Introduction

Customization in manufacturing is really shaking things up! It’s changing how we design, sell, and even experience products. Have you ever thought about how digital product configurators are leading this charge? They give manufacturers the power to whip up tailored solutions that fit individual customer needs while also making operations smoother. Sounds great, right?

But here’s the catch: with all this potential for boosting sales efficiency and making customers happier, there’s a challenge lurking in the background. How do manufacturers effectively roll out these sophisticated tools? What steps should they take to successfully integrate a digital product configurator into their processes? And how can they dodge the common pitfalls along the way?

Let’s dive into this together!

Define Digital Product Configurator and Its Role in Manufacturing

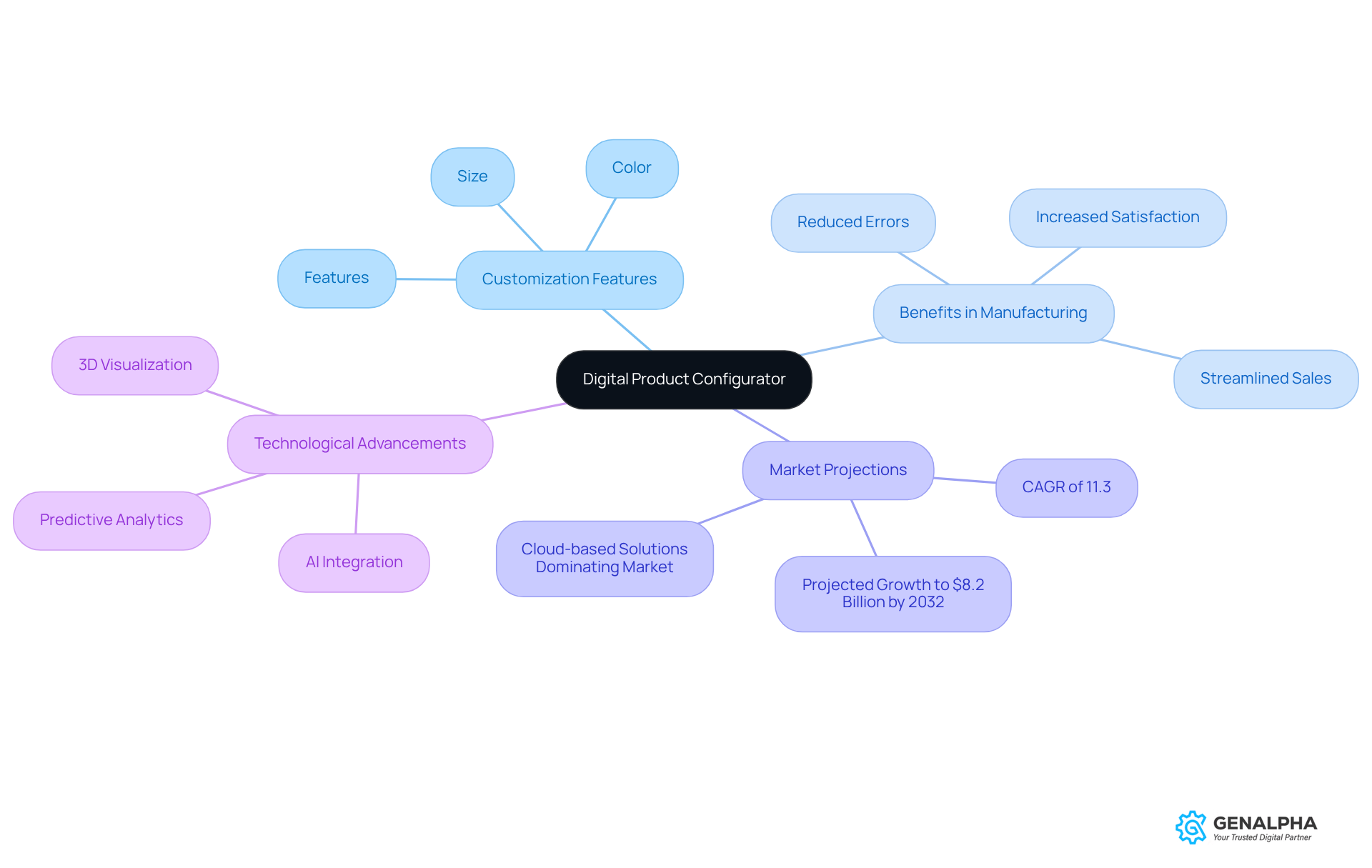

Have you ever wished for a product that fits your exact needs? Well, that’s where a digital configurator comes in! This nifty software lets manufacturers offer customizable items tailored just for you. Imagine being able to pick your favorite size, color, and features in real-time, creating a unique item that meets your specific requirements.

In the manufacturing world, these tools are game-changers. They streamline sales processes, cut down on order errors, and boost client satisfaction. When buyers can visualize their items during setup, it builds trust and makes the whole purchasing experience more engaging and fulfilling. And as the demand for personalized products keeps growing, manufacturers using digital configurators can expect to see improved sales efficiency and stronger connections with clients. This is crucial in today’s competitive marketplace.

But wait, there’s more! Experts say that integrating AI and 3D visualization technologies into these configurators takes user engagement to the next level. It makes shopping not just intuitive but genuinely enjoyable. As producers strive to meet rising expectations for customized solutions, this evolution in customer interaction is vital.

Did you know that the item customization market is projected to hit $8.2 billion by 2032? That’s a clear sign of how important these tools are becoming in the industry. Plus, with AI and predictive analytics enhancing configuration logic, manufacturers have a lot to gain. However, they also need to tackle the skills gap in managing configuration logic to fully reap the benefits of these advanced tools. So, are you ready to embrace the future of customization?

Identify Key Benefits of Implementing a Digital Product Configurator

Implementing a digital product configurator offers manufacturers some pretty awesome benefits.

-

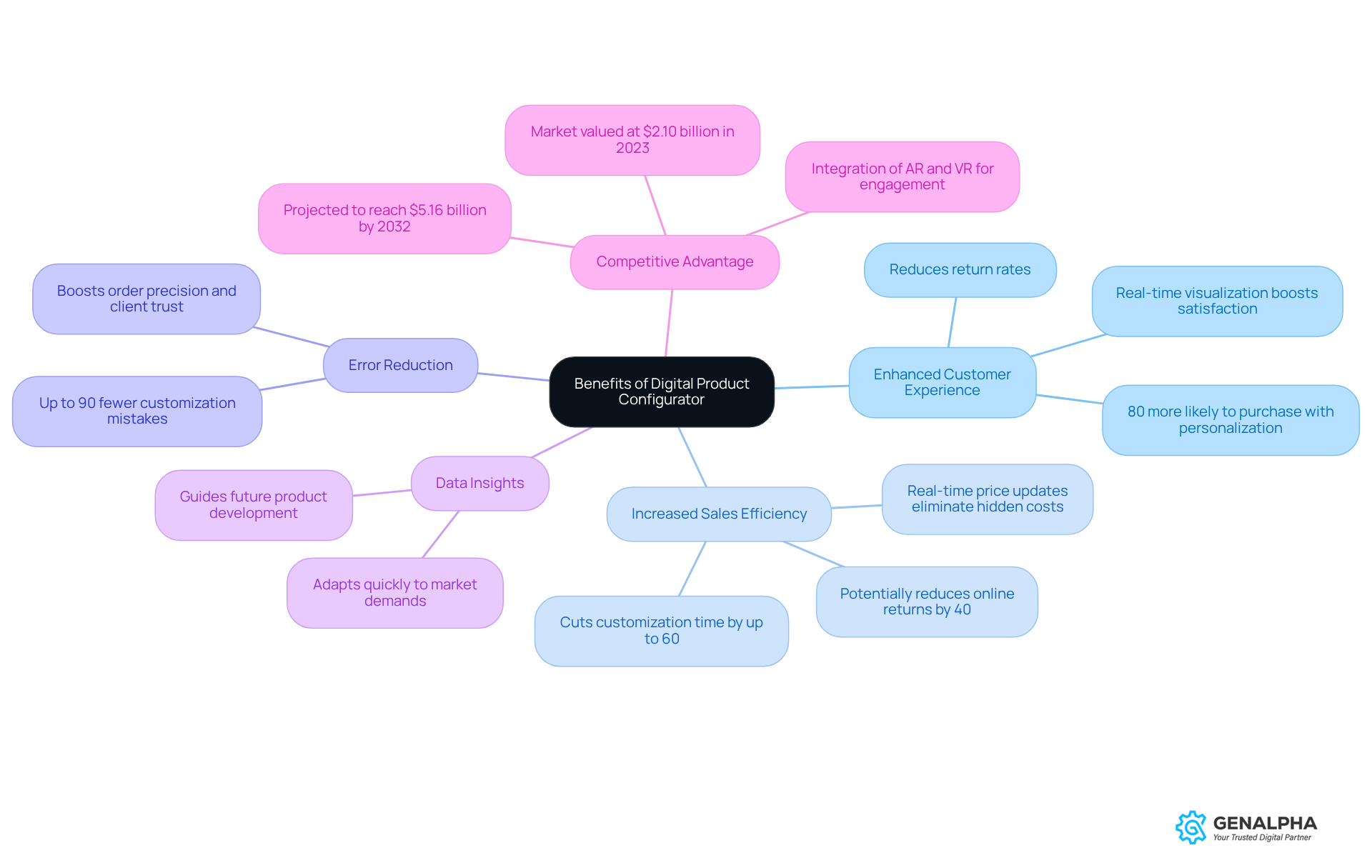

Enhanced Customer Experience: Imagine being able to visualize and customize products in real-time! This not only boosts satisfaction levels but also helps reduce return rates. In fact, research shows that clients are 80% more likely to make a purchase when brands offer personalized experiences through a digital product configurator. Pretty compelling, right?

-

Increased Sales Efficiency: By streamlining the ordering process, sales teams can handle more inquiries and close deals faster. A digital product configurator can cut down customization time by up to 60%, allowing manufacturers to respond to client needs quickly and effectively. Plus, with real-time price updates, hidden costs are a thing of the past, which can potentially reduce online returns by 40%. Who wouldn’t want that?

-

Error Reduction: Nobody likes mistakes, especially when it comes to orders. The digital product configurator helps minimize the risk of errors by validating all configurations against predefined rules. This automation can lead to up to 90% fewer customization mistakes, boosting overall order precision and client trust.

-

Data Insights: Manufacturers can gather valuable insights on consumer preferences and trends, guiding future product development and marketing strategies. This data-driven approach allows businesses to adapt quickly to market demands and enhance their offerings.

-

Competitive Advantage: Offering a digital product configurator can truly differentiate a manufacturer in a crowded market, attracting clients who desire tailored solutions. Did you know the item customization market was valued at $2.10 billion in 2023 and is projected to reach $5.16 billion by 2032, growing at a 10.5% CAGR? Investing in this technology lets producers tap into emerging trends and consumer expectations, including the exciting integration of augmented reality (AR) and virtual reality (VR) for even better engagement.

So, what do you think? Are you ready to explore how a digital product configurator can transform your business?

Outline Steps for Implementing a Digital Product Configurator

To successfully implement a digital product configurator, manufacturers should follow these essential steps:

-

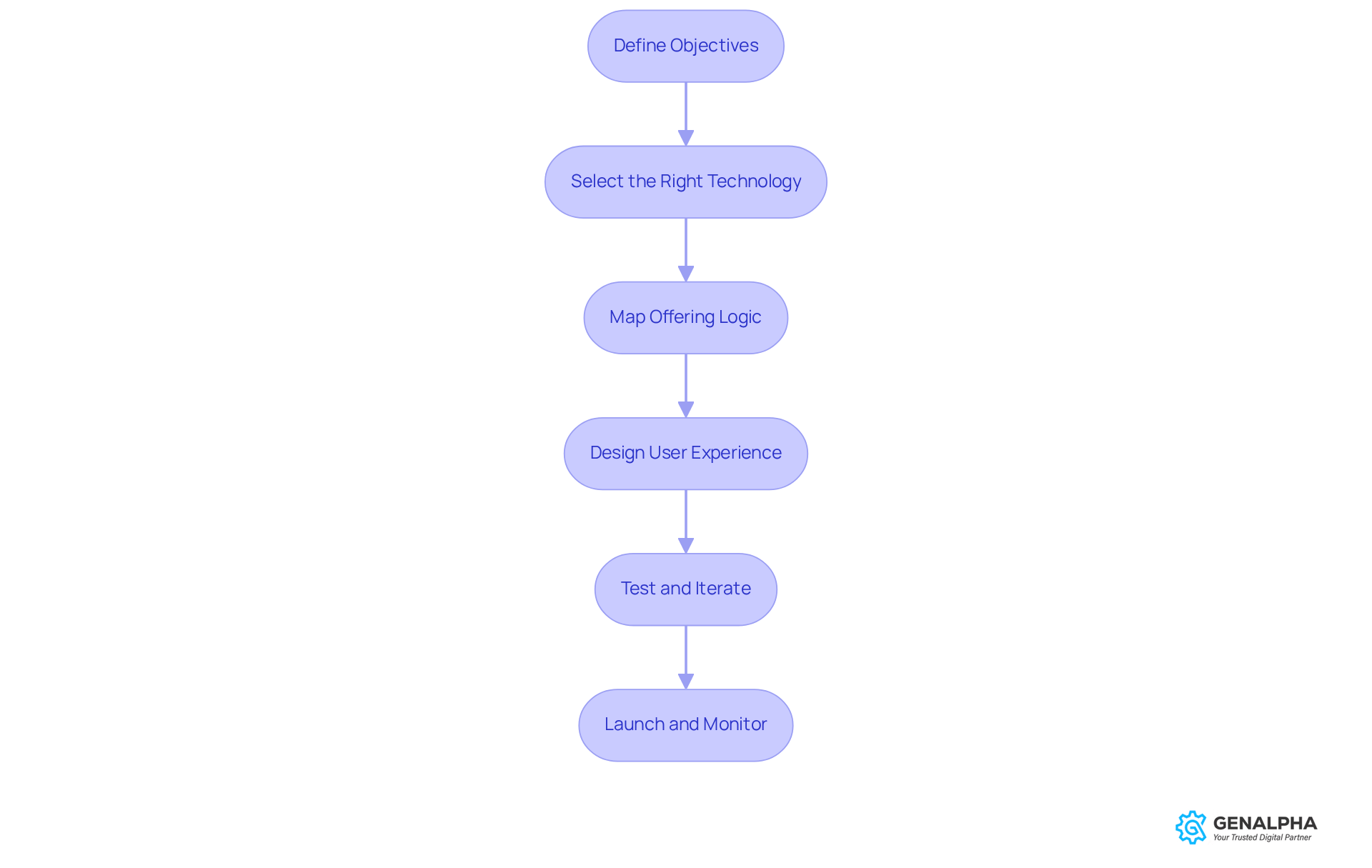

Define Objectives: First things first, let’s get clear on what you want from your configurator. Are you looking to boost client engagement, ramp up sales efficiency, or cut down on order errors? This foundational step is crucial for aligning with your business strategies and meeting customer needs. Did you know that consumers who see 3D visuals of products are 11 times more likely to make a purchase? That really highlights why setting clear goals is so important!

-

Select the Right Technology: Next up, you’ll want to choose a configurator platform that fits right in with your existing systems, like ERP and CRM, and meets your specific operational needs. The right tech can really enhance user experience and streamline your processes. Muchaneta Kapfunde puts it well: "The capability to view the item from every perspective enhances satisfaction and trust, particularly for users on mobile devices."

-

Map Offering Logic: Now, let’s dive into understanding your offerings. It’s essential to know all possible configurations and the rules that govern them. This clarity will help you develop a tool that accurately represents what you offer and meets client expectations.

-

Design User Experience: Think about creating an intuitive interface that makes it easy for users to navigate and customize their products. High-quality visuals and interactive elements, like Floating UIs and Hotspots, can really amp up user engagement and satisfaction.

-

Test and Iterate: Before you launch, make sure to conduct thorough testing. This is your chance to identify any issues and gather user feedback for improvements. Research shows that 3D configurators can reduce returns by an average of 5%. That’s a solid reason to invest time in testing!

-

Launch and Monitor: Finally, roll out your setup tool and keep an eye on its performance. Use data analytics to track user interactions and make adjustments based on feedback. This way, your system can evolve with client preferences and market trends.

By following these steps, you can harness the power of a digital product configurator to enhance customer experiences, optimize operations, and drive growth in a competitive landscape. So, are you ready to take the plunge?

Anticipate Challenges and Solutions During Implementation

Implementing a digital product configurator can be a bit tricky, especially regarding its integration with existing systems. But don’t worry! With the right strategies, you can tackle these challenges head-on:

-

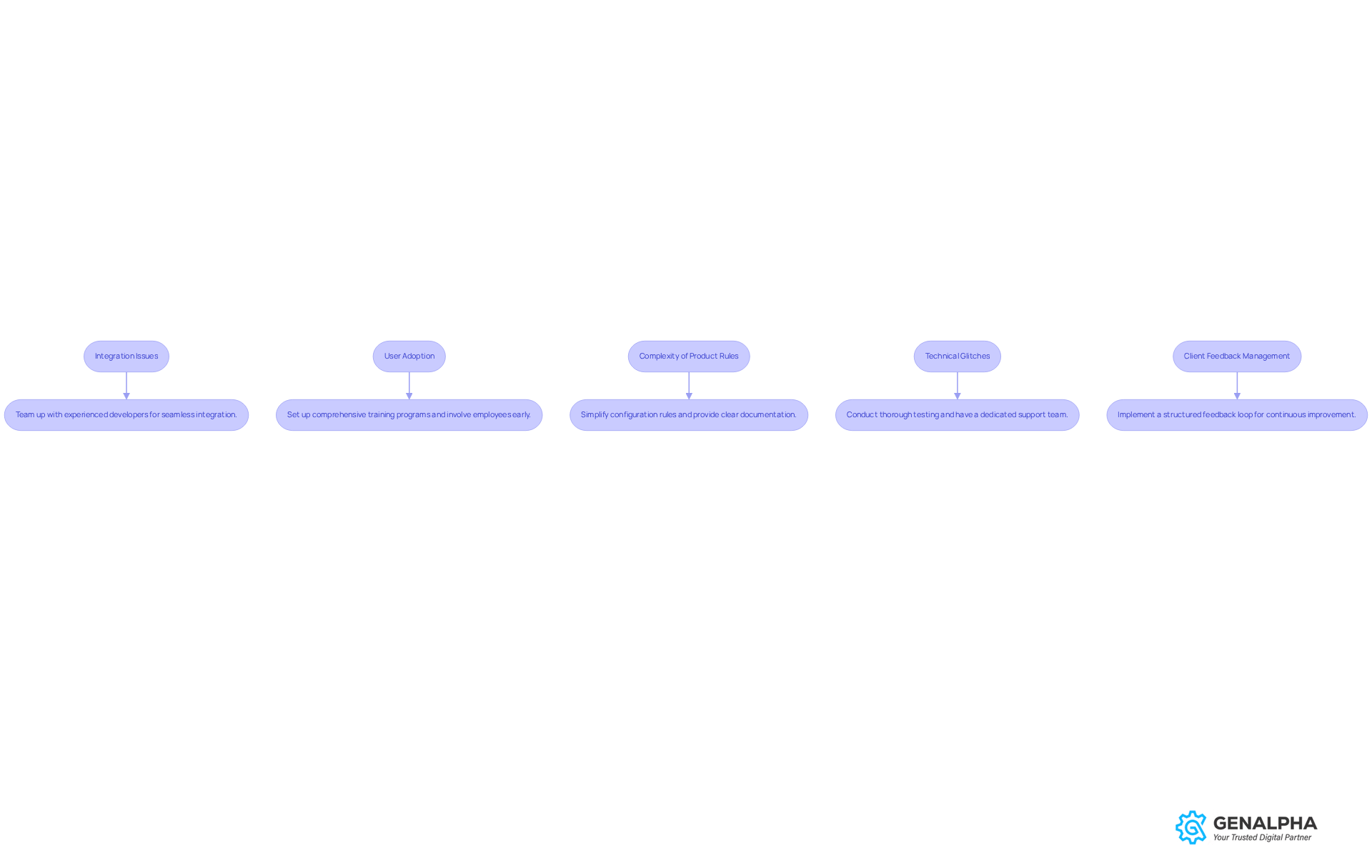

Integration Issues: Many manufacturers struggle to merge configurators with their ERP and CRM systems, which can create data silos that slow things down. Did you know that the software segment made up 73% of the product setup market revenue in 2023? That shows just how much we rely on these tools! To overcome this hurdle, it’s essential to team up with experienced developers who know how to make integration seamless. For instance, Siemens has rolled out a system that automates documentation generation and keeps everything in line with technical specs - definitely a great example of effective integration.

-

User Adoption: Let’s face it, new technology can be met with some resistance from employees. To help everyone get on board, it’s a good idea to set up comprehensive training programs that highlight the tool’s benefits and show just how user-friendly it is. Getting employees involved early on can also boost acceptance. As Kohler points out, clear visualization builds trust, which is key for getting users to embrace new tools.

-

Complexity of Product Rules: Managing complex product configurations can feel overwhelming. Simplifying configuration rules when possible and providing clear, easy-to-understand documentation can really help users navigate these complexities. This not only reduces errors but also boosts user confidence. Take A-dec’s customization tool, for example - it cut personalization time by 60%, showcasing the benefits of managing complexity effectively.

-

Technical Glitches: We all know that software issues can throw a wrench in the user experience and lead to frustration. That’s why thorough testing before launch is crucial, along with having a dedicated support team ready to tackle any technical challenges that pop up afterward. Companies that prioritize testing and support can really lessen the impact of those pesky glitches on user experience.

-

Client Feedback Management: Gathering and acting on client feedback can be a bit of a challenge, but it’s essential for continuous improvement. Implementing a structured feedback loop, like what Threekit’s platform does, allows producers to tweak the configurator based on user experiences, which ultimately enhances satisfaction and engagement.

By proactively addressing these challenges, manufacturers can harness the power of digital product configurators to enhance operations and improve customer interactions. This approach not only drives growth but also helps you stand out in a competitive marketplace. So, are you ready to take the plunge?

Conclusion

Implementing a digital product configurator isn’t just about upgrading technology; it’s a game-changer in how manufacturers connect with their customers. Imagine being able to create products that fit your exact needs - that’s what these tools offer! They boost satisfaction and build loyalty, which is crucial as the demand for customization keeps growing. For manufacturers wanting to stay ahead in a fast-paced market, integrating a digital configurator is becoming essential.

Throughout this article, we’ve highlighted some key benefits of digital product configurators. Think about:

- Enhanced customer experiences

- Increased sales efficiency

- A significant drop in errors

With the power to visualize and customize products in real-time, manufacturers can not only meet but truly exceed customer expectations. Plus, by leveraging data insights, businesses can quickly adapt to market trends, giving them a competitive edge.

Now, the journey to implementing a digital product configurator might come with its challenges. But don’t worry! With some strategic planning and a focus on user experience, these hurdles can be tackled effectively. Embracing this technology means unlocking new levels of operational efficiency and customer satisfaction. The future of manufacturing is all about personalization and engagement. So, taking the leap into the world of digital configurators isn’t just an option; it’s a must for anyone looking to thrive in today’s marketplace. Are you ready to make that leap?

Frequently Asked Questions

What is a digital product configurator?

A digital product configurator is software that allows manufacturers to offer customizable products tailored to individual customer needs, enabling users to select sizes, colors, and features in real-time.

How do digital configurators benefit manufacturers?

Digital configurators streamline sales processes, reduce order errors, and enhance client satisfaction by allowing buyers to visualize their products during setup, which builds trust and engagement.

Why is customization important in manufacturing today?

The demand for personalized products is growing, and manufacturers using digital configurators can expect improved sales efficiency and stronger connections with clients, which is crucial in a competitive marketplace.

How can AI and 3D visualization technologies enhance digital configurators?

Integrating AI and 3D visualization technologies into digital configurators improves user engagement, making the shopping experience more intuitive and enjoyable.

What is the projected market size for item customization by 2032?

The item customization market is projected to reach $8.2 billion by 2032, indicating the increasing importance of digital configurators in the industry.

What challenges do manufacturers face when implementing advanced configurators?

Manufacturers need to address the skills gap in managing configuration logic to fully benefit from advanced tools like AI and predictive analytics in digital configurators.