Introduction

Engineer-to-order manufacturing is really taking off! As consumers, we’re all looking for products that fit our unique needs, right? This production method not only boosts customer satisfaction but also brings its own set of challenges, especially when it comes to communication and documentation. With a whopping 74% of producers expected to jump into this sector by 2025, it begs the question: how can manufacturers tackle the complexities of engineer-to-order processes and still ensure project success?

Let’s dive into some key practices and strategies that can help overcome these hurdles. By exploring these insights, we can uncover the path to excellence in ETO manufacturing. So, are you ready to find out how to navigate this exciting landscape?

Define Engineer-to-Order Manufacturing

Have you ever thought about how some products are made just for you? That’s the essence of engineer to order manufacturing! It’s a unique production method where products are customized to fit specific customer needs. Unlike Make-to-Order (MTO) or Make-to-Stock (MTS) methods, engineer to order manufacturing truly excels in personalization and teamwork between producers and clients.

The journey usually kicks off with a request for quotation (RFQ). From there, it dives into detailed engineering and design phases, ensuring the final product matches client specifications perfectly. This approach is especially crucial in industries like aerospace, heavy machinery, and specialized equipment, where engineer to order manufacturing solutions are essential.

Did you know that by 2025, around 74% of producers will identify as part of the engineer to order manufacturing (ETO) sector? That’s a clear sign of a growing trend towards engineer to order manufacturing, driven by consumers wanting more personalized products. However, there’s a catch: over 80% of companies involved in engineer to order manufacturing face challenges with documentation and traceability. This can create significant hurdles in the ETO process.

Industry leaders stress that successful engineer to order manufacturing depends on effective communication and understanding client needs. In fact, studies show that a whopping 70% of product strategy failures stem from a lack of this insight. So, how can we ensure project success? It all comes down to fostering open lines of communication. What do you think? How can we improve this process together?

Highlight Benefits of ETO Manufacturing

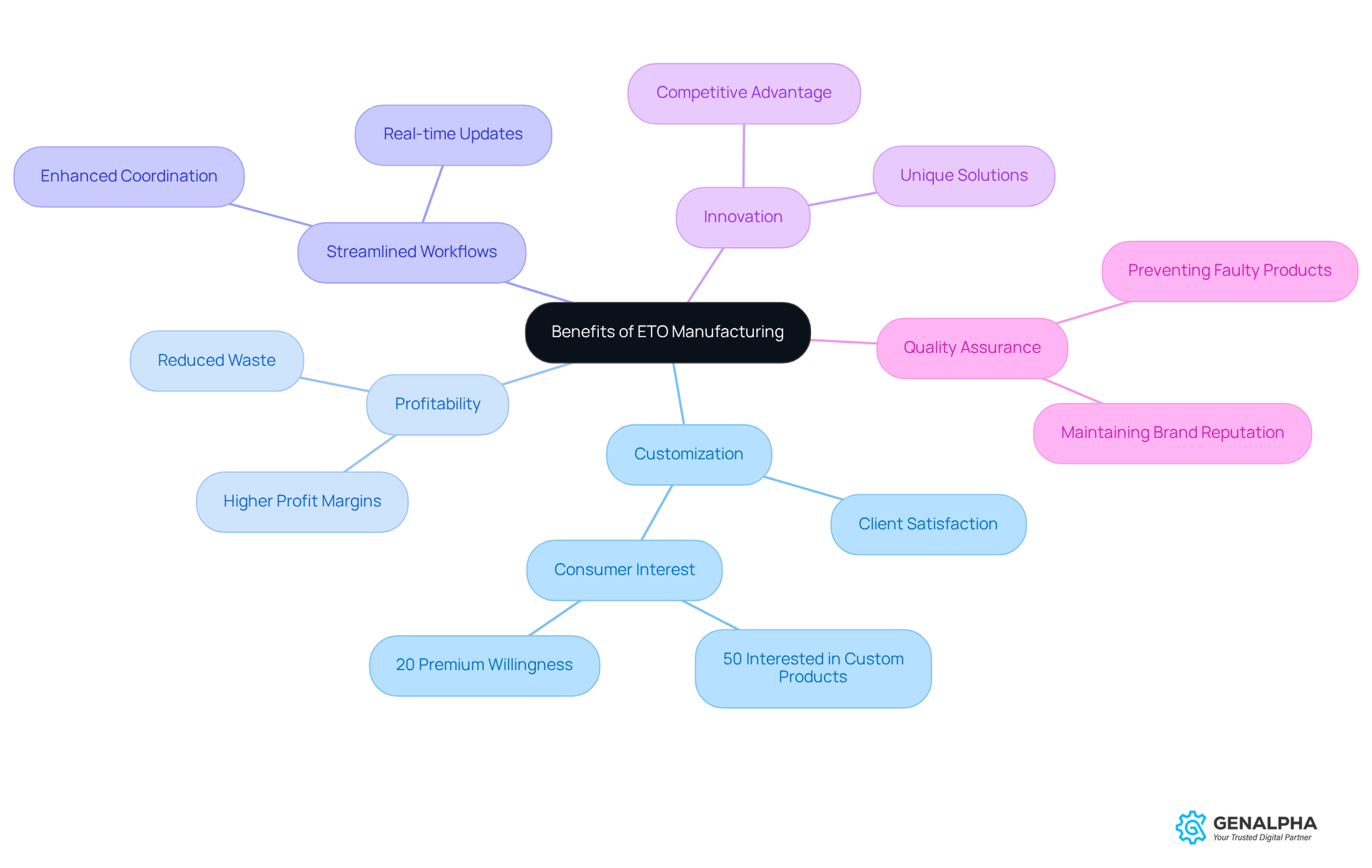

Engineer to order manufacturing offers some pretty amazing benefits that really resonate with both producers and clients. Have you ever thought about how much customization matters? With engineer to order manufacturing, manufacturers can customize products to meet specific client needs, which not only boosts client satisfaction but also builds loyalty. In fact, did you know that over 50% of consumers are interested in buying customized products? And one in five is even willing to pay a 20% premium for something personalized!

But that’s not all. ETO processes often lead to higher profit margins, thanks to the premium pricing that comes with engineer to order manufacturing of bespoke products. This profitability is enhanced by streamlined workflows that cut down on waste, as every task is carefully aligned with client specifications. Plus, the integration of cloud-based ERP systems is a game changer for engineer to order manufacturing, enabling real-time updates and enhancing coordination between engineering and production teams. This can really help reduce lead times and optimize production processes.

And let’s not forget about innovation! Engineer to order manufacturing encourages producers to develop unique solutions that distinguish them in a competitive market. Take KparK, for example. Their success story shows how using visual CPQ solutions can significantly boost client engagement and satisfaction. By automating their sales process, they reduced quote times and improved operational efficiencies. By focusing on these key aspects, manufacturers can not only meet but exceed client expectations, solidifying their market position. And remember, maintaining quality assurance throughout the ETO process is crucial to avoid client dissatisfaction and the risk of losing business to competitors.

Address Challenges in ETO Manufacturing

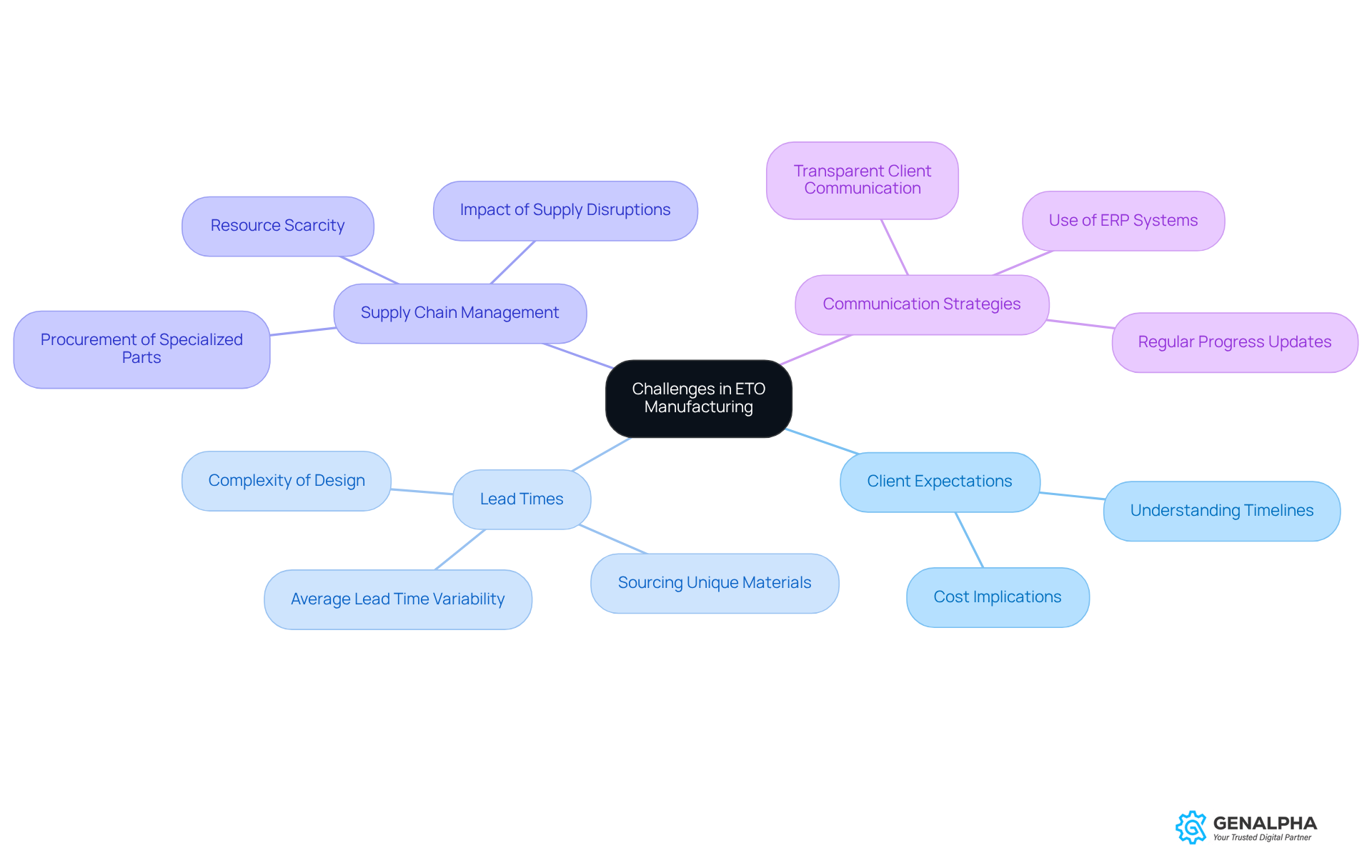

Engineer to order manufacturing is impressive due to its customization abilities, but it also presents several challenges, particularly in managing client expectations. Have you ever thought about how the intricate nature of ETO can lead to misunderstandings? Sometimes, customers might not fully grasp how tailored solutions can impact timelines and costs. For example, average lead times for engineer to order manufacturing projects can stretch out significantly, often taking several months or even years to complete, depending on the complexity of the design and the sourcing of unique materials. It’s crucial to understand that lead times can vary based on project specifics, right? Setting realistic expectations is key.

Now, let’s talk about supply chain management. It’s essential in engineer to order manufacturing scenarios because producers need to navigate the procurement of specialized parts that aren’t just sitting on the shelf. This complexity can lead to delays if not managed well, and supply disruptions can cost producers an average of 8% in revenue loss. Ouch! Plus, integrating design and engineer to order manufacturing processes is vital; any disconnect between these stages can lead to increased costs and further delays. So, what can producers do? Embrace strong management practices! Transparent communication with clients about timelines, potential challenges, and progress updates can make a world of difference.

By using ERP systems to keep an eye on lead times and improve communication, producers can boost transparency and responsiveness. Establishing achievable expectations and ensuring openness throughout the lifecycle can really enhance client satisfaction and help build long-term relationships. So, what do you think? Ready to take your ETO game to the next level?

Implement Best Practices for ETO Success

Do you want to succeed in engineer to order manufacturing? Let’s chat about some key practices that can really make a difference!

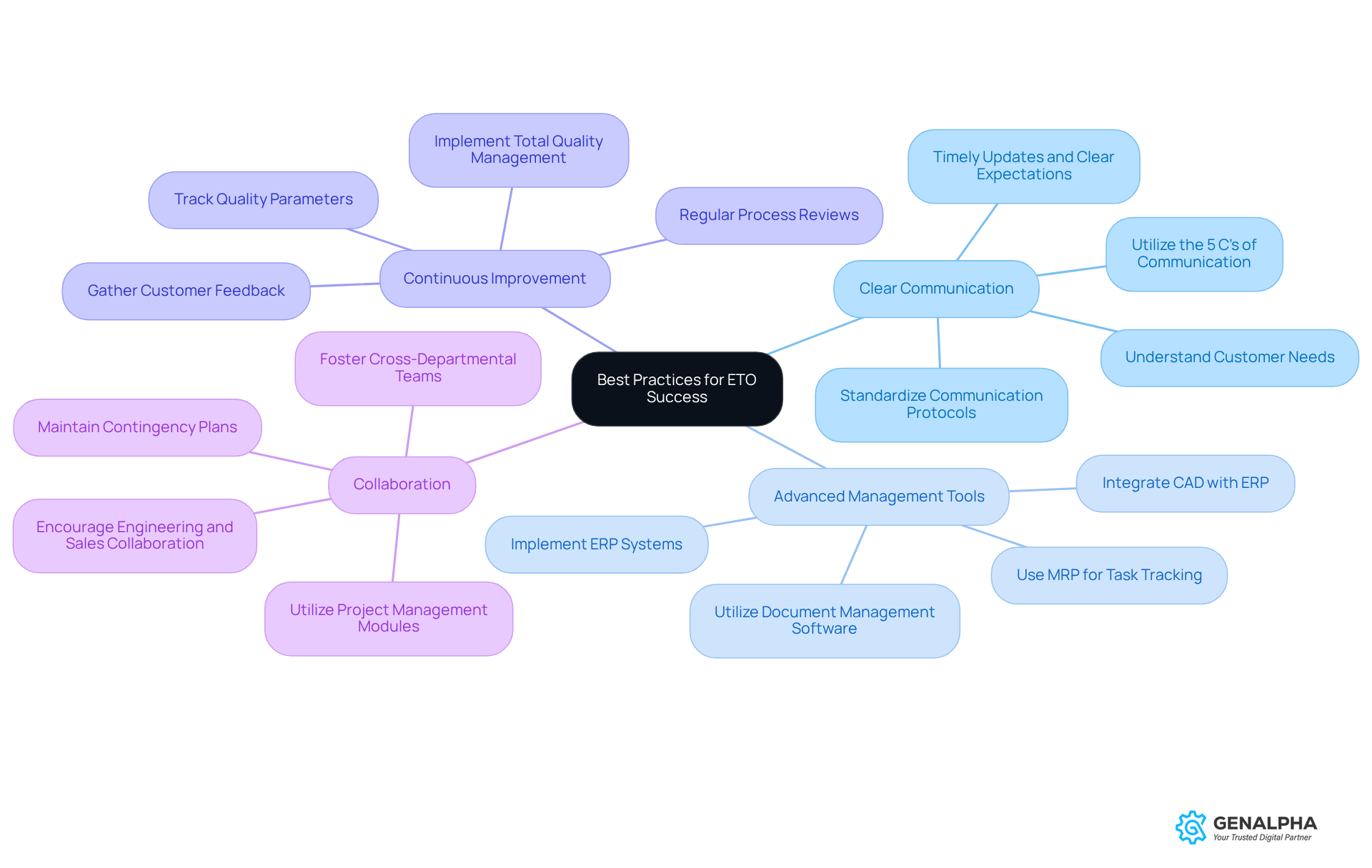

First off, clear communication with your customers is a must. Think about it: when everyone’s on the same page regarding specifications and timelines, it just makes everything smoother, right?

Next up, have you considered using advanced management tools? They can really help streamline workflows and boost coordination among your teams. Plus, implementing a solid ERP system designed for engineer to order manufacturing can provide you with better visibility into your progress and how resources are allocated.

But it doesn’t stop there! Continuous improvement is vital. Regularly reviewing your processes and gathering feedback from customers can help you spot areas that need a little extra love.

And let’s not forget about collaboration! Fostering a culture where engineering, manufacturing, and sales teams work together can lead to innovative solutions and better project outcomes. So, what do you think? Ready to take these steps and see the difference?

Conclusion

Engineer-to-order manufacturing really shines when it comes to delivering customized products that fit individual client needs. This approach not only boosts customer satisfaction but also sparks innovation and profitability across various industries. By focusing on effective communication and teamwork throughout the manufacturing process, businesses can tackle the complexities of ETO while making sure they meet-and even exceed-client expectations.

So, what are the key takeaways from our look at ETO manufacturing? First off, understanding client requirements and keeping communication transparent is crucial. The perks of customization, smoother workflows, and the use of advanced management tools like ERP systems play a big role in overcoming common hurdles, such as long lead times and supply chain issues. Plus, emphasizing continuous improvement and collaboration among engineering, manufacturing, and sales teams can really elevate project outcomes and strengthen those all-important client relationships.

In the end, embracing best practices in engineer-to-order manufacturing is a must for thriving in today’s competitive landscape. Companies should take a proactive stance by implementing effective communication strategies, leveraging technology, and nurturing a culture of collaboration. By doing this, they can not only achieve operational excellence but also position themselves as leaders in delivering personalized solutions that truly resonate with today’s consumers. So, are you ready to take the leap and transform your approach to ETO manufacturing?

Frequently Asked Questions

What is engineer-to-order manufacturing?

Engineer-to-order manufacturing is a production method where products are customized to fit specific customer needs, focusing on personalization and collaboration between producers and clients.

How does engineer-to-order manufacturing differ from other methods?

Unlike Make-to-Order (MTO) or Make-to-Stock (MTS) methods, engineer-to-order manufacturing emphasizes customization and teamwork, ensuring that the final product aligns perfectly with client specifications.

What is the initial step in the engineer-to-order manufacturing process?

The journey typically begins with a request for quotation (RFQ), which leads into detailed engineering and design phases.

In which industries is engineer-to-order manufacturing particularly important?

Engineer-to-order manufacturing is crucial in industries such as aerospace, heavy machinery, and specialized equipment.

What is the projected trend for engineer-to-order manufacturing by 2025?

By 2025, it is estimated that around 74% of producers will identify as part of the engineer-to-order manufacturing sector, reflecting a growing demand for personalized products.

What challenges do companies face in engineer-to-order manufacturing?

Over 80% of companies involved in engineer-to-order manufacturing encounter challenges related to documentation and traceability, which can hinder the ETO process.

What is essential for successful engineer-to-order manufacturing?

Successful engineer-to-order manufacturing relies on effective communication and a clear understanding of client needs, as studies indicate that 70% of product strategy failures arise from a lack of insight into these areas.

How can communication be improved in the engineer-to-order manufacturing process?

Fostering open lines of communication between producers and clients is key to improving the engineer-to-order manufacturing process and ensuring project success.