Introduction

In the fast-paced world of manufacturing, managing product information efficiently isn’t just a nice-to-have-it’s essential for success. Think about it: Product Data Management (PDM) tools are key players in streamlining operations, cutting down on errors, and boosting collaboration across teams. As the manufacturing landscape keeps evolving, getting a grip on the ins and outs of PDM becomes crucial.

But here’s the kicker: many manufacturers find themselves wrestling with challenges like integration complexities and information security. So, how can they tackle these hurdles to fully harness the power of PDM tools and drive operational excellence? Let’s dive in and explore!

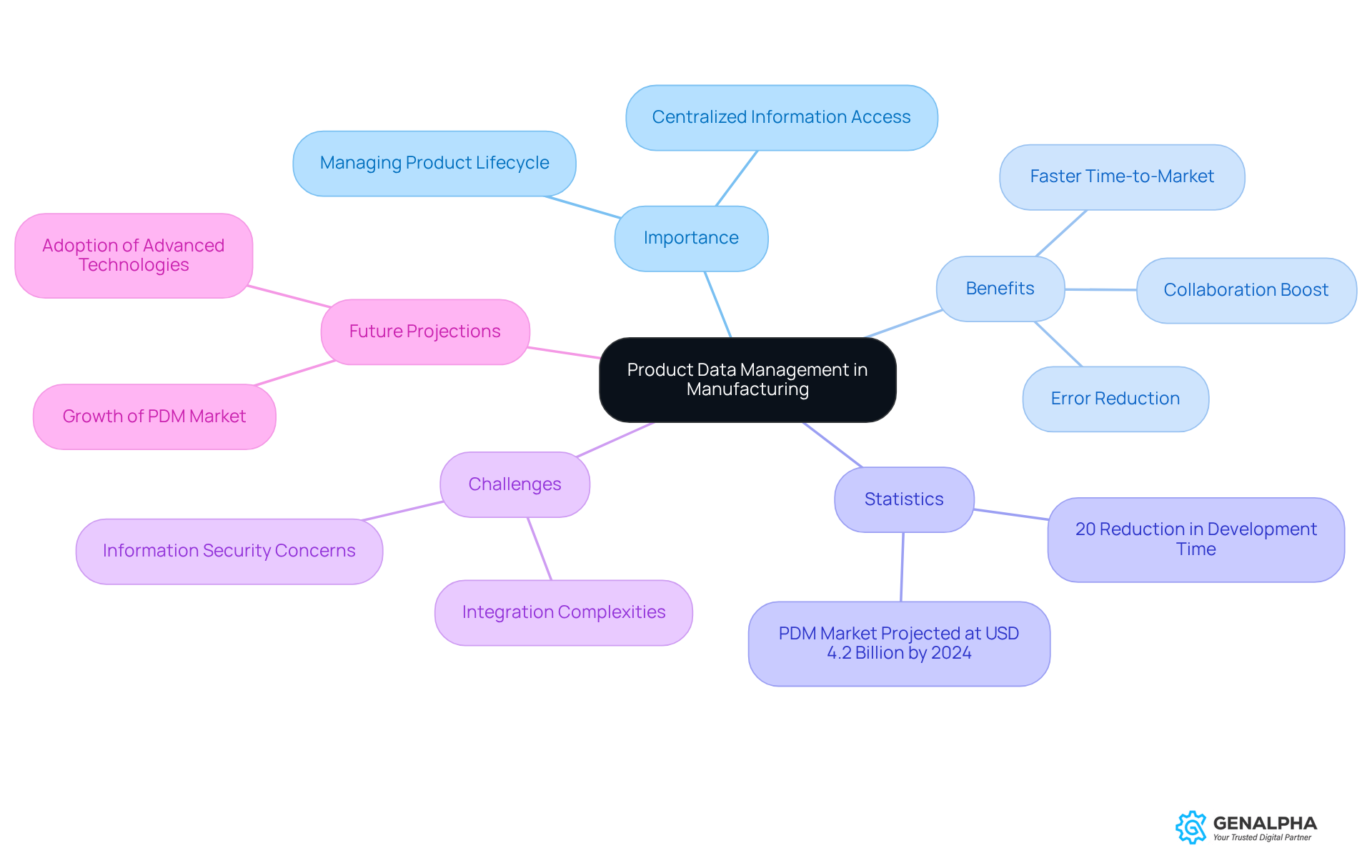

Understand Product Data Management in Manufacturing

Have you ever thought about how crucial Product Information Management (PIM) is in the manufacturing world? It’s all about managing product-related information throughout its lifecycle. When it comes to manufacturing, an effective product data management tool is key. It ensures that everyone - from design to production to sales - has access to accurate and up-to-date information. By using a product data management tool to centralize product info, manufacturers can cut down on errors, boost collaboration, and speed up time-to-market.

For example, a study by Deloitte found that companies with strong PDM systems see a 20% reduction in product development time. That means they can respond to market demands much faster! Plus, those using advanced technologies like centralized information platforms have achieved 85% more accurate forecasting. That’s some serious operational efficiency!

As we look ahead, the global Product Data Management market is projected to hit USD 4.2 billion by 2024. So, understanding and implementing effective product data management tool strategies isn’t just a nice-to-have; it’s essential for driving customer satisfaction and staying competitive. But it’s not all smooth sailing - manufacturers also face challenges like information security concerns and integration complexities. How can they navigate these hurdles to fully reap the benefits of PDM? Let's explore that together!

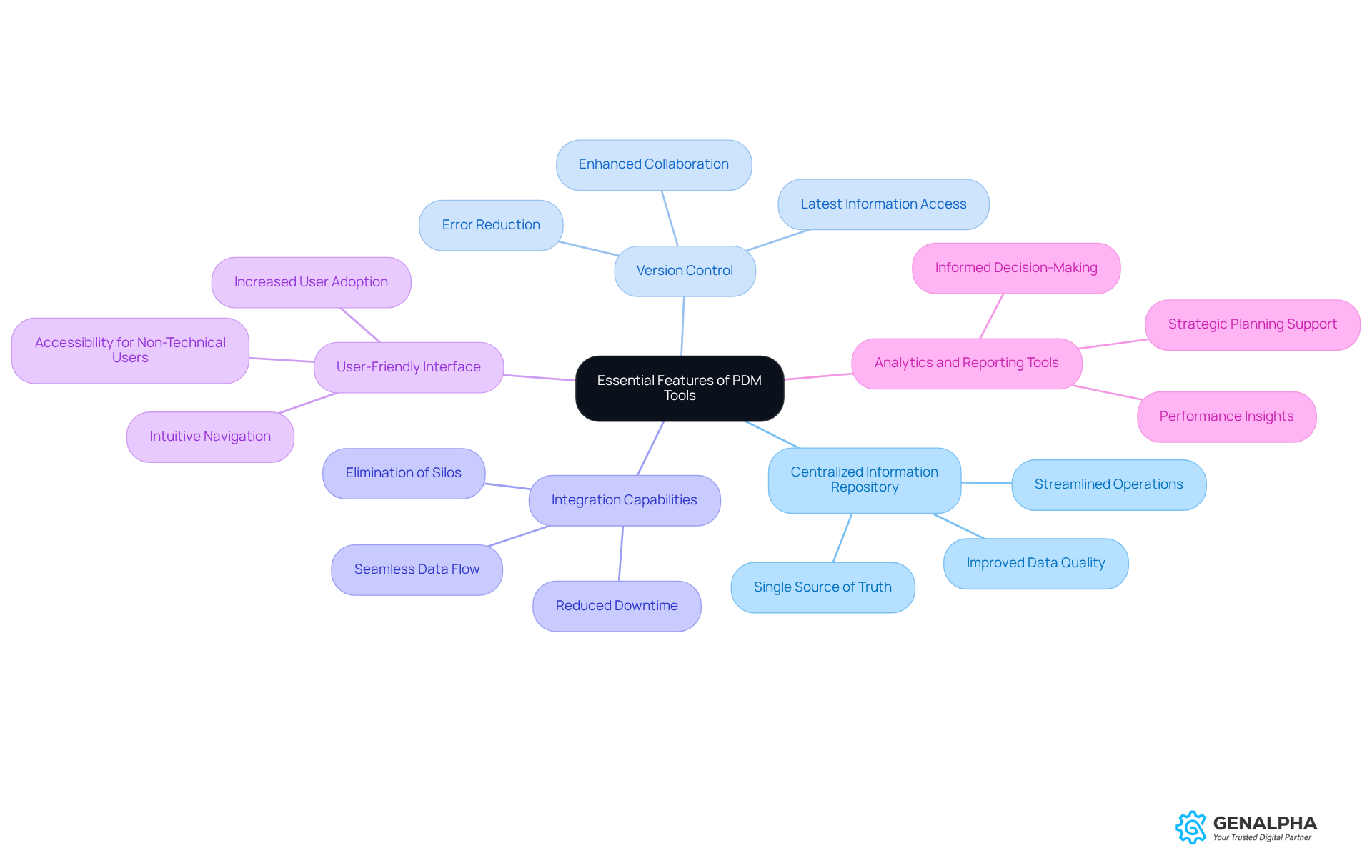

Identify Essential Features of PDM Tools

When it comes to selecting a product data management tool, manufacturers really need to focus on features that enhance information accuracy, collaboration, and accessibility. So, what should you look for? Here are some essential features:

-

Centralized Information Repository: Think of this as your go-to source for all product-related details. It helps cut down on discrepancies and keeps information integrity intact across the organization. TrustCloud points out that having centralized information means you can access everything from one spot, which really streamlines operations and boosts efficiency.

-

Version Control: This feature ensures that everyone on the team is working with the latest information. No more confusion or errors during product development-just smooth sailing and enhanced efficiency.

-

Integration Capabilities: You want your PIM tool to easily connect with your existing ERP and other platforms. This seamless integration allows for smooth information flow and eliminates those pesky information silos. Plus, it helps reduce downtime and the costs that come with repetitive tasks, as noted by Shivaram P R.

-

User-Friendly Interface: An intuitive design is key! It makes it easier for your staff to navigate the system, which can really boost user adoption rates.

-

Analytics and Reporting Tools: These features provide valuable insights into product performance and information quality. They empower you to make informed decisions and plan strategically. Did you know that inaccurate product data can cost businesses a whopping $12.9 million a year? Gartner highlights just how crucial effective product data management tools are in the industry.

Take Procter & Gamble, for example. They’ve effectively used a product data management tool that includes these features to streamline their product development processes, leading to significant cost savings and improved product quality. This case really shows how a well-implemented PDM strategy can transform manufacturing efficiency.

So, are you ready to explore how these tools can benefit your organization? Let’s dive in!

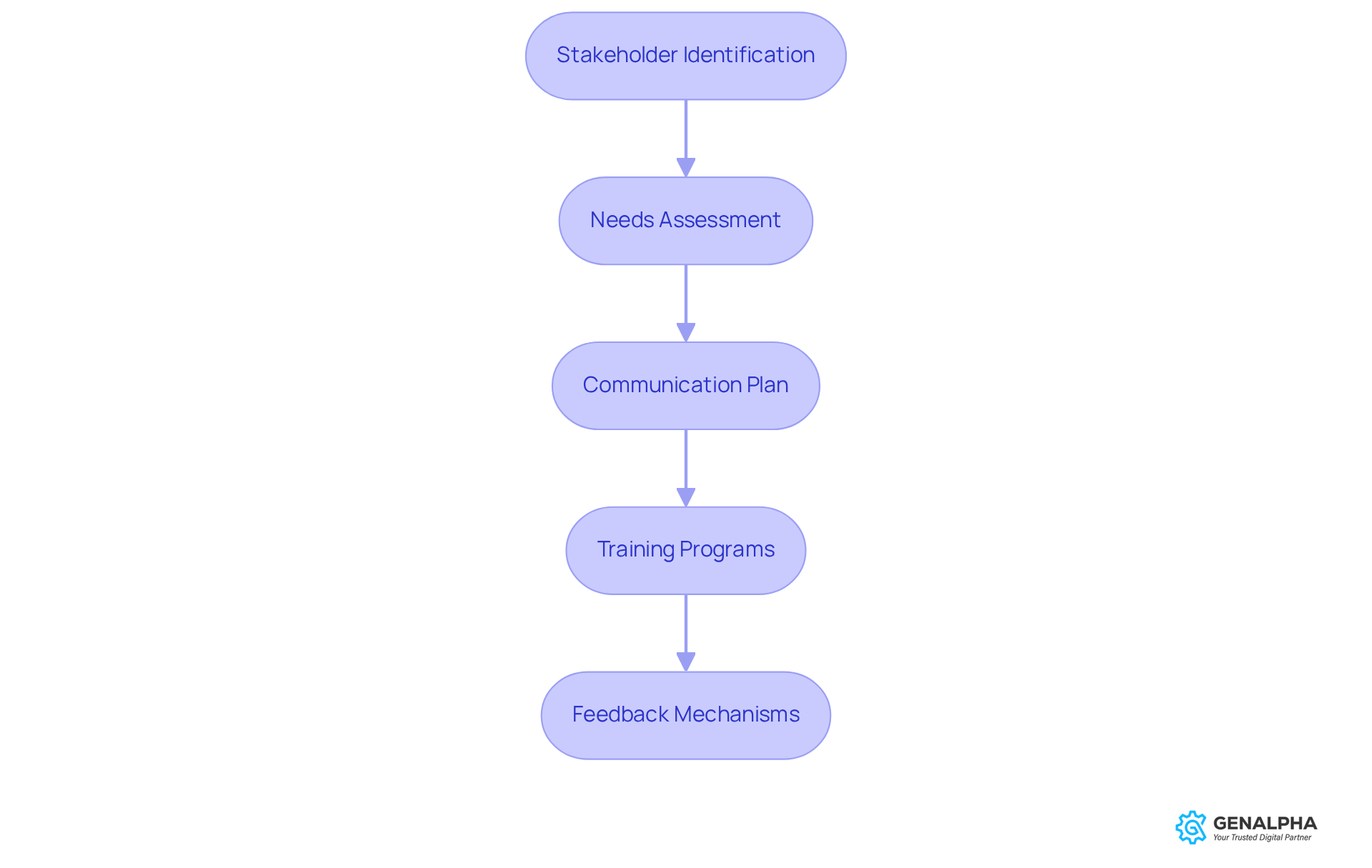

Plan for Successful Implementation and Stakeholder Engagement

To effectively implement Product Data Management (PDM) tools, manufacturers should follow these strategic steps:

-

Stakeholder Identification: First things first, let’s recognize all the key players involved in the PDM process. This includes teams from design, engineering, production, and sales. Everyone has a role to play!

-

Needs Assessment: Next up, it’s time to dive into a comprehensive analysis of what each stakeholder group really needs. By customizing the product data management tool to address their unique challenges, you’ll significantly boost adoption rates. Remember, as Changefirst points out, engaging influential people in the process is crucial for successful change.

-

Communication Plan: Now, let’s talk about communication. Creating a solid strategy to keep everyone in the loop about the implementation process, its benefits, and timelines is key. Regular updates foster transparency and trust, which are essential for successful engagement. Did you know that companies that effectively engage with stakeholders are 50% more likely to hit their big goals?

-

Training Programs: Don’t forget about training! Conducting comprehensive sessions ensures everyone is comfortable with the new setup. Well-trained individuals are more likely to embrace the product data management tool, which leads to higher adoption rates and smoother transitions. A study found that only 25% of recipients fully commit to a specific change, so effective training is a must.

-

Feedback Mechanisms: Finally, establish channels for ongoing feedback through a product data management tool. This way, you can refine and enhance the PDM system after implementation. An iterative process helps address any issues promptly and improves customer satisfaction.

For example, a manufacturing firm that prioritized early stakeholder engagement during its PDM implementation saw a remarkable 30% increase in user satisfaction. This really highlights the critical role of stakeholder involvement in achieving a successful transition. Plus, it’s worth noting that about 70% of companies fail to make the changes they intend, which emphasizes the importance of prioritizing stakeholder engagement in PDM implementation.

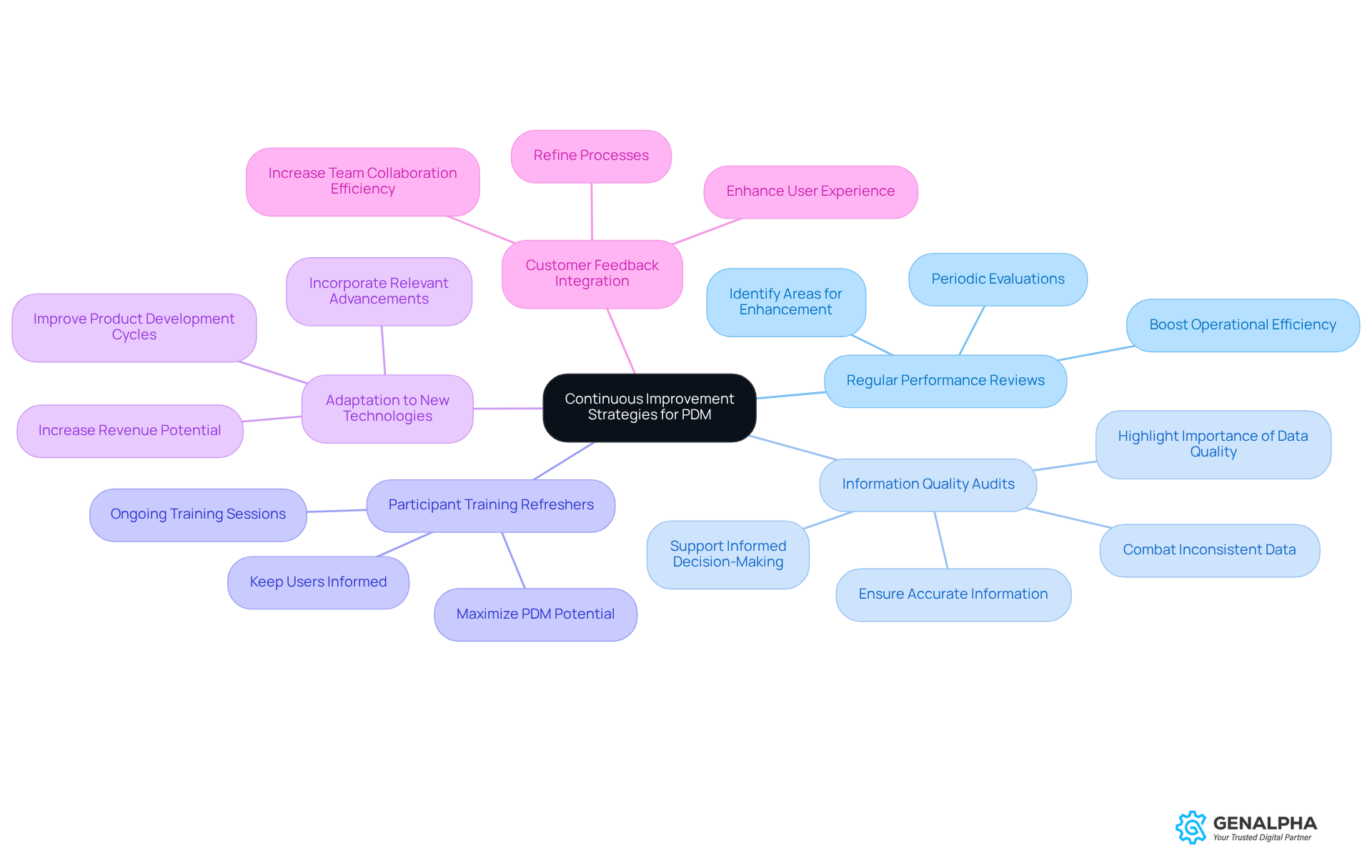

Establish Continuous Improvement and Support Mechanisms

To ensure the long-term success of the product data management tool, manufacturers should think about implementing some continuous improvement strategies.

-

Regular Performance Reviews: How often do you take a step back to evaluate your PDM framework? Scheduling periodic evaluations is key to assessing the effectiveness of the product data management tool and identifying areas for enhancement. Companies that regularly review their product data management tool often find they can boost operational efficiency and cut down on errors.

-

Information Quality Audits: Have you ever made a decision based on inaccurate information? Conducting audits to ensure that the product data management tool contains accurate, complete, and current information is crucial. Regular quality assessments are enhanced by a product data management tool, which helps in making informed decisions, as incorrect information can lead to flawed business strategies. As Brian M. Morgan puts it, "Investing in information quality is not merely a technical necessity but a vital business strategy that yields benefits in both the short and long term." A study shows that 58% of business leaders say their key decisions are often based on inconsistent information, highlighting the need for rigorous auditing processes. Abdul Qayyum also emphasizes that "data quality audits are the primary defense against bad data and the flawed decisions it causes."

-

Participant Training Refreshers: When was the last time you brushed up on your skills? Ongoing training sessions on the product data management tool are essential to keep everyone informed about new features and best practices. This not only boosts individual proficiency but also maximizes the potential of the PDM framework.

-

Adaptation to New Technologies: Are you keeping up with the latest tech trends? Staying informed about emerging technologies in the product data management tool can help you incorporate relevant advancements into your current framework. Companies that adapt to these changes can significantly improve their product development cycles by utilizing a product data management tool. Research shows that speeding up these cycles by just 20% can lead to a revenue boost of up to 30%.

-

Customer Feedback Integration: How often do you ask for feedback from your end-users? Actively seeking and incorporating feedback can refine processes and enhance the overall experience when using a product data management tool. For example, a leading automotive manufacturer rolled out a continuous improvement program for its PDM system, resulting in a 25% reduction in data errors and better collaboration across departments. This really highlights the tangible benefits of integrating user insights into strategies for the product data management tool. Plus, companies using PDM report up to a 25% increase in team collaboration efficiency, showcasing the value of continuous improvement initiatives.

Conclusion

Mastering product data management tools is crucial for manufacturers looking to thrive in today’s competitive landscape. Think about it: effective PDM systems not only streamline operations but also boost collaboration and accuracy throughout the product development process. By centralizing information and leveraging key features like version control and integration capabilities, manufacturers can cut down on errors and speed up their time-to-market.

In this article, we’ve explored the importance of implementing solid PDM strategies. From grasping the essential features that drive efficiency to planning successful stakeholder engagement, every aspect plays a vital role in unlocking the full potential of product data management. Plus, continuous improvement strategies - like regular performance reviews and integrating user feedback - help ensure these tools evolve to meet ever-changing demands and technologies.

The importance of product data management in manufacturing is huge. As the industry keeps growing and adapting, embracing these tools will not only enhance operational efficiency but also spark innovation and boost customer satisfaction. So, why not take proactive steps to implement and refine your PDM systems? Staying ahead in a rapidly evolving market is key, and it all starts with making the most of your product data management!

Frequently Asked Questions

What is Product Information Management (PIM) in manufacturing?

Product Information Management (PIM) in manufacturing involves managing product-related information throughout its lifecycle, ensuring that accurate and up-to-date information is accessible to all stakeholders from design to production to sales.

Why is an effective product data management tool important in manufacturing?

An effective product data management tool is crucial as it helps centralize product information, reduces errors, boosts collaboration, and speeds up time-to-market for manufacturers.

What benefits do companies experience with strong Product Data Management (PDM) systems?

Companies with strong PDM systems experience a 20% reduction in product development time and can respond to market demands more quickly. Additionally, those using advanced technologies for centralized information platforms achieve 85% more accurate forecasting.

What is the projected market value of Product Data Management by 2024?

The global Product Data Management market is projected to reach USD 4.2 billion by 2024.

What challenges do manufacturers face when implementing Product Data Management?

Manufacturers face challenges such as information security concerns and integration complexities when implementing Product Data Management strategies.

Why is it essential for manufacturers to understand and implement effective PDM strategies?

Understanding and implementing effective PDM strategies is essential for driving customer satisfaction and maintaining competitiveness in the manufacturing industry.