Introduction

Understanding the ins and outs of Configure, Price, Quote (CPQ) can really change the game for equipment manufacturers. Imagine a powerful software that makes the selling process smoother, helping sales teams configure complex products, calculate pricing accurately, and whip up quotes in no time. Sounds great, right? But here’s the catch: while the benefits of increased efficiency and happier customers are enticing, many manufacturers find themselves facing hurdles during implementation. So, what can they do to seamlessly integrate CPQ solutions and tap into their full potential?

Understand the Basics of CPQ

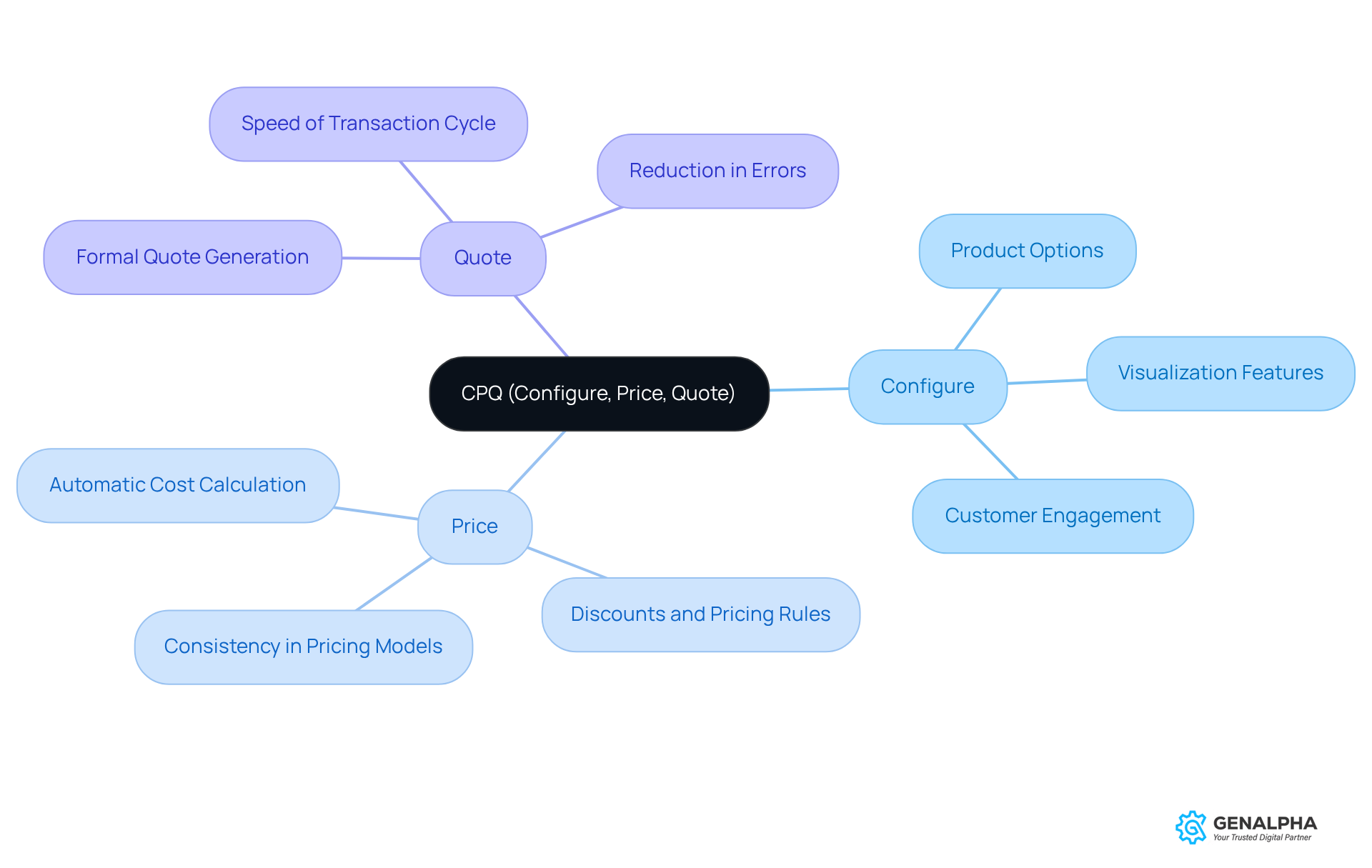

To define CPQ, or Configure, Price, Quote, it serves as a game-changer for manufacturers looking to streamline their selling process. Imagine a sales team that can quickly configure complex products, calculate accurate pricing, and generate quotes in a flash. Sounds great, right? Let’s break down the three core components of CPQ that make this possible:

-

Configure: This is where the magic begins. Clients get to pick and choose product options and features that fit their needs. For example, an industrial equipment manufacturer might let clients select from different sizes, colors, and functionalities, ensuring they get exactly what they want. Plus, many modern CPQ tools come with visualization features that really boost customer engagement. This not only helps bridge the gap between engineering specs and what customers expect but also increases conversion rates.

-

Price: Next up is pricing. CPQ software takes the guesswork out of pricing by automatically calculating costs based on the chosen configurations. It applies discounts and pricing rules, so sales teams can offer accurate pricing without worrying about manual errors. The software sticks to established guidelines, which means no more inconsistencies in product setups and pricing models.

-

Quote: Finally, we have the quote generation. This step wraps everything up by creating a formal quote that can be sent to the client, complete with detailed specs and a pricing breakdown. This streamlined process cuts down on mistakes and speeds up the transaction cycle, allowing manufacturers to close deals more efficiently. In fact, research shows that reps can cut quote completion times by over 50% with CPQ software! Without it, they often need 73% more time to whip up a typical quote or proposal. That’s a huge difference!

By understanding these basics, manufacturers can truly appreciate the significant benefits that come when they define CPQ, such as faster quoting times and happier clients. And with the CPQ market expected to soar past $7 billion by 2030, it is becoming essential for manufacturers to define CPQ solutions in order to boost their revenue strategies and stay ahead of the competition. As industry leaders put it, "Every day you rely on manual quoting is another day you’re losing revenue, clients, and time." So, why wait? Embrace CPQ solutions today!

Identify the Benefits of CPQ for Equipment Manufacturers

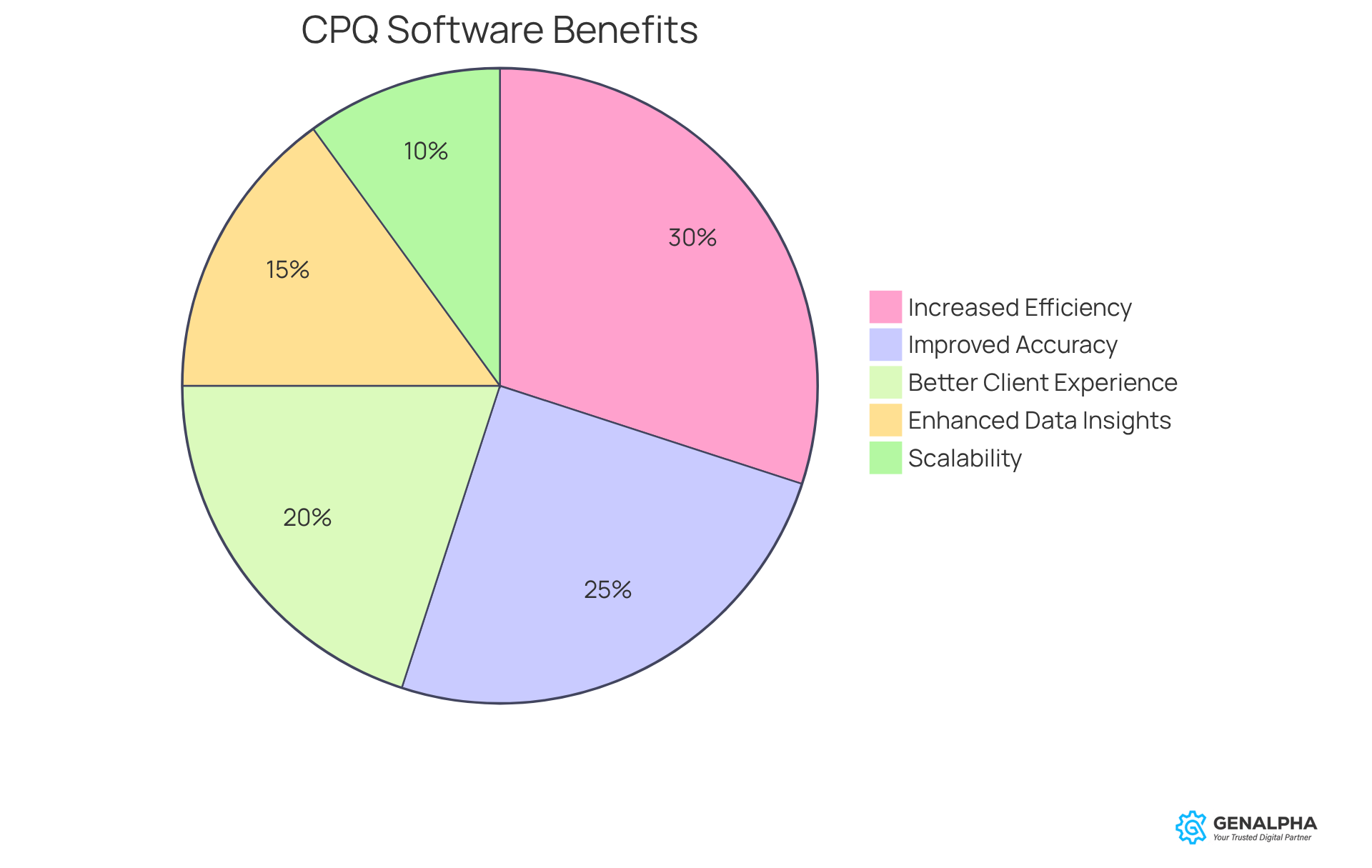

To understand the advantages for equipment manufacturers, it's essential to define CPQ when implementing CPQ software. Let’s break it down:

-

Increased Efficiency: Imagine your sales team spending less time on generating quotes and more time selling. When we define CPQ, we see that it automates the quoting process, enabling teams to focus on what they do best-closing deals instead of getting bogged down in admin tasks.

-

Improved Accuracy: We’ve all seen how human errors can creep in during manual quoting. To define CPQ, it automates pricing and configuration, resulting in fewer mistakes and more reliable quotes. This leads to fewer discrepancies in orders, making life easier for everyone involved.

-

Better Client Experience: Who doesn’t love a quick and precise quote? To define CPQ, it is important to note that clients enjoy a smoother purchasing process. Manufacturers can respond swiftly to inquiries, which boosts client satisfaction and loyalty. It’s a win-win!

-

Enhanced Data Insights: CPQ systems often come with analytics tools that provide insights into trends, customer preferences, and pricing strategies. This data can help manufacturers make smarter business decisions and craft better strategies.

-

Scalability: As manufacturers grow, their needs change. To define CPQ, it's important to note that CPQ systems can easily adapt to increased product complexity and volume, ensuring transactions remain efficient even as demands evolve.

These advantages work together to create a more efficient sales system, helping manufacturers thrive in a competitive marketplace. So, why not consider implementing CPQ software and see how it can transform your sales process?

Implement CPQ Software in Your Operations

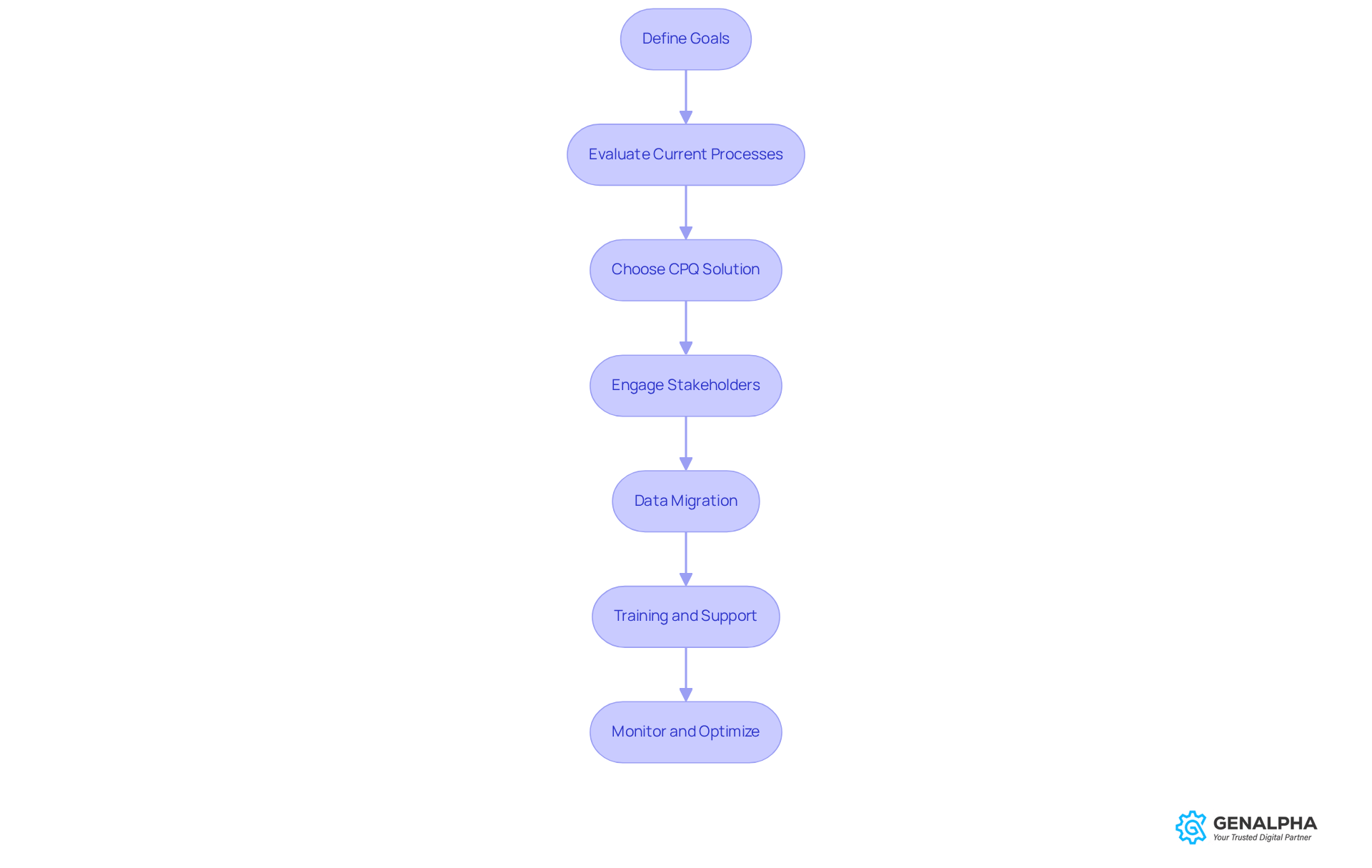

Want to successfully implement CPQ software in your operations? Here are some essential steps to get you started:

-

To define CPQ, first things first, let’s get clear on what you want to achieve. Are you looking to cut down on quote generation times, boost pricing accuracy, or maybe enhance customer satisfaction? Setting specific, measurable goals will help steer your implementation in the right direction.

-

Evaluate Your Current Processes: Take a good look at your existing transaction workflows. What’s working? What’s not? To tackle those pesky challenges head-on, it is important to understand your current methods and define CPQ implementation accordingly.

-

Choose the Right CPQ Solution: Now, it’s time to do some research. Look into different CPQ software options and find one that fits your business needs like a glove. Think about integration with your current systems, scalability for future growth, and how user-friendly it is - because you want your team to adopt it quickly!

-

Engage Stakeholders: Don’t forget to involve key players from commerce, IT, and management during the implementation phase. Their insights and feedback are gold when it comes to making sure the CPQ system meets everyone’s needs and aligns with your organizational goals.

-

Data Migration: Get your product and pricing data ready for migration into the CPQ system. Make sure everything is accurate and up-to-date to avoid any hiccups during the transition. Trust me, inaccurate data can lead to some serious headaches down the line.

-

Training and Support: Once you’ve got the system in place, it’s time to train your sales team on how to use it effectively. Ongoing support is crucial to help them adapt and make the most of the new system.

-

Monitor and Optimize: After everything’s up and running, keep an eye on how the system performs. Gather user feedback and regularly check key performance metrics like quote generation time and win rates. This way, you can spot areas for improvement and optimize the CPQ system.

By following these steps, manufacturers can define CPQ to achieve a successful implementation that significantly boosts revenue capabilities, leading to improved efficiency and happier clients. So, are you ready to take the plunge?

Overcome Challenges in CPQ Implementation

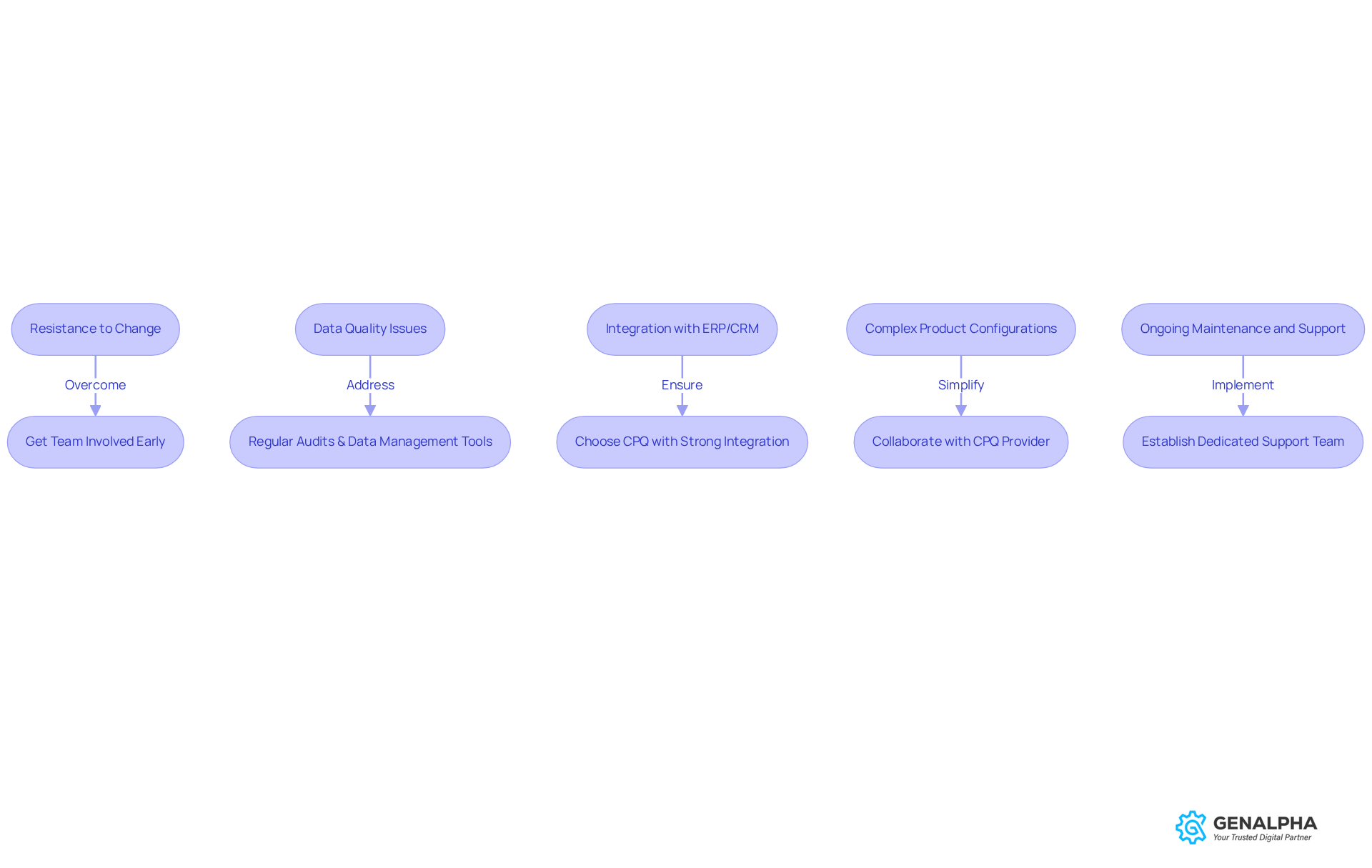

Implementing CPQ software can be a bit of a rollercoaster ride for manufacturers, right? There are several challenges to tackle, but don’t worry-we’ve got some strategies to help you navigate through them:

-

Resistance to Change: Let’s face it, change can be scary! Employees often hesitate to jump on board with new technologies because they fear the unknown. To ease those worries, get your team involved early in the process. Provide thorough training that highlights the perks of CPQ. When employees feel like they’re part of shaping the change, they’re more likely to commit. In fact, organizations that take an employee-driven approach complete change initiatives about 33% faster than those that stick to a top-down strategy.

-

Data Quality Issues: Nobody likes dealing with inaccurate data, especially when it leads to flawed quotes. Before you define CPQ, ensure that your data is clean and organized. Regular audits and data quality management tools can help keep things in check. Remember, poor data quality can cost organizations an average of $15 million annually-yikes!

-

To define CPQ effectively, the software must integrate seamlessly with your existing ERP and CRM systems. Choosing a CPQ solution with strong integration capabilities can minimize disruptions and enhance data flow. This is crucial for accurate quoting and keeping operations running smoothly.

-

Complex Product Configurations: If your products are intricate, configuring them can feel like solving a puzzle. Collaborate with your CPQ provider to define CPQ rules and logic that simplify the configuration process. This way, your teams can quickly adjust product setups to meet specific client needs.

-

Ongoing Maintenance and Support: Once you’ve implemented CPQ, continuous support is key to tackling any issues that pop up. Establish a dedicated support team to assist users and ensure everything runs smoothly. Organizations that prioritize effective communication and support during change initiatives often see a significant drop in employee resistance, creating a more adaptable workforce.

By proactively addressing these challenges, manufacturers can boost their chances to define CPQ successfully during implementation. This leads to improved sales efficiency and happier customers. So, are you ready to tackle these challenges head-on?

Conclusion

Embracing CPQ, or Configure, Price, Quote, is a game changer for equipment manufacturers looking to boost their sales processes. Imagine automating the configuration, pricing, and quoting of complex products - sounds great, right? CPQ solutions empower sales teams to work more efficiently and effectively, which can lead to increased revenue and happier customers.

Let’s break down the essentials of CPQ: configuration, pricing, and quoting. Each of these components plays a vital role in streamlining the sales process. Think about it - improved accuracy, enhanced client experiences, and valuable data insights all highlight why adopting CPQ software is a must. Plus, the step-by-step guide for implementation and strategies to tackle common challenges offer a clear path for manufacturers to integrate CPQ into their operations successfully.

So, why is defining and implementing CPQ so crucial? As the market for CPQ solutions keeps growing, manufacturers need to recognize the urgency of adopting these technologies to stay competitive. By taking proactive steps toward implementation, they can not only overcome obstacles but also tap into the full potential of their sales capabilities.

Why wait? Embrace CPQ today and transform your manufacturing processes for a more efficient and prosperous future. Let's make it happen!

Frequently Asked Questions

What does CPQ stand for?

CPQ stands for Configure, Price, Quote.

How does CPQ benefit manufacturers?

CPQ helps manufacturers streamline their selling process by allowing sales teams to quickly configure complex products, calculate accurate pricing, and generate quotes efficiently.

What are the three core components of CPQ?

The three core components of CPQ are Configure, Price, and Quote.

What happens during the 'Configure' stage of CPQ?

In the 'Configure' stage, clients can select product options and features that meet their needs, such as sizes, colors, and functionalities. Modern CPQ tools often include visualization features to enhance customer engagement.

How does CPQ handle pricing?

CPQ software automatically calculates costs based on the chosen configurations and applies discounts and pricing rules, reducing the risk of manual errors and ensuring consistent pricing models.

What is the purpose of the 'Quote' generation in CPQ?

The 'Quote' generation creates a formal document that includes detailed specifications and pricing breakdowns for the client, streamlining the process and speeding up transaction cycles.

How much time can CPQ software save in quote completion?

CPQ software can reduce quote completion times by over 50%, compared to the traditional process, which often takes 73% more time.

What is the projected growth of the CPQ market by 2030?

The CPQ market is expected to exceed $7 billion by 2030.

Why is it important for manufacturers to adopt CPQ solutions?

Adopting CPQ solutions is crucial for manufacturers to enhance revenue strategies, improve quoting times, and maintain a competitive edge in the market.