Introduction

Navigating the complexities of equipment manufacturing can feel pretty overwhelming, right? Especially when it comes to the quoting process. That’s where Configure, Price, Quote (CPQ) software comes in - a game-changer designed to simplify and automate this crucial function. With CPQ, manufacturers can quickly respond to the growing demand for customization, making life a whole lot easier.

Imagine being able to enhance your operational efficiency while also boosting customer satisfaction. Sounds great, doesn’t it? But here’s the kicker: as the CPQ market grows, manufacturers are left wondering how to effectively implement these integrations. How can they maximize the benefits while tackling the common challenges that come with it?

Let’s dive into this together and explore how CPQ can transform your quoting process!

Understand CPQ Software and Its Role in Equipment Manufacturing

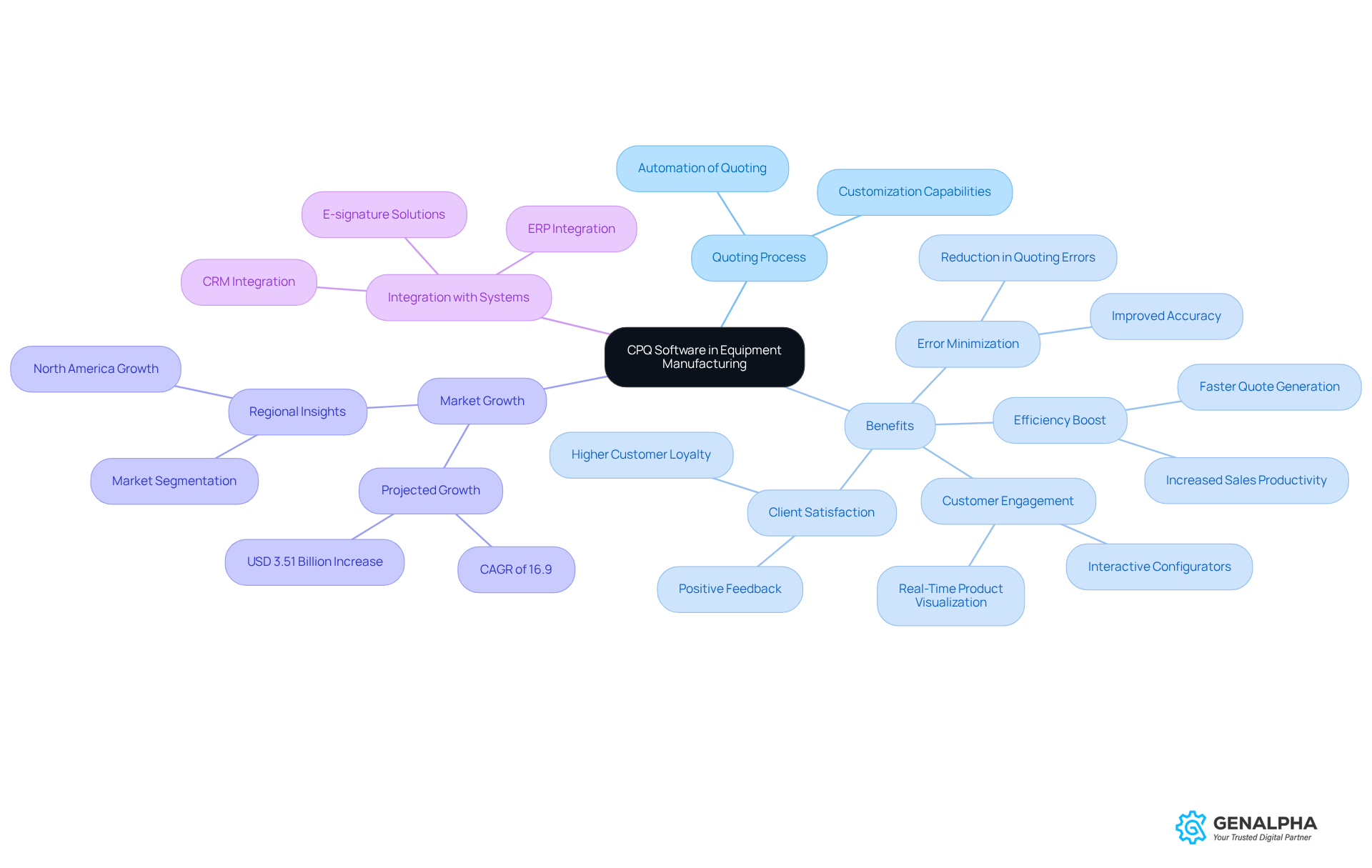

Have you ever felt overwhelmed by the quoting process in equipment manufacturing? Well, that’s where Configure, Price, Quote (CPQ) software comes in! It’s a game changer for manufacturers, automating and streamlining the quoting process to keep up with the rising demand for customization. Imagine your sales team being able to whip up precise quotes in no time, tailored to client specifications. That’s the efficiency boost CPQ systems bring to the sales cycle.

By utilizing CPQ integrations for product configurations, pricing rules, and discount structures, CPQ minimizes errors and speeds up the sales process. For example, producers using CPQ can implement real-time product configurators. This not only enhances customer engagement but also boosts satisfaction by delivering customized solutions. Who wouldn’t want that? This capability helps build stronger client relationships and positions manufacturers to respond effectively to market demands.

And here’s a fun fact: the CPQ software market is expected to grow by a whopping USD 3.51 billion from 2025 to 2029, with a projected CAGR of 16.9%. That’s a clear sign that its impact on revenue efficiency is being recognized more and more. Companies that have embraced interactive visual tools have reported up to a 25% increase in online transactions thanks to improved quoting processes.

Industry leaders are saying that adopting CPQ systems is crucial for manufacturers looking to optimize their workflows and boost overall productivity. Plus, when you utilize CPQ integrations with CRM and ERP systems, you maximize operational efficiency, leading to a reported 20% increase in client satisfaction. So, why not consider making the switch? It could be the key to elevating your business!

Ensure Seamless Integration with ERP Systems

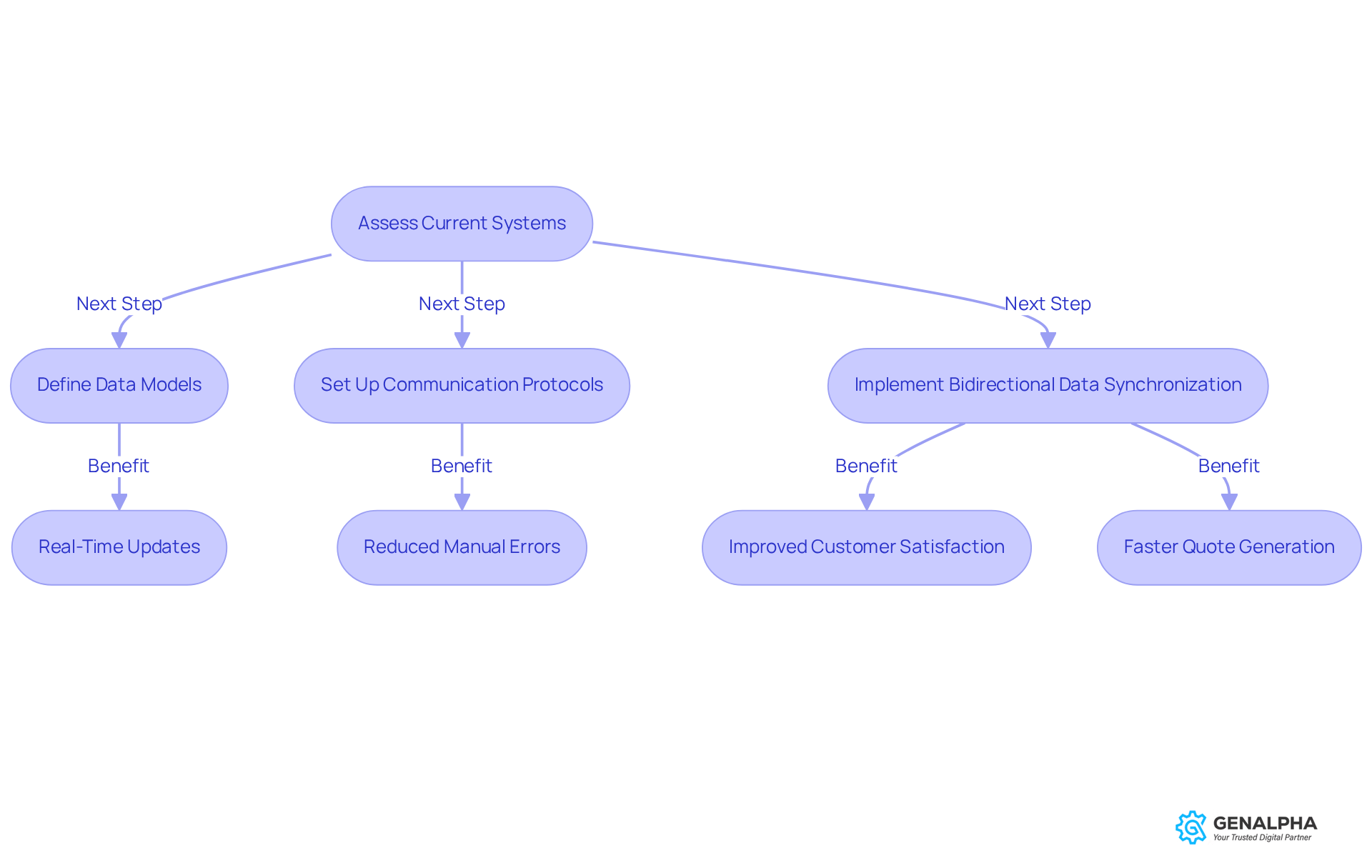

Are you looking into cpq integrations with your existing ERP systems? That’s a game changer for keeping your data accurate and your operations running smoothly. Imagine this: you’re a manufacturer, and you decide to go for a bidirectional data synchronization approach. What does that mean for you? Well, it allows for real-time updates between systems, which can really cut down on those pesky manual data entry mistakes. Plus, your team will always have access to the latest product info and pricing.

For example, one producer who successfully utilized cpq integrations with their ERP system saw a whopping 30% decrease in quote generation time! That’s not just a number; it translates to quicker transaction cycles and happier customers. Who wouldn’t want that?

So, how do you achieve this seamless integration? Start by taking a good look at your current systems. Define your data models clearly and set up communication protocols between your teams. It’s all about making sure everyone’s on the same page. Ready to take the plunge?

Prioritize User Training and Adoption for Effective CPQ Use

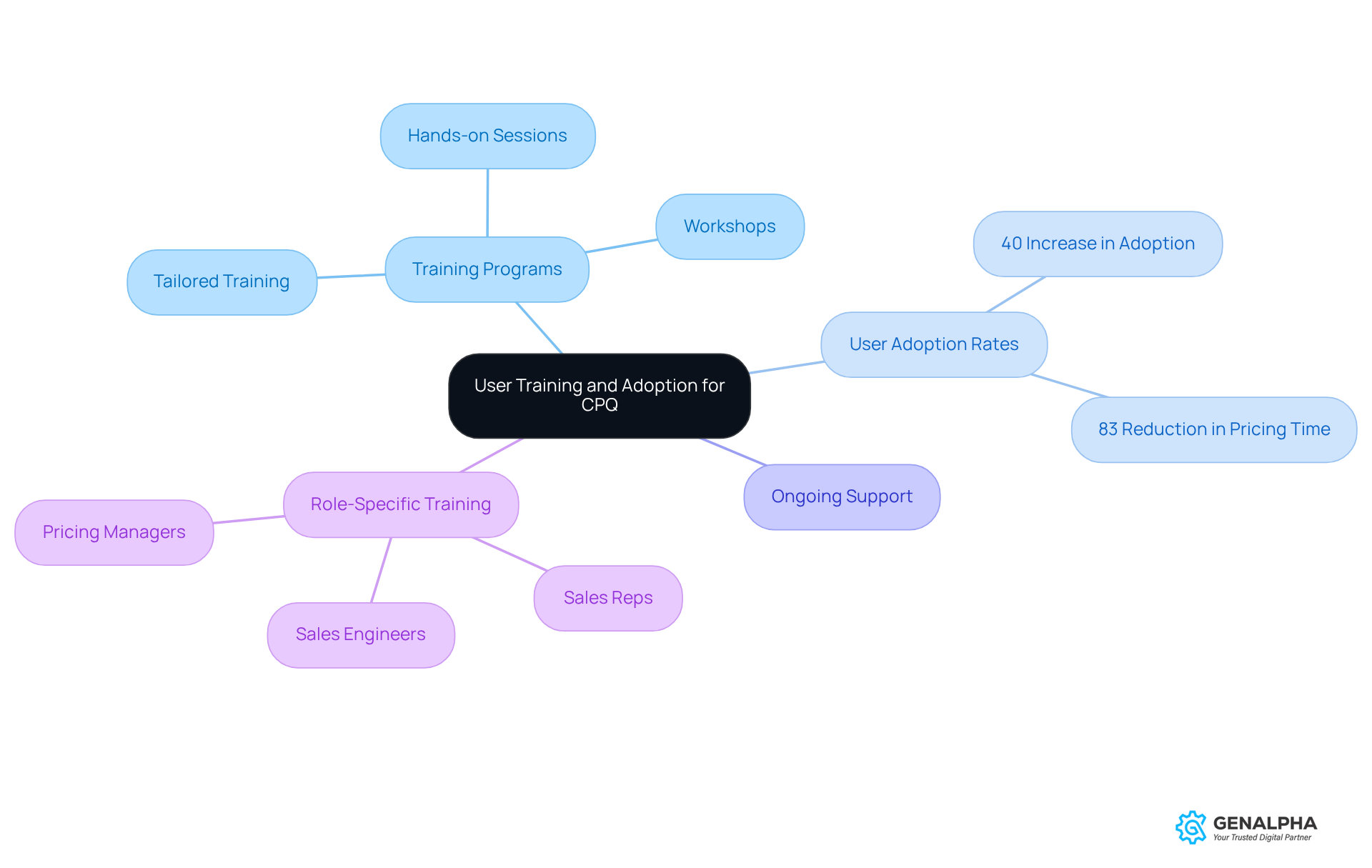

To really get the most out of CPQ software, it’s essential for producers to focus on user training and adoption. Think about it: creating solid training programs is key to helping teams understand how to use the CPQ system effectively. This includes everything from product configuration to applying pricing rules and generating quotes. Regular workshops and hands-on training sessions can really boost user confidence and skills.

For example, one well-known producer rolled out a structured training program and saw a fantastic 40% jump in user adoption rates in just three months! Plus, companies using Cincom CPQ have reported an impressive 83% reduction in pricing time for orders. That’s a clear win from effective training and embracing CPQ.

But it doesn’t stop there. Setting up ongoing support and feedback channels is super important too. This way, any challenges users face can be addressed, ensuring the CPQ system is used to its fullest potential. And let’s not forget about tailoring training sessions for different roles, like engineering reps and pricing managers. This can really enhance overall proficiency and cut down on errors in the quoting process.

Interestingly, 33% of producers say that training team members is a big hurdle when implementing CPQ integrations. So, by investing in strong training programs, manufacturers can truly transform their quoting processes, leading to better efficiency and happier clients. What do you think? Ready to take that step?

Align Sales and Product Teams for Enhanced Collaboration

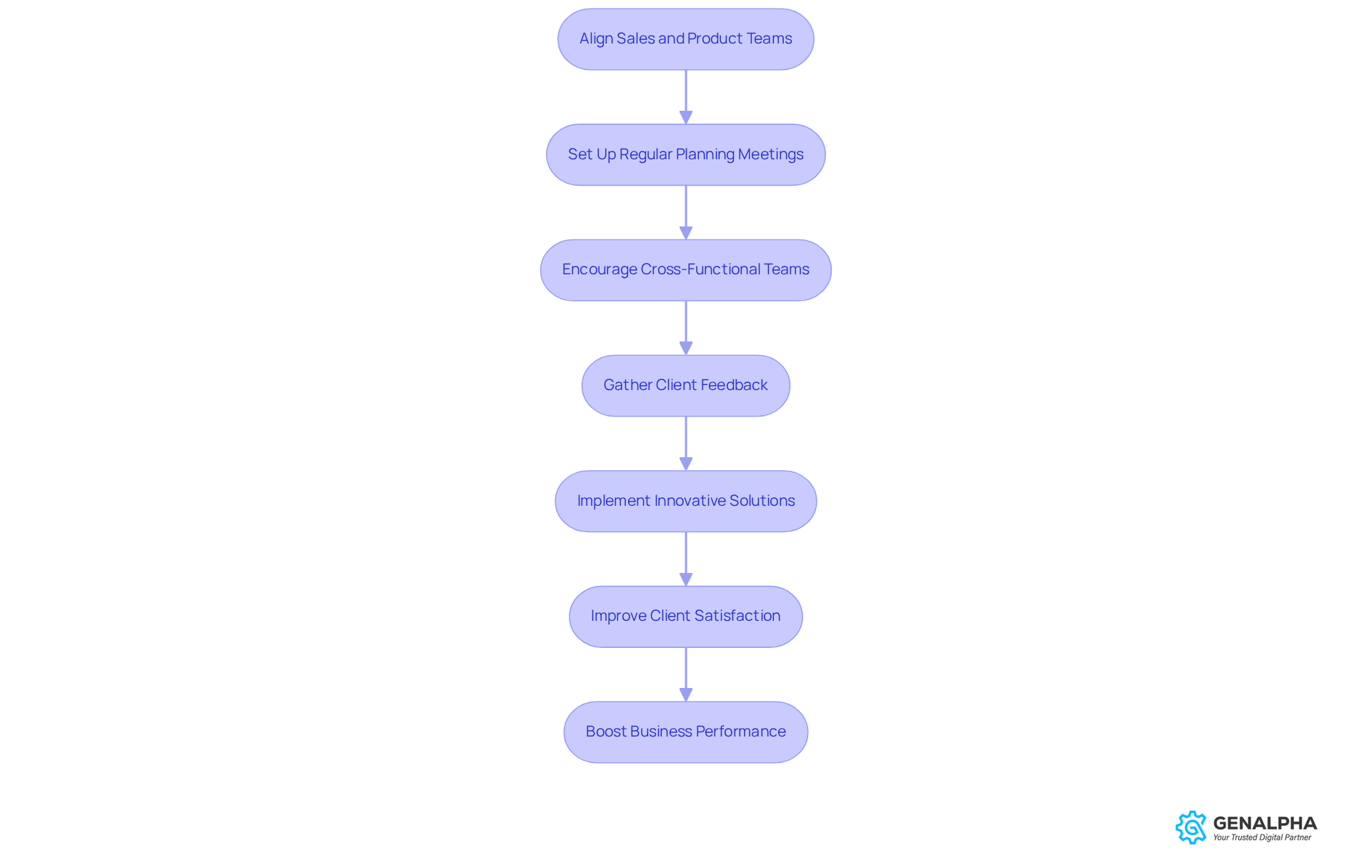

Successful teamwork between marketing and product teams is key to meeting client needs and driving business growth. Have you ever thought about how consistent communication can make a difference? By setting up regular planning meetings, teams can stay aligned on product offerings and client feedback.

Imagine cross-functional teams made up of both marketing and product development members. This collaboration can lead to innovative solutions that truly respond to what the market wants. For instance, one producer that embraced this approach saw a 25% increase in client satisfaction ratings. Why? Because their sales team was better equipped to share product features and gather valuable feedback for future improvements.

According to the Q3 2025 ACSI results, there’s a clear link between high client satisfaction and strong financial performance. Companies that treat their clients well tend to do better financially. So, by fostering a culture of collaboration, manufacturers can really enhance their responsiveness to client needs, which boosts overall business performance.

As Claes Fornell, Chairman of ACSI, puts it, firms are rewarded for good customer treatment and punished for poor treatment. This definitely impacts earnings and stock prices. So, what steps can your team take to improve collaboration and client satisfaction?

Conclusion

Integrating CPQ software into equipment manufacturing isn’t just a trend; it’s a game-changer for boosting efficiency and keeping customers happy. Imagine automating the quoting process and connecting seamlessly with ERP systems-this means fewer errors and faster response times. When sales teams can whip up tailored quotes in no time, it leads to stronger client relationships and, yes, more sales.

Let’s talk about some best practices for a successful CPQ integration. First off, user training is key. Aligning your sales and product teams is crucial, too. And don’t forget about making sure everything works well with your existing ERP systems. By focusing on solid training and encouraging teamwork, manufacturers can tackle the common hurdles that come with adopting CPQ. Plus, the stats speak for themselves: happier clients and quicker quote generation times highlight the real benefits of these best practices.

In today’s competitive landscape, being able to respond to client needs quickly and accurately can really set you apart. Investing in CPQ integrations not only streamlines your operations but also boosts overall business performance. As the market for CPQ software keeps growing, it’s a smart move for manufacturers to embrace these tools and strategies. Taking action now can lead to greater efficiency and customer loyalty down the road. So, why wait? Let’s get started on this journey together!

Frequently Asked Questions

What is CPQ software and its purpose in equipment manufacturing?

CPQ software, which stands for Configure, Price, Quote, is designed to automate and streamline the quoting process in equipment manufacturing, helping manufacturers keep up with the rising demand for customization.

How does CPQ software improve the quoting process?

CPQ software improves the quoting process by allowing sales teams to quickly generate precise quotes tailored to client specifications, minimizing errors and speeding up the overall sales cycle.

What are some features of CPQ software?

CPQ software features include product configurations, pricing rules, discount structures, and real-time product configurators, which enhance customer engagement and satisfaction by delivering customized solutions.

What impact does CPQ software have on client relationships?

By providing tailored solutions and improving the quoting process, CPQ software helps build stronger client relationships and positions manufacturers to respond effectively to market demands.

What is the projected growth of the CPQ software market?

The CPQ software market is expected to grow by USD 3.51 billion from 2025 to 2029, with a projected compound annual growth rate (CAGR) of 16.9%.

How has the adoption of CPQ systems affected online transactions?

Companies that have embraced interactive visual tools within CPQ systems have reported up to a 25% increase in online transactions due to improved quoting processes.

Why is adopting CPQ systems considered crucial for manufacturers?

Adopting CPQ systems is considered crucial for manufacturers as it optimizes workflows, boosts overall productivity, and enhances operational efficiency when integrated with CRM and ERP systems.

What benefits can manufacturers expect from utilizing CPQ integrations?

Manufacturers can expect a reported 20% increase in client satisfaction by utilizing CPQ integrations with CRM and ERP systems, leading to greater operational efficiency.