Introduction

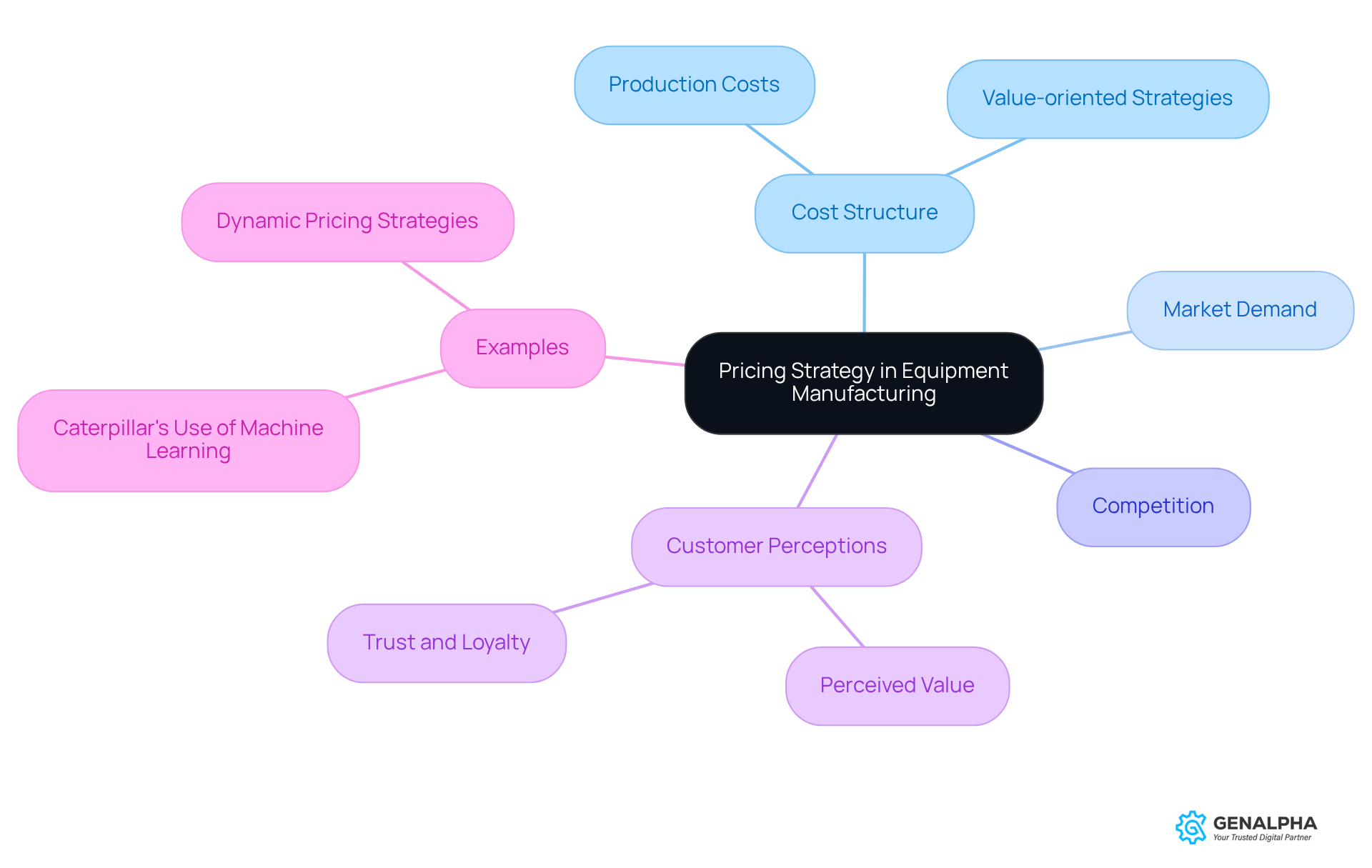

The world of equipment manufacturing is getting pretty competitive, right? That’s why having effective pricing strategies is more important than ever. Manufacturers are juggling a tricky mix of production costs, market demand, and what customers think to set prices that not only draw buyers in but also keep profits healthy.

As businesses deal with rising costs and changing consumer expectations, a solid pricing strategy becomes a must-have tool for success. So, how can manufacturers strike that balance between these competing pressures while also boosting their market share and keeping customers happy?

Let’s dive into this together!

Define Pricing Strategy and Its Importance in Equipment Manufacturing

A cost structure is like a roadmap for producers, helping them set product prices while keeping an eye on production costs, market demand, and competition. In the equipment manufacturing world, having a solid cost strategy is crucial. Why? Because it directly impacts sales volume, profitability, and how happy clients are with their purchases.

For example, producers can adopt value-oriented cost strategies that align prices with what customers believe their products are worth. This approach not only builds loyalty but also drives sales growth. Did you know that 86% of producers plan to pass at least some cost increases onto consumers? This highlights the need for a smart financial strategy to navigate market ups and downs effectively.

Moreover, businesses that practice clear billing can really boost client trust, which is key for long-term success. The introduction of pricing strategy allows manufacturers to understand how these strategies interact with market conditions, enabling them to adjust their rates to enhance profitability while meeting customer expectations. Take Caterpillar, for instance; they use machine learning to tweak prices based on changes in raw material costs, ensuring their margins stay stable even when the market gets shaky.

As Warren Buffett wisely puts it, "Price is what you pay. Value is what you receive." This underscores the importance of aligning costs with perceived value. But producers should also watch out for common pitfalls in implementing their cost strategies. For instance, failing to communicate price changes clearly or overlooking customer perceptions can really undermine their efforts. So, how can you ensure the introduction of pricing strategy hits the mark?

Explore Effective Pricing Strategies for Equipment Manufacturers

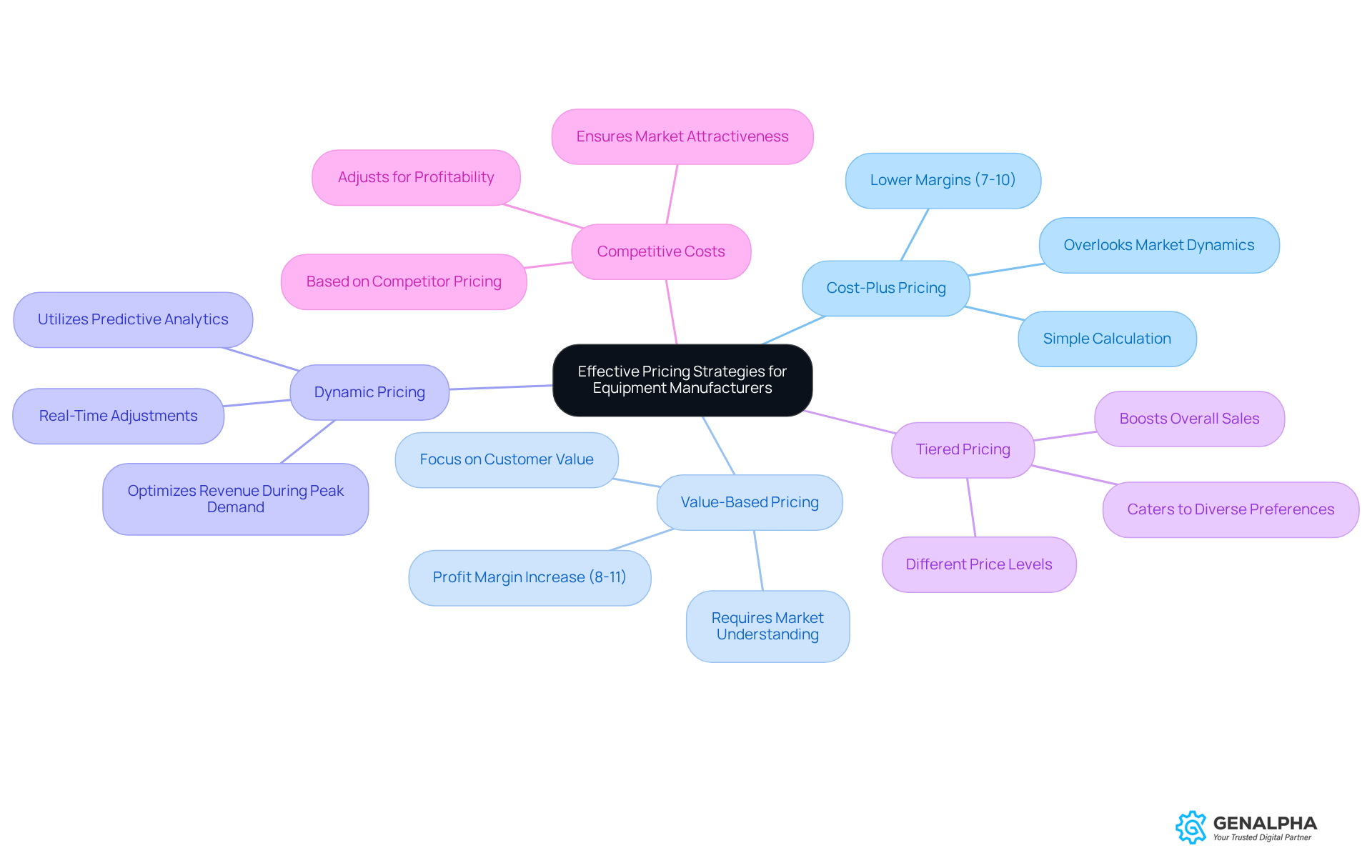

The introduction of pricing strategy can significantly boost the profitability and market share of equipment manufacturers. Let’s break down a few of them:

-

Cost-Plus Pricing: This is a pretty straightforward method where you calculate the total production cost and then add a markup for profit. It sounds easy, right? But here’s the catch: it often overlooks market dynamics. For instance, producers might miss out on competitive pressures or what consumers are willing to pay, which can lead to less-than-ideal pricing. Research shows that industrial firms using cost-based pricing models earn margins that are 7-10 percentage points lower than those using value-based pricing. That really highlights the limitations of this approach!

-

Value-Based Pricing: Now, this strategy is all about setting prices based on how much value your product brings to the customer, rather than just the production costs. It requires a deep understanding of what your customers need and the market landscape. Companies that adopt value-based strategies can see profit margins jump by 8-11% with just a 1% price improvement. That’s pretty impressive, right?

-

Dynamic Pricing: This flexible method lets producers adjust prices in real-time based on market demand, competitor rates, and other external factors. By using predictive analytics, manufacturers can optimize their pricing during peak demand times, ensuring they capture maximum revenue. Who wouldn’t want that?

-

Tiered Pricing: Offering different price levels for various product configurations or service tiers can cater to a wider range of preferences. This not only boosts overall sales but also allows customers to pick options that fit their needs and budgets best. It’s a win-win!

-

Competitive Costs: This approach involves setting prices based on what competitors are charging, ensuring that producers remain attractive in a crowded market. By keeping an eye on rival costs, producers can tweak their pricing strategies to stay competitive without sacrificing profitability.

By exploring and implementing these strategies, producers can discover the most effective ways to enhance their cost structures with the introduction of pricing strategy. So, why not take a closer look at these options and see how they can help you grow and strengthen your market position?

Implement Steps for Successful Pricing Strategy Execution

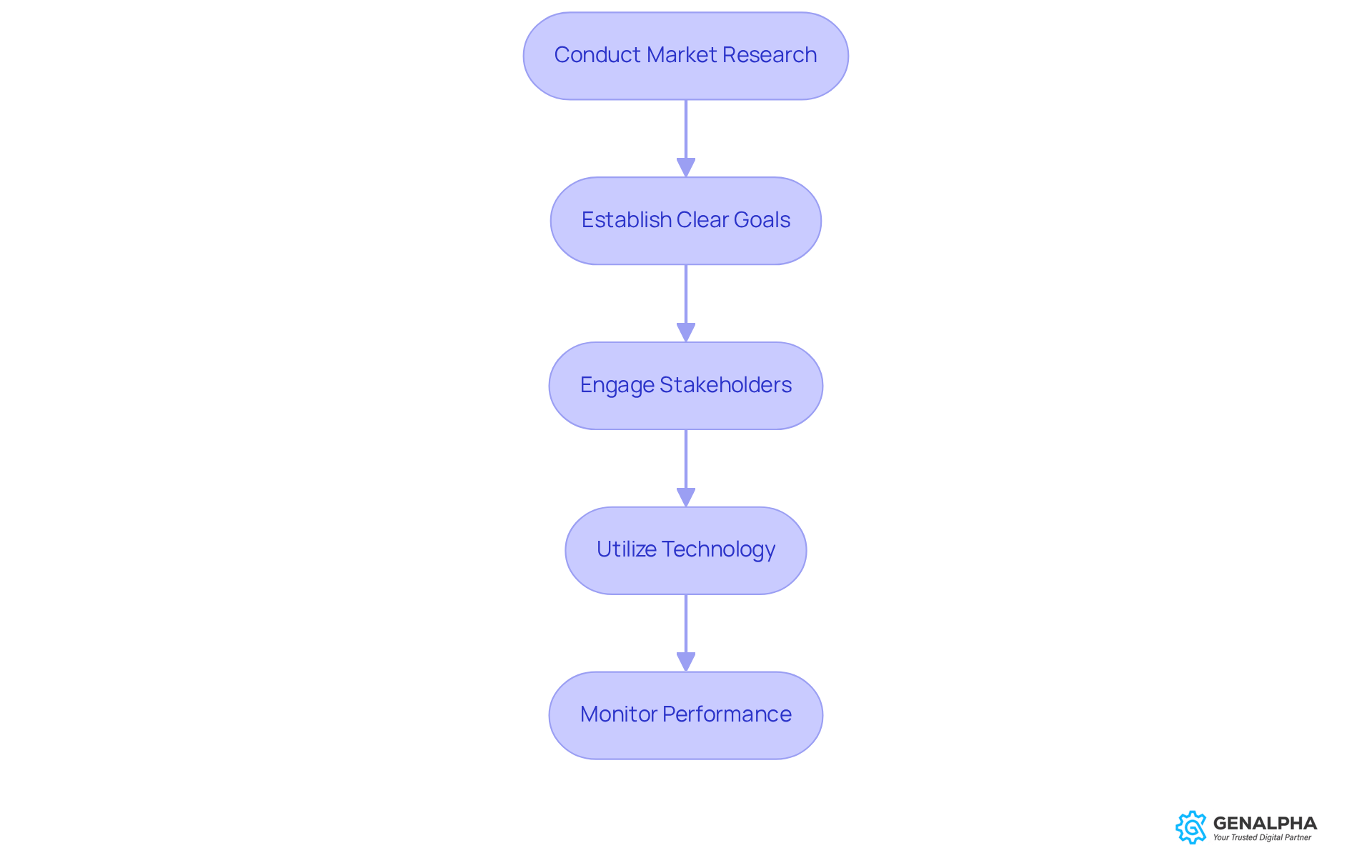

To nail down a pricing strategy, equipment manufacturers can follow these key steps:

-

Conduct Market Research: First off, it’s crucial to get a grip on the competitive landscape, client preferences, and market trends. This info will help guide your cost decisions and spot opportunities for standing out.

-

Establish Clear Goals: What do you want your pricing strategy to achieve? Whether it’s boosting market share, maximizing profit margins, or enhancing client loyalty, having clear goals is essential.

-

Engage Stakeholders: Don’t forget to involve key players like sales teams and client service reps in the pricing development process. Their insights can ensure everyone’s on the same page and ready to support the strategy.

-

Utilize Technology: Make the most of cost management software and analytics tools. These can help you track expenses, analyze market data, and adjust prices on the fly based on real-time insights.

-

Monitor Performance: Keep an eye on how well your pricing strategy is working. Regularly check key performance indicators (KPIs) like sales volume, profit margins, and customer feedback. If something’s off, don’t hesitate to tweak your approach based on what the data tells you.

By adhering to these steps, producers can ensure the introduction of pricing strategy that is not only effectively executed but also continuously improved. So, what’s your next move?

Refine Pricing Strategies Through Feedback and Experimentation

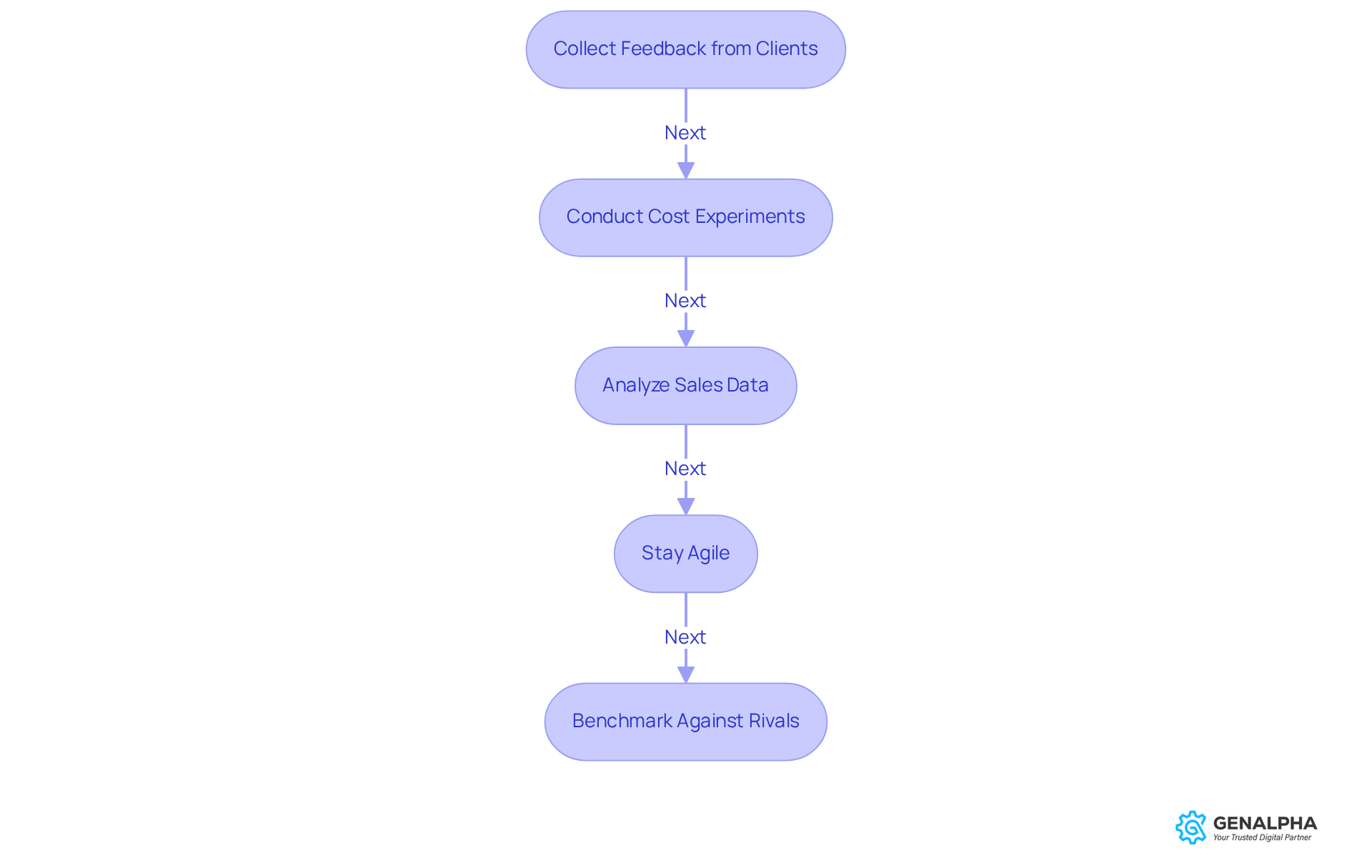

To keep ahead of the competition, equipment manufacturers really need to focus on the introduction of pricing strategy to fine-tune their cost strategies. How? By embracing feedback and trying out new ideas! Here are some key practices to think about:

-

Collect Feedback from Clients: Ever thought about how your clients view your costs and value? Regularly asking for their insights can be a game changer. Use surveys, interviews, or focus groups to gather a variety of opinions. Did you know that 86% of people hesitate to engage with a company that has too many negative reviews? That’s why understanding client sentiment is crucial.

-

Conduct Cost Experiments: Why not run some controlled cost experiments? Testing different models and strategies can uncover valuable insights into customer behavior and help you find the best cost structures. With dynamic cost strategies becoming more popular in manufacturing, experimenting with various value models can really help you adapt to market shifts.

-

Analyze Sales Data: Take a look at your historical sales data. What trends and patterns can you spot? By correlating cost changes with sales performance, you can see how they impact each other. Businesses that dive into data analysis often find they can enhance client experiences, which is vital for nailing down your cost strategies.

-

Stay Agile: Are you ready to pivot your cost strategies when the market changes? Being flexible is key! For instance, Ford adjusts its prices based on supply chain disruptions, which helps maintain margin stability during shortages. An agile approach lets you seize new opportunities as they arise.

-

Benchmark Against Rivals: Keep an eye on what your competitors are doing. Regularly evaluating your cost strategies against theirs ensures your offerings remain competitive and meet market expectations. As Honeywell points out, companies using AI-driven cost strategies are already seeing better profitability and client retention.

By creating a culture of feedback and experimentation, manufacturers can seriously boost the introduction of pricing strategy. This leads to happier customers and, ultimately, increased profits. So, what are you waiting for? Let’s get started!

Conclusion

You know, having a solid pricing strategy is crucial for equipment manufacturers trying to navigate the market's twists and turns. When you align your pricing with production costs, customer perceptions, and what the competition is doing, you’re not just boosting your profits-you’re also building stronger relationships with your clients. A smart pricing approach can really drive sales growth and foster loyalty, setting you up for long-term success in a competitive landscape.

Throughout this article, we’ve explored a variety of effective pricing strategies, like:

- Cost-plus pricing

- Value-based pricing

- Dynamic pricing

- Tiered pricing

- Competitive costs

Each of these strategies comes with its own set of advantages and insights that can help you fine-tune your pricing structure. Plus, we’ve highlighted how important market research, engaging stakeholders, and leveraging technology are in executing these strategies. It’s all about taking a holistic approach to pricing.

So, let’s wrap this up. The importance of refining your pricing strategies through continuous feedback and experimentation really can’t be overstated. By embracing these practices, you can stay agile, adapt to market changes, and meet your customers’ expectations more effectively. Remember, the journey toward a successful pricing strategy is ongoing and requires commitment, but the rewards-happier customers and increased profits-are absolutely worth it. So, why wait? Take action now and implement these best practices to secure your competitive edge in the industry!

Frequently Asked Questions

What is a pricing strategy in equipment manufacturing?

A pricing strategy is a plan that helps producers set product prices while considering production costs, market demand, and competition. It is crucial for impacting sales volume, profitability, and customer satisfaction.

Why is a solid cost strategy important for manufacturers?

A solid cost strategy is important because it directly influences sales volume, profitability, and customer satisfaction, which are essential for long-term success in equipment manufacturing.

How can value-oriented cost strategies benefit producers?

Value-oriented cost strategies align prices with what customers believe their products are worth, which can build customer loyalty and drive sales growth.

What percentage of producers plan to pass cost increases onto consumers?

86% of producers plan to pass at least some cost increases onto consumers, highlighting the need for an effective financial strategy.

How does clear billing impact client trust?

Clear billing practices can boost client trust, which is key for long-term success in the manufacturing industry.

How can manufacturers adjust their pricing strategies effectively?

Manufacturers can adjust their pricing strategies by understanding how these strategies interact with market conditions, enabling them to enhance profitability while meeting customer expectations.

Can you provide an example of a company that effectively uses pricing strategies?

Caterpillar is an example; they use machine learning to adjust prices based on changes in raw material costs, ensuring their profit margins remain stable even during market fluctuations.

What are some common pitfalls in implementing pricing strategies?

Common pitfalls include failing to communicate price changes clearly and overlooking customer perceptions, which can undermine the effectiveness of pricing strategies.