Introduction

Factory digitalization is shaking things up in the manufacturing world, turning old-school processes into high-tech operations that run on the latest technology. Just think about it: with innovations like the Internet of Things (IoT), artificial intelligence (AI), and real-time data analytics, manufacturers can boost efficiency, enhance product quality, and respond to market demands with greater agility. Sounds great, right?

But let’s be real - the road to digital transformation isn’t always smooth. Outdated systems, resistance to change, and cybersecurity worries can throw a wrench in the works. So, how can manufacturers tackle these challenges and tap into the full potential of digitalization? What steps can they take to gain that competitive edge in a constantly changing industry?

Let’s dive in and explore!

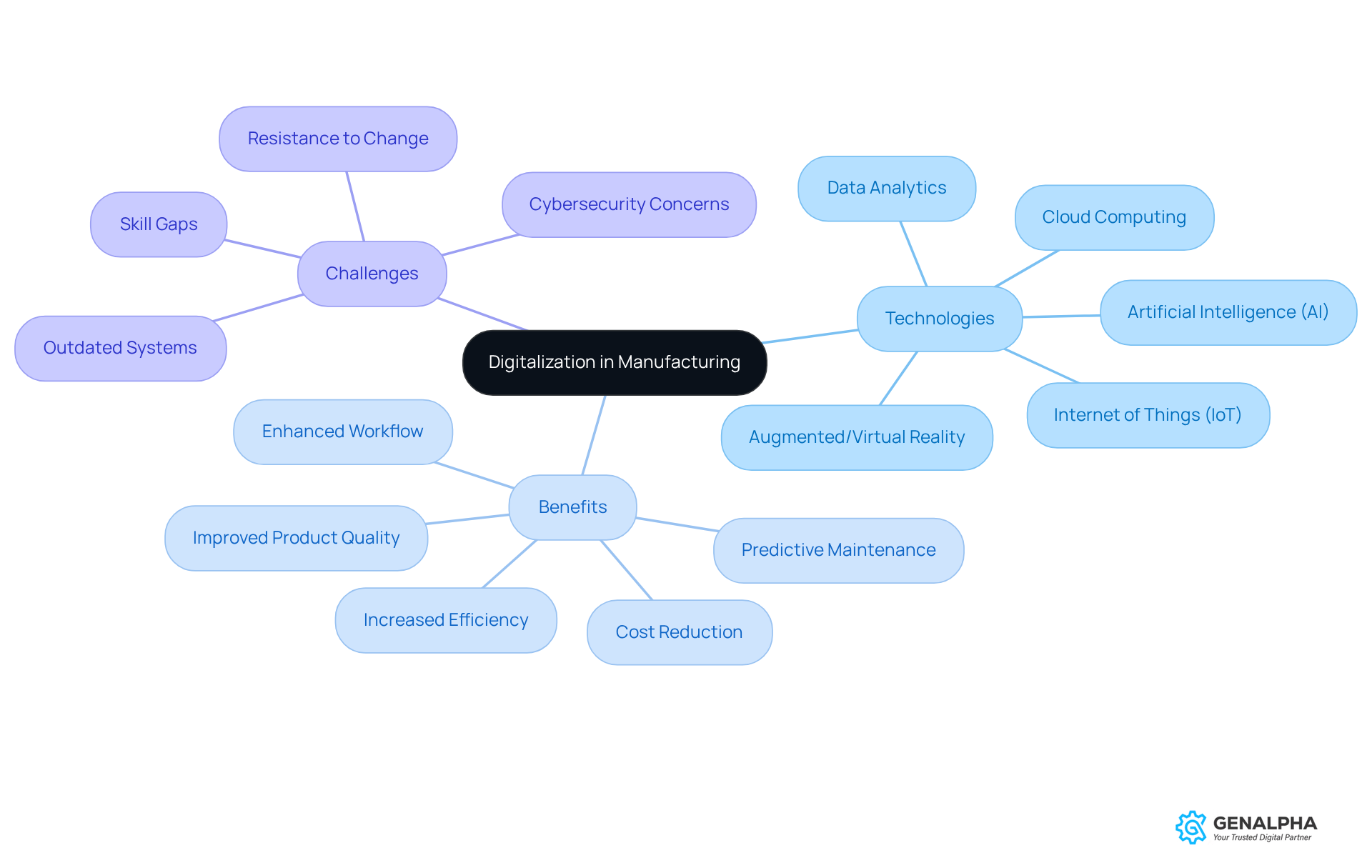

Define Digitalization in Manufacturing

Have you ever thought about how factory digitalization is shaking up the manufacturing world? It’s all about weaving in tech innovations into every nook and cranny of production processes. Imagine using cool tools like the Internet of Things (IoT), artificial intelligence (AI), and data analytics to boost efficiency, improve product quality, and make workflows smoother than ever. By flipping those old-school analog processes into digital ones, manufacturers can implement factory digitalization to gather and analyze data in real-time. This shift not only ramps up production but also helps decision-makers respond quickly to what the market and customers are asking for.

As Zvi Feuer, Senior Vice President of Digital Manufacturing Software Solutions at Siemens, puts it, 'By embracing factory digitalization, producers can bring together data, cloud computing, artificial intelligence and the industrial metaverse to reduce operational expenses, increase throughput and boost profits.' Sounds great, right? But let’s be real - there are bumps along the road. Many producers face hurdles like outdated systems, cybersecurity worries, and a bit of pushback when it comes to change.

For example, AI and machine learning are stepping in to automate processes, leading to some serious efficiency gains and cost savings. Plus, with IoT devices in the mix, predictive maintenance becomes a game-changer, cutting down on downtime and ramping up productivity. Take a look at successful initiatives like using electronic threads in manufacturing; they show just how these innovations can fine-tune production processes and foster better teamwork.

So, as producers dive into factory digitalization and these tech advancements, they’re not just keeping up - they’re setting themselves up for a competitive edge in a fast-evolving market. Are you ready to join the digital revolution?

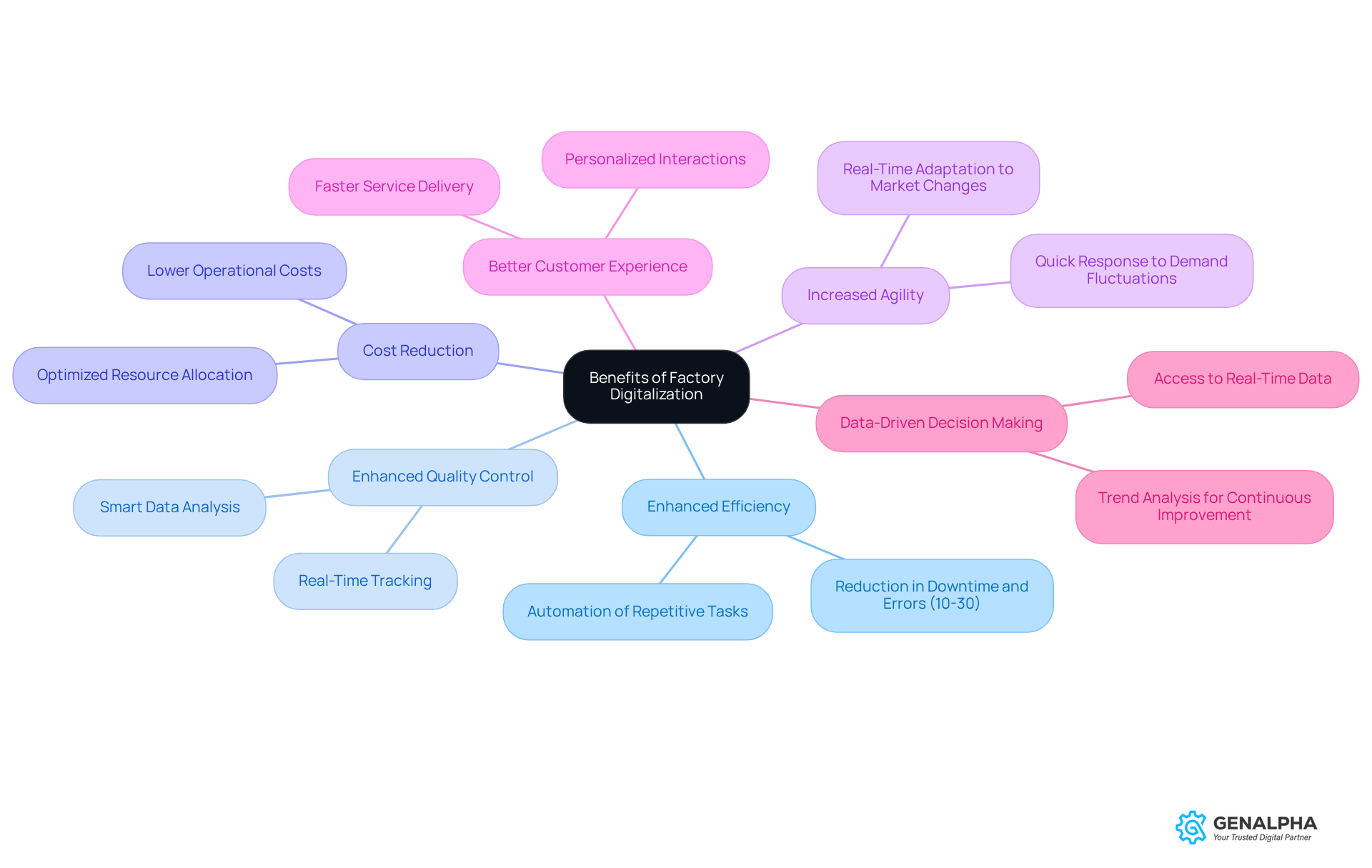

Highlight Benefits of Digitalization

Factory digitalization in manufacturing is a game changer, offering numerous benefits that significantly enhance operational efficiency and overall performance. Let’s break down some of the key advantages:

-

Enhanced Efficiency: Imagine automating those repetitive tasks that eat up your time. By doing so, you not only cut down on manual errors but also speed up production cycles. Many manufacturers are seeing downtime and errors drop by 10-30% as they embark on their factory digitalization journey. Pretty impressive, right?

-

Enhanced Quality Control: With real-time tracking and smart data analysis, producers can keep their quality standards high. This means they can spot and fix defects on the fly, ensuring that every product meets those tough quality benchmarks.

-

Cost Reduction: Digital tools are like a magic wand for optimizing resource allocation. They help reduce waste and lower operational costs. By tapping into technologies like AI and IoT, producers gain better visibility into their processes, leading to significant cost savings and smarter resource use.

-

Increased Agility: Think about how quickly you can respond to changes in demand or market conditions. Factory digitalization provides producers with an edge, enabling them to adapt their operations in real-time to meet customer needs. This agility is key to staying competitive.

-

Better Customer Experience: Who doesn’t love a personalized touch? Digitalization lets manufacturers offer tailored interactions and faster service delivery. When customers feel valued, satisfaction rates soar, leading to loyalty and repeat business.

-

Data-Driven Decision Making: Access to real-time data is a game changer for making informed strategic decisions. Manufacturers can analyze trends and operational metrics to fine-tune processes and drive continuous improvement.

All these benefits come together through factory digitalization to create a more resilient and responsive manufacturing environment. It’s all about positioning companies for lasting success in a competitive landscape. So, what do you think? Ready to embrace digitalization?

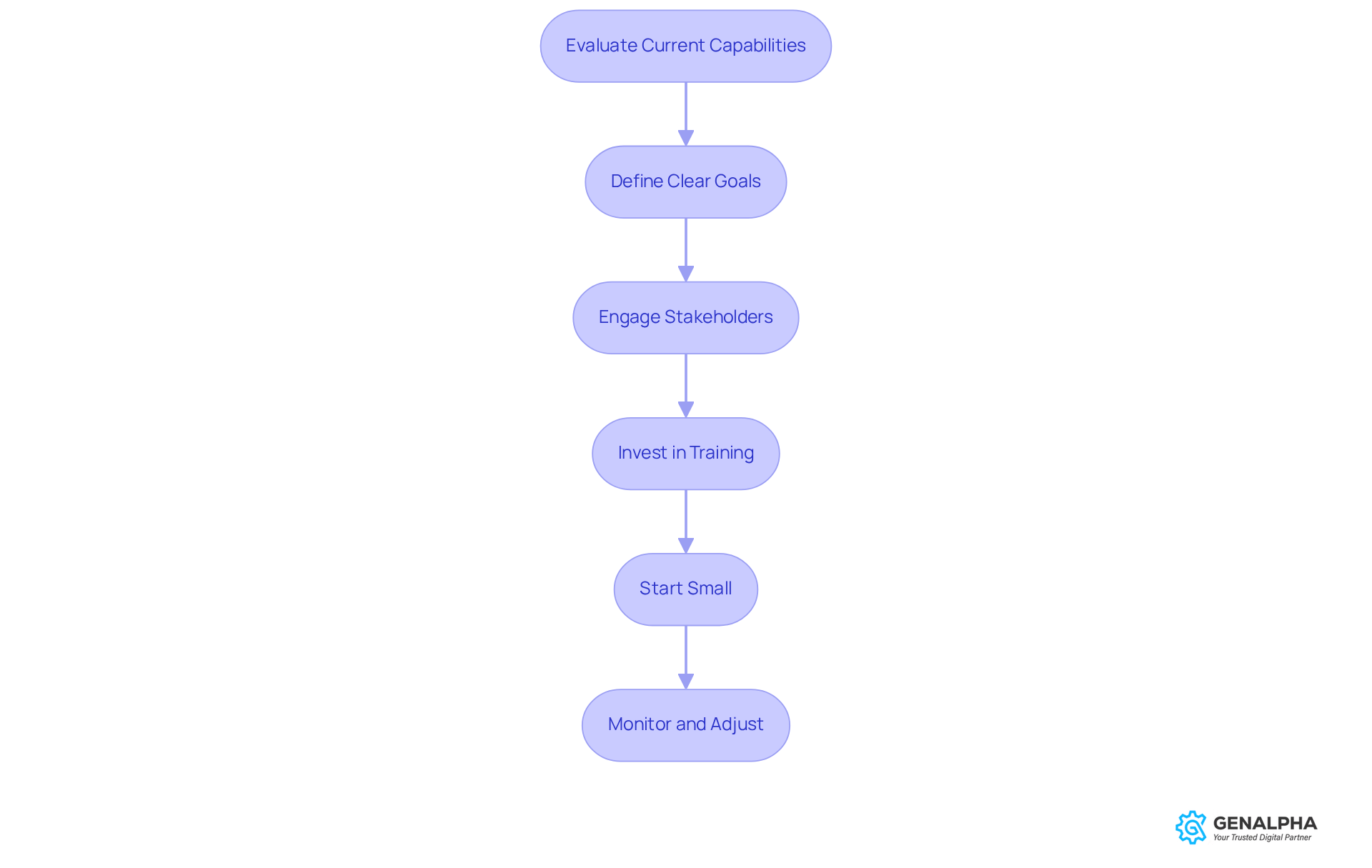

Outline Steps for Effective Implementation

Implementing digitalization in manufacturing? It’s a big deal, and it calls for a strategic approach that covers some essential steps:

-

Evaluate Current Capabilities: First things first, take a good look at what you’ve got. Assess your existing processes and tools to spot gaps and opportunities for integration. This means checking out those legacy systems and seeing how they stack up against new technologies. You want to know exactly where you stand before making any changes. Many manufacturing facilities are still running on outdated software, which can really throw a wrench in the works, so don’t skip this step!

-

Define Clear Goals: Next up, let’s talk goals. What do you want to achieve with your digital initiative? Maybe it’s boosting operational efficiency, enhancing customer experience, or being more agile in response to market shifts. Whatever it is, make sure these goals align with your overall business strategy. Industry experts can’t stress enough how crucial this alignment is for success.

-

Engage Stakeholders: Don’t forget to bring everyone on board! Involve key stakeholders from IT, operations, and leadership to ensure buy-in and gather diverse insights. This collaborative approach not only sparks creativity but also helps you spot potential roadblocks early on - like pushback from staff, which is pretty common during tech changes.

-

Invest in Training: Now, let’s talk about your team. Equip them with the skills they need to make the most of new technologies. Training programs should focus on change management and nurturing a culture of continuous improvement. After all, as Prosci points out, successful tech changes happen when smart tools meet empowered individuals.

-

Start Small: Here’s a tip: kick things off with pilot projects. Testing tech solutions on a smaller scale before going all in allows you to refine your strategies based on real-world feedback. Plus, it minimizes risks associated with larger rollouts. For instance, Varoc saw a 20% boost in overall equipment effectiveness through remote monitoring - proof that starting small can lead to big wins!

-

Monitor and Adjust: Finally, keep an eye on your progress. Use key performance indicators (KPIs) that reflect both operational metrics and employee engagement. Be ready to tweak things based on what the data tells you, ensuring that your tech changes stay in line with your business goals. This ongoing evaluation is key to reaping the benefits of digital transformation, like improved efficiency and happier customers.

By following these steps, you can navigate the complexities of factory digitalization with confidence, leading to successful outcomes that boost your competitiveness and operational resilience. So, are you ready to take the plunge?

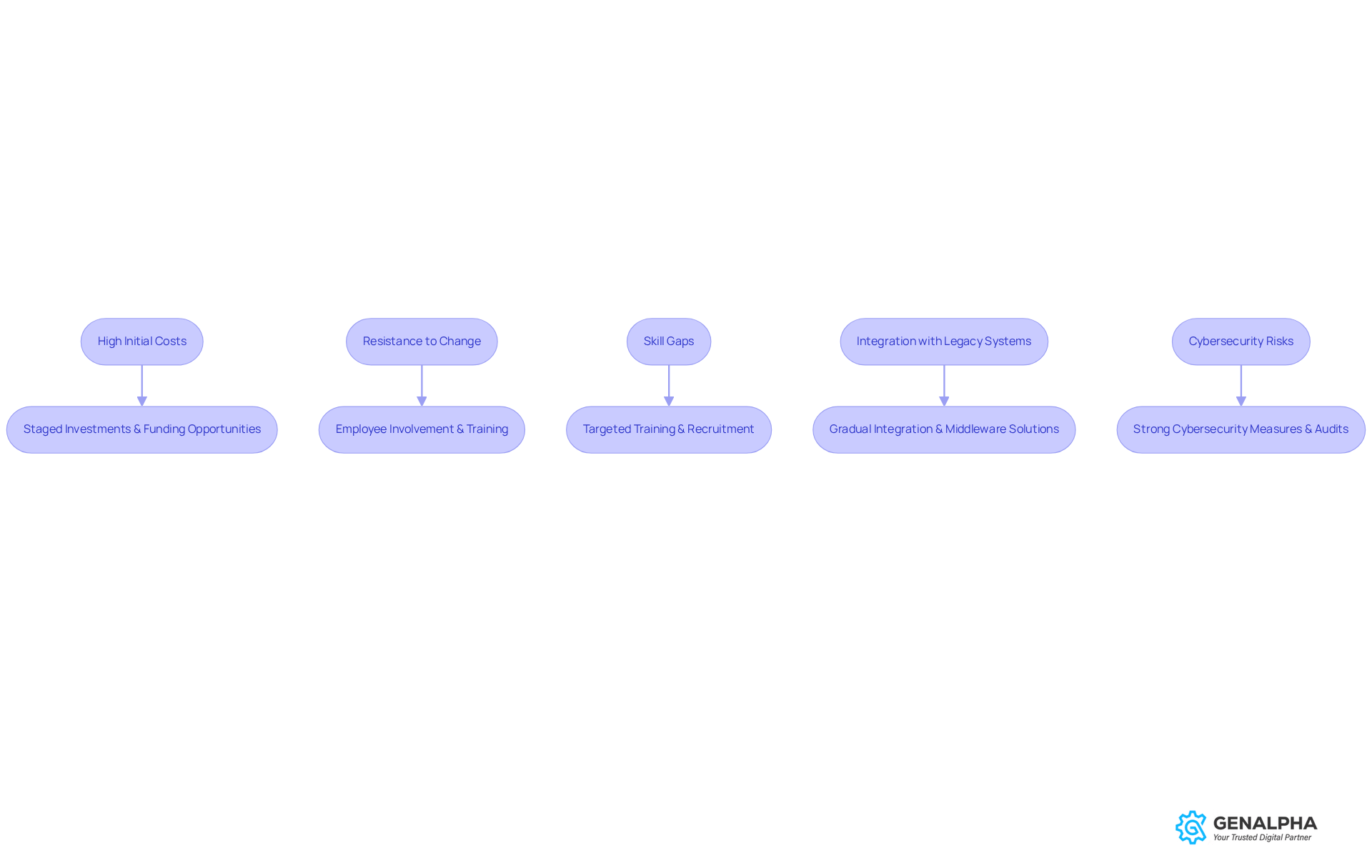

Address Challenges and Solutions in Digitalization

Digitalization offers some pretty exciting advantages for manufacturers, but let’s be real - there are challenges to tackle along the way:

-

High Initial Costs: The upfront investment in new equipment can feel overwhelming. To lighten this load, manufacturers might want to think about staged investments. Phased implementation with clear success metrics often works better than trying to change everything at once. Plus, don’t forget to explore available funding opportunities to help spread those costs over time.

-

Resistance to Change: It’s not uncommon for employees to hesitate when it comes to embracing new technologies. In fact, 57% of industrial leaders have reported some resistance to AI and other innovations. Getting employees involved early in the transformation process and providing thorough training can really help ease those transitions and foster a culture of acceptance.

-

Skill Gaps: A lack of digital skills in the workforce can slow down implementation efforts. Investing in targeted training programs and actively recruiting skilled personnel are key strategies to bridge this gap. As Eddy Azad pointed out, training AI agents specifically for operations is crucial for maximizing effectiveness.

-

Integration with Legacy Systems: Existing systems can sometimes complicate the integration of new technologies. Manufacturers should plan for gradual integration and consider middleware solutions to ensure everything works together smoothly and minimizes disruption.

-

Cybersecurity Risks: With increased connectivity from digitalization comes a heightened risk of cyber threats. Implementing strong cybersecurity measures and conducting regular audits are essential steps to protect sensitive data and maintain operational integrity. It’s worth noting that 68% of implementation failures are linked to inadequate training and change management, highlighting the need for comprehensive training programs.

By proactively addressing these challenges, manufacturers can significantly boost their chances of successful factory digitalization. This ultimately leads to improved operational efficiency and competitiveness. So, what steps can you take today to start this journey?

Conclusion

Embracing factory digitalization is a game-changer for manufacturers. It’s all about integrating the latest technologies to shake up production processes. This shift doesn’t just boost operational efficiency; it also helps organizations respond quickly to market demands, setting them up for long-term success in a competitive world.

Throughout this article, we’ve highlighted some key benefits of digitalization. Think:

- Improved efficiency

- Better quality control

- Significant cost savings

- Increased agility

- Enhanced customer experiences

By taking strategic steps - like evaluating current capabilities, defining clear goals, engaging stakeholders, investing in training, starting small, and keeping an eye on progress - manufacturers can tackle the complexities of digital transformation head-on. Plus, it’s crucial to address challenges such as high initial costs, resistance to change, skill gaps, integration issues, and cybersecurity risks to ensure a smooth transition.

As the manufacturing industry keeps evolving, we can’t stress enough how important digitalization is. By leveraging the insights and strategies we’ve discussed, manufacturers can not only break down barriers but also tap into the full potential of digital technologies. So, why wait? Now’s the time to embrace this digital revolution and pave the way for a more resilient and responsive manufacturing future.

Frequently Asked Questions

What is digitalization in manufacturing?

Digitalization in manufacturing refers to the integration of technology innovations, such as the Internet of Things (IoT), artificial intelligence (AI), and data analytics, into production processes to enhance efficiency, improve product quality, and streamline workflows.

How does factory digitalization improve production?

Factory digitalization allows manufacturers to convert analog processes into digital ones, enabling real-time data gathering and analysis. This shift enhances production speed and helps decision-makers quickly respond to market demands and customer needs.

What are some benefits of embracing factory digitalization?

Benefits include reduced operational expenses, increased throughput, enhanced profits, and improved collaboration through the use of data, cloud computing, AI, and the industrial metaverse.

What challenges do manufacturers face in digitalization?

Manufacturers often encounter challenges such as outdated systems, cybersecurity concerns, and resistance to change when implementing digitalization strategies.

How do AI and machine learning contribute to manufacturing efficiency?

AI and machine learning automate processes, leading to significant efficiency gains and cost savings, which enhance overall productivity in manufacturing.

What role do IoT devices play in factory digitalization?

IoT devices facilitate predictive maintenance, which reduces downtime and increases productivity by allowing manufacturers to anticipate and address equipment issues before they occur.

Can you provide an example of successful digitalization in manufacturing?

An example of successful digitalization is the use of electronic threads in manufacturing, which demonstrates how innovations can optimize production processes and improve teamwork.

Why is it important for manufacturers to adopt digitalization?

Adopting digitalization is crucial for manufacturers to maintain a competitive edge in a rapidly evolving market by leveraging technology to enhance production and operational capabilities.