Overview

Mastering digitalization in manufacturing is all about focusing on a few key steps. Have you ever thought about how assessing current processes, setting clear objectives, investing in training, and choosing the right technology can transform your operations? This article dives into these essential steps while also highlighting the drivers of digitalization, like customer expectations and operational efficiency.

By strategically implementing these ideas, you can significantly boost productivity and competitiveness in the manufacturing sector. Imagine what that could mean for your business! So, are you ready to take the leap into digitalization and see the benefits for yourself?

Introduction

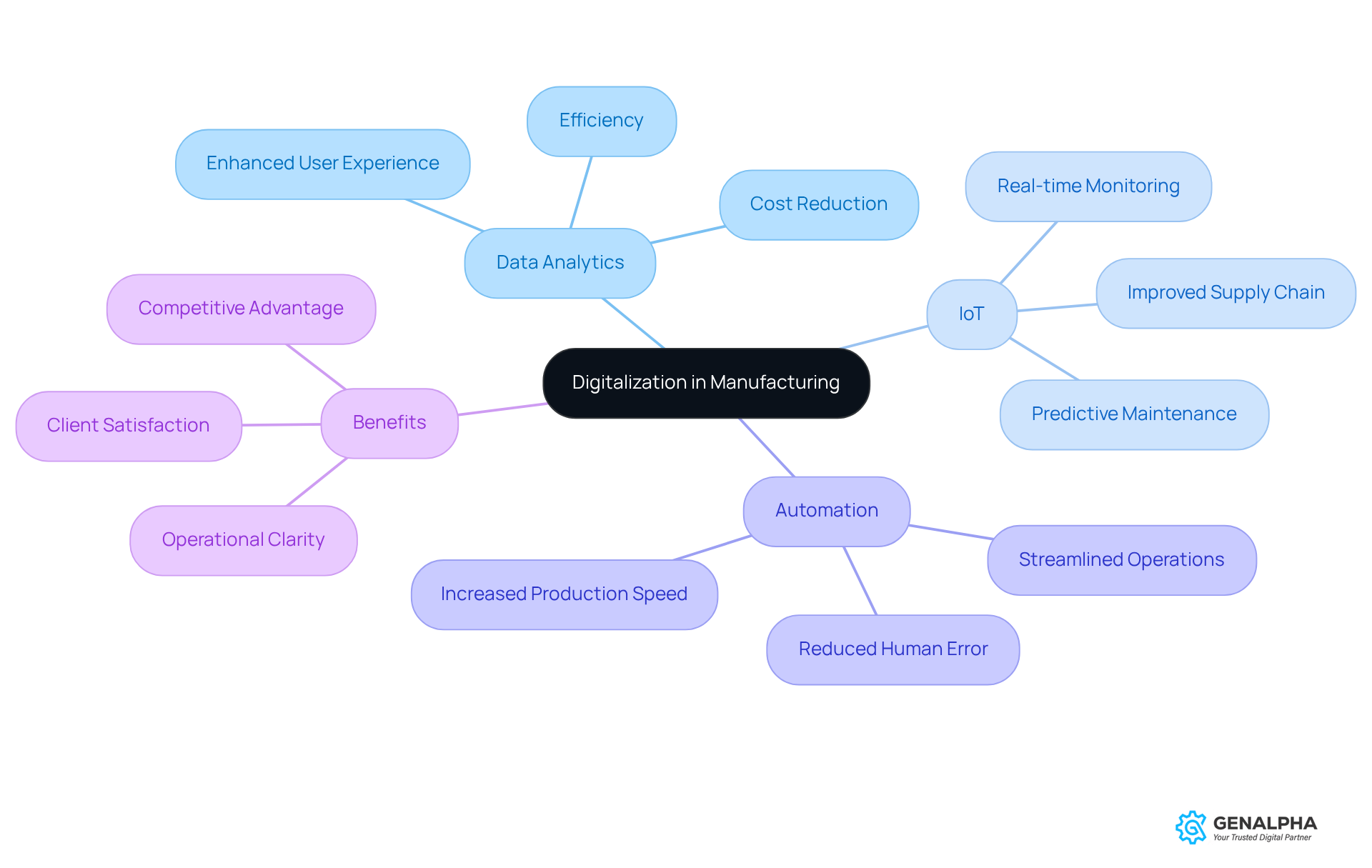

Digitalization is shaking things up in the manufacturing world! With advanced technologies like IoT, data analytics, and automation stepping into the spotlight, manufacturers are finding new ways to boost efficiency and keep customers happy.

But as the market evolves at lightning speed, it’s crucial for manufacturers to grasp the key drivers and best practices for a successful digital transformation.

So, how do we tackle the bumps along the road? Navigating resistance to change, integration issues, and skill gaps can be tricky, but it’s all part of fully embracing the benefits of digitalization.

Let’s dive in and explore how we can make this journey smoother together!

Define Digitalization in Manufacturing

Imagine a world where digitalization in manufacturing enables electronic technologies to be seamlessly integrated into every aspect. This shift towards digitalization in manufacturing involves utilizing data analytics, IoT (Internet of Things), and automation to boost efficiency, cut costs, and enhance user experiences. By moving away from traditional methods and embracing electronic solutions, manufacturers can leverage digitalization in manufacturing to streamline their operations, improve their supply chains, and provide top-notch service to their clients.

For instance, think about how adopting an electronic warranty management system can transform the way claims are processed. It can make everything smoother and increase client satisfaction by offering real-time updates and clarity on warranty status. How cool is that? So, if you're in manufacturing, it might be time to consider how digitalization in manufacturing can revolutionize your business!

Identify Key Drivers of Digitalization

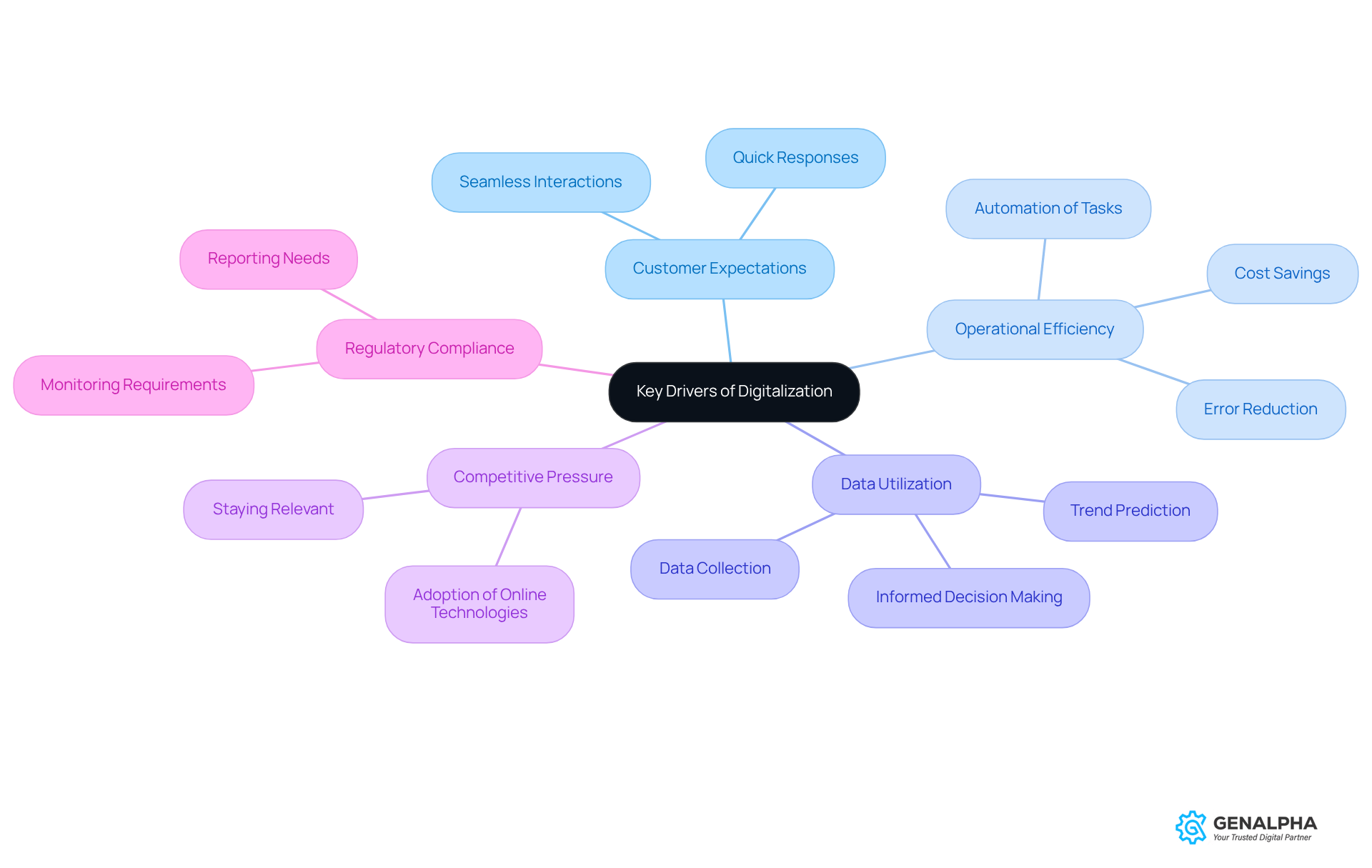

Let’s discuss the factors that are driving digitalization in manufacturing today. First up, we have Customer Expectations. Nowadays, customers want seamless and quick interactions. They expect manufacturers to keep up, and that means embracing technology.

Next, consider Operational Efficiency. Digital tools are game-changers in the digitalization in manufacturing, as they can automate those repetitive tasks we all dread, cut down on errors, and boost productivity. Who doesn’t love saving costs?

Then there’s Data Utilization. Imagine being able to collect and analyze data to make smarter decisions. It’s like having a crystal ball that helps predict trends and enhance what you offer.

Don’t forget about Competitive Pressure. As competitors dive into online technologies, manufacturers have to step up by adopting digitalization in manufacturing to stay relevant. It’s a fast-paced world out there!

Lastly, we have Regulatory Compliance. With growing regulations, manufacturers often find themselves needing better monitoring and reporting. Thankfully, technology can help with that too.

So, what do you think? Are you ready to embrace these changes and see how they can benefit your manufacturing processes?

Implement Best Practices for Digitalization

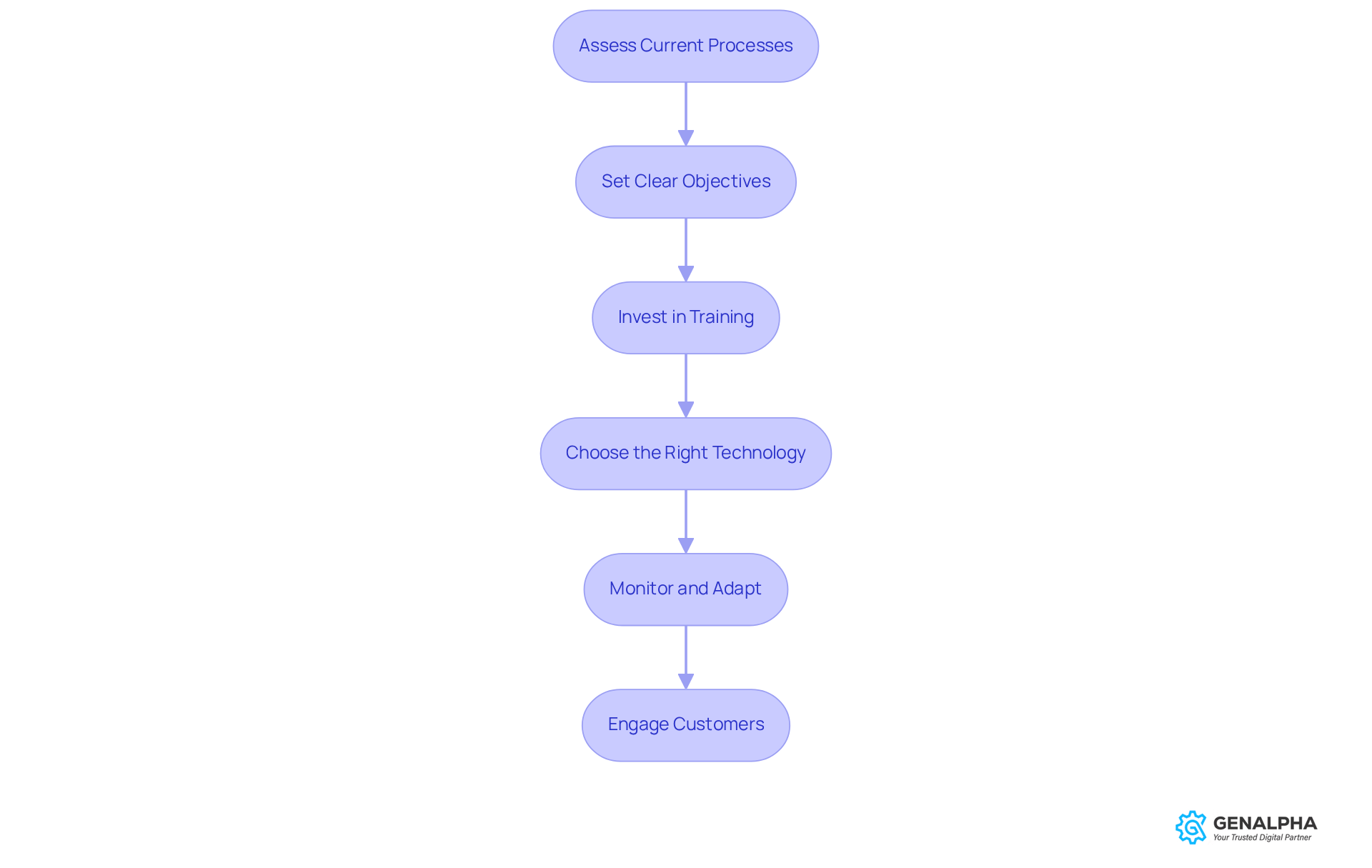

To successfully implement digitalization in manufacturing, let’s explore some best practices together:

-

Assess Current Processes: Take a moment to evaluate your existing workflows. Where do you think technology could really make a difference?

-

Set Clear Objectives: What do you hope to achieve with digitalization? Whether it's improving customer satisfaction or cutting down on operational costs, defining your goals is key.

-

Invest in Training: It’s crucial to ensure that your team is well-equipped to handle new technologies. How about fostering a culture of technological literacy?

-

Choose the Right Technology: Selecting the right electronic tools can be a game-changer. Look for solutions that align with your business objectives and integrate smoothly with your current systems, like ERP solutions.

-

Monitor and Adapt: Don’t forget to keep an eye on how your online initiatives are performing. Are you willing to adjust your strategies based on feedback and results?

-

Engage Customers: Let’s not overlook the importance of customer interaction. Utilize online channels to enhance this experience—think personalized marketing and improved service delivery.

By following these steps, you’re setting yourself up for successful digitalization in manufacturing!

Overcome Challenges in Digitalization

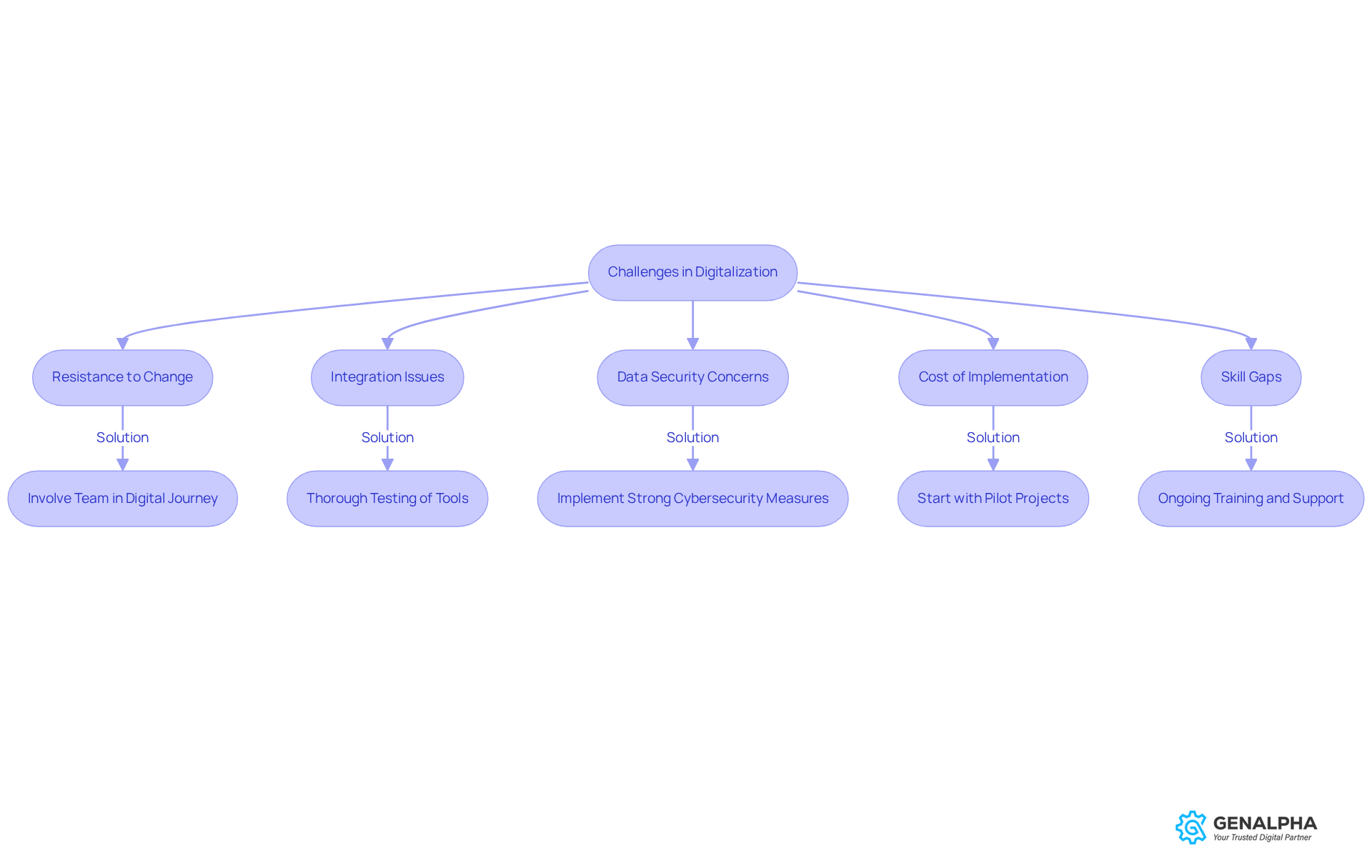

Digitalization can throw a few curveballs our way, but don’t worry; we can handle them! Let’s break it down:

-

Resistance to Change: You know how it goes—new tech can be intimidating. To ease those nerves, why not involve your team in the digital journey? Highlighting the perks can really help!

-

Integration Issues: It’s crucial that new digital tools play nicely with what you already have. A little thorough testing goes a long way, so choose solutions that fit seamlessly with your existing systems.

-

Data Security Concerns: Keeping sensitive data safe is a big deal. Implementing strong cybersecurity measures and ensuring you’re in line with regulations is a must.

-

Cost of Implementation: Sure, going digital can come with a price tag. Starting with pilot projects is a smart move to show the value before you dive in deeper.

-

Skill Gaps: Make sure your team is ready to embrace new tech. Ongoing training and support can bridge those gaps and empower everyone to thrive.

So, what do you think? Are you ready to tackle these challenges head-on and make digitalization work for you?

Conclusion

Embracing digitalization in manufacturing isn’t just an option anymore; it’s a must if you want to stay competitive and efficient in today’s fast-paced market. Think about it—advanced technologies like data analytics, IoT, and automation are fundamentally changing how we manufacture. This shift leads to better operational efficiency and enhances customer experiences. By adopting these digital solutions, manufacturers can streamline their operations and elevate their service offerings, ensuring they meet the ever-evolving expectations of their clients.

Throughout this article, we’ve highlighted some key drivers of digitalization:

- Customer expectations

- Operational efficiency

- Data utilization

- Competitive pressure

- Regulatory compliance

All play significant roles in motivating manufacturers to embrace digital technologies. Additionally, we’ve discussed best practices for successful implementation, stressing the importance of:

- Assessing current processes

- Setting clear objectives

- Investing in training

- Choosing the right technology

Let’s not forget—addressing potential challenges like resistance to change and integration issues is just as crucial for a smooth transition.

The significance of digitalization in manufacturing truly can’t be overstated. As industries continue to evolve, the ability to adapt and harness the power of technology will be what sets successful manufacturers apart. We encourage you to take proactive steps towards digital transformation. By doing so, you’ll not only keep pace with competitors but also create innovative solutions that drive growth and efficiency. Remember, the future of manufacturing lies in digitalization—embracing it today will pave the way for a more efficient and customer-centric tomorrow. So, what’s your next move?

Frequently Asked Questions

What is digitalization in manufacturing?

Digitalization in manufacturing refers to the integration of electronic technologies into all aspects of manufacturing, utilizing data analytics, IoT (Internet of Things), and automation to enhance efficiency, reduce costs, and improve user experiences.

What are the benefits of digitalization in manufacturing?

The benefits include streamlined operations, improved supply chains, enhanced service quality, increased efficiency, and cost reduction.

How does digitalization impact warranty management in manufacturing?

Digitalization, such as adopting an electronic warranty management system, can transform the claims processing by providing real-time updates and clarity on warranty status, leading to smoother operations and increased client satisfaction.

Why should manufacturers consider digitalization?

Manufacturers should consider digitalization to revolutionize their business practices, move away from traditional methods, and leverage electronic solutions for better operational performance and customer service.