Introduction

The manufacturing landscape is really changing, isn’t it? Companies are increasingly turning to digital solutions to boost efficiency and connect better with customers. Take a look at GenAlpha Technologies; their case study shows how a smart digital transformation can streamline operations and significantly ramp up online sales and customer satisfaction. But here’s the kicker: with technology evolving so quickly, manufacturers are left wondering-how can they effectively integrate these innovations while tackling existing operational challenges?

Exploring the insights and results from this transformation journey reveals some critical lessons. What if these lessons could redefine success in the manufacturing sector? Let’s dive in and see how embracing digital solutions can make a real difference!

Background of the Manufacturing Company

Hey there! Have you ever wondered how some companies just seem to get it right when it comes to online sales? Well, Alpha Technologies is one of those leaders in tech solutions, especially for producers and suppliers in the machinery and replacement parts game. Their mission? To empower businesses to thrive in today’s ever-changing online landscape.

They offer a whole suite of eCommerce solutions designed to boost your online revenue and enhance customer experiences. At the heart of it all is Equip360, an advanced B2B eCommerce platform that not only streamlines inventory management but also supercharges your digital revenue performance.

Now, if you’re in the equipment production or aftermarket sector, you know the struggle with clunky online transaction methods and the pressing need for better customer engagement. But here’s the good news: by embracing eCommerce solutions in a digital transformation in manufacturing case study, manufacturers can optimize their operations, gain real-time visibility into inventory, and build direct relationships with customers. This leads to improved efficiency and happier customers.

As the demand for personalized online experiences continues to rise, GenAlpha’s innovative approach is setting its clients up for success in a competitive marketplace. They’re making sure businesses are ready to meet the evolving expectations of today’s B2B buyers. So, why not take a step forward and explore how these solutions can work for you?

Challenges Encountered in the Manufacturing Process

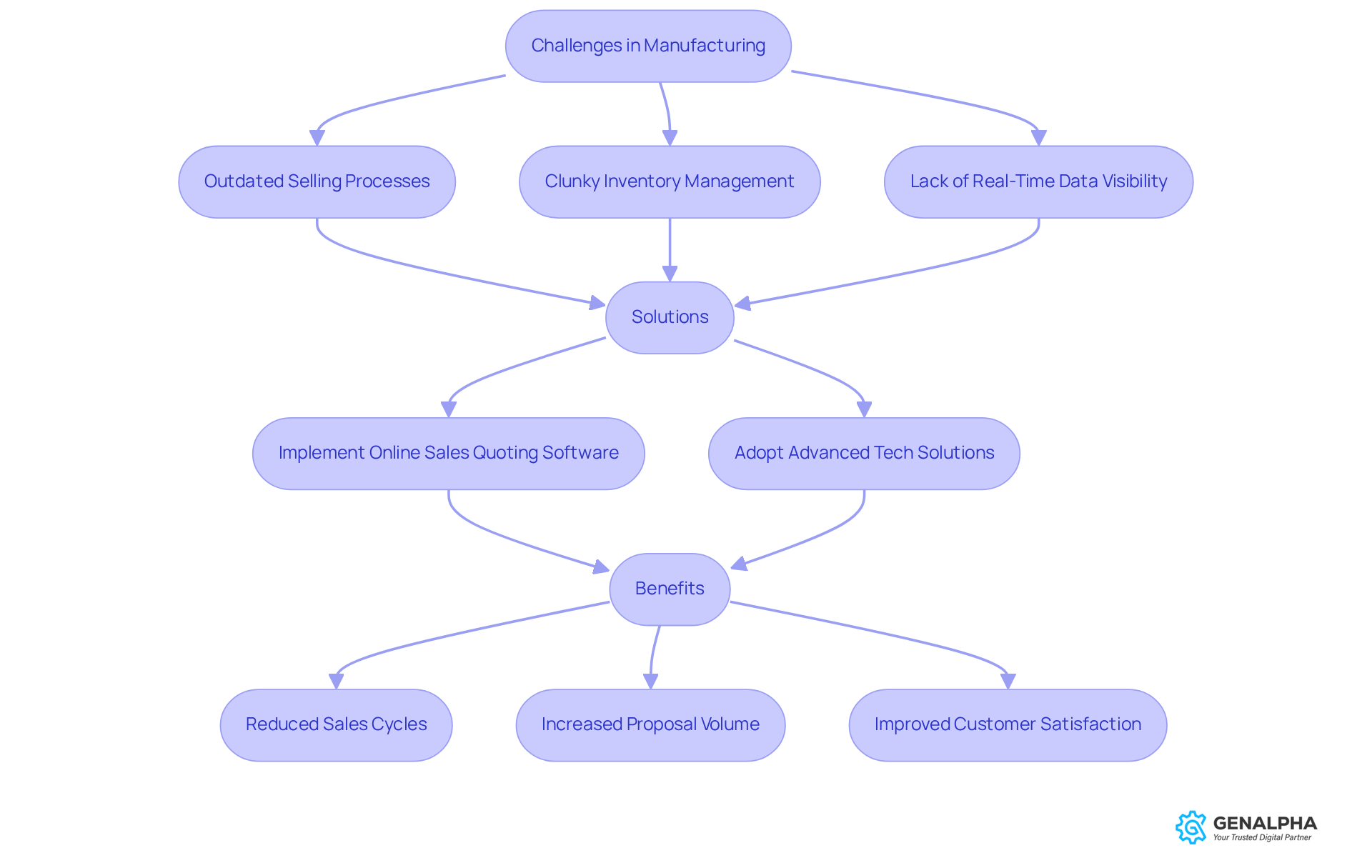

The manufacturing sector is facing some pretty big challenges these days, especially when it comes to outdated selling processes and clunky inventory management. These issues really hit operational efficiency hard. Many producers are stuck with disjointed systems that make communication and data exchange a hassle, leading to delays and mistakes in transaction cycles. For example, did you know that creating a quote can take anywhere from 20 to 40 minutes on average? But here’s the good news: implementing online sales quoting software can cut sales cycles by 28% and approval times by a whopping 95%! Plus, a study by Aberdeen Group found that companies using automated quoting tools saw a 49% boost in proposal volume. That’s a clear win for embracing electronic solutions! This inefficiency doesn’t just slow things down; it also impacts customer satisfaction, as businesses struggle to keep up with the demand for smooth purchasing experiences.

Now, let’s talk about real-time data visibility. The lack of it makes these problems even worse, making it tough for producers to respond quickly to market changes. Experts agree that organizations need to focus on integrating digital technologies with their current processes, as highlighted in the digital transformation in manufacturing case study, to build operational resilience. Don Rogers points out that having a solid strategy that aligns business needs with tech principles is key for producers, as demonstrated in a digital transformation in manufacturing case study, to close those competitive gaps. As producers feel the heat to cut costs while improving service delivery, modernizing becomes a must. By adopting advanced tech solutions, including IoT innovations-something 35% of manufacturing firms have already jumped on-manufacturers can streamline their operations, improve inventory management, and ultimately boost their competitive edge in a fast-changing marketplace.

Solution Strategies for Digital Transformation

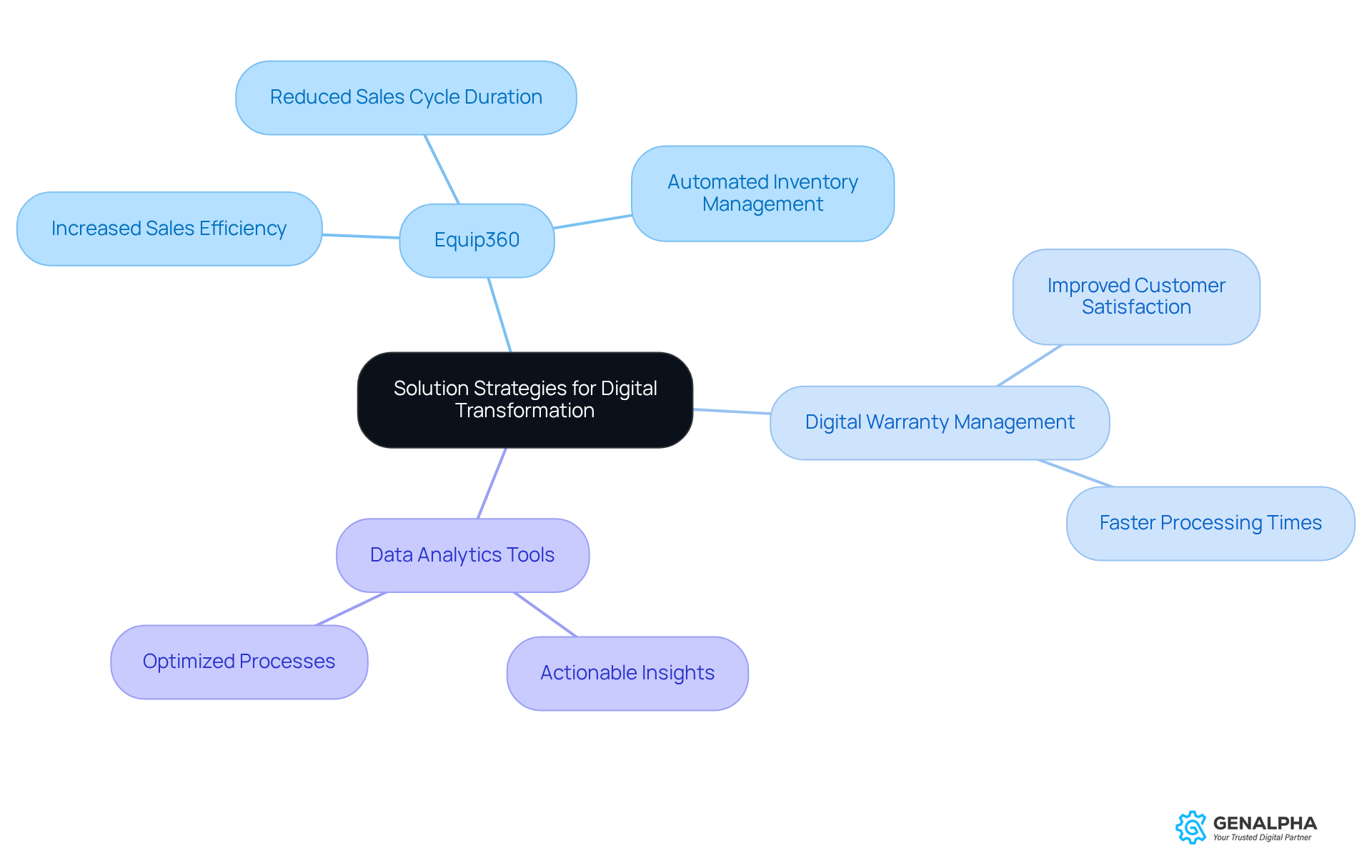

GenAlpha Technologies is implementing a bold digital transformation in manufacturing case study aimed at tackling the real challenges producers face today. At the heart of this initiative is Equip360, a powerful eCommerce platform that’s making inventory management a breeze and boosting online revenue. By automating processes, Equip360 helps producers cut down on operational hiccups, leading to a notable increase in sales productivity. In fact, companies using platforms like this have seen sales efficiency soar by up to 34% and cut their sales cycle duration by 14%.

But that’s not all! Alongside Equip360, the company has rolled out digital warranty management solutions that are crucial for ramping up customer satisfaction and speeding up processing times. Plus, with data analytics tools in the mix, manufacturers can now pull actionable insights from their operations, making informed decisions that optimize their processes. This well-rounded approach not only tackles immediate operational hurdles but also sets GenAlpha up for long-term growth in a competitive market.

Industry leaders are taking notice of Equip360’s game-changing impact, underscoring that effective tech solutions are vital as demonstrated in a digital transformation in manufacturing case study. As the industry evolves, being able to leverage technology for better inventory management and smoother transaction processes will be key to standing out and succeeding.

So, what do you think? Are you ready to embrace the tech revolution in manufacturing?

Results and Impact of Digital Transformation

Have you ever wondered how a digital transformation in manufacturing case study can truly change the game for businesses? Well, let me tell you about the amazing results from GenAlpha Technologies. Their initiatives led to some impressive improvements that clients are raving about.

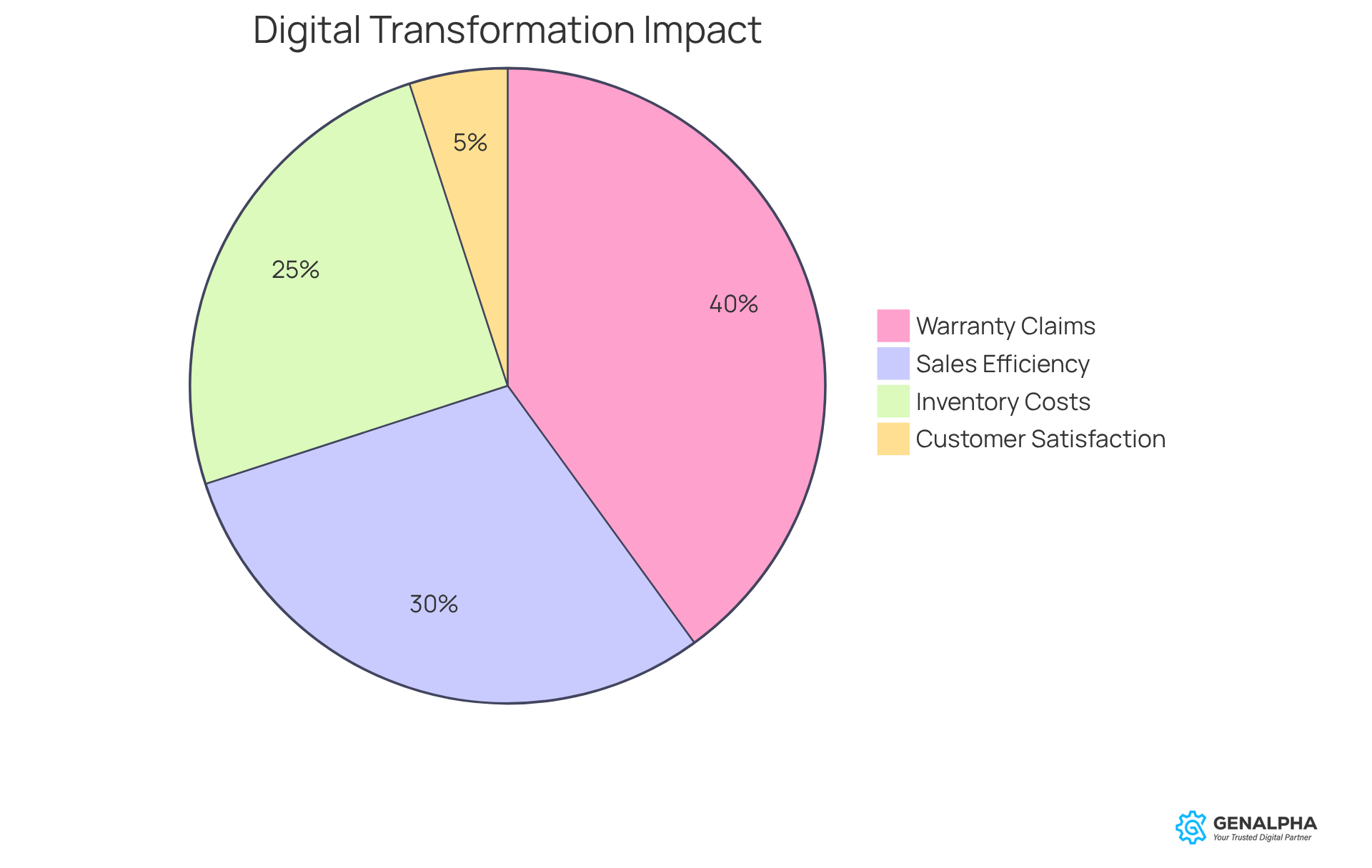

For starters, clients saw a whopping 30% boost in online sales efficiency! That’s not all - inventory holding costs dropped by 25%. Can you imagine how much that can save a business? Plus, customer satisfaction scores shot up, thanks to better warranty management processes. This led to a fantastic 40% decrease in the time it takes to process warranty claims.

But wait, there’s more! The integration of data analytics tools gave producers real-time insights, allowing them to respond quickly to market demands and fine-tune their operations. These results really showcase how effective GenAlpha's online solutions are in driving operational efficiencies and enhancing customer experiences.

So, what do you think? Isn’t it exciting to see how technology can make such a difference? If you’re looking to improve your own business operations, maybe it’s time to consider a digital transformation in manufacturing case study as well!

Insights and Lessons Learned from the Case Study

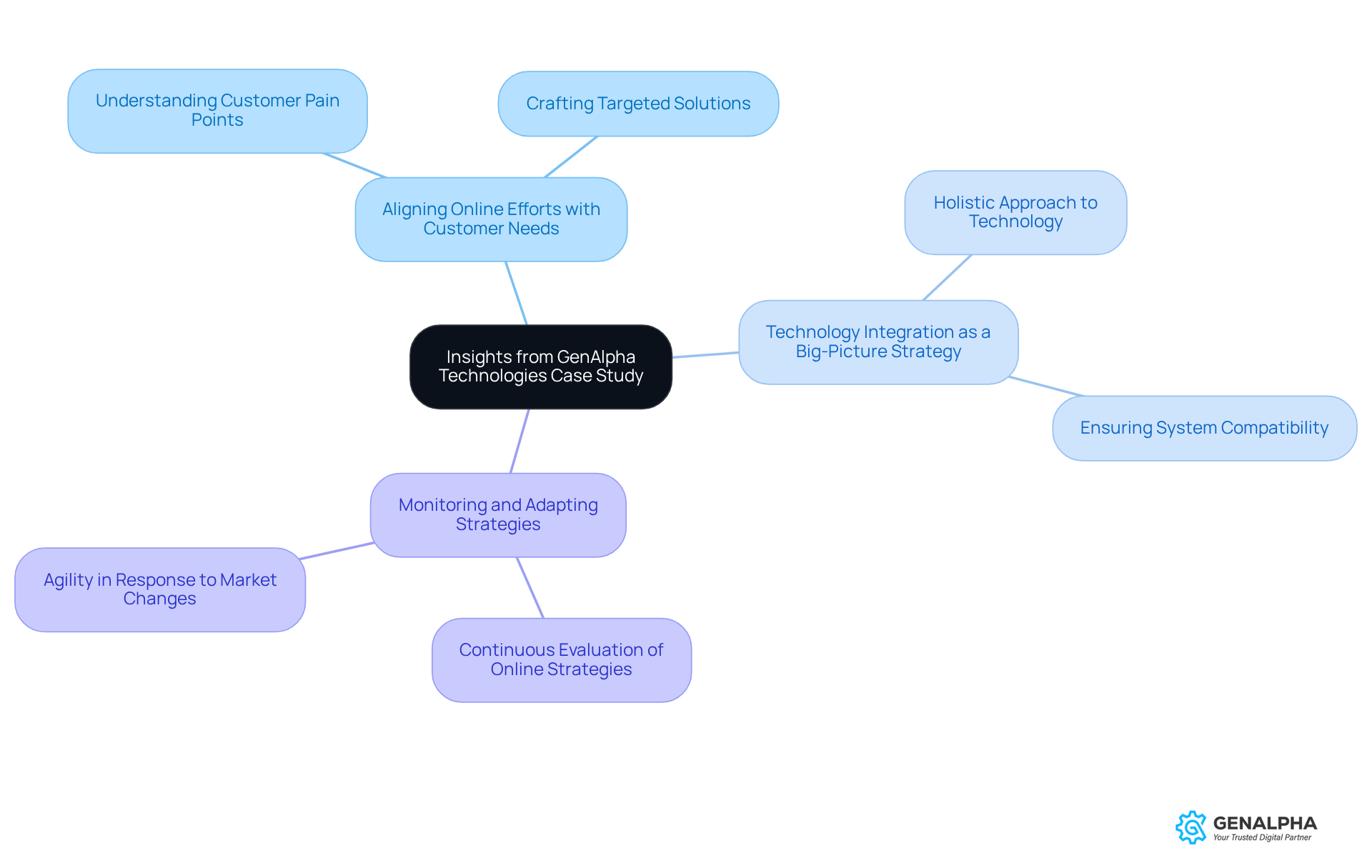

The digital transformation in manufacturing case study of GenAlpha Technologies really opens our eyes to some important lessons for manufacturers thinking about making a tech leap. First off, let’s talk about how crucial it is to align online efforts with what customers actually need. Seriously, understanding their pain points is key to crafting solutions that hit the mark.

Next, think of technology integration as a big-picture strategy, not just a bunch of separate projects. It’s all about making sure everything works together smoothly. And don’t forget, keeping an eye on your online strategies and tweaking them as needed is vital if you want to stay competitive in this fast-paced market.

So, what do these insights tell us? They highlight the importance of a proactive, customer-focused approach to the digital transformation in manufacturing case study. Are you ready to embrace this change?

Conclusion

As we wrap up our exploration of digital transformation in manufacturing, let’s take a moment to reflect on the journey of GenAlpha Technologies. It really highlights how crucial it is for companies to keep up with the ever-changing tech landscape and what customers expect from them. By tapping into advanced eCommerce solutions like Equip360, manufacturers can not only streamline their operations but also elevate the customer experience. This leads to impressive boosts in both efficiency and satisfaction.

Throughout our discussion, we’ve seen some key challenges pop up - think outdated selling processes, clunky inventory management, and that frustrating lack of real-time data visibility. But here’s the good news: implementing digital solutions has tackled these issues head-on. The results? A whopping 30% increase in online sales efficiency and a 25% drop in inventory holding costs! Plus, with data analytics in the mix, manufacturers can make smarter decisions and react quickly to what the market demands.

So, what’s the takeaway here? Embracing digital transformation isn’t just a nice-to-have; it’s a must for manufacturers who want to thrive in today’s competitive landscape. The lessons from this case study really drive home the point that aligning technology with customer needs and keeping a cohesive strategy across all digital efforts is vital. As the manufacturing sector keeps evolving, taking proactive steps toward digital transformation can truly set the stage for lasting growth and success. Are you ready to take that leap?

Frequently Asked Questions

What is Alpha Technologies known for?

Alpha Technologies is a leader in tech solutions for producers and suppliers in the machinery and replacement parts industry, focusing on empowering businesses to succeed in the online landscape.

What eCommerce solutions does Alpha Technologies offer?

They offer a suite of eCommerce solutions designed to boost online revenue and enhance customer experiences, with Equip360 being a key advanced B2B eCommerce platform that streamlines inventory management and improves digital revenue performance.

What challenges does the manufacturing sector currently face?

The manufacturing sector faces challenges such as outdated selling processes, clunky inventory management, disjointed systems that hinder communication, and inefficiencies that impact operational efficiency and customer satisfaction.

How does outdated selling processes affect manufacturers?

Outdated selling processes lead to delays and mistakes in transaction cycles, making operations less efficient and negatively impacting customer satisfaction due to the struggle to provide smooth purchasing experiences.

What is the impact of implementing online sales quoting software?

Implementing online sales quoting software can reduce sales cycles by 28% and approval times by 95%, while companies using automated quoting tools have seen a 49% increase in proposal volume.

Why is real-time data visibility important for manufacturers?

Real-time data visibility is crucial as it allows producers to respond quickly to market changes and enhances operational resilience, helping them to better meet customer demands and improve service delivery.

What strategies can manufacturers adopt to modernize their operations?

Manufacturers can modernize their operations by integrating digital technologies with existing processes, adopting advanced tech solutions, and leveraging IoT innovations to streamline operations and improve inventory management.

How can embracing eCommerce solutions benefit manufacturers?

Embracing eCommerce solutions can help manufacturers optimize their operations, gain real-time visibility into inventory, and build direct relationships with customers, leading to improved efficiency and higher customer satisfaction.