Introduction

In today’s fast-paced manufacturing world, companies like GenAlpha Technologies are leading the charge in digital transformation. They’re tackling challenges like outdated sales processes and clunky inventory management head-on. This case study takes a closer look at how GenAlpha is shaking things up, showing that by embracing innovative solutions, they’re not just improving efficiency but also making customers a whole lot happier.

But here’s a question for you: as the industry faces the urgent need for change, how can manufacturers use technology to not just keep up but really thrive in this competitive landscape? Let’s explore this together!

Background of GenAlpha Technologies: Industry Context and Challenges

GenAlpha Technologies is right at the cutting edge of manufacturing and distribution, focusing on equipment manufacturers and aftermarket parts organizations. You know, this industry is really buzzing with rapid technological changes, and everyone’s expecting seamless digital experiences more than ever. But here’s the kicker: manufacturers are facing some serious challenges. Think outdated sales processes, clunky inventory management, and a real need for better customer engagement. In fact, did you know that a whopping 88% of surveyed manufacturers reported losing deals because of inefficiencies in quote generation and approval processes? That really highlights how urgent it is for change.

As digital transformation in manufacturing case study becomes a must-have, companies like GenAlpha are stepping up to lead the charge. They’re offering innovative solutions that tackle these challenges head-on. Their goal? To boost operational efficiencies and ramp up client satisfaction. This way, manufacturers can not just survive but truly thrive in a competitive landscape. So, what do you think? Isn’t it time to embrace these changes and see how they can benefit your business?

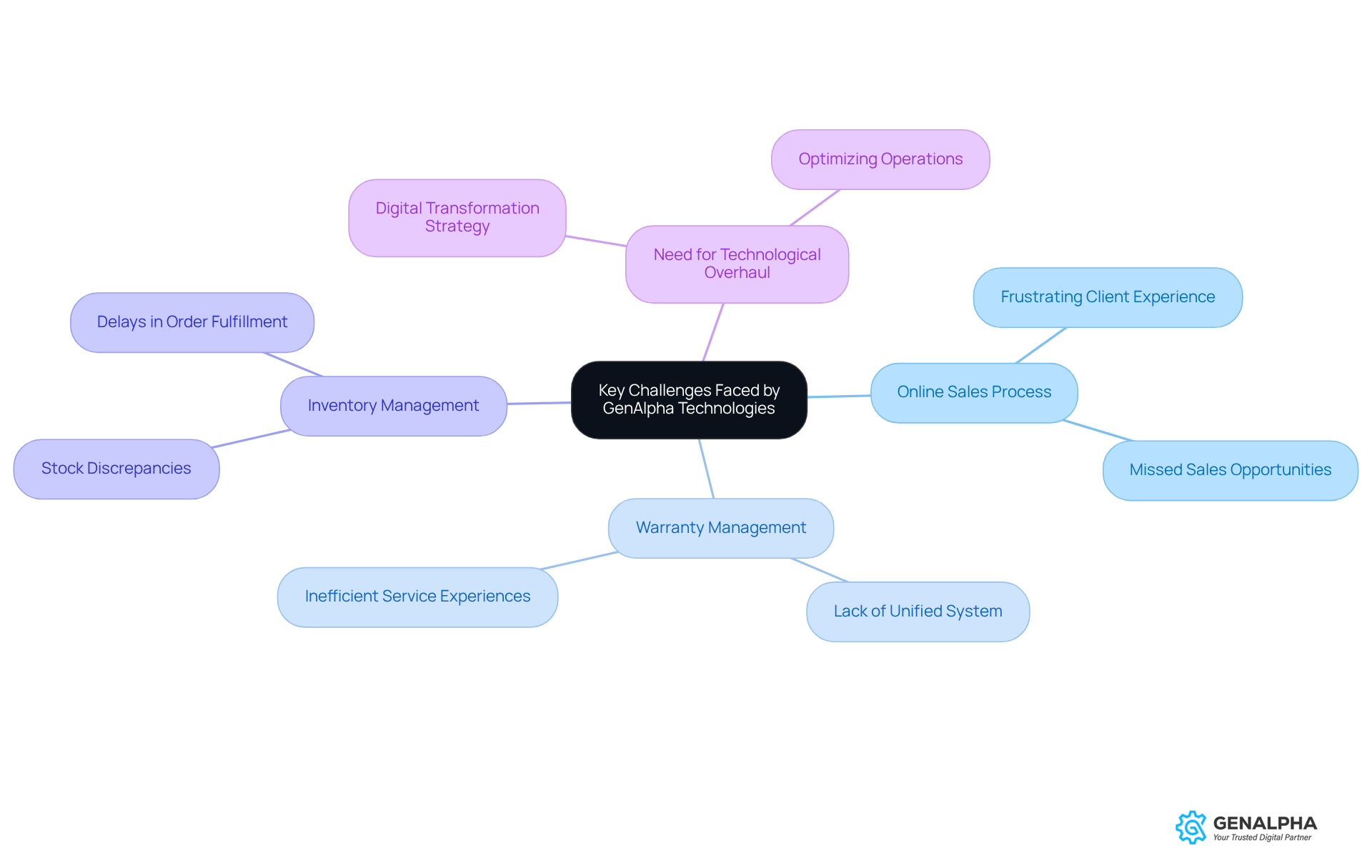

Identifying Key Challenges: Problems Faced by GenAlpha Technologies

GenAlpha Technologies has been facing some pretty tough challenges that are really getting in the way of growth and keeping clients happy. For starters, their online sales process is all over the place, which can be super frustrating for clients and leads to missed sales opportunities. Plus, without a unified electronic warranty management system, things get inefficient, and service experiences just don’t cut it.

On top of that, managing inventory effectively has been a struggle, resulting in stock discrepancies and delays in order fulfillment. It’s clear that these issues highlight a pressing need for a solid technological overhaul strategy, which is exemplified in a digital transformation in manufacturing case study. By optimizing operations, GenAlpha can really improve client interactions and satisfaction.

So, what do you think? Isn’t it time for a change that could make a real difference?

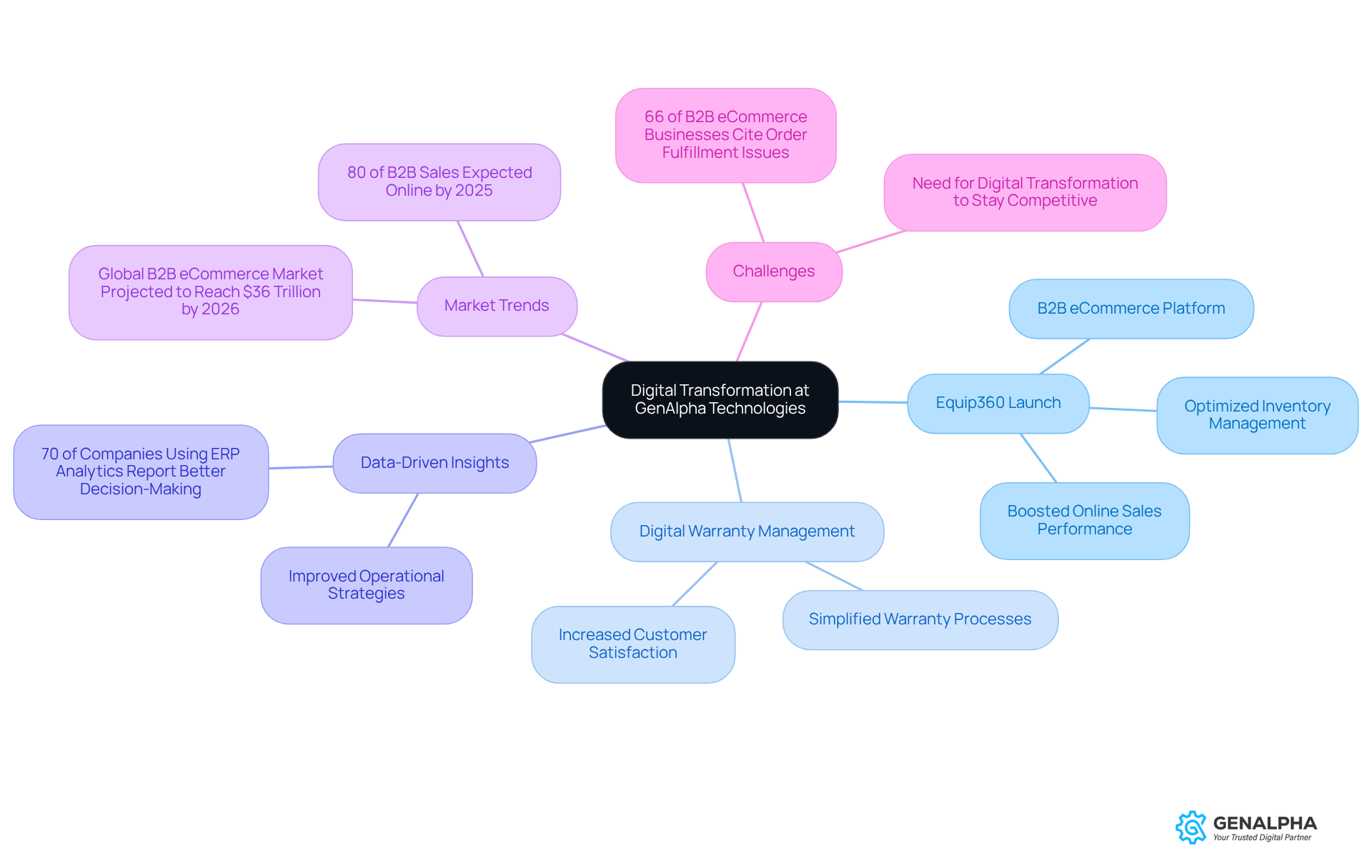

Solution Approach: Strategies for Digital Transformation at GenAlpha Technologies

Facing some tough challenges, GenAlpha Technologies decided to shake things up with a solid transformation strategy. At the core of this initiative? The launch of Equip360, a robust B2B eCommerce platform designed to optimize inventory management and boost online sales performance. This platform fits right in with existing ERP systems, making the transition smooth for clients and ramping up operational efficiency.

But that’s not all! GenAlpha also rolled out digital warranty management solutions that simplified warranty processes, leading to a noticeable uptick in customer satisfaction. By tapping into data-driven insights, the organization fine-tuned its operational strategies, creating a more efficient and customer-focused business model. This approach is right on trend, especially considering that 70% of companies using ERP analytics report better decision-making capabilities.

And here’s something to think about: with 80% of B2B sales expected to happen online by the end of 2025, the need for solutions like Equip360 is crystal clear. The global B2B eCommerce market is projected to reach an astounding $36 trillion by 2026, which underscores the importance of a digital transformation in manufacturing case study for manufacturers and distributors to adopt tech advancements and remain competitive.

Moreover, tackling challenges like the 66% of B2B eCommerce businesses that cite order fulfillment and tracking as their biggest hurdles is key to thriving in this ever-evolving landscape. So, what’s your take on these shifts? Are you ready to adapt and thrive?

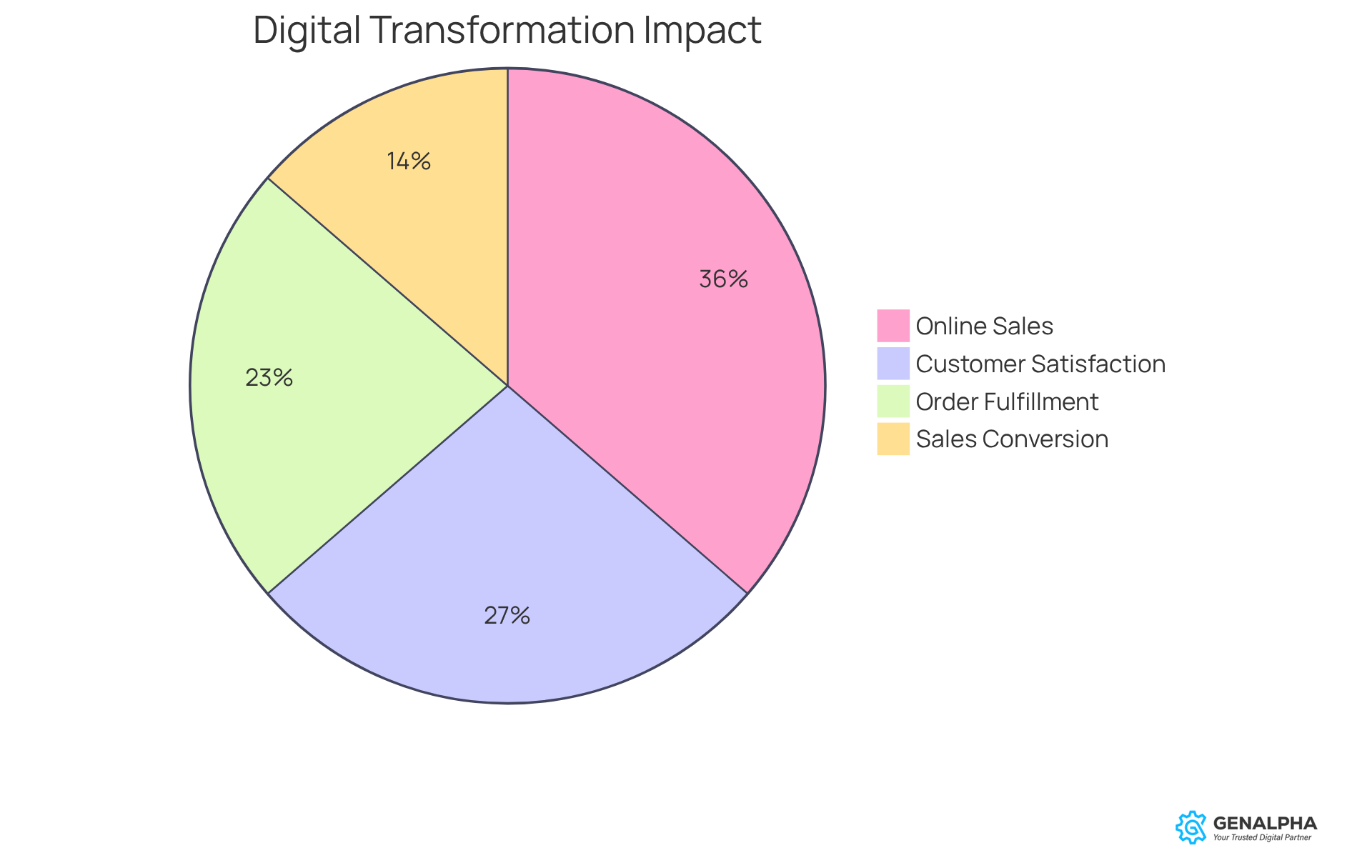

Results and Impact: Measuring Success Post-Transformation

After rolling out its online innovation strategies, GenAlpha Technologies saw some pretty impressive improvements across key operational metrics. Can you believe customer satisfaction scores jumped by 30%? This boost came from a smoother online purchasing experience and more efficient warranty processes. It’s interesting to note that studies show digital transformation can lead to a 20-30% increase in client satisfaction, and businesses that focus on experience tend to have 1.6 times higher satisfaction rates.

But that’s not all! The company also reported a 25% drop in order fulfillment times, which is crucial for meeting customer expectations. After all, 75% of online shoppers expect a response within five minutes. And here’s a kicker: 88% of customers are less likely to return after a bad website experience, which really highlights how important quick response times are.

Sales efficiency got a nice boost too, with online sales soaring by 40% in the first year after launching Equip360. This aligns with data showing that companies using online sales strategies see a 15% increase in sales conversion rates. These results really showcase how technology can transform GenAlpha's overall business performance and strengthen client relationships. It’s clear that embracing technology is vital in a digital transformation in manufacturing case study. So, what do you think? Is your business ready to take the leap into digital transformation?

Insights and Lessons Learned: Best Practices for Future Transformations

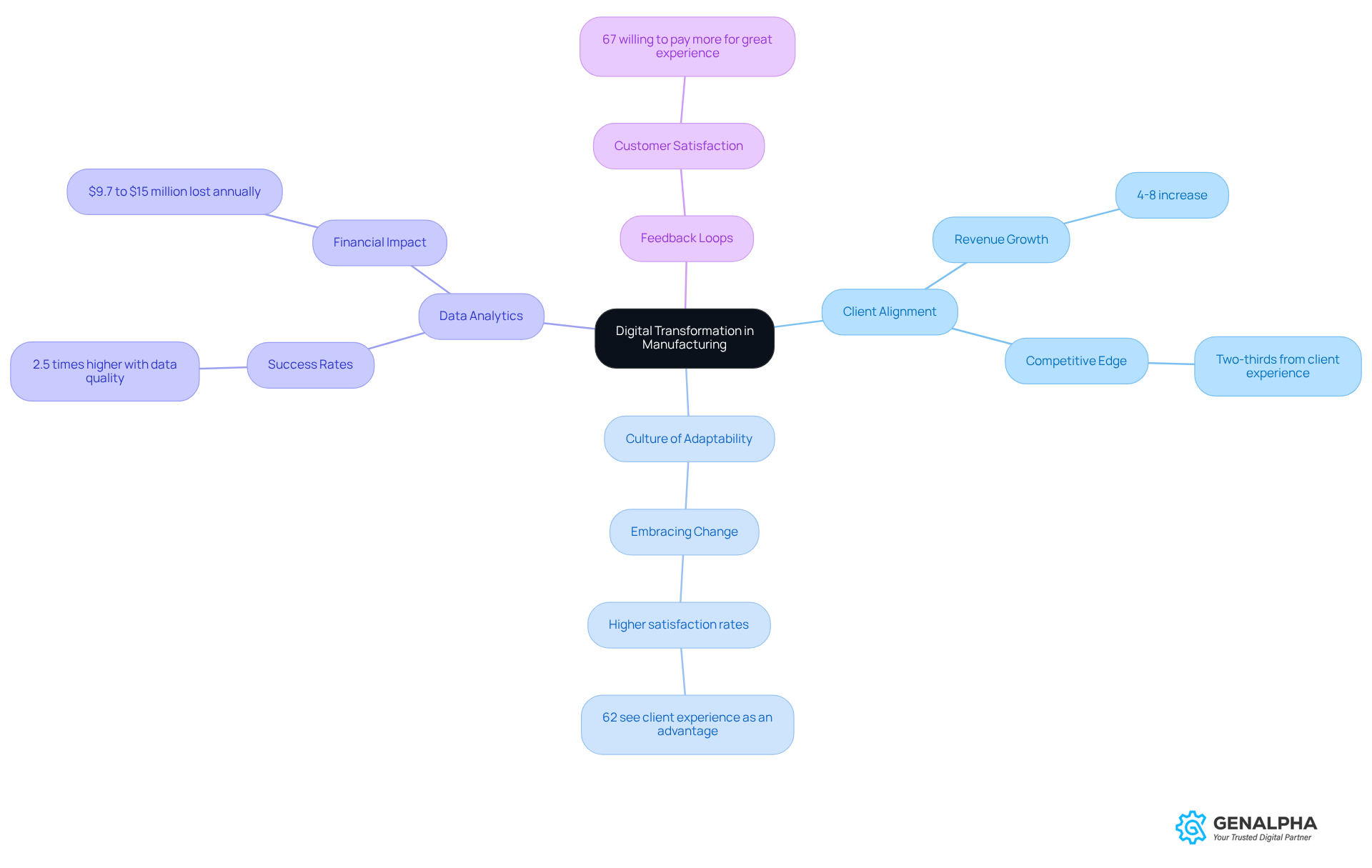

The digital transformation in manufacturing case study conducted by GenAlpha Technologies has revealed some key insights that can really help organizations in the manufacturing sector. First off, aligning technology solutions with client needs is super important. You’ve got to understand the client journey inside and out for a successful implementation. Did you know that organizations excelling in client experience can see revenue growth of 4% to 8% more than their competitors? That really shows the financial perks of getting this alignment right! Plus, two-thirds of a company’s competitive edge comes from its client experience, which makes it clear that client-focused strategies are a must.

Now, let’s talk about fostering a culture of adaptability within your organization. Embracing change and tackling resistance are crucial for making the most of new technologies. Companies that put client-focused tech solutions first report much higher satisfaction rates - 62% of them see client experience as a competitive advantage. That’s something to think about!

Additionally, using data analytics to guide decision-making has proven to be a game changer for optimizing operations. Companies that tackle data quality issues first see 2.5 times higher success rates in their transformations. On the flip side, they lose an average of $9.7 to $15 million each year due to poor data quality. That really highlights the financial impact of not getting your data right.

Finally, creating ongoing feedback loops with clients is key to enhancing your tech solutions, ensuring they stay relevant and effective. This iterative approach not only boosts customer satisfaction but also builds loyalty - 67% of consumers are willing to pay more for a great experience! These lessons together really stress the importance of a strategic, customer-centric approach to the digital transformation in manufacturing case study. So, what steps are you ready to take to make this happen?

Conclusion

GenAlpha Technologies' journey through digital transformation really highlights a major shift in the manufacturing world. It shows just how crucial it is for companies to keep up with the fast-paced tech changes we’re seeing today. As manufacturers deal with outdated processes and inefficiencies, GenAlpha stands out as a shining example of what can be achieved through smart innovation. By embracing digital solutions, organizations can tackle their challenges head-on while boosting customer satisfaction and operational efficiency.

So, what did GenAlpha do? They rolled out the Equip360 platform and digital warranty management solutions, which led to some impressive results. We’re talking about a 30% increase in customer satisfaction and a 40% jump in online sales! These numbers really emphasize how important it is to align technology with what customers need and to foster a culture that’s adaptable in a competitive landscape. Plus, using data analytics for informed decision-making turned out to be a game-changer in driving successful transformations.

In wrapping up, the lessons from GenAlpha’s digital transformation journey are gold for manufacturers trying to navigate today’s complex marketplace. Embracing a customer-centric approach, nurturing adaptability, and leveraging data-driven insights are key steps for any organization looking to sharpen its competitive edge. The time to act is now! Adopting innovative technologies isn’t just a nice-to-have; it’s a must for future success in the manufacturing industry. So, what’s holding you back from taking that leap?

Frequently Asked Questions

What is GenAlpha Technologies focused on in the manufacturing industry?

GenAlpha Technologies focuses on equipment manufacturers and aftermarket parts organizations, aiming to enhance manufacturing and distribution processes.

What challenges are manufacturers facing according to the article?

Manufacturers are facing outdated sales processes, inefficient inventory management, and a significant need for better customer engagement.

How many manufacturers reported losing deals due to inefficiencies in quote generation and approval processes?

88% of surveyed manufacturers reported losing deals because of inefficiencies in quote generation and approval processes.

What is the goal of GenAlpha Technologies?

The goal of GenAlpha Technologies is to boost operational efficiencies and increase client satisfaction, enabling manufacturers to thrive in a competitive landscape.

What specific challenges has GenAlpha Technologies encountered?

GenAlpha Technologies has faced challenges including a disorganized online sales process, lack of a unified electronic warranty management system, and difficulties in managing inventory effectively.

How do the challenges faced by GenAlpha Technologies impact client satisfaction?

The challenges lead to missed sales opportunities, inefficiencies in service experiences, stock discrepancies, and delays in order fulfillment, all of which negatively affect client satisfaction.

What is suggested as a necessary action for GenAlpha Technologies?

A solid technological overhaul strategy is suggested to optimize operations and improve client interactions and satisfaction.