Introduction

Quoting programs have become essential for equipment manufacturers, changing the game when it comes to managing pricing and configurations. These smart tools make the quoting process smoother, boost accuracy, and, in the end, lead to happier customers. But with so many options out there, how can manufacturers pick the right quoting software and seamlessly integrate it into their current systems?

Let’s explore some best practices that not only simplify the quoting process but also help manufacturers tap into the full potential of these innovative solutions. After all, who wouldn’t want to make their quoting process easier and more effective?

Define Quoting Software and Its Role in Manufacturing

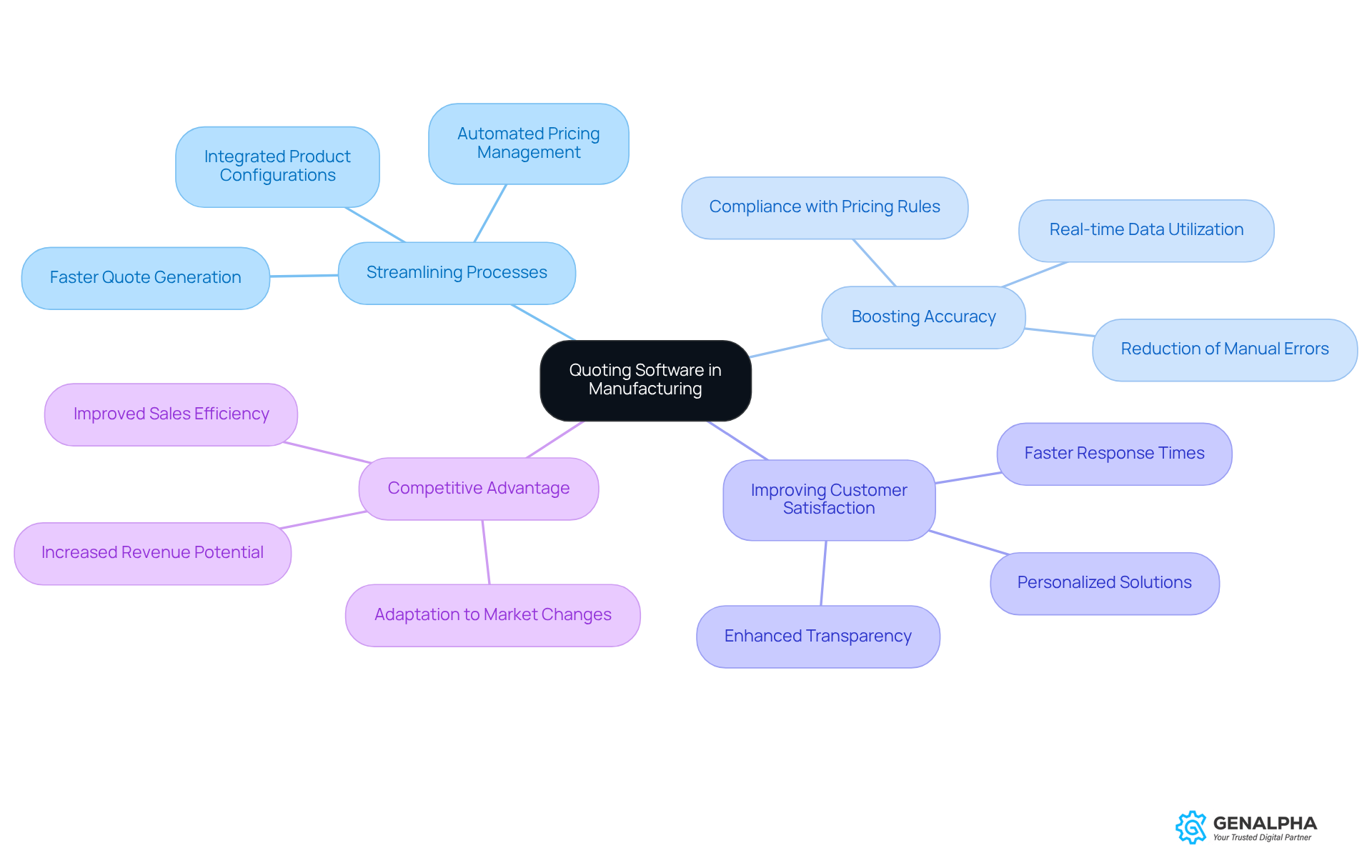

Have you ever found yourself tangled in the quoting process? Well, quoting programs, which are often called Configure, Price, Quote (CPQ) applications, are here to help! These digital resources are designed to make life easier for producers by streamlining the entire quoting programs process. Imagine having all your product configurations, pricing rules, and customer data neatly integrated into one platform. Sounds great, right?

These applications are game-changers in manufacturing. They not only speed up the quoting programs but also boost accuracy, cutting down on those pesky manual errors. Plus, who doesn’t want to improve customer satisfaction? By utilizing these estimation tools, producers can ensure that their quoting programs are not only quick but also reflect the latest pricing and product availability. In a competitive market, that’s crucial!

So, why not give these tools a try? They could be the key to making your quoting programs smoother and more efficient!

Choose the Right Quoting Software for Your Needs

When you're on the hunt for quoting software, there are a few key factors you really should keep in mind:

-

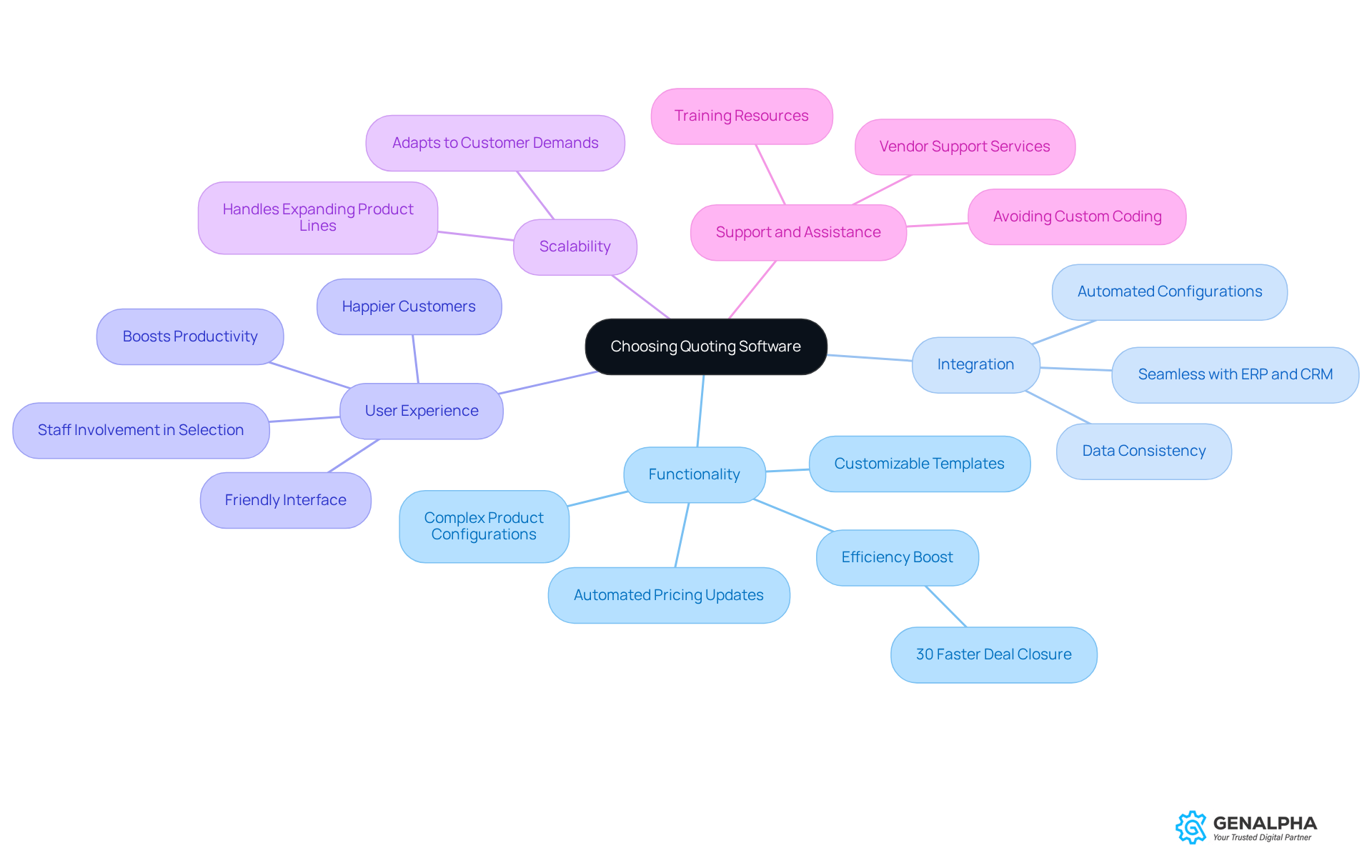

Functionality: First off, the software needs to handle those complex product configurations and pricing structures like a pro. Look for features like customizable templates and automated pricing updates. These can really cut down on manual errors and boost your efficiency. Did you know that companies using modern CPQ tools can close deals up to 30% faster? That just shows how crucial robust functionality is!

-

Integration: Next up, seamless integration with your existing systems - think ERP and CRM platforms - is a must. This keeps your data consistent and makes workflows smoother, creating a more cohesive operational environment. Plus, automated configurations help prevent those pesky manual errors, which is another reason why effective integration is so important.

-

User Experience: Now, let’s talk about user experience. A friendly interface is key to getting your team on board. Involving your staff in the selection process can really help ensure the system meets their needs and boosts overall productivity. A great user experience can even lead to happier customers since sales reps will spend less time on admin tasks.

-

Scalability: It’s also smart to choose applications that can grow with your business. You want something that can handle expanding product lines and increasing customer demands without slowing down. This adaptability is super important in today’s fast-paced market.

-

Support and Assistance: Finally, don’t forget to check out the vendor's support services and training resources. Proper training is essential to make sure your team can use the program effectively and get the most out of it. Just be cautious of potential downsides, like choosing a system that requires a lot of custom coding for implementation, which can lead to higher costs and complexity.

By taking the time to assess these factors, you can find a pricing solution that not only boosts efficiency in quoting programs but also enhances accuracy. In the end, this means happier customers and improved sales performance!

Integrate Quoting Software with Existing Systems

To effectively integrate quoting software with your existing systems, let’s explore some best practices that can make this process smoother:

-

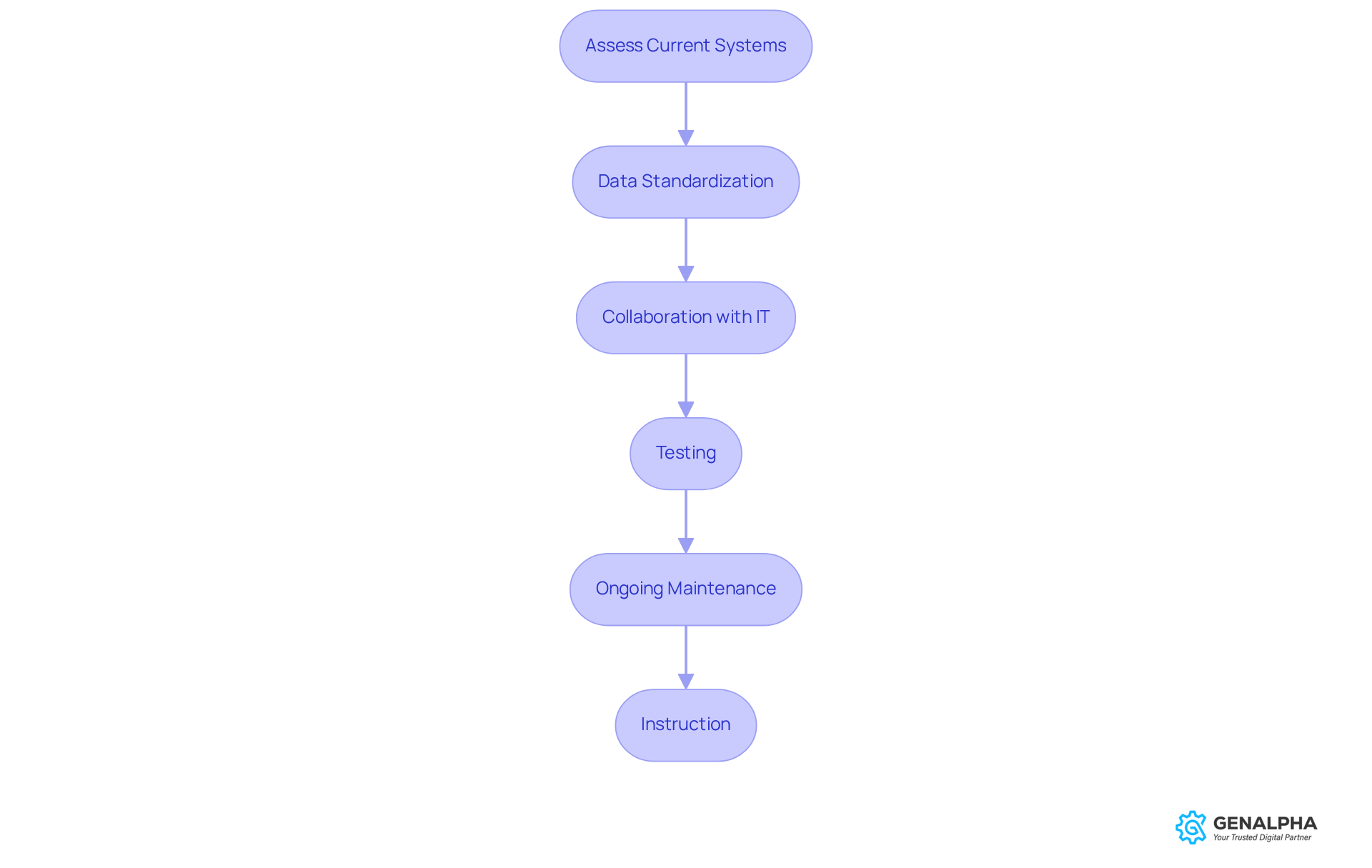

Assess Current Systems: Start by taking a good look at your current ERP, CRM, and other relevant systems. What integration points can you find? Understanding how data flows is key here. Did you know that 89% of companies see accounting as the most critical ERP function? This really underscores the need for seamless integration, especially in accounting processes.

-

Data Standardization: Consistency is crucial! Make sure your data formats are uniform across systems to ensure smooth data transfer. Sometimes, this means cleaning up and standardizing existing data. Frequent data standardization issues can lead to misalignment with customer needs, which can mess with the accuracy of your estimates.

-

Collaboration with IT: Team up with your IT department or even external consultants to craft a solid integration plan. This plan should lay out timelines, responsibilities, and potential challenges. Remember, effective collaboration can really boost the success rate of your integration projects.

-

Testing: Don’t skip this step! Thoroughly test the integrated systems to catch and fix any issues before going live. Validate data accuracy and ensure workflows are working as they should. It’s worth noting that 50% of ERP implementations fail on the first try, often due to not enough testing. So, make this step a priority!

-

Ongoing Maintenance: Think ahead! Plan for regular maintenance and testing of your integrations to keep everything running smoothly over time. Regular reviews can help you spot issues before they become big problems, ensuring you stay aligned with your business needs.

-

Instruction: Don’t forget to provide clear instructions for your staff on how to navigate the integrated systems. Highlight the benefits of the new pricing process. Proper preparation is key, especially since new hires might struggle to access historical cost data, which can affect quotation accuracy.

By following these steps, you can ensure that your quoting programs enhance your operational capabilities rather than complicate them. This will lead to better customer satisfaction and improved sales efficiency. So, are you ready to take your quoting software integration to the next level?

Provide Comprehensive Training and Support for Teams

To really make the most of quoting software, manufacturers should kick off a solid training program that covers a few key areas:

-

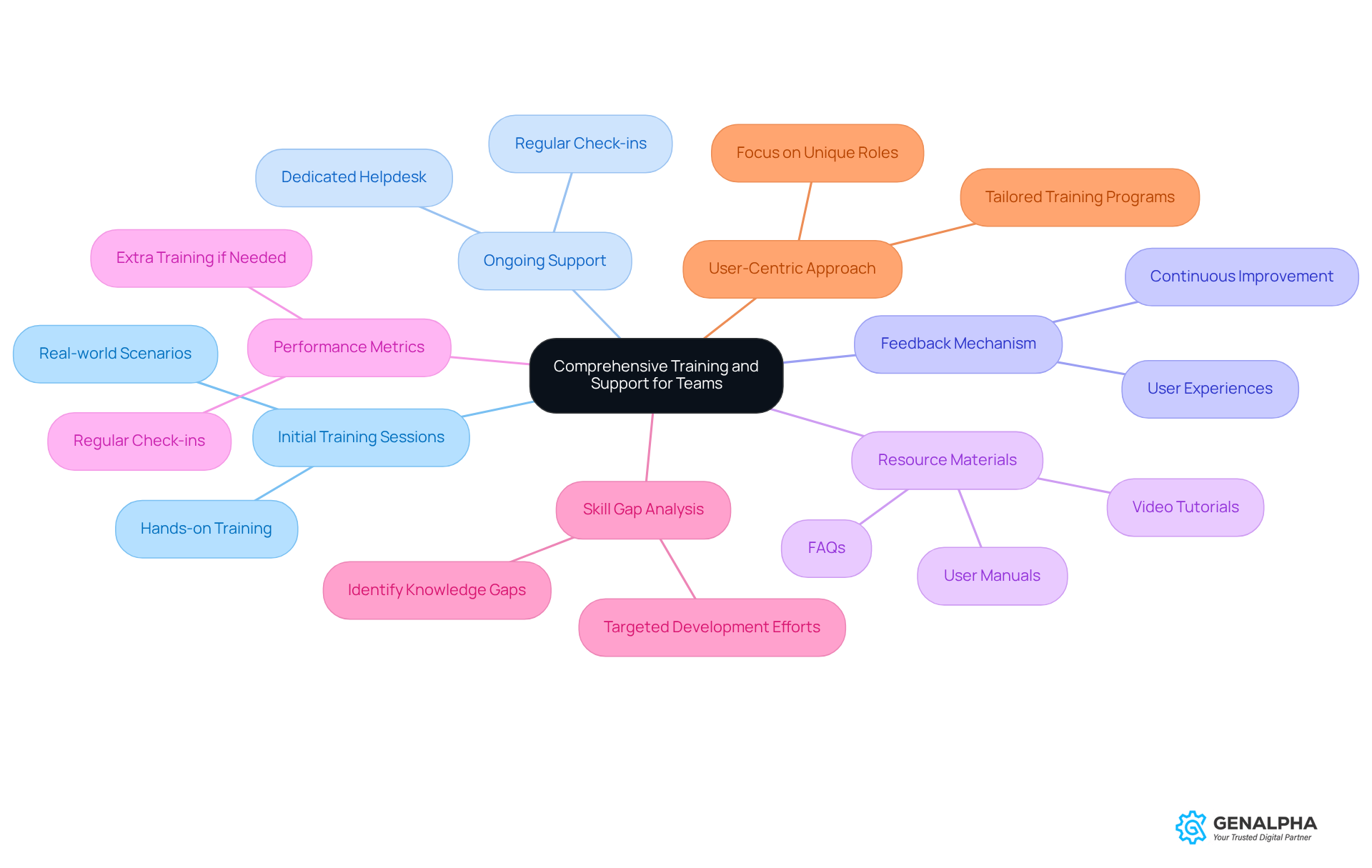

Initial Training Sessions: Let’s start with hands-on training sessions that dive into the app’s features and functionalities. Using real-world scenarios will show how it works in the quoting process, making it easier to grasp and remember.

-

Ongoing Support: It’s super important to set up a support system where team members can get help as they get used to the new application. Think about having a dedicated helpdesk or regular check-ins with tech experts to tackle any challenges and offer guidance.

-

Feedback Mechanism: How about creating a feedback loop? This way, users can share their experiences and suggest improvements. Not only does this help in developing the software, but it also builds a culture of continuous improvement, encouraging everyone to get involved and take ownership.

-

Resource Materials: Make sure users have access to a variety of support materials, like user manuals, video tutorials, and FAQs. These resources should be easy to find and regularly updated to help with self-learning and answer common questions.

-

Performance Metrics: Regularly check how team members are doing with the software and offer extra training if needed. This proactive approach helps everyone get up to speed, boosting the overall efficiency of the quoting process.

-

Skill Gap Analysis: Conduct a skill gap analysis to pinpoint any knowledge or ability gaps among team members. This step is crucial for targeting development efforts effectively, addressing real needs, and cutting down on frustration.

-

User-Centric Approach: Tailor training programs to focus on the unique roles and contexts of users. By customizing the learning experience, manufacturers can increase engagement and ensure team members have the skills they need for their specific tasks.

By investing in a comprehensive training and support framework, manufacturers can really ramp up user adoption rates and optimize their quoting programs. So, what do you think? Ready to take the plunge?

Conclusion

Quoting software is really shaking things up in the manufacturing world! It’s making the quoting process smoother, boosting accuracy, and ultimately keeping customers happy. When manufacturers bring these powerful tools into their operations, they can cut down on manual errors and respond to market demands much quicker. Adopting solid quoting programs isn’t just about tech upgrades; it’s a smart strategy that can lead to a more efficient and competitive business.

In this article, we’ve highlighted some key practices for picking and implementing quoting software. Think about:

- Assessing functionality

- Ensuring it fits seamlessly with your existing systems

- Providing thorough training and ongoing support

Each of these elements is crucial for getting the most out of quoting software. They not only help operations run more smoothly but also empower teams to use technology effectively, leading to better sales performance and happier customers.

As manufacturers tackle the complexities of quoting processes, embracing these best practices is a must. Investing in the right quoting software and making sure your teams are well-trained and supported can really change the quoting experience for the better. By doing this, manufacturers set themselves up for success in a competitive market, making it essential to prioritize these strategies for long-term growth and efficiency. So, are you ready to take the leap and transform your quoting process?

Frequently Asked Questions

What is quoting software?

Quoting software, often referred to as Configure, Price, Quote (CPQ) applications, are digital tools designed to streamline the quoting process in manufacturing by integrating product configurations, pricing rules, and customer data into one platform.

What role does quoting software play in manufacturing?

Quoting software speeds up the quoting process, enhances accuracy by reducing manual errors, and improves customer satisfaction by ensuring quotes reflect the latest pricing and product availability.

How does quoting software improve efficiency?

By automating and organizing the quoting process, quoting software allows producers to generate quotes more quickly and accurately, which is essential in a competitive market.

Why is it important to use quoting software in a competitive market?

In a competitive market, using quoting software is crucial because it helps manufacturers provide timely and accurate quotes, which can enhance customer satisfaction and give them an edge over competitors.