Introduction

Understanding the ins and outs of product configuration is crucial for manufacturers who want to keep up with their customers' ever-changing needs.

Think about it: how often do we find ourselves wanting something just a bit different from what's available?

This guide takes you through the basic principles and step-by-step processes that can help producers fine-tune their offerings with both precision and efficiency.

But as we move toward a world where customization is king, how can manufacturers not just keep up but actually lead the way in product configuration?

Let's dive in!

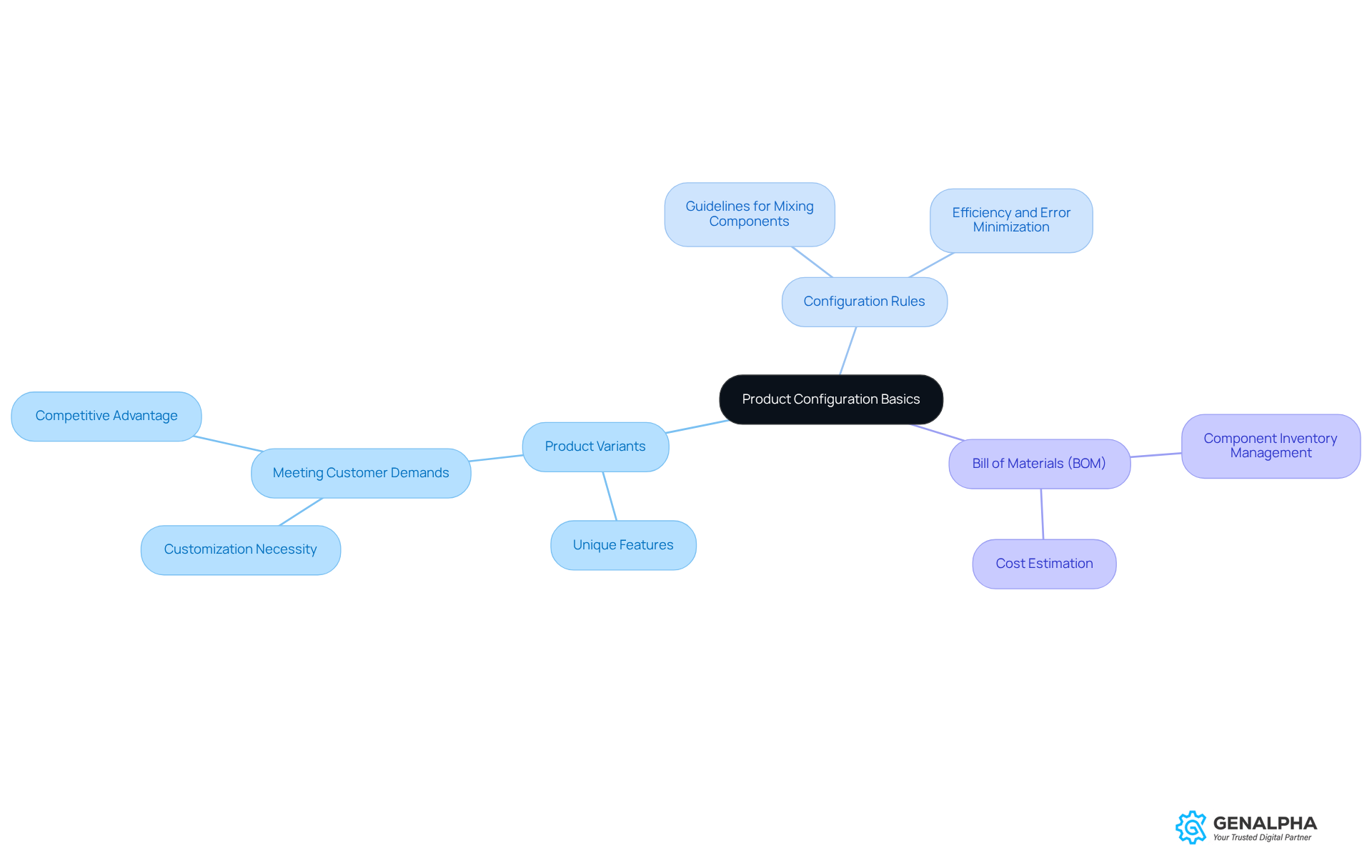

Understand Product Configuration Basics

Configuration involves the process to configure products to meet specific customer needs. It’s like putting together a puzzle, where you configure products by selecting and arranging different components and features to create the perfect solution. Let’s break down some key concepts:

- Product Variants: Think of these as different flavors of a product, each with its own unique features or specifications. As Will Haines pointed out, staying competitive means producers across various sectors need to configure products that precisely meet customer demands.

- Configuration Rules: These are the guidelines that tell you how components can be mixed and matched. Knowing these rules is crucial for keeping things efficient and minimizing errors during production.

- Bill of Materials (BOM): This is your go-to list of all the components needed to create an item. A well-organized BOM is essential for accurate inventory management and cost estimation.

Understanding these basics is key. They lay the groundwork for effective item arrangement, helping producers meet diverse customer needs efficiently. By 2026, manufacturers who don’t adapt to the demand for customized items might find themselves lagging in efficiency and responsiveness. A recent report highlights that companies not integrating AI could fall behind in these areas. Plus, the expected funding for manufacturing training initiatives underscores the importance of skilled labor in improving item arrangement processes.

So, grasping variations and configuration rules isn’t just helpful; it’s vital for manufacturers looking to configure products to optimize their offerings and keep up with changing customer demands. What steps are you taking to stay ahead in this evolving landscape?

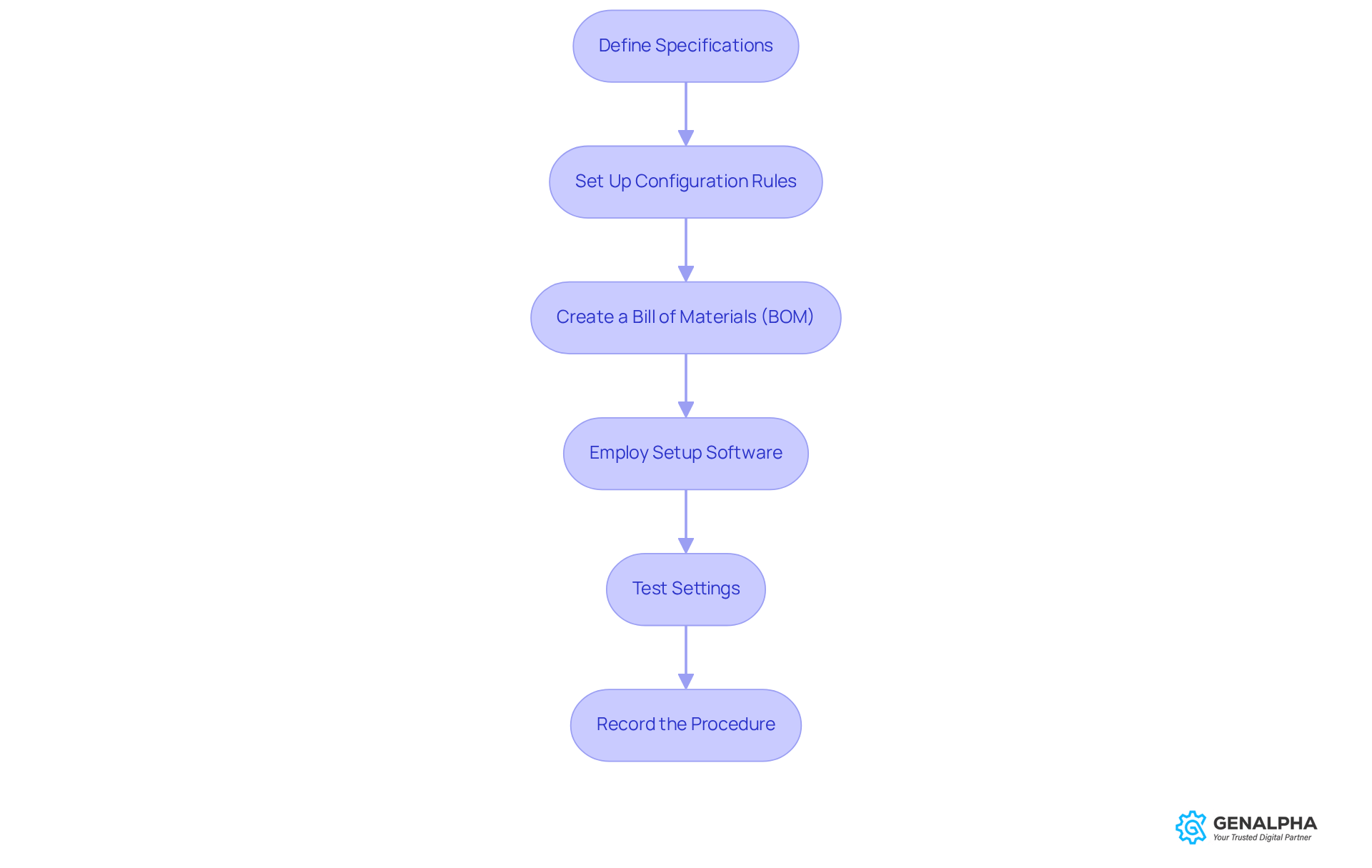

Follow the Step-by-Step Configuration Process

To configure products effectively, let’s walk through some simple steps together:

- Define Specifications: First things first, gather all the necessary info about the item. Think dimensions, materials, and features. It’s all about knowing what you’re working with!

- Set Up Configuration Rules: Next, let’s establish some rules for how different components can be combined. You might want to use software tools that allow for rule-based setups - this can really streamline the process.

- Create a Bill of Materials (BOM): Now, it’s time to list all the components you’ll need for the item. Make sure every element is accounted for and accurately specified. This is crucial!

- Employ Setup Software: Consider using product setup software to automate parts of the workflow. This can help reduce manual mistakes and boost efficiency - who doesn’t want that?

- Test Settings: Before you wrap things up, run some tests on the setups. You want to ensure they meet quality standards and customer requirements. It’s all about getting it right!

- Record the Procedure: Finally, keep thorough documentation of your setups. This will be super helpful for future reference and can enhance your upcoming procedures.

By following these steps, you’ll be well on your way to configuring products for a smooth and effective setup. Ready to get started?

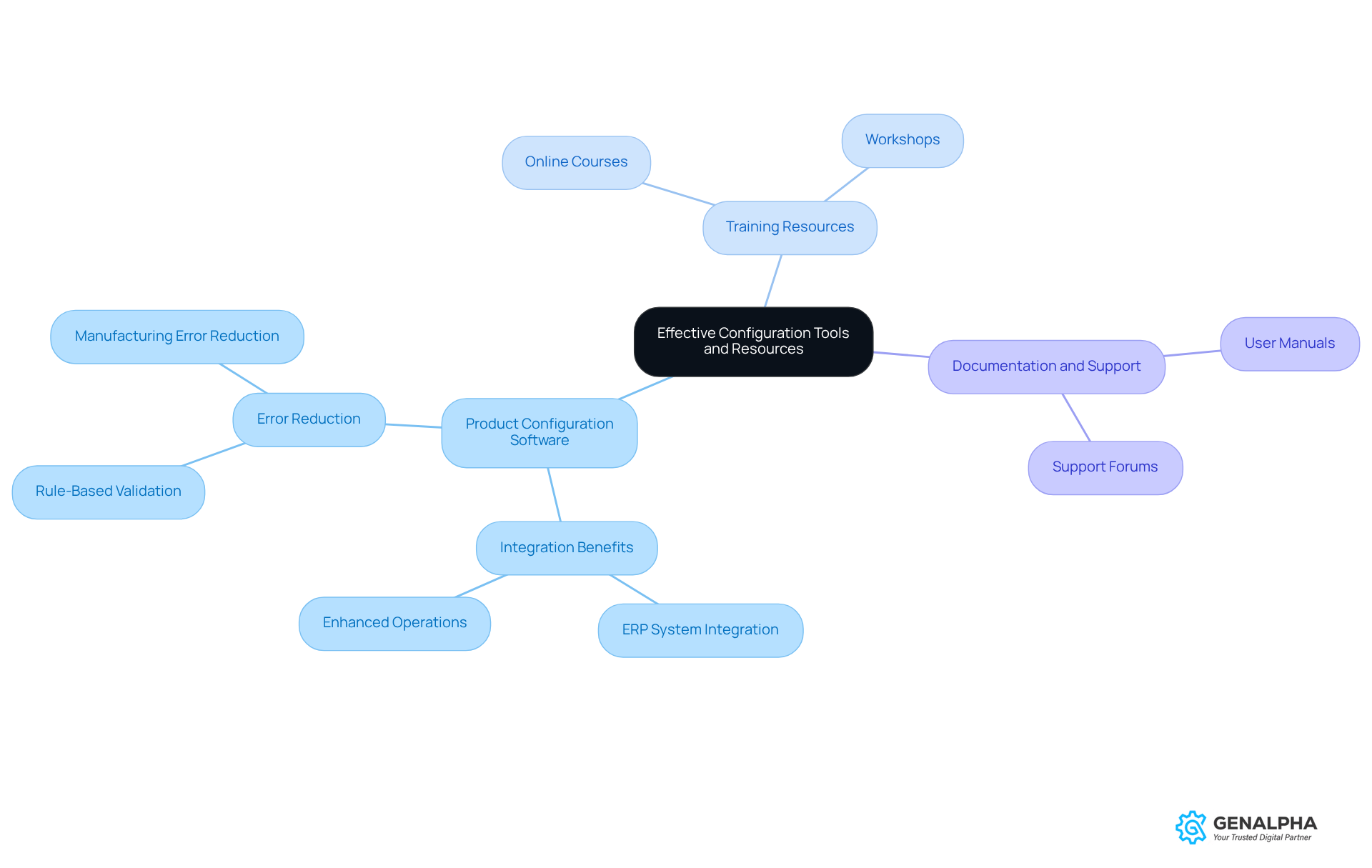

Utilize Tools and Resources for Effective Configuration

Looking to configure products in a more streamlined manner? Let’s explore some handy tools and resources that can make a real difference:

- Product Configuration Software: Automating your configuration process can really boost user experience and accuracy. Think about solutions that mesh well with what you already have in place.

By integrating item setup with ERP systems, you can effectively configure products to enhance operations and keep everything aligned across departments. This kind of integration can cut down manufacturing errors by up to 60% through rule-based validation, which builds reliability and trust with your customers-just check out the case studies! - Training Resources: Why not dive into some online courses or workshops focused on best practices for item setup? It’s a great way to level up your team’s skills and expertise.

- Documentation and Support: Make sure you have access to user manuals and support forums for your setup software. They can be a lifesaver when you need a little extra help.

Using these tools can help you configure products to ramp up the efficiency and precision of what you offer, leading to better business results. So, what are you waiting for? Let’s get started!

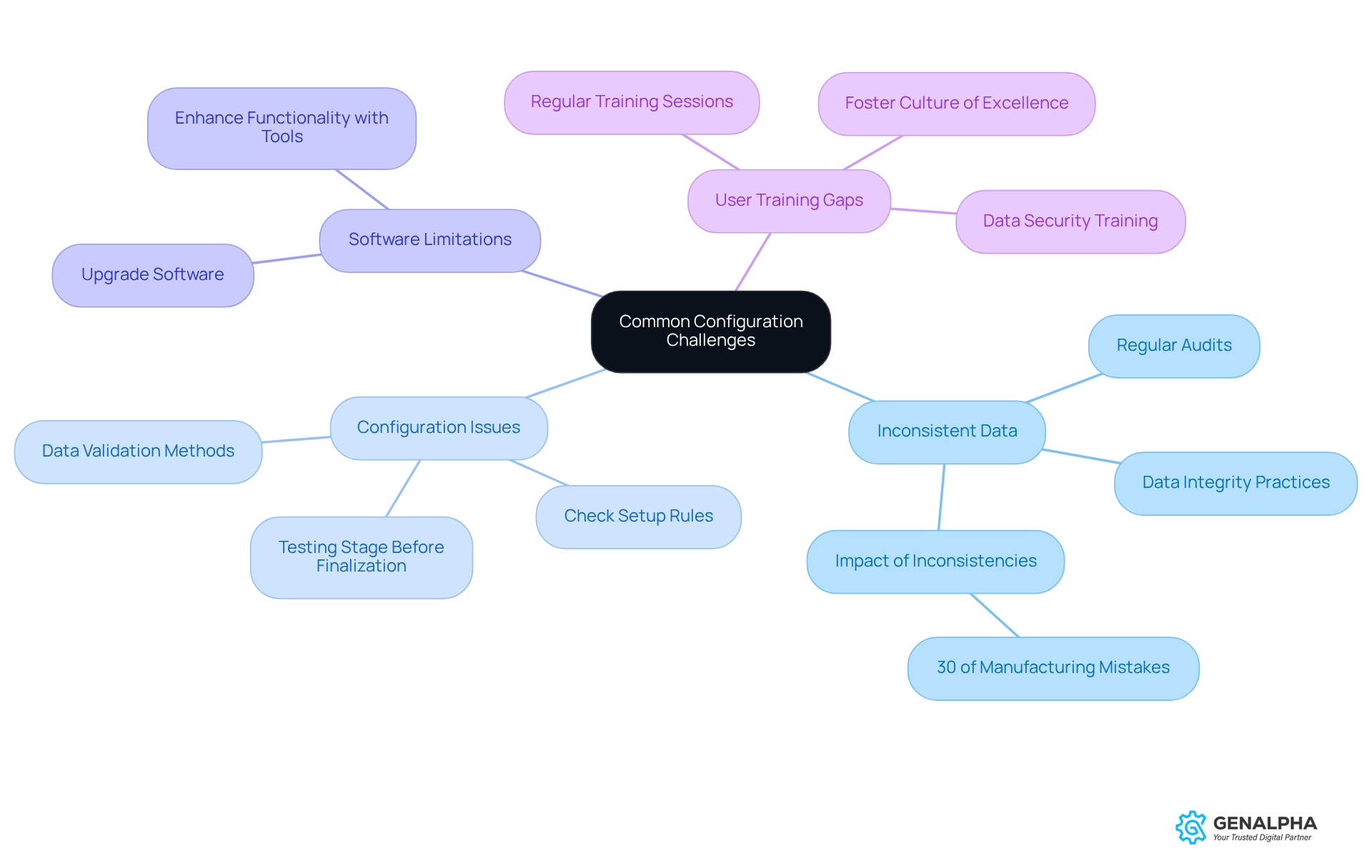

Troubleshoot Common Configuration Challenges

Let’s talk about some common challenges in product configuration that many of us face:

-

Inconsistent Data: Keeping product specifications and Bills of Materials (BOMs) consistent across all platforms is super important. Regular audits are key to ensuring data integrity. Did you know that up to 30% of manufacturing mistakes come from inconsistent data? That really highlights how crucial it is to have solid data management practices. So, make it a point to conduct regular data audits to catch any issues before they snowball.

-

Configuration Issues: Ever run into a situation where product specs don’t match what the customer wants? It can be frustrating! To avoid this, it’s essential to check setup rules and BOMs for any discrepancies. Using data validation methods can help reduce these issues. Plus, adding a testing stage before finalizing setups can help catch mistakes early, saving you from costly revisions later on.

-

Software Limitations: If your current setup software isn’t cutting it, it might be time for an upgrade. Sometimes, adding extra tools can really enhance functionality, making the setup process smoother and boosting productivity.

-

User Training Gaps: Training is vital for everyone involved in the setup process. Regular training sessions not only keep skills sharp but also significantly reduce mistakes. When you involve your team in ongoing education, you foster a culture of excellence and responsibility, which is essential for maintaining high standards in product configuration. And don’t forget about data security! Establishing a solid security policy and providing regular training on best practices is crucial for keeping data integrity intact and preventing errors.

By tackling these challenges head-on, manufacturers can configure products more smoothly. This not only enhances operational efficiency but also boosts customer satisfaction. So, what steps will you take to address these issues in your organization?

Conclusion

Mastering product configuration is key for manufacturers who want to keep up with their customers' ever-changing needs. Think about it: when you understand product variants, configuration rules, and how a well-organized Bill of Materials (BOM) works, you can create solutions that not only satisfy your customers but also boost your operational efficiency.

In this guide, we’ve highlighted some essential strategies. We walked through a step-by-step configuration process that includes:

- Defining specifications

- Setting up configuration rules

- Using effective software tools

Plus, we tackled common challenges like inconsistent data and configuration hiccups, emphasizing the importance of ongoing training to keep everything running smoothly.

As the manufacturing landscape evolves, adopting effective product configuration practices can really streamline your operations and cultivate a culture of excellence. So, why not invest in the right tools, resources, and training? Staying competitive is crucial, and the journey to optimize product configuration is ongoing. Taking proactive steps today can set you up for success tomorrow!

Frequently Asked Questions

What is product configuration?

Product configuration is the process of selecting and arranging different components and features of a product to meet specific customer needs, similar to putting together a puzzle.

What are product variants?

Product variants are different versions of a product, each with its own unique features or specifications, allowing producers to meet diverse customer demands.

What are configuration rules?

Configuration rules are guidelines that dictate how components can be mixed and matched during the product configuration process, which helps maintain efficiency and minimize errors in production.

What is a Bill of Materials (BOM)?

A Bill of Materials (BOM) is a comprehensive list of all the components needed to create an item, essential for accurate inventory management and cost estimation.

Why is understanding product configuration basics important for manufacturers?

Understanding product configuration basics is crucial for manufacturers to effectively arrange items, meet diverse customer needs, and remain competitive in a rapidly evolving market.

What risks do manufacturers face if they do not adapt to customized item demands by 2026?

Manufacturers that do not adapt to the demand for customized items by 2026 may lag in efficiency and responsiveness, potentially falling behind competitors.

How does AI integration relate to product configuration?

Companies that do not integrate AI into their product configuration processes may struggle with efficiency and responsiveness, highlighting the importance of technology in modern manufacturing.

What role does skilled labor play in product configuration?

Skilled labor is vital for improving item arrangement processes, and there is expected funding for manufacturing training initiatives to enhance these skills in the workforce.