Introduction

You know, effective B2B processes really are the backbone of successful manufacturing operations. They help create smooth connections between producers and their clients. When equipment manufacturers take the time to refine these processes, they can see some pretty impressive gains in efficiency, cut down on errors, and boost customer satisfaction. And let’s be honest, in today’s competitive landscape, that kind of loyalty is gold.

But here’s the kicker: how can manufacturers pinpoint and roll out the right strategies to elevate their B2B operations? It’s a tough nut to crack, especially with clients’ needs constantly changing. So, what do you think? How can we tackle this challenge together?

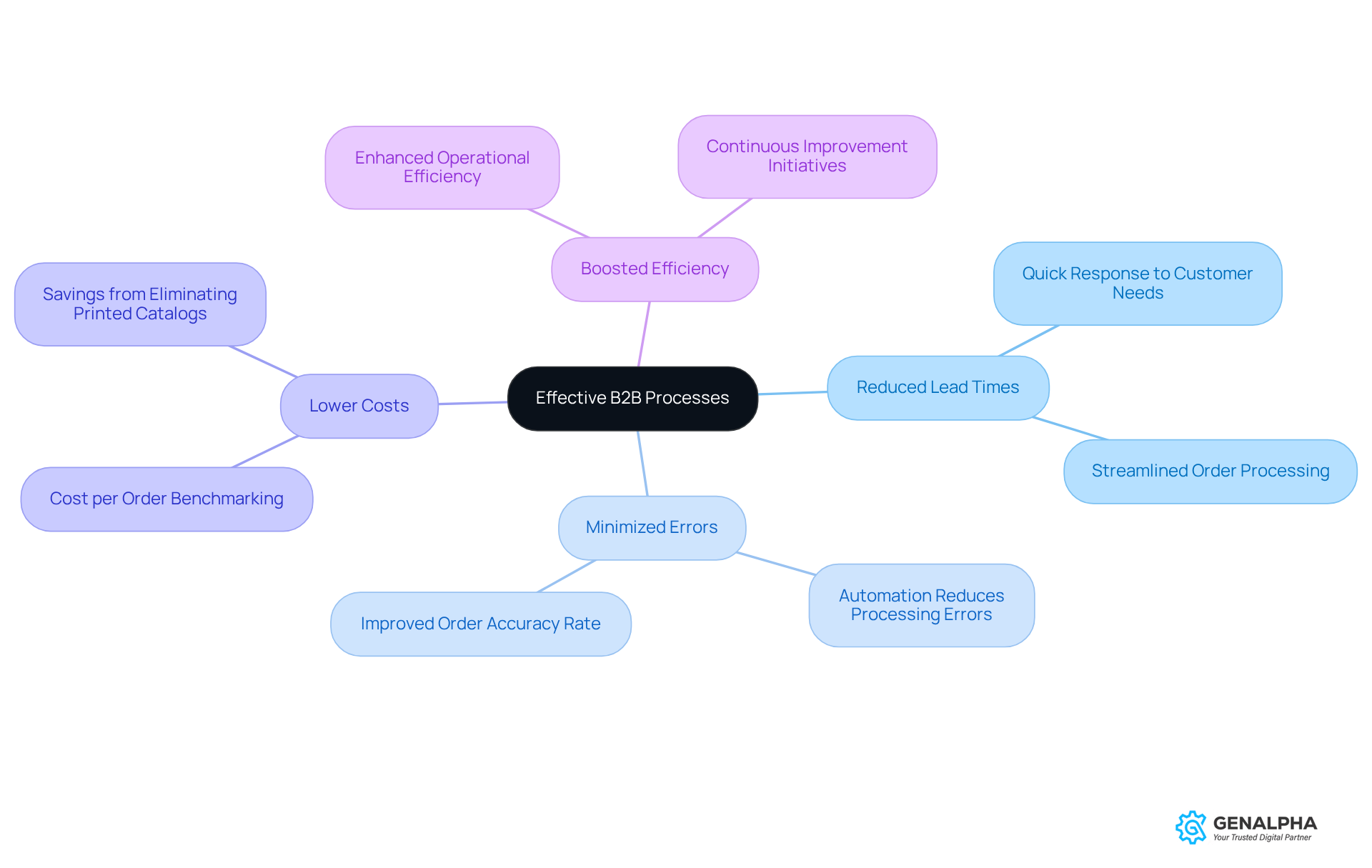

Understand the Importance of Effective B2B Processes

You know, effective b2b processes truly serve as the backbone of successful manufacturing operations. They make it easy for producers and their clients to connect, ensuring that client needs are met quickly and accurately. When producers recognize how important these processes are, they can spot areas that need improvement, leading to happier clients and stronger loyalty.

For instance, think about how an efficient processing system can dramatically cut down lead times. This means producers can respond to customer needs in a flash! Additionally, effective b2b processes contribute to minimizing errors, lowering costs, and boosting overall operational efficiency. These factors are crucial for staying competitive in today’s market.

So, what do you think? Are your current processes helping you keep up with client demands? It's worth taking a closer look!

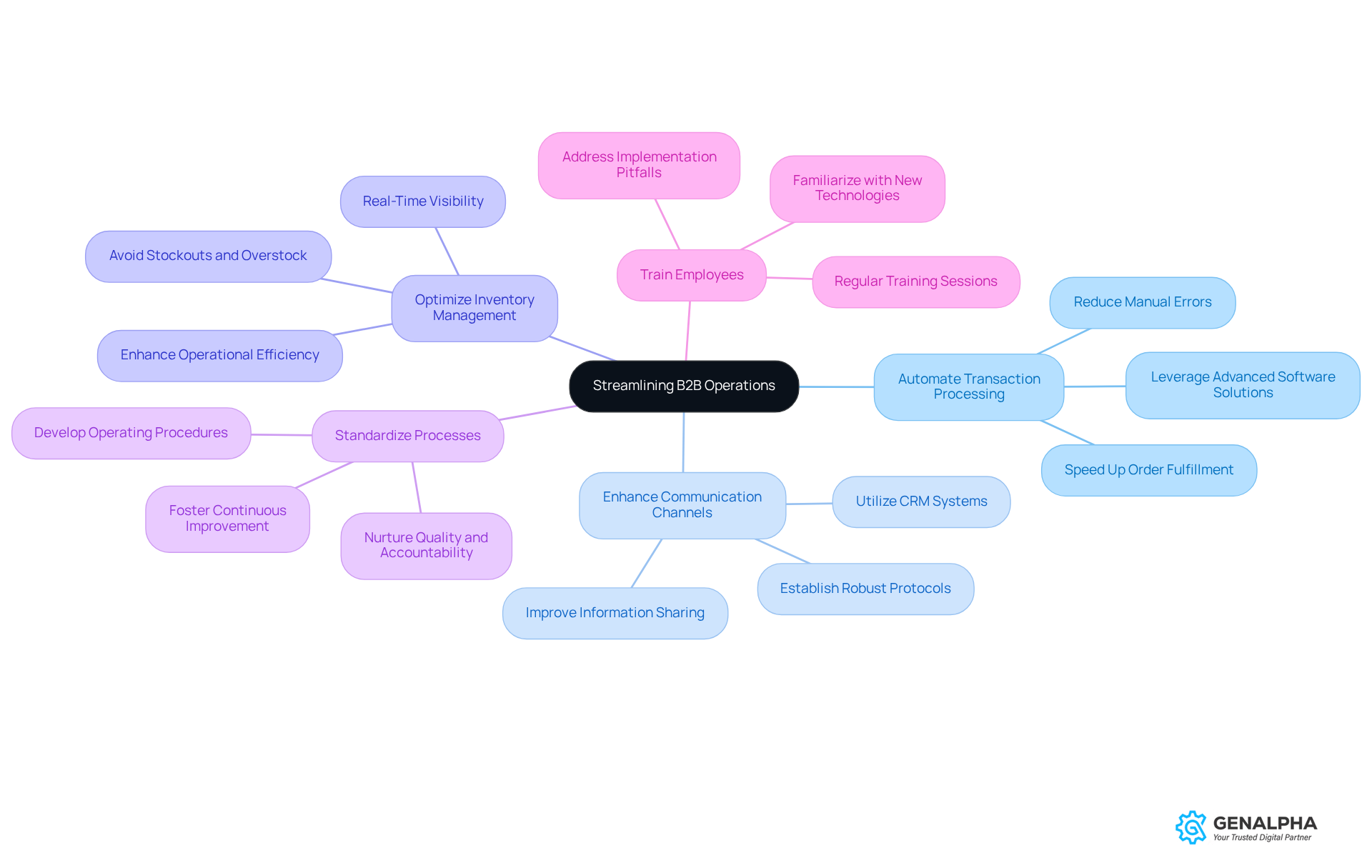

Implement Strategies for Streamlining B2B Operations

To streamline B2B operations, manufacturers might want to think about these strategies:

-

Automate Transaction Processing: Imagine cutting down on all those manual errors! By leveraging advanced software solutions to automate entry, invoicing, and payment processing within B2B processes, you can speed up the order fulfillment cycle. This means your team can focus on what really matters - higher-value activities. Did you know that the demand for industrial automation is expected to grow by 9.3% per year, reaching a whopping USD $307.7 billion by 2030? That really highlights how crucial it is to adopt these technologies.

-

Enhance Communication Channels: Have you ever felt like your teams weren’t on the same page? Establishing robust communication protocols among sales, support, and production teams can improve B2B processes. Using Customer Relationship Management (CRM) systems can significantly improve information sharing, ensuring everyone is coordinated and attentive to client needs. As Peter Hory, CFO and CIO of Swagelok Southeast Texas, noted, the speed at which teams adapted to automation was impressive - users became skilled in just four hours! This allowed them to focus on building stronger client relationships.

-

Optimize Inventory Management: Picture this: you have real-time visibility into your stock levels. Implementing sophisticated inventory management systems can enhance your B2B processes by helping you avoid stockouts and overstock situations, ultimately boosting operational efficiency and client satisfaction. It’s worth noting that about 60% of all occupations could automate at least 30% of their tasks. That’s a huge opportunity for automation across various roles in manufacturing!

-

Standardize Processes: Consistency is key! Developing and enforcing standardized operating procedures for routine tasks enhances efficiency and strengthens B2B processes, while also nurturing a culture of quality and accountability within your organization. This contributes to a mindset of continuous improvement.

-

Train Employees: Regular training sessions can make a world of difference. Familiarizing employees with new technologies and processes enhances productivity and engagement. Plus, addressing common pitfalls during implementation - like resistance to change or inadequate training - can really set these strategies up for success.

So, what do you think? Are you ready to take these steps and see the difference in your operations?

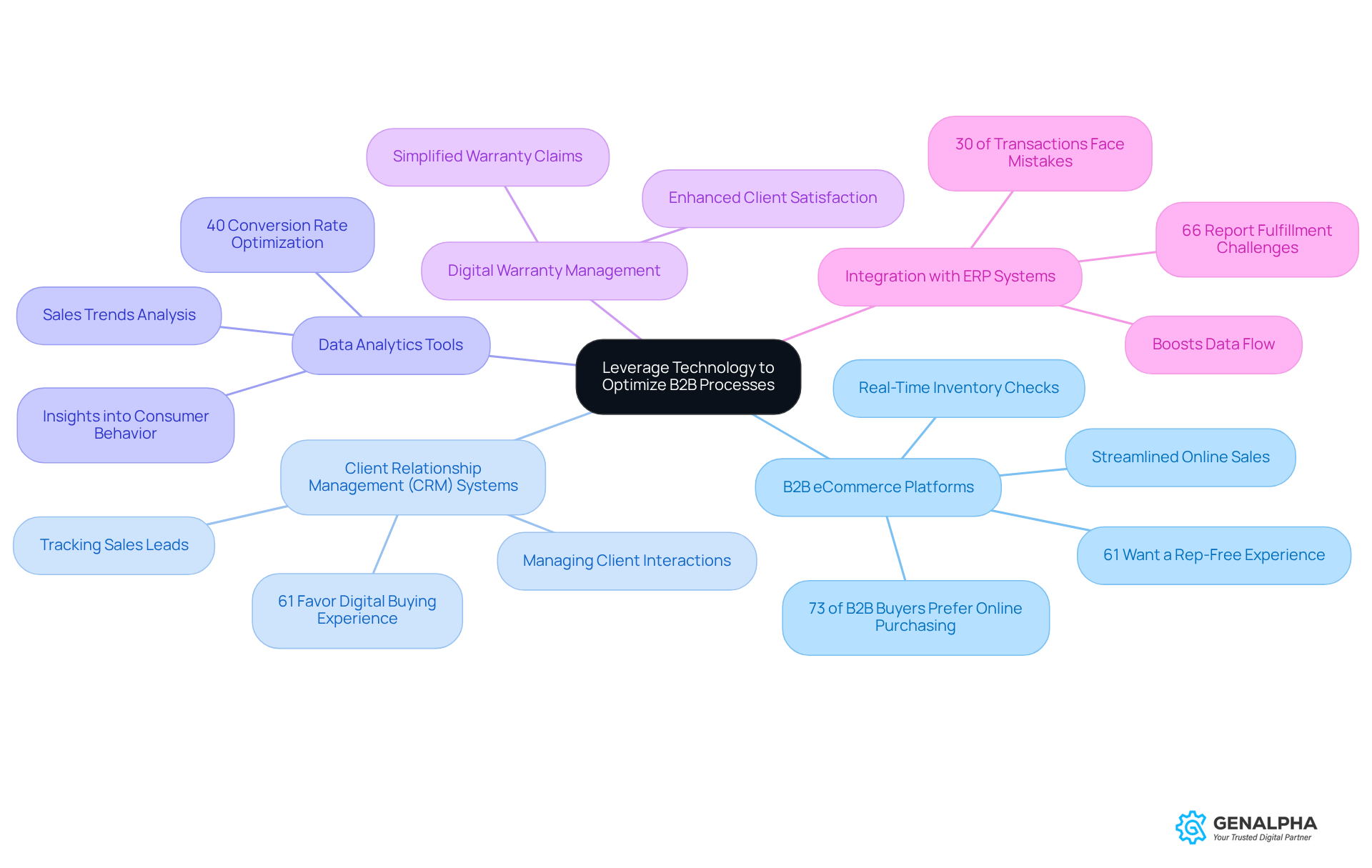

Leverage Technology to Optimize B2B Processes

Leveraging technology is essential for optimizing B2B processes in manufacturing. Let’s dive into some key technologies that can really drive efficiency and enhance customer experiences:

-

B2B eCommerce Platforms: Think about platforms like Equip360. They let manufacturers streamline online sales, so clients can place orders directly, check real-time inventory, and track shipments without a hitch. This shift is crucial since 73% of B2B buyers prefer to buy online. It shows just how vital self-service digital models are! Plus, 61% of B2B buyers want a rep-free and digital purchasing experience, which underscores the importance of these platforms in meeting client expectations.

-

Client Relationship Management (CRM) Systems: CRM systems are key for managing client interactions, tracking sales leads, and analyzing client data. With 61% of B2B buyers favoring a rep-free and digital buying experience, using CRM effectively is essential for maintaining those relationships and improving service.

-

Data Analytics Tools: Using advanced analytics gives insights into consumer behavior, sales trends, and operational efficiencies. This data-driven approach is becoming more important, especially since businesses that excel in personalization can see conversion rate optimization of up to 40%. That’s a big deal! It really highlights how crucial data analytics tools are for boosting client engagement and sales.

-

Digital Warranty Management: Implementing digital warranty solutions can really enhance client satisfaction. They simplify the warranty claim process and provide better service. This tech not only improves customer experiences but also streamlines internal processes.

-

Integration with ERP Systems: Making sure all tech solutions integrate smoothly with existing ERP systems boosts data flow and operational efficiency. As producers shift to the internet, being able to align inventory and handle requests efficiently is key. Did you know that over 30% of B2B transactions still face mistakes? And 66% of B2B eCommerce businesses say order fulfillment and tracking are their biggest headaches? That really shows the need for solid integration.

By adopting these technologies, producers can enhance their operational efficiencies and effectively address the evolving expectations of B2B buyers in their B2B processes within a competitive landscape. So, what are you waiting for? Let’s get started!

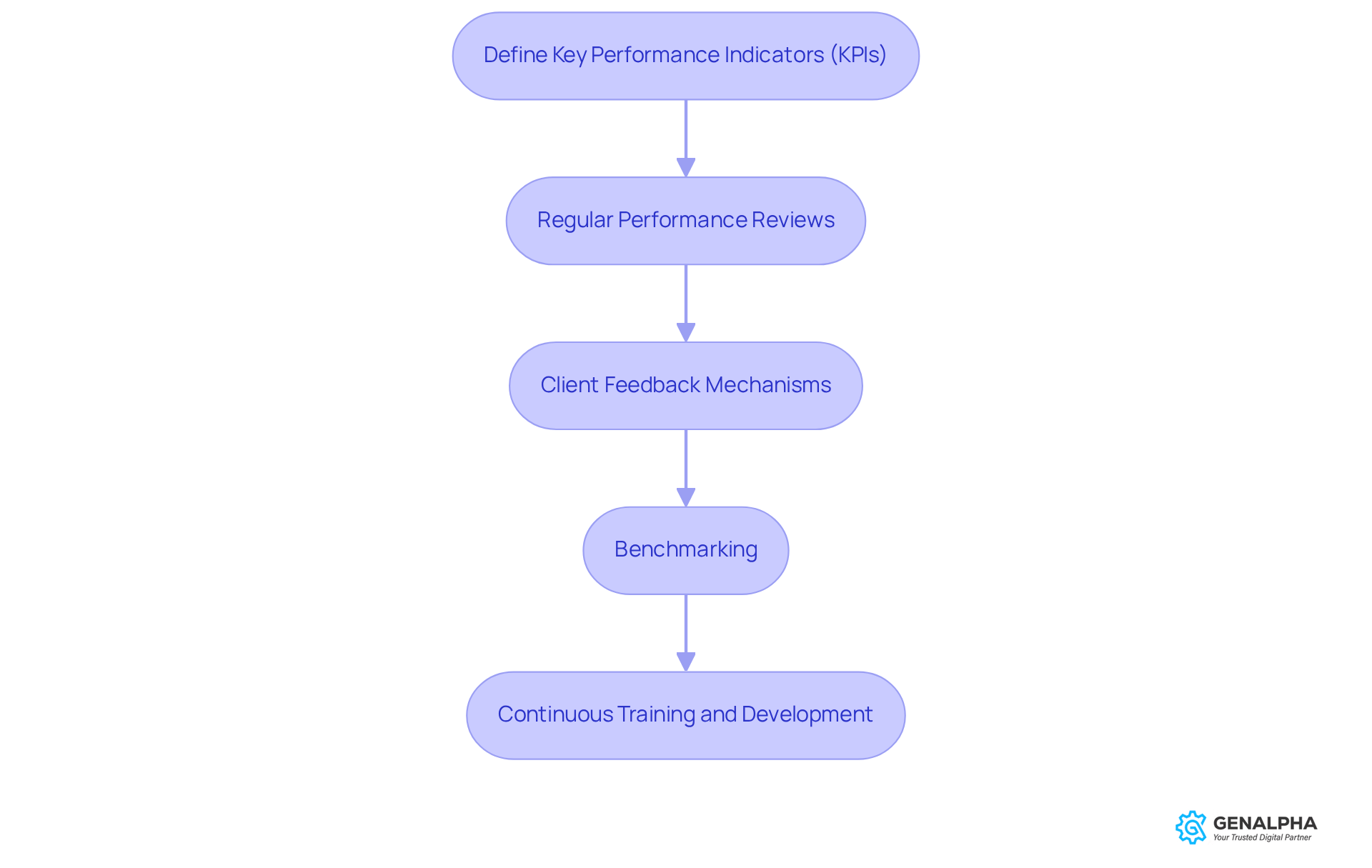

Measure and Analyze Performance for Continuous Improvement

To drive continuous improvement in b2b processes, manufacturers must adopt a systematic approach to measuring and analyzing performance. Let’s break it down:

-

Define Key Performance Indicators (KPIs): First things first, establish KPIs that align with your business goals. Think about metrics like order fulfillment time, client satisfaction scores, and sales conversion rates. For instance, the Client Satisfaction Score (CSAT) is crucial here. It typically ranges from 0 to 100, showing how happy clients are with your products and services. A score of 75? That means 75% of your respondents are satisfied. Pretty telling, right?

-

Regular Performance Reviews: Next up, make it a habit to conduct frequent reviews of your performance data. This helps you spot trends, celebrate successes, and pinpoint areas that need a little TLC. It’s not just about recognizing what works; it’s also about uncovering potential weaknesses that could use some attention.

-

Client Feedback Mechanisms: Now, let’s talk about gathering client feedback. Implement systems like surveys or follow-up calls to really understand their experiences and expectations. Did you know that over half of consumers will look for alternatives after a negative experience? That’s why it’s so important to get a handle on client sentiment.

-

Benchmarking: How do you stack up against the competition? Benchmarking is key. Compare your performance against industry standards or competitors to find gaps and opportunities for improvement. Take the Net Promoter Score (NPS), for example. It measures loyalty and how likely clients are to recommend your business. Bell Canada, for instance, boosted their NPS by 57% after creating a dedicated service experience team. Talk about a game changer!

-

Continuous Training and Development: Last but not least, invest in ongoing training for your employees. Keeping them updated on best practices and new technologies fosters a culture of continuous improvement. Companies that prioritize exceptional customer service can see revenue growth between 4% and 8% above the market average. That’s the power of a well-trained workforce!

So, what do you think? Are you ready to take these steps to enhance your B2B processes?

Conclusion

Effective B2B processes are the backbone of successful manufacturing operations, creating smooth connections between producers and clients. When manufacturers recognize how crucial these processes are, they can pinpoint areas for improvement, leading to happier customers and stronger loyalty. By streamlining operations, companies can cut down on lead times, reduce errors, and boost overall efficiency-essential for staying competitive in today’s market.

So, what can manufacturers do to optimize their B2B processes? There are several strategies worth considering. Think about:

- Automating transaction processing

- Enhancing communication channels

- Optimizing inventory management

- Standardizing procedures

- Investing in employee training

Plus, leveraging technology like B2B eCommerce platforms, CRM systems, and data analytics tools can really ramp up operational efficiencies and meet the changing expectations of B2B buyers. Regularly measuring and analyzing performance also plays a key role in continuous improvement, helping manufacturers stay responsive to client needs while driving growth.

In a world where customer expectations keep rising, refining B2B processes is more important than ever. Manufacturers should definitely consider adopting these best practices and tech solutions-not just to streamline operations but also to build lasting relationships with clients. By taking proactive steps to optimize B2B processes, you’ll likely see improved business success and a stronger foothold in the competitive manufacturing sector. So, why not start today?

Frequently Asked Questions

What is the importance of effective B2B processes in manufacturing operations?

Effective B2B processes are crucial as they serve as the backbone of successful manufacturing operations, facilitating connections between producers and clients to meet client needs quickly and accurately.

How can recognizing the importance of B2B processes benefit producers?

By recognizing the importance of B2B processes, producers can identify areas for improvement, which leads to happier clients and stronger loyalty.

What impact does an efficient processing system have on lead times?

An efficient processing system can dramatically cut down lead times, allowing producers to respond to customer needs rapidly.

In what ways do effective B2B processes contribute to operational efficiency?

Effective B2B processes help minimize errors, lower costs, and boost overall operational efficiency, which are essential for maintaining competitiveness in the market.

Should businesses evaluate their current B2B processes?

Yes, businesses should evaluate their current processes to ensure they are effectively meeting client demands.