Introduction

The manufacturing landscape is changing fast, and so are the tools that help boost efficiency and keep customers happy. Have you heard about CPQ software? That’s Configure, Price, Quote software, and it’s really shaking things up for manufacturers. It automates those tricky product configurations and makes the quoting process a breeze.

As manufacturers look to step up their sales strategies and improve how they connect with customers, implementing CPQ systems can be a game-changer. But it’s not all smooth sailing - there are challenges to tackle along the way. So, how can manufacturers navigate these hurdles and tap into the full potential of CPQ technology? It’s all about driving success in a market that’s getting more competitive by the day. Let’s dive in!

Understand CPQ Software and Its Role in Manufacturing

The logiciel cpq application is a fantastic tool designed to simplify life for manufacturers. It automates product configuration, calculates pricing based on what customers need, and whips up accurate quotes in no time. This logiciel cpq excels in the manufacturing world, where products can get pretty complex and customizable.

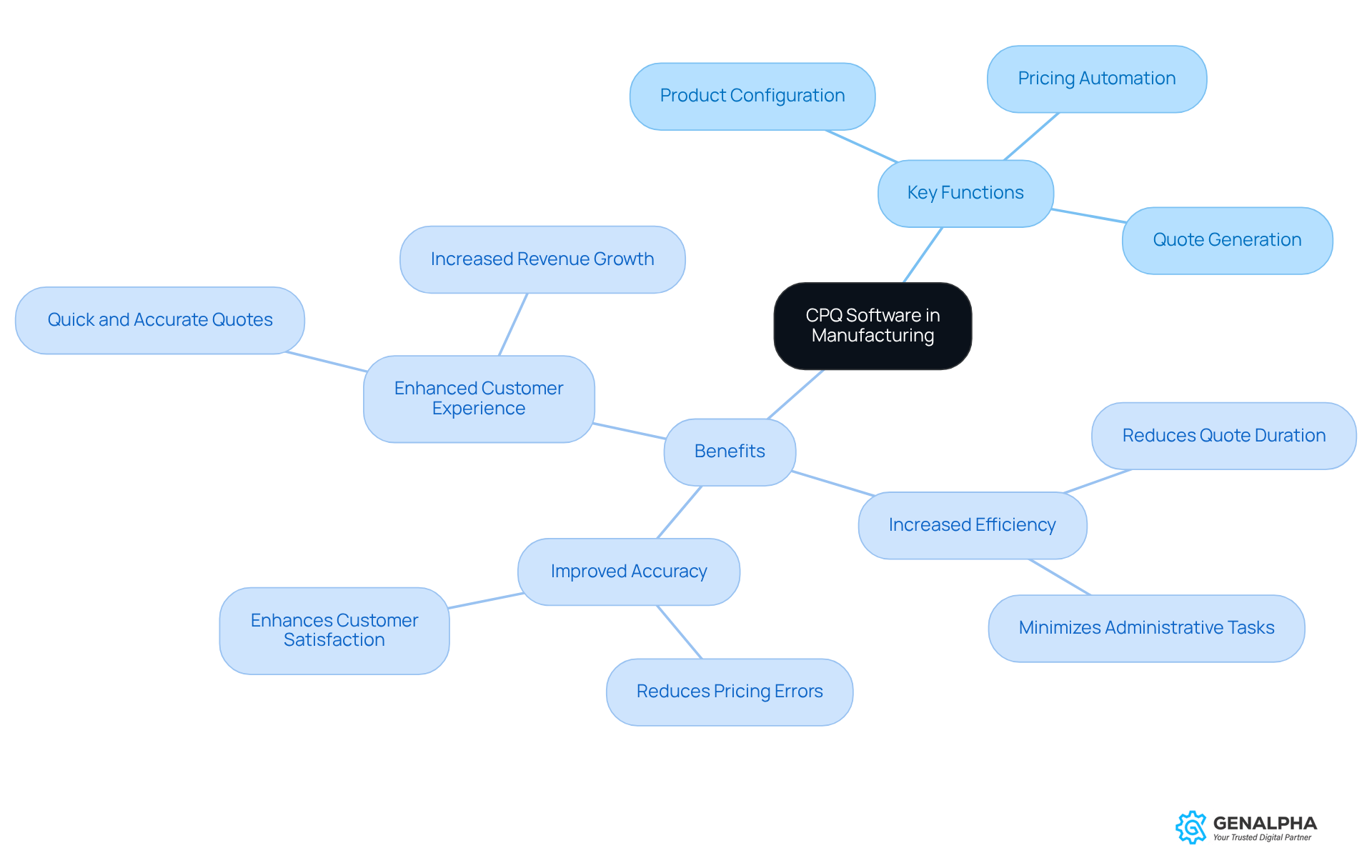

Key Functions of CPQ Software:

- Product Configuration: It lets sales teams tailor products to fit customer specifications, ensuring every option and feature is spot on.

- Pricing Automation: Prices are calculated automatically based on set rules, discounts, and customer agreements, which cuts down on manual errors.

- Quote Generation: It quickly churns out professional quotes that can be sent to customers, speeding up the sales cycle significantly.

Benefits of CPQ in Manufacturing:

- Increased Efficiency: Say goodbye to the long hours spent on manual quoting! With logiciel cpq, sales teams can instead focus on closing deals. Studies show that solutions utilizing logiciel cpq can cut quote duration from weeks to just minutes, allowing manufacturers to handle more customers in the sales pipeline. Plus, quoting inefficiencies can leak about 5% of annual revenue-roughly $2.5M per year for a mid-sized manufacturer.

- Improved Accuracy: CPQ minimizes errors in pricing and product configurations, which leads to happier customers. With 53% of manufacturers pointing to complex approval processes as a reason for lost deals, the accuracy that CPQ brings can really boost revenue.

- Enhanced Customer Experience: Customers get quick and accurate quotes, which makes their buying experience much smoother. As more producers adopt logiciel cpq solutions, many report a 35% revenue increase in the first year of use, demonstrating how logiciel cpq can drive sales growth. Kiana Mostajabian notes that '69% of manufacturing organizations plan to increase their investment in logiciel cpq technology this year,' highlighting its growing importance in the industry.

Integrating logiciel cpq solutions into manufacturing not only streamlines sales tasks but also transforms the way manufacturers interact with customers. It’s a must-have for those looking to thrive in a competitive landscape. But, let’s not forget about the potential bumps in the road, like training team members and the learning curve that comes with new tech. Understanding these aspects of CPQ systems is key for manufacturers aiming to enhance their sales strategies and customer interactions.

Follow a Step-by-Step Implementation Process for CPQ

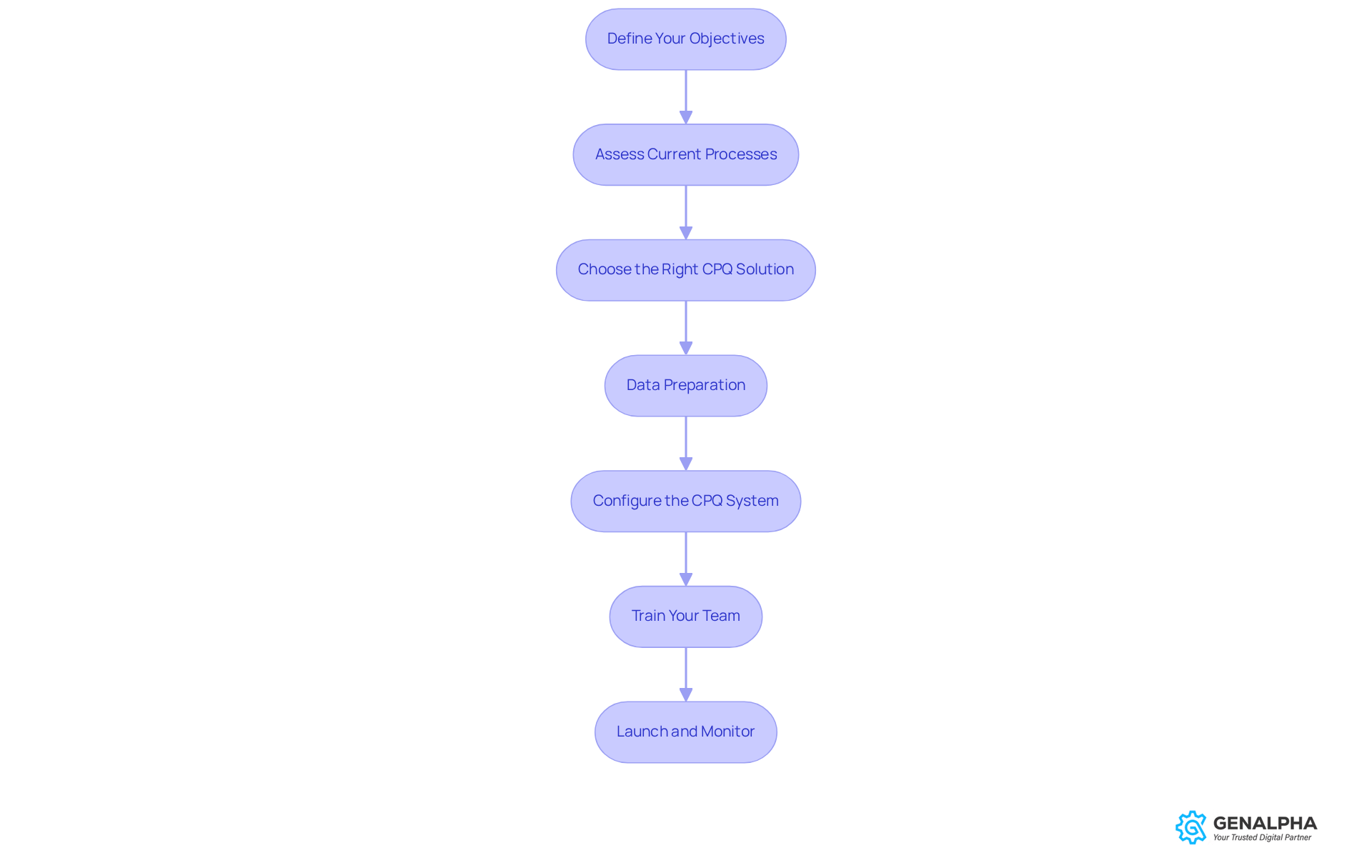

Implementing CPQ software? It’s all about careful planning and execution! Let’s walk through a step-by-step guide to make sure your implementation is a success:

-

Define Your Objectives

First things first, what do you want to achieve with CPQ? Maybe it’s cutting down quote times or boosting accuracy. Whatever it is, get clear on those goals! -

Assess Current Processes

Next up, take a good look at your existing sales processes. What’s working? What’s not? Identifying these areas will help you see how logiciel cpq can step in and make things better. -

Choose the Right CPQ Solution

Now, it’s time to do some research. Find a logiciel cpq solution that meets your business needs and works well with your current systems. This is crucial for a smooth transition! -

Data Preparation

Gather your product and pricing data and give it a good clean-up. You want everything to be accurate and ready to roll into the CPQ system. -

Configure the CPQ System

Here’s where the magic happens! Set up the logiciel cpq in accordance with your business rules. Think product configurations, pricing structures, and approval workflows. -

Train Your Team

Don’t forget about your sales team! Provide them with comprehensive training so they feel comfortable using the new system and understand all the benefits it brings. -

Launch and Monitor

Finally, it’s showtime! Roll out the logiciel cpq and monitor its performance closely. Gather feedback from users to make any necessary tweaks.

By following these steps, manufacturers can effectively implement CPQ solutions, leading to improved sales efficiency and happier customers. Ready to get started?

Integrate CPQ Software with Existing Systems and Processes

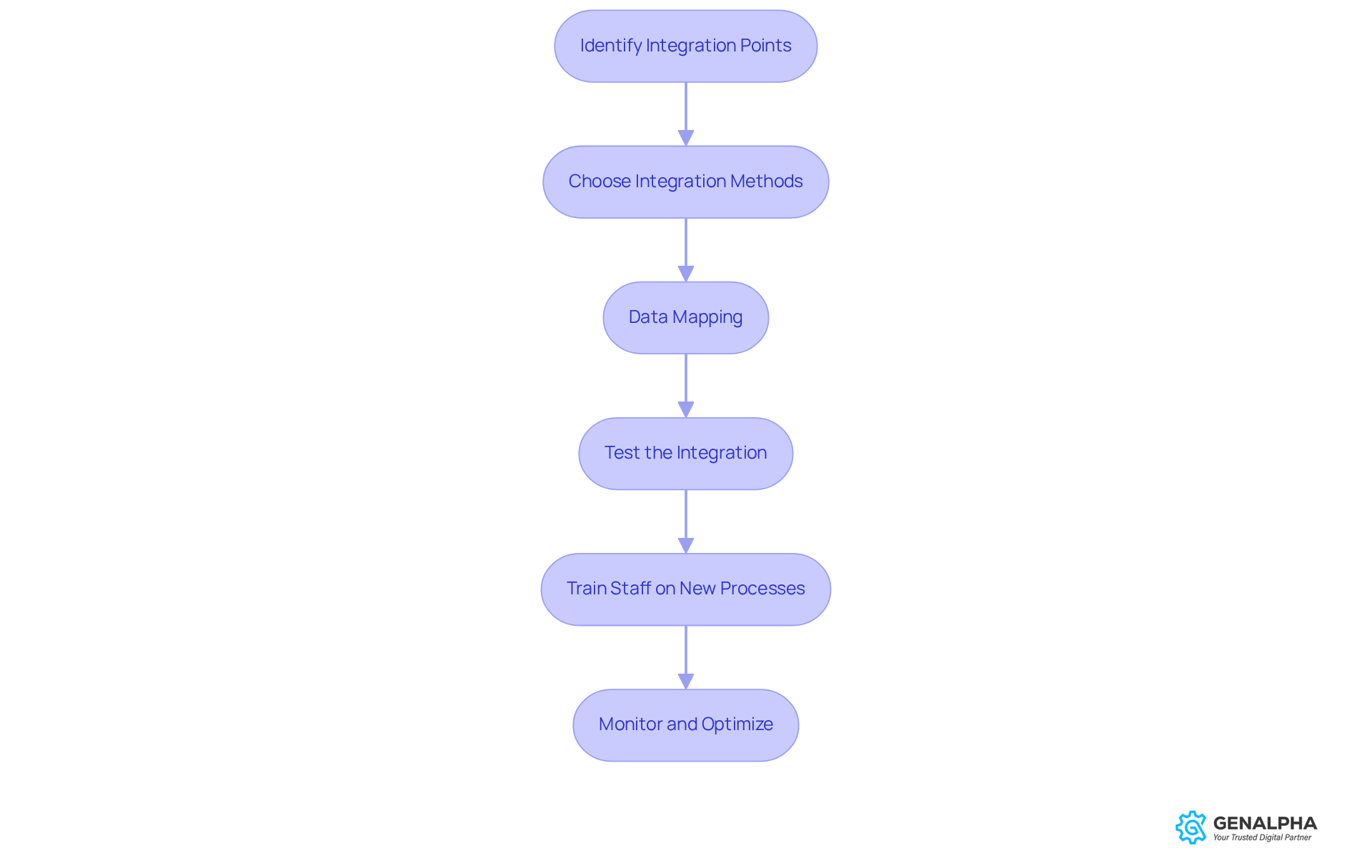

Integrating CPQ tools with your current setup is key to unlocking their full potential. So, how do you go about this integration process? Let’s break it down step by step:

-

Identify Integration Points

First things first, figure out which systems - like your ERP or CRM - need to connect with the CPQ software. This ensures that information flows seamlessly between them. -

Choose Integration Methods

Next up, decide how you want to integrate. Will it be through APIs, middleware, or direct connections? Choose the method that fits your technical skills and resources best. -

Data Mapping

Now, let’s talk data mapping. You’ll want to outline how data will move between systems. Make sure product configurations, pricing, and customer info sync up accurately. -

Test the Integration

Once you’ve set everything up, it’s time to test! Conduct thorough checks to ensure data transfers correctly and that the systems are communicating like they should. -

Train Staff on New Processes

Don’t forget about your team! Make sure everyone understands how to use the integrated systems and knows the benefits of the new workflows. -

Monitor and Optimize

Finally, after the integration, keep an eye on things. Monitor the systems for any hiccups and optimize processes as needed to boost efficiency.

By effectively integrating your existing systems with logiciel cpq tools, you’re not just enhancing operational efficiency - you’re also setting the stage for a better customer experience. Ready to get started?

Address Implementation Challenges and Troubleshoot Effectively

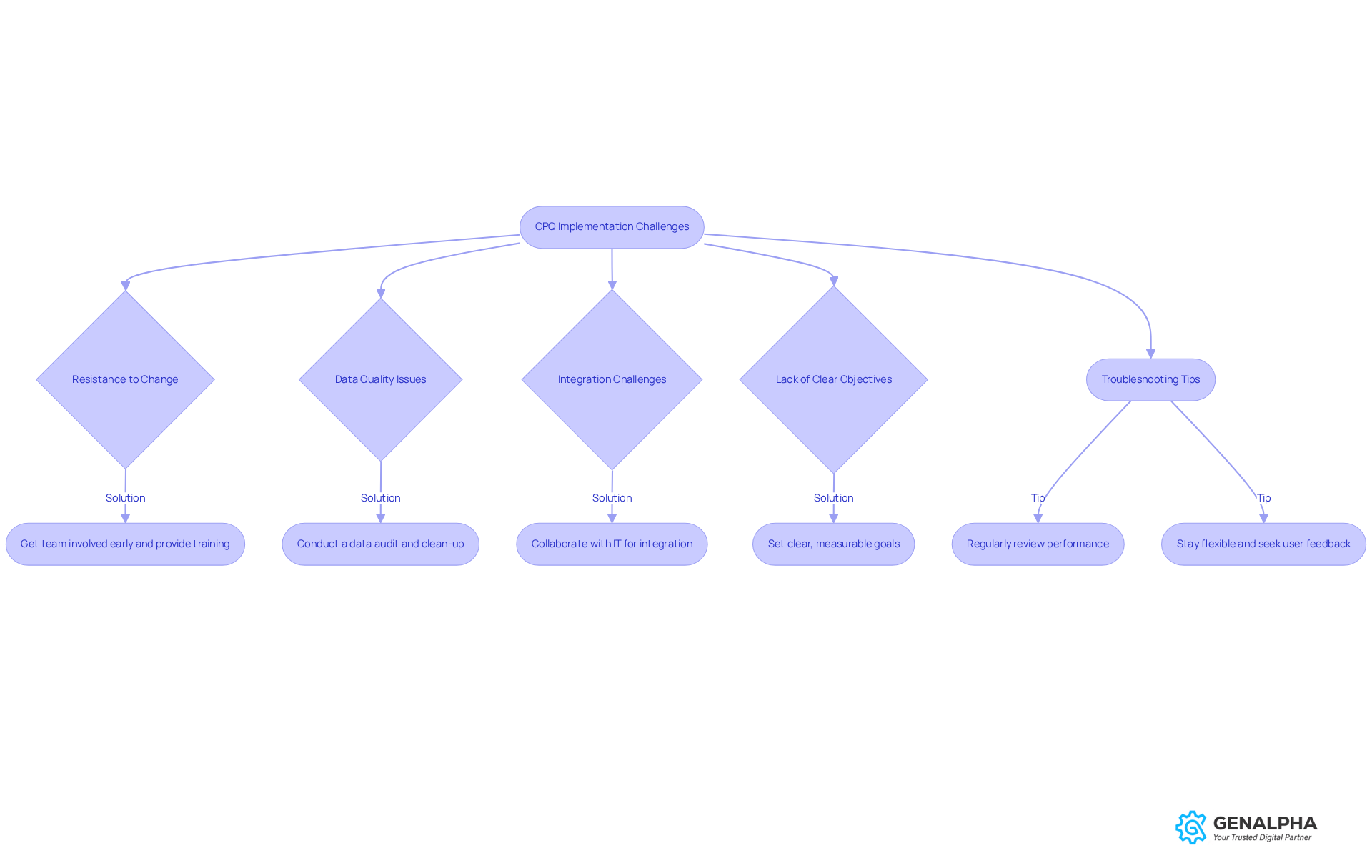

Implementing CPQ systems can be a bit tricky, right? Let’s dive into some common challenges and how we can tackle them together:

Common Challenges:

-

Resistance to Change: You know how it goes - people can be hesitant to embrace new technology. In fact, studies show that up to 67% of CPQ implementations stumble due to human factors and planning issues, not only because of logiciel cpq glitches.

- Solution: Get your team involved early on! Providing thorough training can really help ease the transition. Plus, showing off the perks of CPQ and setting up rewards for adopting new practices can make a big difference in reducing resistance.

-

Data Quality Issues: Let’s face it, if your data isn’t spot-on, it can throw a wrench in the works. Inaccurate or incomplete data can lead to quoting errors and delays in fulfilling orders.

- Solution: Before you jump into implementation, do a solid data audit and clean-up. Making sure all your info is accurate and up-to-date is crucial. Remember, just transferring unstructured data into a new logiciel cpq system won’t address the underlying problems.

-

Integration Challenges: Connecting CPQ with your existing systems can be a real puzzle. It often leads to data silos, which can cause inconsistent quoting and communication hiccups.

- Solution: Collaborate closely with your IT team to ensure a smooth integration. Using middleware can really help bridge the gap between different platforms.

-

Lack of Clear Objectives: If you don’t have clear goals, it’s like sailing without a map. It can be tough to measure success without defined objectives.

- Solution: Set clear, measurable goals for what you want to achieve with logiciel cpq. Establishing Key Performance Indicators (KPIs) will help you evaluate how well the framework is working after it’s up and running.

Troubleshooting Tips:

- Regularly Review Performance: Keep an eye on how the system is performing and gather feedback from users. Engaging with stakeholders, like sales teams and product managers, is key to a successful implementation.

- Stay Flexible: Be ready to tweak processes and configurations based on user feedback and changing business needs. Actively seeking input from users can guide ongoing improvements and upgrades to the CPQ application. This adaptability can really enhance user experience and keep the system aligned with your operational goals.

By proactively addressing these challenges, we can ensure a successful CPQ implementation that boosts our sales processes and improves customer interactions.

Conclusion

Integrating CPQ software into manufacturing processes is a game-changer for boosting efficiency and keeping customers happy. By automating product configuration, pricing, and quote generation, CPQ solutions help manufacturers streamline their sales operations. This not only leads to increased revenue but also enhances customer experiences.

In this guide, we’ve shared some key insights about CPQ software’s functionalities and benefits. For instance, it can significantly reduce quote durations, minimize errors, and improve overall sales efficiency. The step-by-step implementation process we outlined acts as a roadmap for manufacturers looking to adopt CPQ systems. It’s all about:

- Setting clear objectives

- Preparing your data

- Training your teams effectively

Plus, tackling common challenges like resistance to change and data quality issues is essential for a smooth transition.

But embracing CPQ technology isn’t just about making operations smoother; it’s a strategic move that can redefine how manufacturers connect with their customers and compete in the marketplace. As the manufacturing landscape evolves, investing in CPQ solutions is crucial for anyone wanting to stay ahead. So, why wait? Now’s the perfect time to explore how CPQ software can revolutionize your manufacturing processes and pave the way for a successful future in an increasingly competitive environment.

Frequently Asked Questions

What is CPQ software and what is its role in manufacturing?

CPQ software, or Configure Price Quote software, is designed to simplify the manufacturing process by automating product configuration, calculating pricing based on customer needs, and generating accurate quotes quickly.

What are the key functions of CPQ software?

The key functions of CPQ software include product configuration, pricing automation, and quote generation. It allows sales teams to tailor products to customer specifications, automatically calculates prices based on rules and agreements, and quickly produces professional quotes for customers.

How does CPQ software increase efficiency in manufacturing?

CPQ software significantly reduces the time spent on manual quoting, allowing sales teams to focus on closing deals. It can cut quote duration from weeks to minutes, enabling manufacturers to manage more customers and preventing revenue loss due to quoting inefficiencies.

What impact does CPQ software have on accuracy?

CPQ software minimizes errors in pricing and product configurations, leading to improved customer satisfaction. By reducing inaccuracies, it addresses complex approval processes that can cause lost deals, ultimately boosting revenue.

How does CPQ software enhance the customer experience?

CPQ software provides customers with quick and accurate quotes, making their buying experience smoother. Many manufacturers report significant revenue increases after adopting CPQ solutions, highlighting its positive effect on sales growth.

What are some challenges of integrating CPQ solutions in manufacturing?

Challenges may include the need for training team members and navigating the learning curve associated with new technology. Understanding these aspects is crucial for manufacturers looking to improve their sales strategies and customer interactions.

What is the current trend regarding investments in CPQ technology among manufacturers?

A significant number of manufacturing organizations, specifically 69%, plan to increase their investment in CPQ technology, indicating its growing importance in the industry.