Introduction

The manufacturing sector is at a crucial turning point. It’s not just about keeping up with trends anymore; integrating digital technologies has become essential for survival. With innovations like the Internet of Things (IoT) and artificial intelligence (AI) changing the game, companies are faced with both exciting opportunities and some pretty big challenges.

So, how can organizations navigate this tricky transformation? It’s all about enhancing productivity and securing that competitive edge in a digital marketplace that’s only getting more crowded. Let’s explore the key steps and strategies for mastering digital transformation in manufacturing. There’s a lot of potential rewards out there, but also some significant hurdles to overcome.

Are you ready to dive in and see what’s possible?

Understand Digital Transformation in Manufacturing

The manufacturing industry digital transformation is all about weaving electronic innovations into every corner of a manufacturing business. This manufacturing industry digital transformation is shaking up operational procedures and enhancing the delivery of value to clients. Think about tools like the Internet of Things (IoT), artificial intelligence (AI), and advanced analytics. Together, they’re driving productivity, cutting costs, and enhancing product quality.

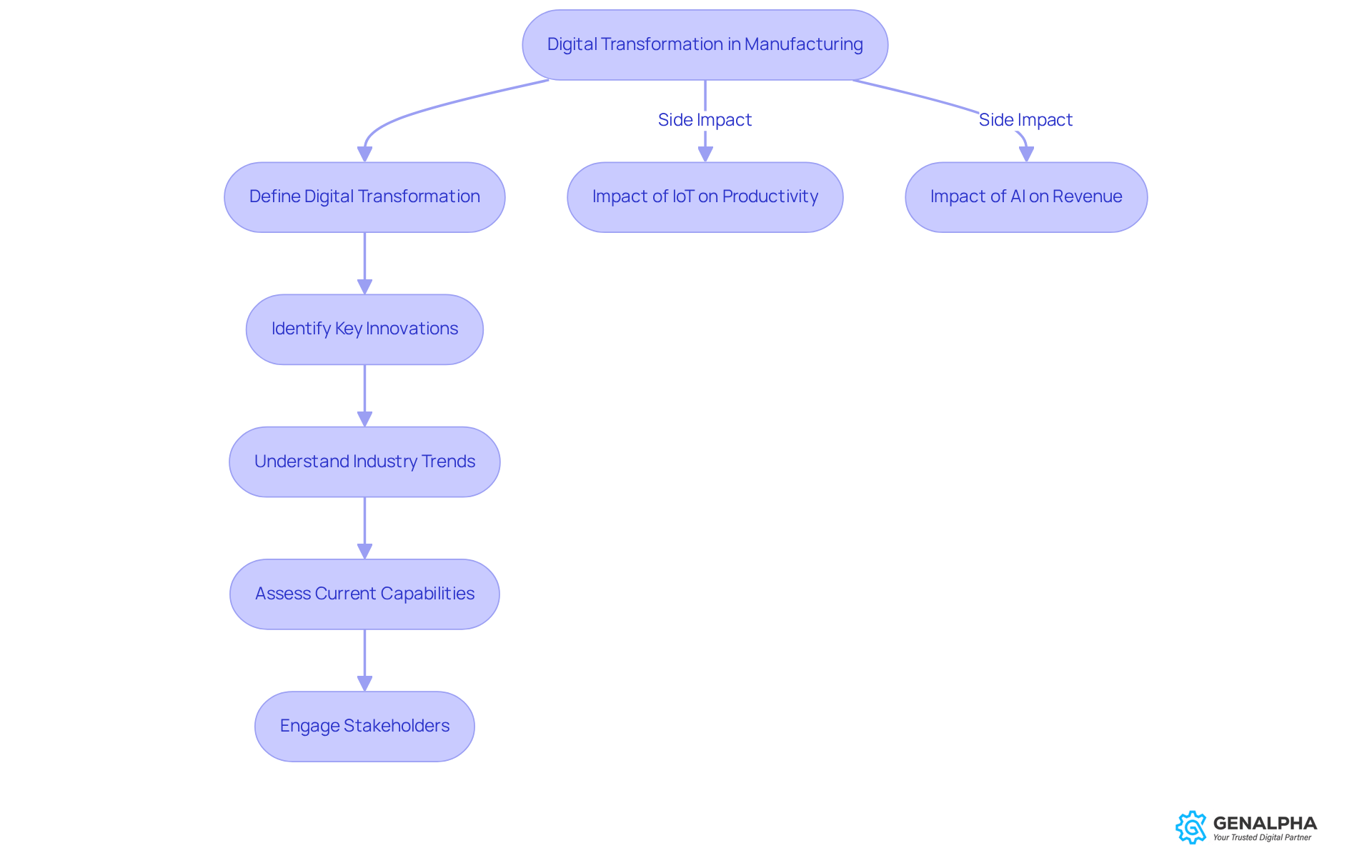

So, how can you effectively navigate this digital transformation? Here are some steps to consider:

- Define Digital Transformation: It’s not just about adopting new tech; it’s a holistic strategy that requires a cultural shift within your organization.

- Identify Key Innovations: Get familiar with essential advancements like IoT for real-time data collection, AI for predictive analytics, and automation to streamline processes.

- Understand Industry Trends: Stay updated on trends like smart manufacturing and Industry 4.0, which emphasize interconnected systems and data-driven decision-making. Did you know that 64% of organizations need to establish new online enterprises to stay competitive beyond 2024?

- Assess Current Capabilities: Take a good look at your existing processes and technologies to spot gaps that tech changes can fill.

- Engage Stakeholders: Bring key stakeholders into the conversation about tech changes to ensure everyone’s on board and supportive.

Now, let’s talk about the impact of IoT on manufacturing efficiency. Companies are seeing productivity boosts of 5-15% from well-implemented tech changes. Plus, AI initiatives can lead to average revenue increases of 5% and cost reductions of 10%. Organizations that integrate these technologies effectively can achieve a whopping 10.3x ROI from AI initiatives. This really highlights the financial benefits of embracing digital change.

Successful examples in the manufacturing industry digital transformation show that companies adopting these technologies not only enhance operational efficiencies but also strengthen customer relationships. This positions them competitively in the ever-evolving market landscape. So, are you ready to take the plunge into digital transformation?

Identify Challenges in Digital Transformation

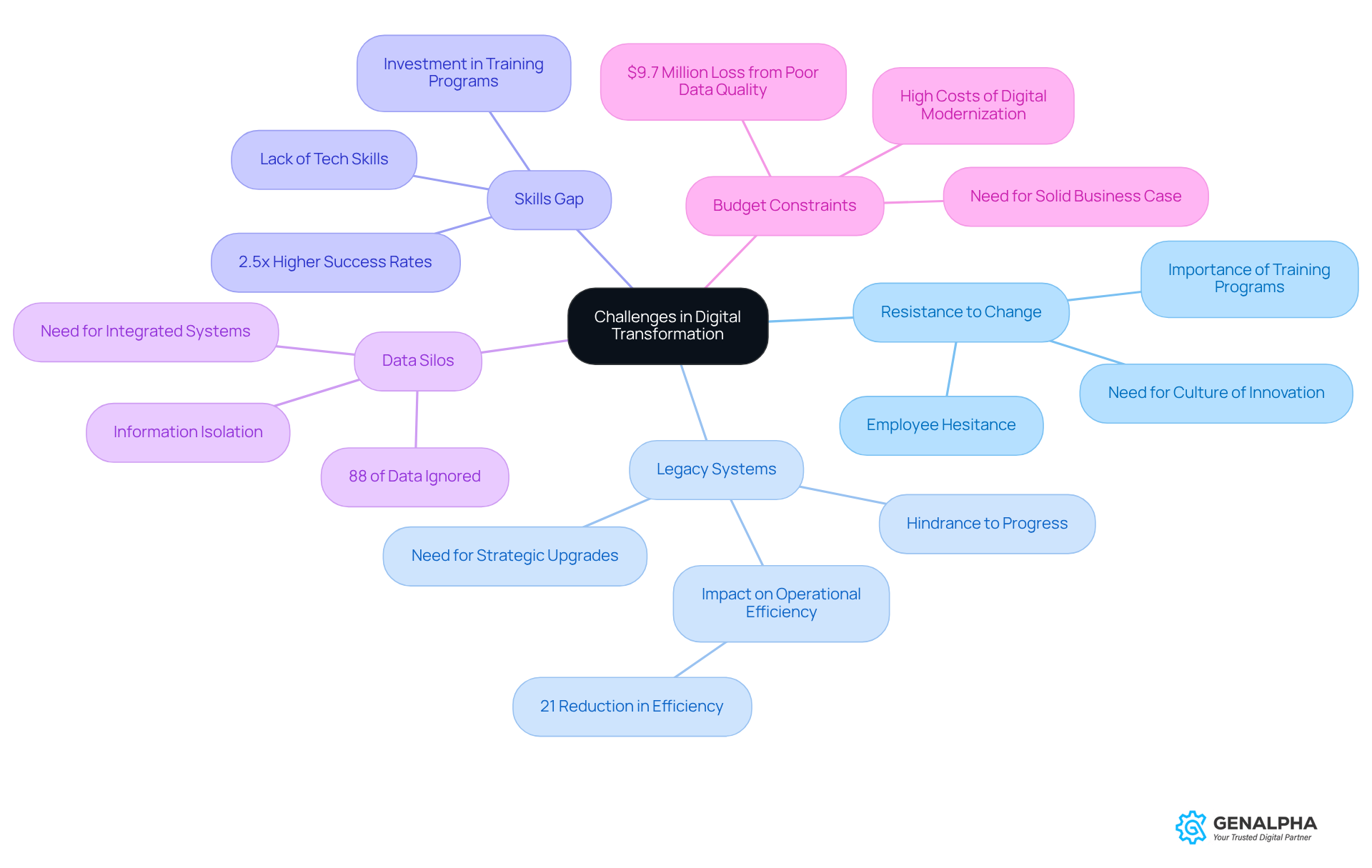

The manufacturing industry digital transformation can be a bit of a rollercoaster, right? Organizations must tackle several challenges head-on to ensure a smooth transition during the manufacturing industry digital transformation. Spotting these hurdles early on can really boost the effectiveness of the transformation journey. Let’s dive into some common challenges:

-

Resistance to Change: Ever noticed how employees can be hesitant to embrace new tools or processes? To ease this, it’s all about cultivating a culture of innovation. Encourage open communication and offer comprehensive training programs to help everyone adjust. Tim O'Reilly once said that the manufacturing industry digital transformation is essential for every industry to adapt in the coming years, highlighting the crucial nature of adaptability.

-

Many manufacturers are still clinging to legacy systems that hinder their progress in the manufacturing industry digital transformation. It’s a good idea to assess what you have and come up with a strategic plan for upgrades or replacements. Did you know that poor data management can cut operational efficiency by 21%? That’s a wake-up call for addressing those legacy systems!

-

Skills Gap: Sometimes, the workforce might not have the tech skills needed to implement and use new technologies effectively. Investing in targeted training programs can really help bridge that gap, giving employees the confidence to use digital tools essential for manufacturing industry digital transformation. Organizations that focus on improving information quality see 2.5 times greater success in their manufacturing industry digital transformation, which is a compelling reason to invest in skill development!

-

Data Silos: Information often gets stuck in isolated departments, which can really hinder collaboration and decision-making. By implementing integrated systems that promote sharing across the organization, you can boost transparency and create a more collaborative environment. A report from IBM shows that 88% of information goes unnoticed by businesses, leading to inefficiencies and missed opportunities. Let’s not let that happen!

-

Budget Constraints: We all know that digital modernization can come with a hefty price tag. It’s essential to craft a solid business case that clearly outlines the expected return on investment (ROI) to gain the funding and support needed for the manufacturing industry digital transformation from stakeholders. The financial impact of poor data quality averages around $9.7 million each year-now that’s a strong argument for investing in tech advancements!

So, what do you think? Are you ready to tackle these challenges head-on and embrace the digital future?

Recognize Critical Success Factors

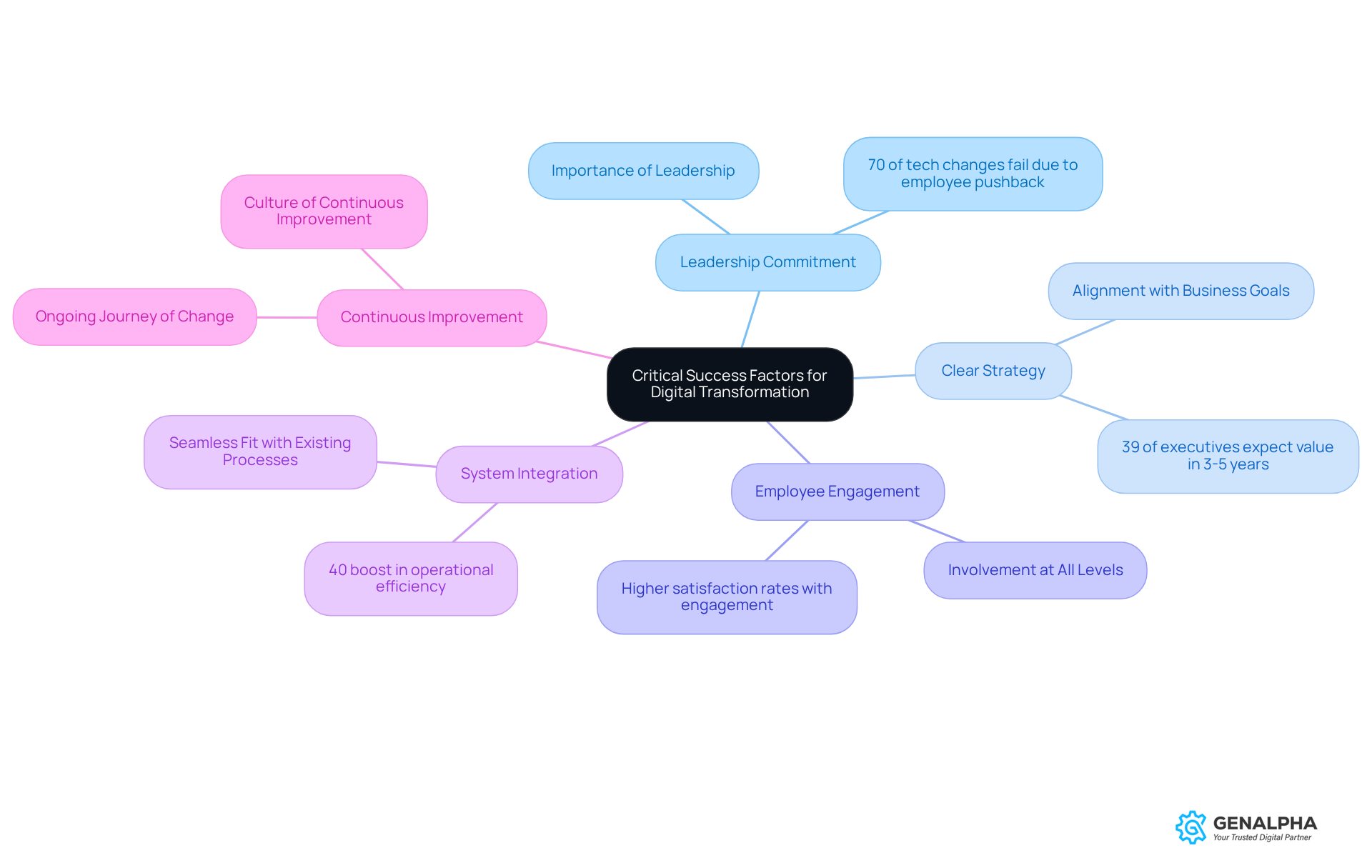

To achieve successful digital transformation in manufacturing, organizations need to focus on a few key factors that can really make a difference:

-

Leadership Commitment: Strong leadership is crucial for driving the vision of change and motivating the workforce. Leaders should be hands-on in the process, clearly sharing the benefits of technological change to rally support across the organization. Did you know that studies show 70% of tech changes fail due to employee pushback? That’s a big deal! It really highlights how important dedicated leadership is.

-

Clear Strategy: Crafting a solid digital overhaul strategy that aligns with your business goals is a must. This strategy should lay out specific objectives, timelines, and metrics for success. Companies with a clear strategy are more likely to see positive results. In fact, 39% of executives believe they’ll get the most value from their initiatives in three to five years. That’s something to think about!

-

Employee Engagement: Getting employees involved at all levels in the change process is vital. Their insights can provide valuable perspectives on challenges and opportunities, making sure the change is relevant and effective. Organizations that prioritize employee engagement often see higher satisfaction rates and better operational performance. As Blake Morgan puts it, "Digital transformation and customer experience go hand in hand."

-

System Integration: It’s critical to ensure that new innovations fit seamlessly into existing processes. This might mean choosing compatible systems and providing the right training for staff. Companies that successfully implement manufacturing industry digital transformation can boost operational efficiency by 40% and better meet customer expectations. That’s a win-win!

-

Continuous Improvement: Remember, digital change isn’t a one-and-done deal. It’s an ongoing journey that needs mechanisms for continuous feedback and enhancement. Organizations should stay adaptable to changing market conditions and tech advancements to keep their competitive edge. Establishing a culture of continuous improvement can lead to lasting success and innovation. Companies that invest in customer experience often see significant financial benefits, and who wouldn’t want that?

So, what’s your take on these factors? How can your organization start implementing them today?

Implement Effective Digital Solutions

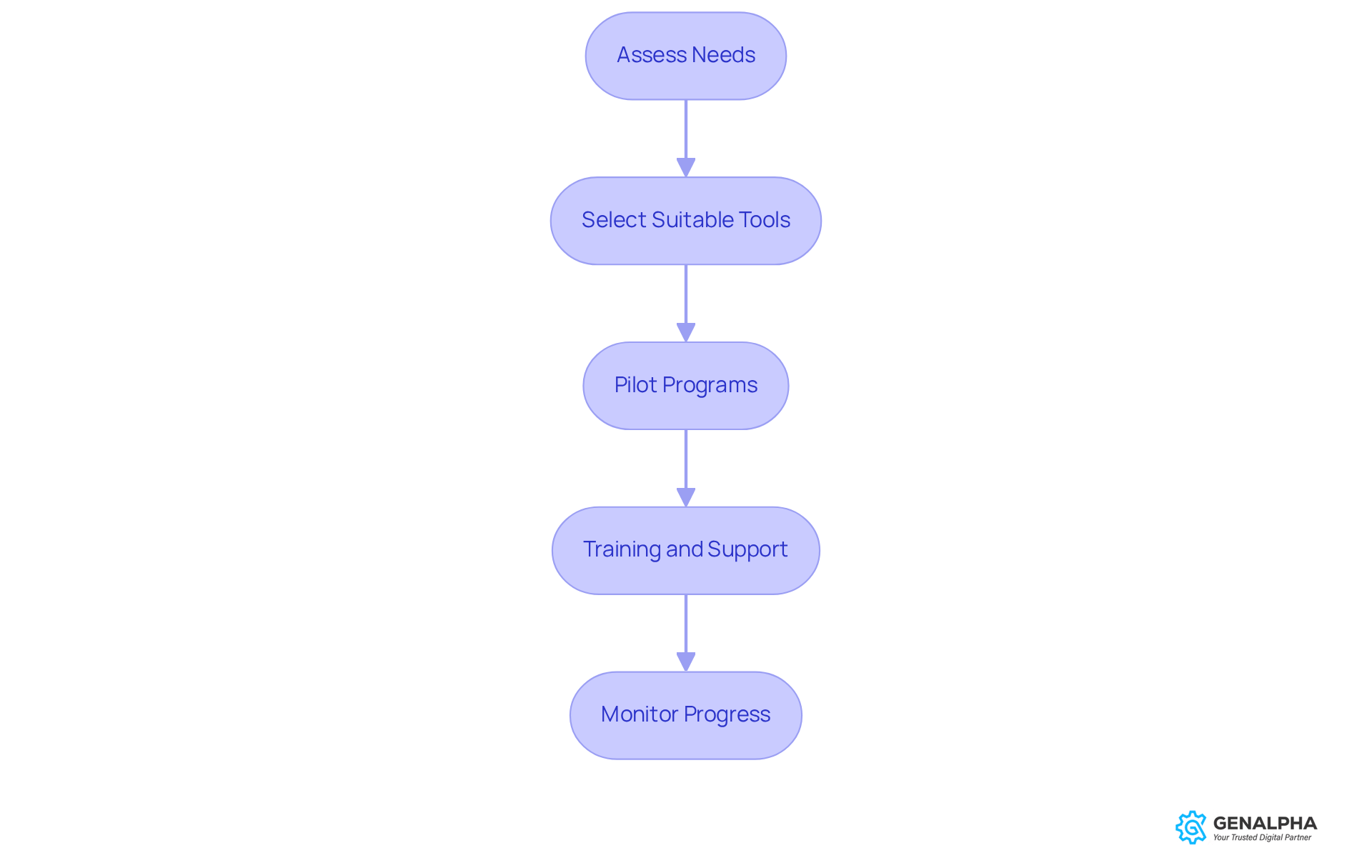

Implementing effective online solutions is crucial for leveraging manufacturing industry digital transformation. So, how do we ensure a successful implementation? Let’s break it down into some simple steps:

-

Assess Needs: Start by taking a good look at your organization’s current operations. What areas could really benefit from some tech upgrades? It’s worth noting that 64% of organizations struggle because of poor information quality, which can seriously impact the success of your digital initiatives.

-

Select Suitable Tools: Next up, choose tools that fit your strategic goals. Think about IoT for real-time equipment monitoring, AI for predictive maintenance, and cloud computing for scalable data storage and accessibility. Did you know that cloud spending is projected to reach $679 billion by 2026? That really highlights how important this option is!

-

Pilot Programs: Before going all in, why not start with pilot programs? Testing your chosen innovations on a smaller scale lets you make adjustments based on real-world feedback. It’s a smart way to ensure everything runs smoothly before full-scale implementation.

-

Training and Support: Don’t forget about your team! Make sure employees get thorough training on the new technologies. This helps them feel comfortable and proficient. Plus, ongoing support is key to tackling any bumps in the road, especially since change management can often meet some cultural resistance.

-

Monitor Progress: Finally, set up key performance indicators (KPIs) to measure how well your new solutions are working. Regularly check these metrics to see how things are going and make informed adjustments as needed. Remember, 92% of manufacturing companies believe that manufacturing industry digital transformation boosts competitiveness, which really underscores the need for effective tech solutions.

So, are you ready to take the plunge into the world of digital transformation?

Measure and Analyze Transformation Impact

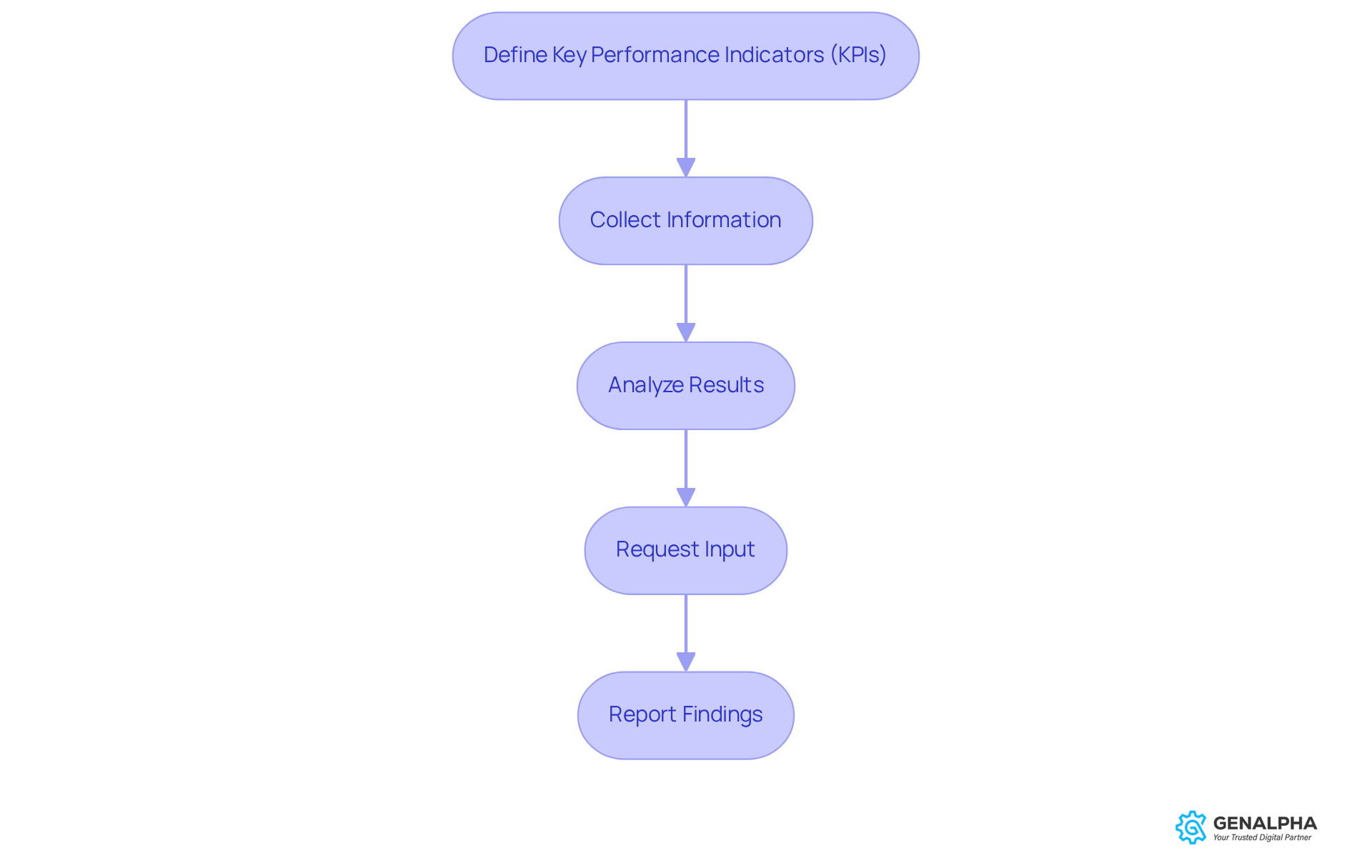

To make sure our electronic advancement efforts really hit the mark, it’s crucial to measure and analyze their impact. So, how do we effectively evaluate transformation outcomes? Let’s break it down:

-

Define Key Performance Indicators (KPIs): First things first, we need to set KPIs that align with our strategic goals. Consider common KPIs in the context of manufacturing industry digital transformation, including operational efficiency, customer satisfaction scores, and revenue growth. Did you know that 81% of organizations use productivity as a primary measure of manufacturing industry digital transformation ROI? That’s a big deal and can lead to some serious performance improvements!

-

Collect Information: Next up, let’s gather information related to those KPIs. This might mean using advanced analytics tools, like IoT and big data technologies, to keep an eye on performance metrics in real-time. It’s all about making sure our information collection methods are solid and comprehensive.

-

Analyze Results: Now, it’s time to dig into the data. Regularly examining the information we’ve gathered helps us spot trends, successes, and areas where we can improve. This analysis should guide our decision-making and strategy tweaks, with metrics like time-to-market and product development cycle time giving us insights into how innovation is impacting us.

-

Request Input: Don’t forget to ask for feedback! Collecting insights from staff and clients about their experiences with the new electronic solutions adds a valuable layer to our quantitative measurements. This qualitative information gives us a fuller picture of effectiveness.

-

Report Findings: Finally, let’s create reports that summarize the impact of our technological changes. Sharing these findings with stakeholders not only highlights our progress but also helps secure ongoing support for future initiatives. It’s all about being open and accountable throughout the change process.

Katherine Kostereva reminds us that digital transformation isn’t just a project; it’s a business discipline. It’s got broader implications that go beyond just metrics. So, what do you think? Are you ready to dive into measuring your transformation outcomes?

Conclusion

Embracing digital transformation in the manufacturing industry isn’t just a passing trend; it’s a vital evolution that weaves advanced technologies into every part of operations. This shift is crucial for organizations looking to boost productivity, enhance customer satisfaction, and stay competitive in a fast-changing market.

So, what’s the takeaway? Key insights from the article stress the need for:

- A clear strategy

- Engaging stakeholders

- Tackling common hurdles like resistance to change and skills gaps

By grasping the critical success factors and rolling out effective digital solutions, manufacturers can navigate this transformation with confidence. The potential benefits - think significant ROI and operational efficiencies - really highlight why adopting innovative technologies like IoT and AI is a must.

Ultimately, the journey of digital transformation in manufacturing is ongoing. It calls for commitment, adaptability, and a readiness to learn from both wins and setbacks. As we look toward 2025 and beyond, it’s clear that organizations need to prioritize this transformation to thrive in an increasingly digital world. Taking proactive steps today can lead to substantial rewards tomorrow, ensuring that manufacturers not only survive but truly flourish amidst technological advancements.

Frequently Asked Questions

What is digital transformation in manufacturing?

Digital transformation in manufacturing involves integrating electronic innovations, such as IoT, AI, and advanced analytics, into all aspects of a manufacturing business to improve operational procedures and enhance value delivery to clients.

What are the steps to navigate digital transformation effectively?

Key steps include defining digital transformation as a holistic strategy, identifying key innovations like IoT and AI, understanding industry trends such as smart manufacturing and Industry 4.0, assessing current capabilities, and engaging stakeholders in the process.

How does IoT impact manufacturing efficiency?

IoT can lead to productivity boosts of 5-15% when implemented effectively, contributing to overall operational efficiency in manufacturing.

What financial benefits can organizations expect from integrating AI?

AI initiatives can result in average revenue increases of 5% and cost reductions of 10%, with organizations achieving a 10.3x ROI from effective AI integration.

What are common challenges faced during digital transformation in manufacturing?

Common challenges include resistance to change, reliance on legacy systems, skills gaps in the workforce, data silos, and budget constraints.

How can organizations address resistance to change during digital transformation?

Organizations can ease resistance by cultivating a culture of innovation, encouraging open communication, and providing comprehensive training programs to help employees adjust to new tools and processes.

Why is it important to address legacy systems in manufacturing?

Legacy systems can hinder progress in digital transformation, and poor data management from these systems can reduce operational efficiency by 21%. Assessing and planning for upgrades is crucial.

How can organizations bridge the skills gap in their workforce?

Investing in targeted training programs can help employees develop the necessary tech skills to implement and use new technologies effectively.

What are data silos, and why are they problematic?

Data silos occur when information is isolated within departments, hindering collaboration and decision-making. Implementing integrated systems can promote data sharing and improve transparency.

How can organizations secure funding for digital transformation initiatives?

Crafting a solid business case that outlines the expected ROI can help gain funding and support from stakeholders for digital transformation efforts.