Introduction

Understanding the ins and outs of manufacturing can feel a bit overwhelming, right? But let’s take a moment to chat about something that often flies under the radar: the Bill of Materials, or BOM for short. This handy list isn’t just a bunch of items; it’s crucial for figuring out what materials and components you need for production. Think of it as the backbone of effective inventory management.

When you get a grip on BOM inventory management, you’re not just checking off boxes. You’re opening the door to some serious efficiencies, cutting down on errors, and boosting communication across your teams. Sounds great, doesn’t it? But here’s the kicker: with all the different types of BOMs out there and the challenges of keeping everything accurate, how can manufacturers like us make sure we’re using this powerful tool to its fullest? Let’s dive in!

Define the Bill of Materials (BOM) and Its Importance in Inventory Management

Have you ever wondered how manufacturers keep everything running smoothly? Enter the Bill of Materials (BOM) - a detailed list that outlines all the components, materials, and subassemblies needed to create a product. Think of it as the ultimate guide for production planning, stock management, and procurement processes.

The role of BOM inventory management in stock management is huge! It ensures that manufacturers have the right materials at the right time, which helps avoid production delays and cuts down on excess stock. Effective BOM inventory management is key for forecasting material needs, helping maintain optimal stock levels and steering clear of those costly stockouts or overages.

But that’s not all! A well-structured BOM also boosts communication across departments. It keeps everyone in the loop about what’s needed for manufacturing. In fact, did you know that firms with a formal BOM process can reduce production errors by 20%, according to Gartner?

Additionally, automated BOM inventory management keeps those forecasts accurate and up-to-date, making the process a breeze. As manufacturers increasingly turn to integrated software solutions like EazyStock, which connects to ERP systems, they can enhance overall operational efficiency and streamline BOM inventory management.

So, why not take a closer look at how a BOM can transform your production process? It might just be the game-changer you need!

Explore Different Types of Bills of Materials and Their Applications

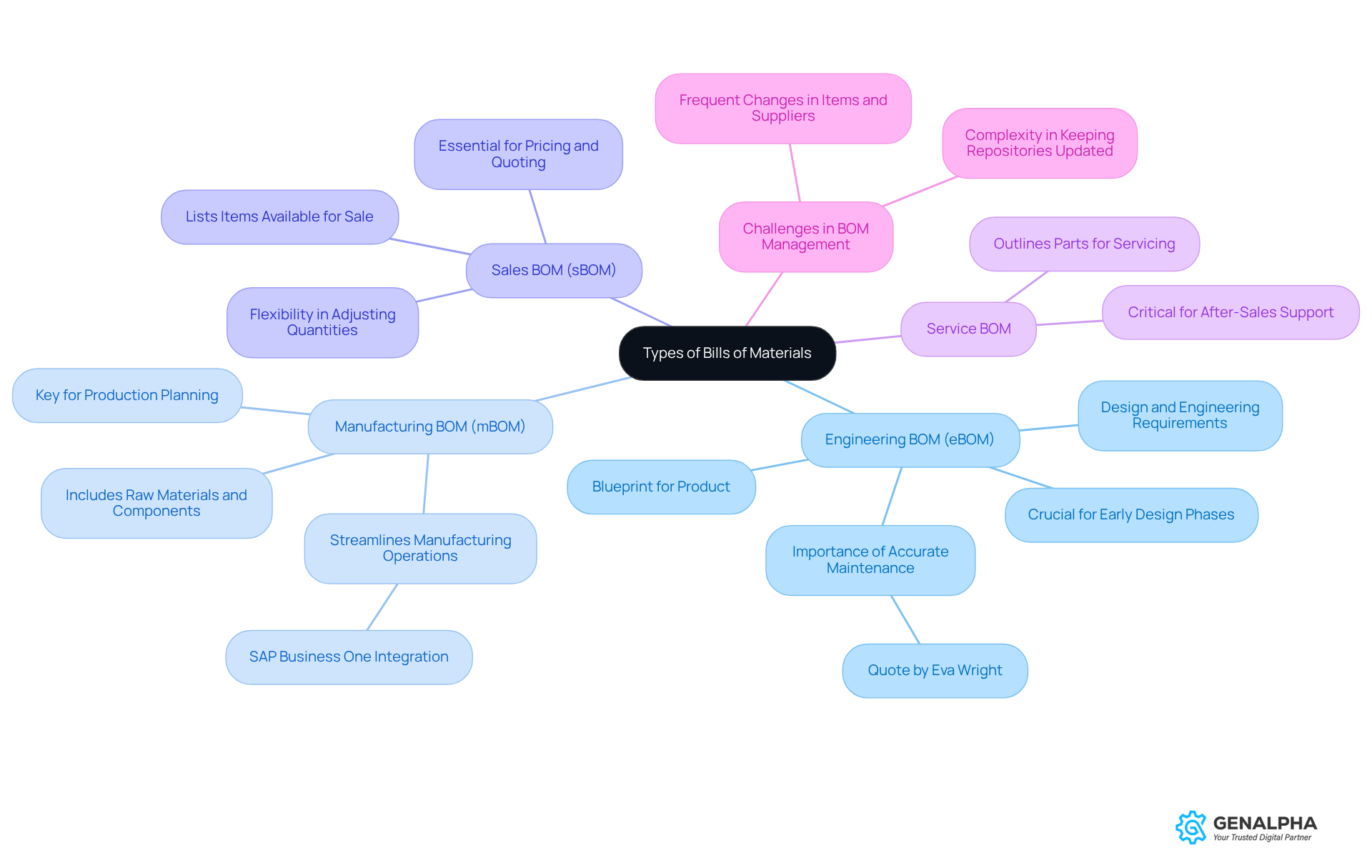

In manufacturing, different types of Bills of Materials (BOMs) play unique roles, each designed for specific stages of the production process. Let’s break down the main types:

-

Engineering BOM (eBOM): Think of this as the blueprint for your product. It highlights the design and engineering requirements, detailing the components needed for development. This BOM is crucial during the early design phases, making sure all necessary parts are lined up before manufacturing kicks off. As Eva Wright, an Internal IT Administrator, puts it, "BOM Maintenance is a beautiful thing." This really underscores how vital it is to keep eBOMs accurate for successful development.

-

Manufacturing BOM (mBOM): Now, this one’s all about the nuts and bolts of the manufacturing process. It includes everything from raw materials to subassemblies and components. The mBOM is key for production planning and stock management, ensuring that all items are ready for smooth manufacturing operations. For instance, in SAP Business One, the Production BOM is automatically generated based on inventory, including the costs needed to create the final product, which really streamlines the whole process.

-

Sales BOM (sBOM): This BOM is your go-to for sales purposes. It lists the items available for sale along with their components, making it essential for pricing and quoting. Sales teams rely on the sBOM to accurately present offerings to customers. Plus, it allows for flexibility in adjusting quantities of child items while keeping control over the assembly process, which boosts sales efficiency.

-

Service BOM: Last but not least, the Service BOM outlines the parts needed for servicing and maintaining an item. This ensures that service teams have quick access to the necessary components, which is critical for keeping customers happy and operations running smoothly in after-sales support.

However, managing BOMs can be tricky. Manufacturers often face challenges due to frequent changes in items, suppliers, and regulations, making it tough to keep eBOM, mBOM, and sBOM repositories up to date.

By understanding these distinct categories of BOMs, manufacturers can select the right one for their specific needs, leading to better BOM inventory management and efficient production scheduling. For example, incorporating Engineering BOMs in development helps align design with manufacturing, ultimately improving quality and reducing time-to-market. Just look at Pacer Group; by updating their legacy ERP system to enhance BOM maintenance processes, they significantly boosted operational efficiency and accuracy.

So, which BOM will you focus on to streamline your operations?

Implement Best Practices for Effective BOM Management

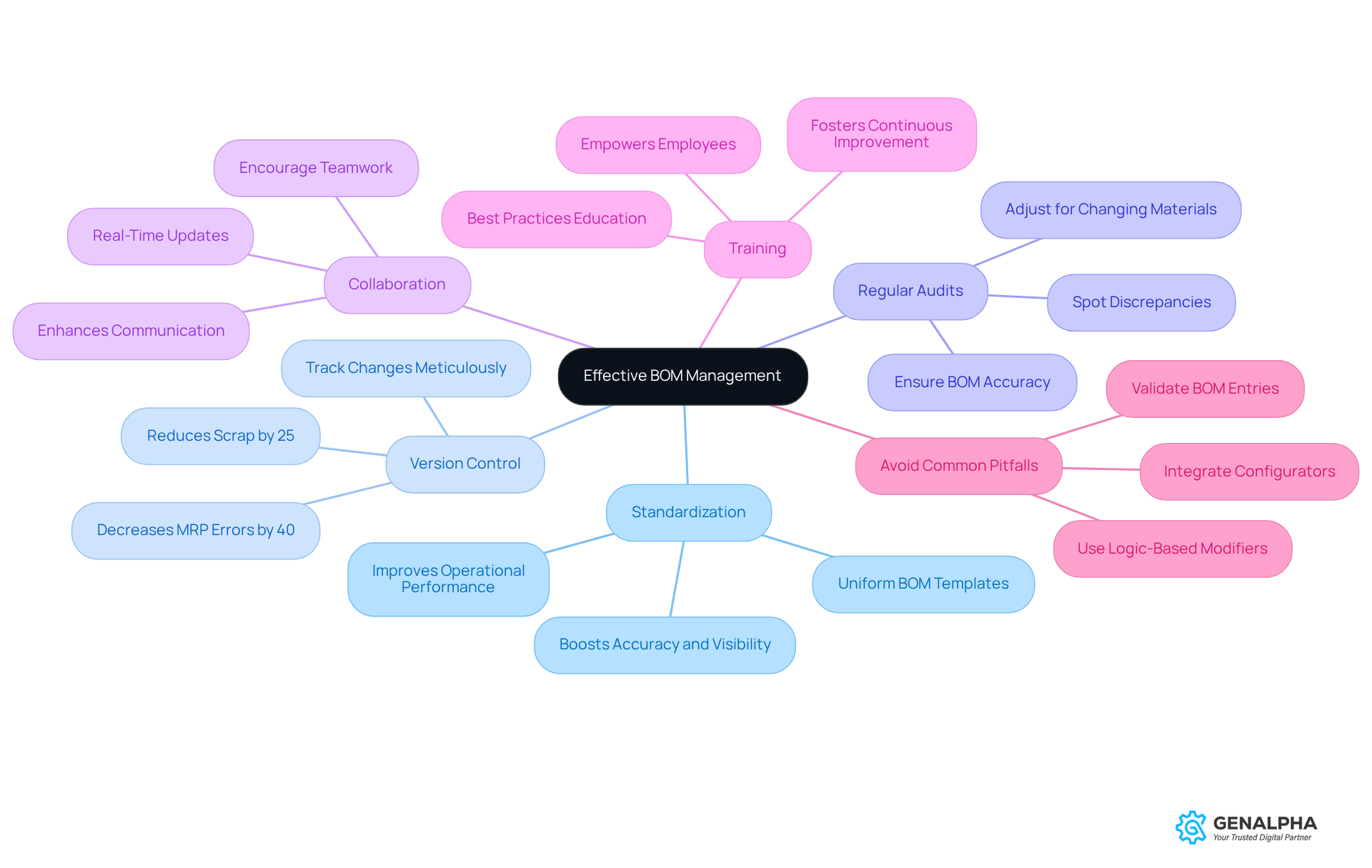

Managing Bills of Materials (BOMs) through effective BOM inventory management doesn’t have to be a headache! Here are some friendly tips to help manufacturers get it right:

-

Standardization: Think about creating uniform BOM templates. This simple step can really help keep things consistent across items and departments. When everyone’s on the same page, confusion and errors during production drop, leading to smoother operations. Plus, data standardization boosts accuracy and visibility-two key ingredients for smart decision-making. Companies that have embraced this practice often see significant improvements in their operational performance.

-

Version Control: Ever tried keeping track of changes without a solid system? It’s tough! That’s why implementing a robust version control system is crucial. It helps you meticulously track changes in your BOM, ensuring everyone’s aligned with the latest info. Companies that have adopted version control have seen a 25% reduction in scrap and a 40% decrease in MRP errors. That’s a big win for BOM inventory management!

-

Regular Audits: How often do you check your BOM? Scheduling regular evaluations is key to making sure your BOM accurately reflects current product requirements and inventory levels. Whether it’s annually or semi-annually, these reviews help spot discrepancies and make necessary adjustments. With materials, costs, and suppliers constantly changing, regular audits keep your operations relevant and efficient.

-

Collaboration: Teamwork makes the dream work! Encourage collaboration among your engineering, production, and procurement teams to create comprehensive and precise BOMs. Integrated software solutions that allow for real-time updates can really enhance this teamwork. When everyone’s informed and engaged, it leads to better communication across shifts and departments. Case studies show that standardized data improves visibility into shop floor operations, making collaboration even smoother.

-

Training: Is your team up to speed on BOM management? Providing thorough training on best practices and tools is essential. When everyone understands the importance of precise BOMs and how to maintain them, it sets the stage for operational success. This training can foster a culture of continuous improvement, empowering employees to contribute to better BOM accuracy and efficiency. As Karol Dabrowski pointed out, data standardization is vital for connecting workers with the information they need to enhance efficiency and decision-making.

-

Avoid Common Pitfalls: Watch out for common mistakes in BOM management! Copy-pasting lists without validation can lead to overstated or understated costs, inaccurate lead times, and incorrect component usage. To avoid these pitfalls, consider using templates with logic-based modifiers or integrating a configurator for highly variable products.

By following these tips, you can streamline your BOM inventory management and position your team for success!

Integrate BOMs with Inventory Management Systems for Enhanced Efficiency

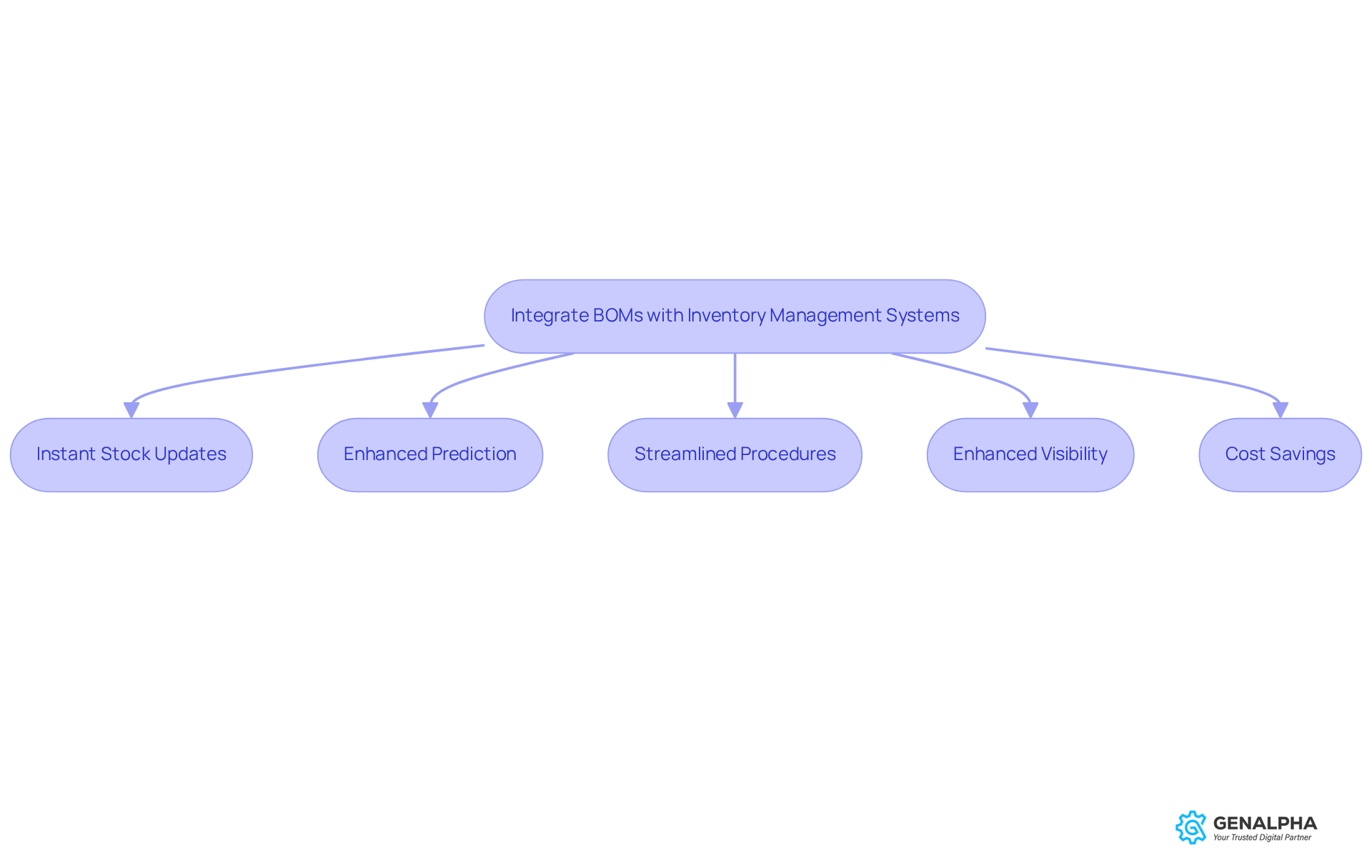

Integrating bills of materials with bom inventory management systems can significantly enhance operational efficiency. Let’s take a look at some key benefits of this integration:

- Imagine getting instant updates on stock levels based on bom inventory management requirements. This means manufacturers can quickly respond to changes in demand, keeping everything running smoothly.

- Enhanced prediction is achievable through bom inventory management, as connecting bills of materials with stock data makes it easier to predict what materials you’ll need. This helps avoid those frustrating stock shortages or having too much on hand.

- Streamlined procedures in bom inventory management involve automated updates between BOMs and stock management systems, making procurement a breeze. You can reorder materials exactly when you need them, without the hassle.

- Enhanced visibility through bom inventory management provides you with a clearer view of the supply chain. Manufacturers can track materials from procurement all the way through production, making everything more transparent.

- Cost Savings: By optimizing stock levels and cutting down on waste, manufacturers can save a lot of money, which is always a win for the bottom line.

So, how can manufacturers make this integration happen? It’s worth considering investing in specialized software that connects BOM inventory management with existing systems. This ensures a smooth data flow and boosts operational efficiency. What do you think? Ready to take the next step?

Conclusion

Mastering BOM inventory management is crucial for manufacturers aiming for efficiency and accuracy in their production processes. Have you ever thought about how the Bill of Materials (BOM) plays a pivotal role in streamlining operations? By understanding this, manufacturers can reduce errors and improve communication across departments. A well-structured BOM not only helps with stock management but also lays the groundwork for effective production planning.

We’ve explored various types of BOMs - Engineering, Manufacturing, Sales, and Service BOMs - each designed for specific stages of the manufacturing process. It’s clear that implementing best practices like:

- Standardization

- Version control

- Regular audits

- Collaboration

- Comprehensive training

is vital to keep BOMs accurate and relevant. Additionally, integrating BOMs with inventory management systems is a smart strategy for boosting operational efficiency, giving manufacturers real-time insights and cost-saving opportunities.

So, why is effective BOM inventory management so important? By embracing these best practices, manufacturers can optimize their production processes and set themselves up for long-term success in a competitive landscape. Now’s the time to take action! Evaluate your current BOM practices, consider investing in integrated software solutions, and foster a culture of collaboration and continuous improvement. Let’s unlock the full potential of BOM management in your organization together!

Frequently Asked Questions

What is a Bill of Materials (BOM)?

A Bill of Materials (BOM) is a detailed list that outlines all the components, materials, and subassemblies needed to create a product.

Why is the BOM important in inventory management?

The BOM is crucial for inventory management as it ensures manufacturers have the right materials at the right time, helping to avoid production delays and reducing excess stock.

How does effective BOM inventory management benefit manufacturers?

Effective BOM inventory management helps forecast material needs, maintain optimal stock levels, and avoid costly stockouts or overages.

What impact does a well-structured BOM have on communication within a company?

A well-structured BOM boosts communication across departments by keeping everyone informed about what is needed for manufacturing.

How much can a formal BOM process reduce production errors?

According to Gartner, firms with a formal BOM process can reduce production errors by 20%.

What role does automated BOM inventory management play?

Automated BOM inventory management keeps forecasts accurate and up-to-date, streamlining the process for manufacturers.

How can integrated software solutions like EazyStock enhance BOM inventory management?

Integrated software solutions like EazyStock connect to ERP systems, enhancing overall operational efficiency and streamlining BOM inventory management.