Introduction

In an industry where precision and speed really matter, manufacturers often find themselves wrestling with the complexities of quoting processes for detailed products. Enter Configure, Price, Quote (CPQ) systems - these tools have become essential for companies looking to streamline their processes and significantly boost efficiency. But as the demand for quick and accurate quotes ramps up, how can manufacturers make sure they’re effectively implementing CPQ solutions that fit their unique needs?

Let’s dive into some key practices and requirements that equipment manufacturers can master when it comes to CPQ. By doing so, you can unlock insights that lead to better operational performance and happier customers. So, are you ready to explore how to make CPQ work for you?

Understand CPQ: Definition and Importance in Manufacturing

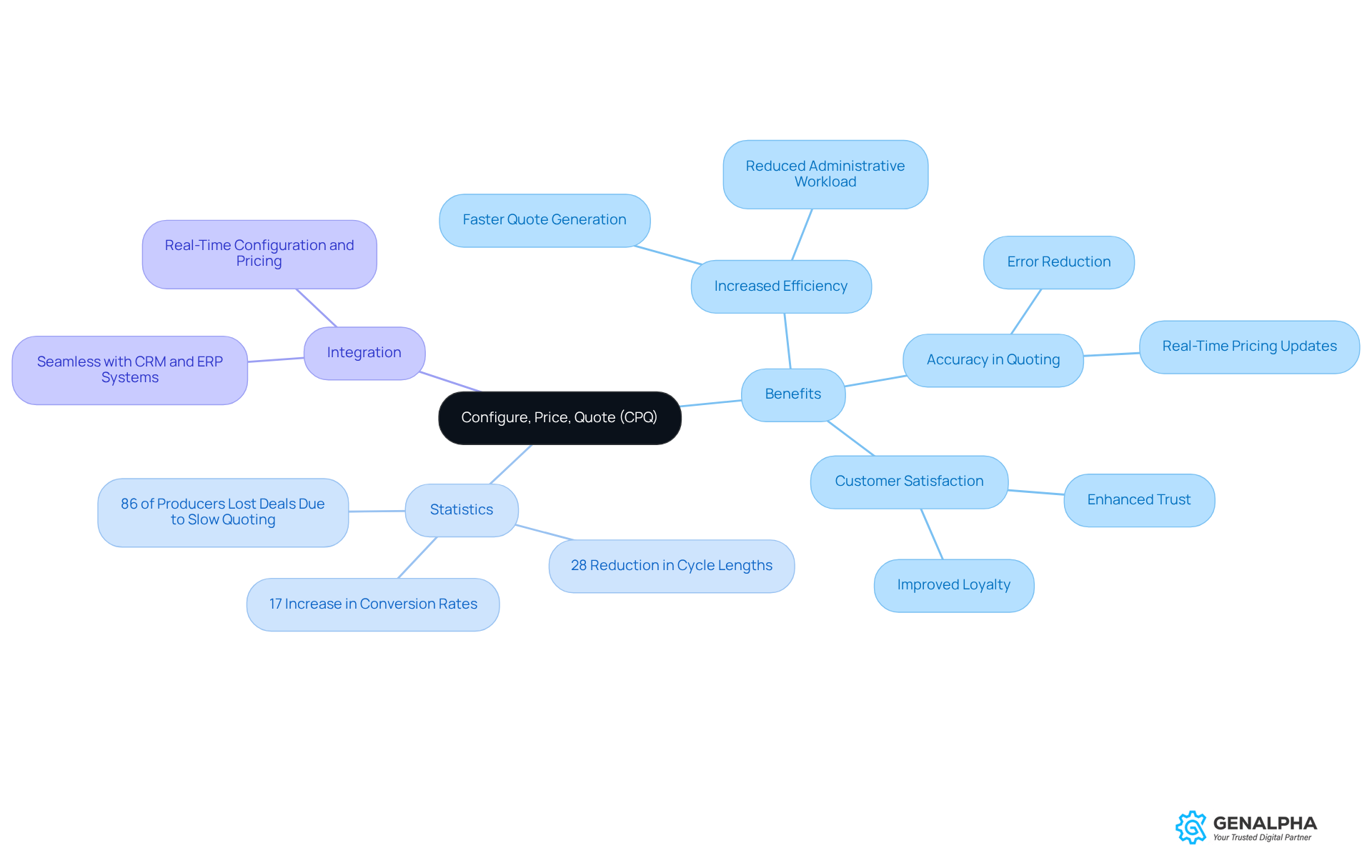

Have you ever felt overwhelmed by the quoting process for complex products? Well, that’s where Configure, Price, Quote (CPQ) comes in! This essential tool helps manufacturers streamline their quoting process, making it easier and faster. By automating product configuration, applying accurate pricing, and generating quotes in a snap, CPQ cuts down on errors and boosts efficiency in transactions.

In the manufacturing world, where products can have intricate configurations and varied pricing structures, adopting CPQ is a game changer. Did you know that companies using CPQ software see an average 17% increase in conversion rates and reduce cycle lengths by 28%? That’s impressive! Plus, a staggering 86% of producers have reported losing deals due to slow or manual quoting methods. Clearly, there’s a pressing need to address CPQ requirements for modernization.

The implementation of CPQ requirements not only speeds up response times but also ensures that quotes are accurate, which leads to happier customers and greater loyalty. And here’s another perk: CPQ systems integrate smoothly with existing CRM and ERP systems, making quoting and order processing workflows a breeze. Imagine how much easier it would be for your customers to configure products and generate quotes on their own-talk about enhancing the customer experience!

As producers work to keep up with the competitive market, addressing CPQ requirements stands out as a vital solution for boosting operational efficiency and sales performance. With the CPQ market set to grow significantly, embracing this technology is essential for producers who want to stay ahead of the game. So, are you ready to take the leap into the future of quoting?

Identify Key CPQ Requirements for Manufacturing Success

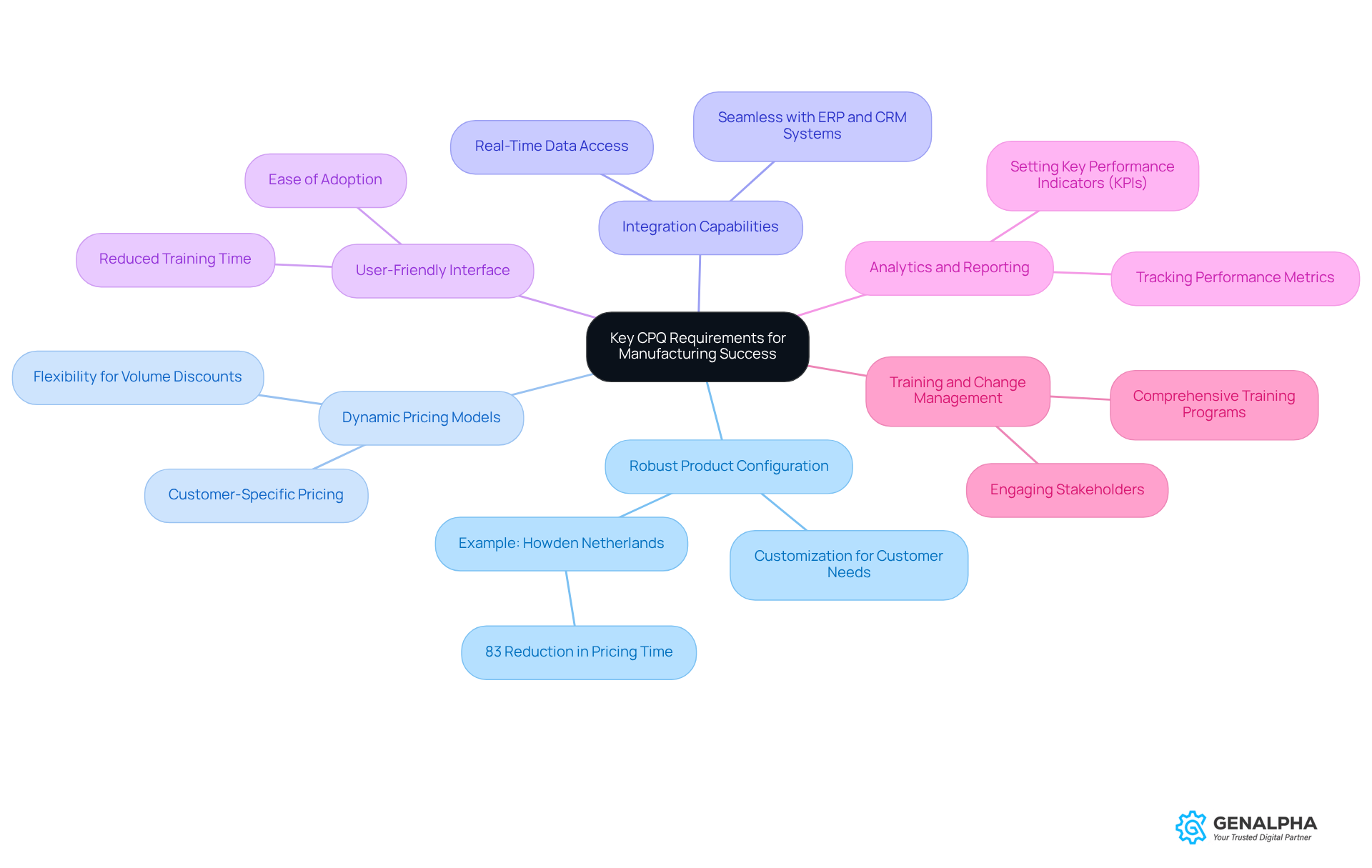

To really nail success with CPQ, manufacturers need to focus on a few key requirements:

-

Robust Product Configuration: Managing complex product configurations is a must. This feature lets producers customize products to meet specific customer needs, boosting satisfaction and cutting down on errors. For example, Howden Netherlands has rolled out CPQ solutions that streamline their product configuration processes, leading to an impressive 83% reduction in pricing time for orders.

-

Dynamic Pricing Models: CPQ should be flexible enough to handle various pricing strategies, like volume discounts and customer-specific pricing. This adaptability is crucial for manufacturers dealing with diverse market demands, helping them stay competitive.

-

Integration Capabilities: Seamless integration with existing ERP and CRM systems is key for keeping data consistent and operations running smoothly. This integration allows for real-time access to inventory and pricing data, which is essential for accurate quoting.

-

User-Friendly Interface: A simple interface makes it easier for users to adopt the system and cuts down on training time. When revenue teams can easily navigate the CPQ system, they can focus more on selling rather than getting bogged down in complex software.

-

Analytics and Reporting: Integrated analytics tools are vital for tracking performance metrics and refining marketing strategies. By setting key performance indicators (KPIs), producers can evaluate how well their CPQ implementation is working and make informed adjustments.

-

Training and Change Management: Effective training and change management are crucial during the switch to CPQ systems. Engaging stakeholders and providing thorough training ensures that teams can fully leverage the CPQ tools, leading to higher adoption rates and better results.

By honing in on these cpq requirements, producers can ensure their CPQ system truly supports their sales processes, ultimately leading to greater accuracy, shorter lead times, and happier customers. Plus, with the CPQ market set to grow significantly in the coming years, embracing these tools is becoming increasingly important for producers looking to stay ahead of the game.

Implement CPQ Solutions: Best Practices for Seamless Integration

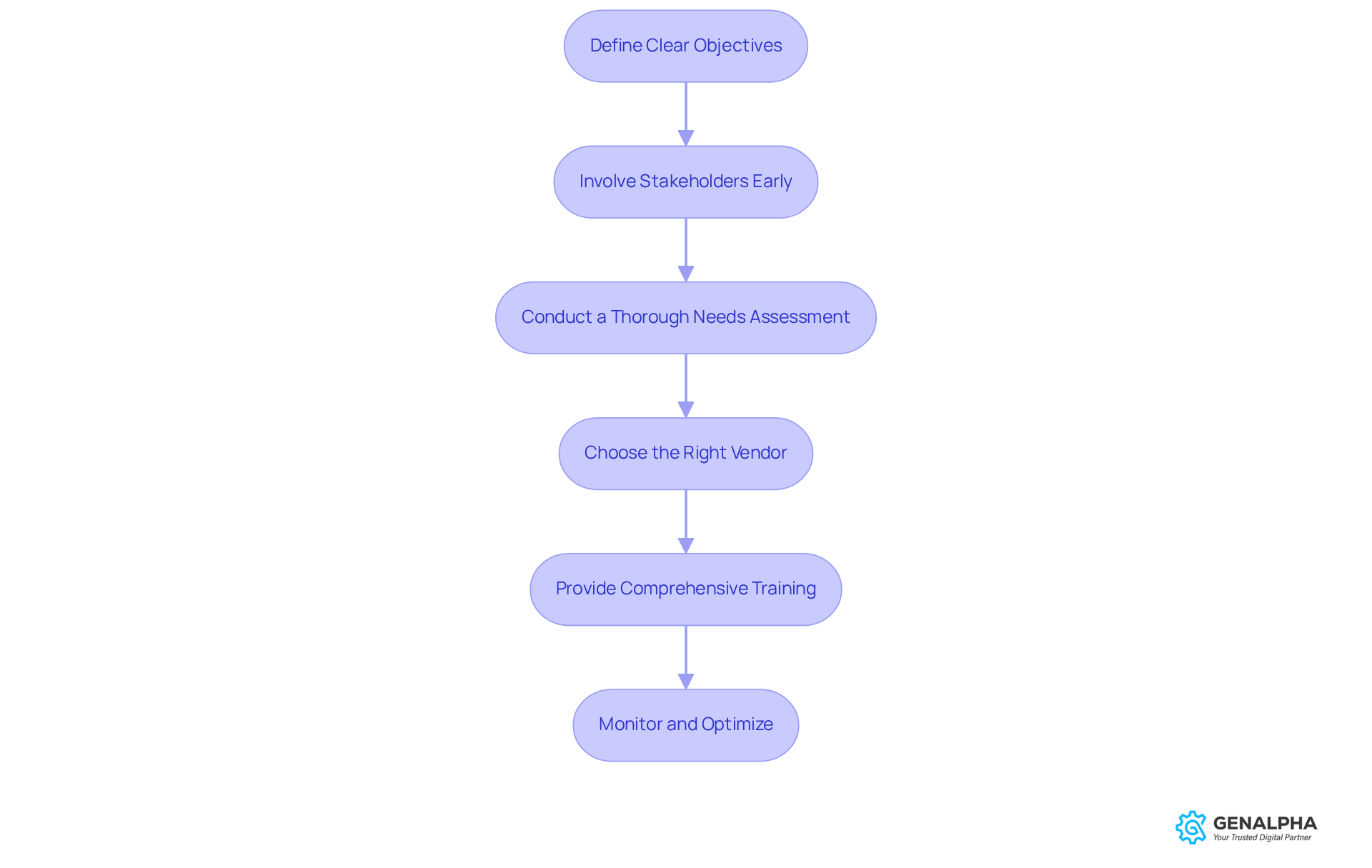

To get the most out of CPQ systems, let’s chat about some best practices you should keep in mind:

-

Define Clear Objectives: What do you want to achieve with your CPQ implementation? Setting measurable goals is key to staying on track.

-

Involve Stakeholders Early: Have you thought about bringing your marketing and IT teams into the planning process? Getting their input early ensures that all perspectives are considered.

-

Conduct a Thorough Needs Assessment: Take a good look at your current processes. What gaps do you see? Identifying areas for improvement can really set you up for success.

-

Choose the Right Vendor: Not all CPQ vendors are created equal. Make sure to pick one that aligns with your specific needs and offers solid support.

-

Provide Comprehensive Training: Training is crucial! Ensure that everyone using the new system feels confident and ready to go. This will help maximize adoption and minimize any resistance.

-

Monitor and Optimize: After you’ve implemented the system, don’t just set it and forget it. Keep an eye on its performance and be ready to make adjustments to boost efficiency and effectiveness.

By following these steps, you’ll be well on your way to executing CPQ systems effectively!

Evaluate CPQ Platforms: Choosing the Right Solution for Your Needs

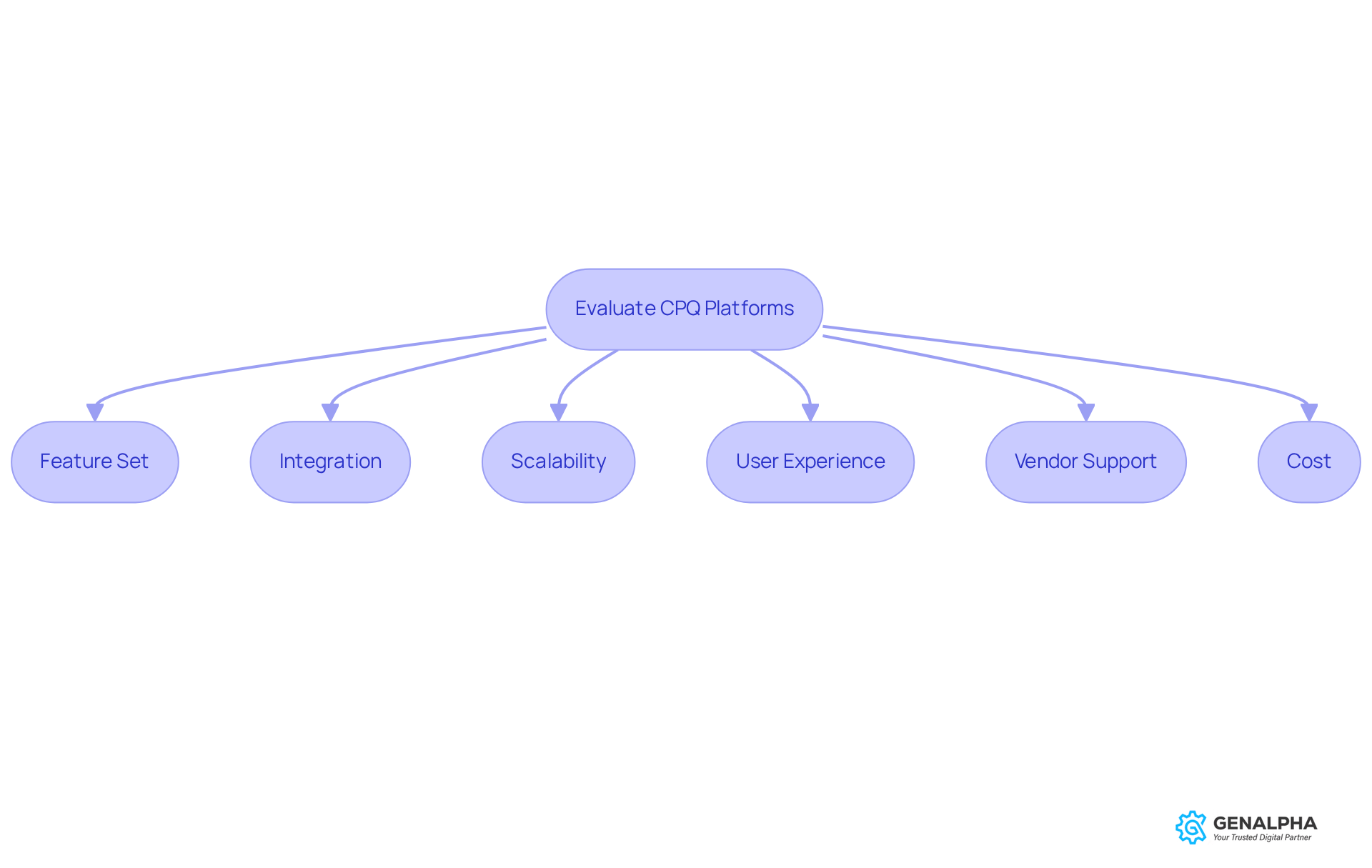

When it comes to selecting the right CPQ platform, manufacturers really need to focus on the cpq requirements. This way, they can find a solution that not only fits their operational needs but also boosts sales efficiency. So, let’s break it down:

-

Feature Set: First off, check if the platform has the must-have features like product configuration, pricing flexibility, and solid quote generation capabilities. A comprehensive quoting tool should encourage teamwork and communication, helping sales teams create accurate and timely quotes. As Joanne puts it, "Finding the right quoting approach is not just about speed. It’s about improving governance and revenue health."

-

Integration: Next, make sure the platform can easily integrate with your existing ERP and CRM systems. This is super important for accessing real-time data, which streamlines quoting processes and cuts down on errors from manual data entry. Did you know that effective integration can shorten sales cycles by an average of 28%? That’s a big deal!

-

Scalability: Look for a solution that can grow with your business. As manufacturers expand, their quoting needs will change, so it’s crucial to have a platform that adapts without needing major overhauls. With the CPQ market expected to grow at a CAGR of 17-20%, choosing a scalable option is key.

-

User Experience: Don’t forget to evaluate how user-friendly the platform is. A simple, intuitive design can really boost adoption rates among sales teams, cutting down on training time and ramping up productivity. A no-code approach can also help minimize the technical skills needed for effective use.

-

Vendor Support: It’s also worth looking into the level of support the vendor offers-think training, troubleshooting, and ongoing maintenance. Good vendor support can make the implementation process smoother and help users get the most out of the platform. Case studies show that proactive training and tracking adoption are vital for successful implementation.

-

Cost: Finally, consider the total cost of ownership. This includes licensing, implementation, and any hidden costs that might pop up. Understanding the financial impact of adopting a CPQ solution is crucial for making a smart choice. Organizations should weigh potential overhead costs linked to quoting software before making a commitment.

By taking the time to evaluate these factors, manufacturers can choose a CPQ platform that not only meets their cpq requirements but also enhances their sales processes. This can lead to improved efficiency and higher conversion rates. In fact, businesses using CPQ software see an average 17% increase in conversion rates, which really highlights the importance of making an informed decision.

Conclusion

Embracing Configure, Price, Quote (CPQ) solutions isn’t just a trend; it’s a must for equipment manufacturers looking to thrive in today’s competitive landscape. Think about it: by streamlining the quoting process, boosting accuracy, and enhancing customer satisfaction, CPQ systems empower manufacturers to respond quickly to market demands and optimize their sales performance.

Throughout our discussion, we’ve highlighted some key practices. For instance:

- Robust product configuration

- Dynamic pricing models

- Seamless integration with existing systems

- Comprehensive training for users

Each of these elements plays a vital role in helping manufacturers leverage CPQ to its fullest potential, ultimately leading to higher conversion rates and better operational efficiency.

As the CPQ market keeps expanding, it’s essential for manufacturers to prioritize evaluating and implementing these systems. The potential for improved efficiency and customer loyalty is huge! So, adopting best practices and choosing the right CPQ platform tailored to your specific operational needs is key. By taking proactive steps today, you can secure your competitive edge and pave the way for future success in the ever-evolving manufacturing landscape. What steps will you take to embrace CPQ solutions?

Frequently Asked Questions

What does CPQ stand for and what is its purpose in manufacturing?

CPQ stands for Configure, Price, Quote. Its purpose is to streamline the quoting process for complex products, making it easier and faster for manufacturers by automating product configuration, applying accurate pricing, and generating quotes quickly.

How does CPQ improve efficiency in the quoting process?

CPQ improves efficiency by reducing errors, speeding up response times, and ensuring that quotes are accurate, which ultimately leads to faster transactions and happier customers.

What are the benefits of using CPQ software for manufacturers?

Manufacturers using CPQ software experience an average 17% increase in conversion rates and a 28% reduction in cycle lengths. Additionally, it helps prevent lost deals due to slow or manual quoting methods.

How does CPQ impact customer experience?

CPQ enhances customer experience by allowing customers to configure products and generate quotes on their own, resulting in a more efficient and satisfying interaction.

Can CPQ systems integrate with other software?

Yes, CPQ systems can integrate smoothly with existing CRM and ERP systems, simplifying quoting and order processing workflows.

Why is addressing CPQ requirements important for manufacturers?

Addressing CPQ requirements is important for manufacturers to boost operational efficiency, improve sales performance, and keep up with competitive market demands.

What is the projected growth of the CPQ market?

The CPQ market is set to grow significantly, making it essential for producers to embrace this technology to stay ahead in the industry.