productivity and happier customers.

Let’s talk about some of the key perks of real-time integration. You’ll see:

- Heightened operational efficiency

- Improved inventory management

- Better teamwork

- Increased customer satisfaction

But it’s not just about the benefits; it’s also about taking strategic steps. Think about:

- Evaluating your current systems

- Investing in solid integration platforms

- Fostering a culture of continuous improvement

By doing these things, you can bridge those connectivity gaps and really optimize your operations for top-notch performance.

As the manufacturing world keeps evolving, embracing real-time integration is crucial if you want to stay ahead of the game. Companies need to recognize how significant this transformation is and take proactive steps to implement effective integration strategies. By doing so, you’re not just enhancing your operational capabilities; you’re also positioning yourself to thrive in an ever-changing market. So, why wait? Now’s the time to seize the opportunity, harness the full potential of real-time integration, and drive your manufacturing processes toward greater efficiency and resilience!

Frequently Asked Questions

What is real-time integration in manufacturing?

Real-time integration in manufacturing refers to the seamless linking and synchronization of systems, applications, and information sources, allowing access to up-to-the-minute information on production, inventory, and supply chain dynamics.

How does real-time integration benefit manufacturers?

It enables manufacturers to make quicker decisions, respond better to market demands, streamline operations, and boost visibility into processes, leading to greater efficiency and improved customer satisfaction.

What technologies enable real-time integration?

Technologies such as the Internet of Things (IoT), cloud computing, and advanced analytics facilitate real-time integration by creating a unified ecosystem where information flows freely and is constantly updated across platforms.

What impact could real-time integration have on manufacturing efficiency by 2026?

Companies that master real-time integration could see efficiency rates increase by 5%, 10%, or even 20%, according to industry experts.

Can you provide an example of a company that has successfully implemented real-time integration?

Daikin Comfort is an example of a company that has quickly adapted to real-time market changes by redesigning their critical planning functions.

What challenges do manufacturers face when transitioning to real-time integration?

The challenge for producers involves not just going digital but also undergoing a systemic and cultural shift that requires a comprehensive strategy to integrate data into every function.

What is the overall goal of embracing real-time integration in manufacturing?

The goal is to position manufacturers to pursue both value and resilience, transforming long-held ideals into competitive advantages.