Introduction

In a world where technology is changing the game, manufacturing finds itself at a crucial turning point. Have you ever felt the pressure to keep up with the rapid pace of change? Now more than ever, having a solid digital transformation roadmap is essential. Companies are eager to boost efficiency, cut costs, and stay ahead in a fast-moving market.

So, how do we tackle this? This article explores the key steps to create a successful digital transformation strategy specifically for manufacturing. We’ll look at important areas like:

- Assessing where you currently stand in terms of digital maturity

- Setting clear goals

- Choosing the right technologies to prioritize

But here’s the big question: how can organizations navigate the tricky waters of change while making sure their teams are ready for what’s next? Let’s dive in and find out!

Assess Current Digital Maturity

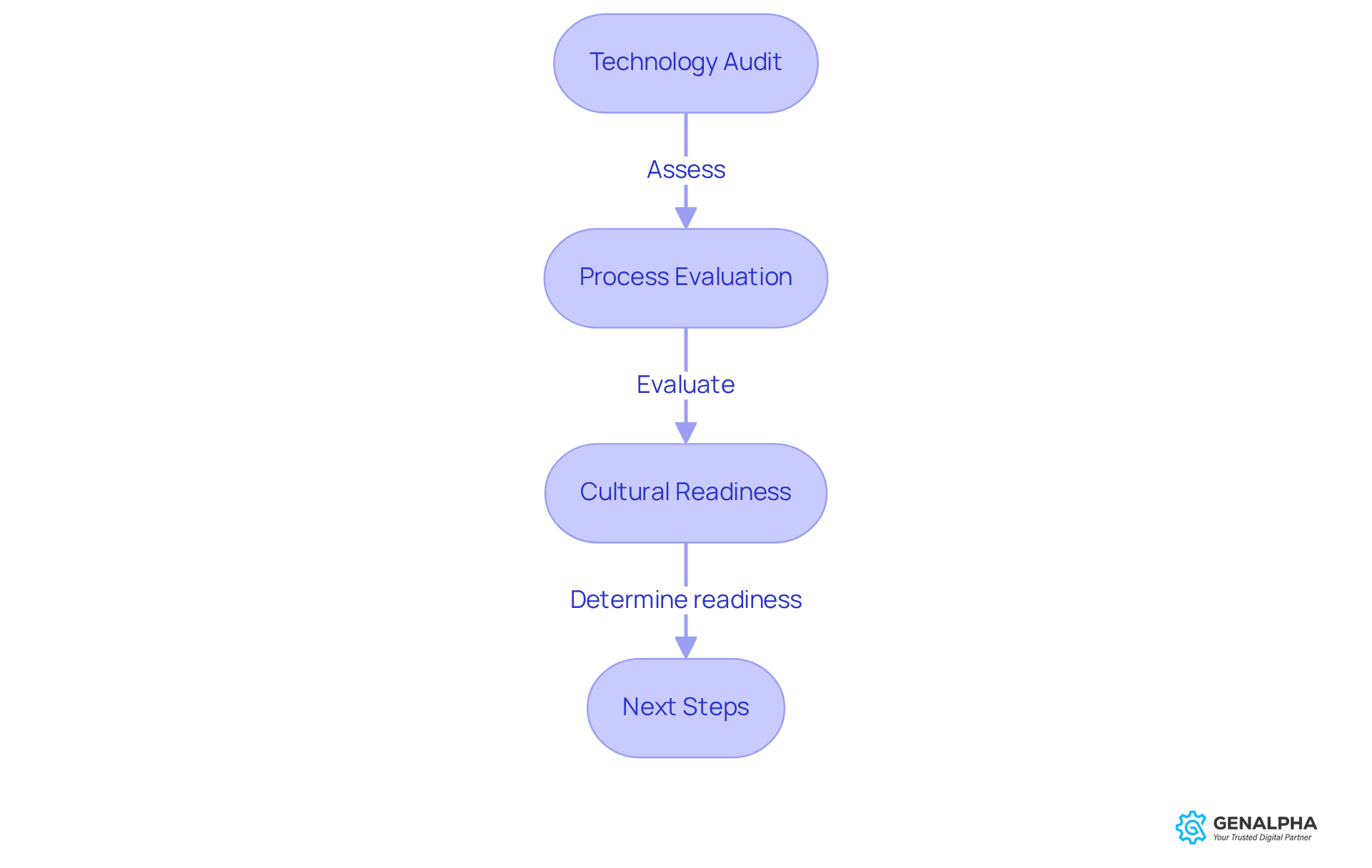

Ready to kick off your transformation roadmap? First things first: let’s take a good look at where your technology stands right now. This means diving into your current tech, processes, and how ready your organization is for change. A great way to do this is by using a maturity model that sorts your organization from 'Ad Hoc' to 'Optimized.' Here’s what you should focus on:

- Technology Audit: Take stock of the digital tools and platforms you’re currently using. Think about your ERP systems, eCommerce solutions, and data analytics tools.

- Process Evaluation: Look at your existing workflows. Are there any bottlenecks or areas that could use a little sprucing up?

- Cultural Readiness: How open is your organization to change? Check in on how your employees feel about adopting new technologies.

By understanding where you currently stand, you’ll be in a much better position to make smart decisions about the digital transformation roadmap for manufacturing and the steps to take next to boost your tech capabilities. So, what’s your next move?

Define Objectives and Vision

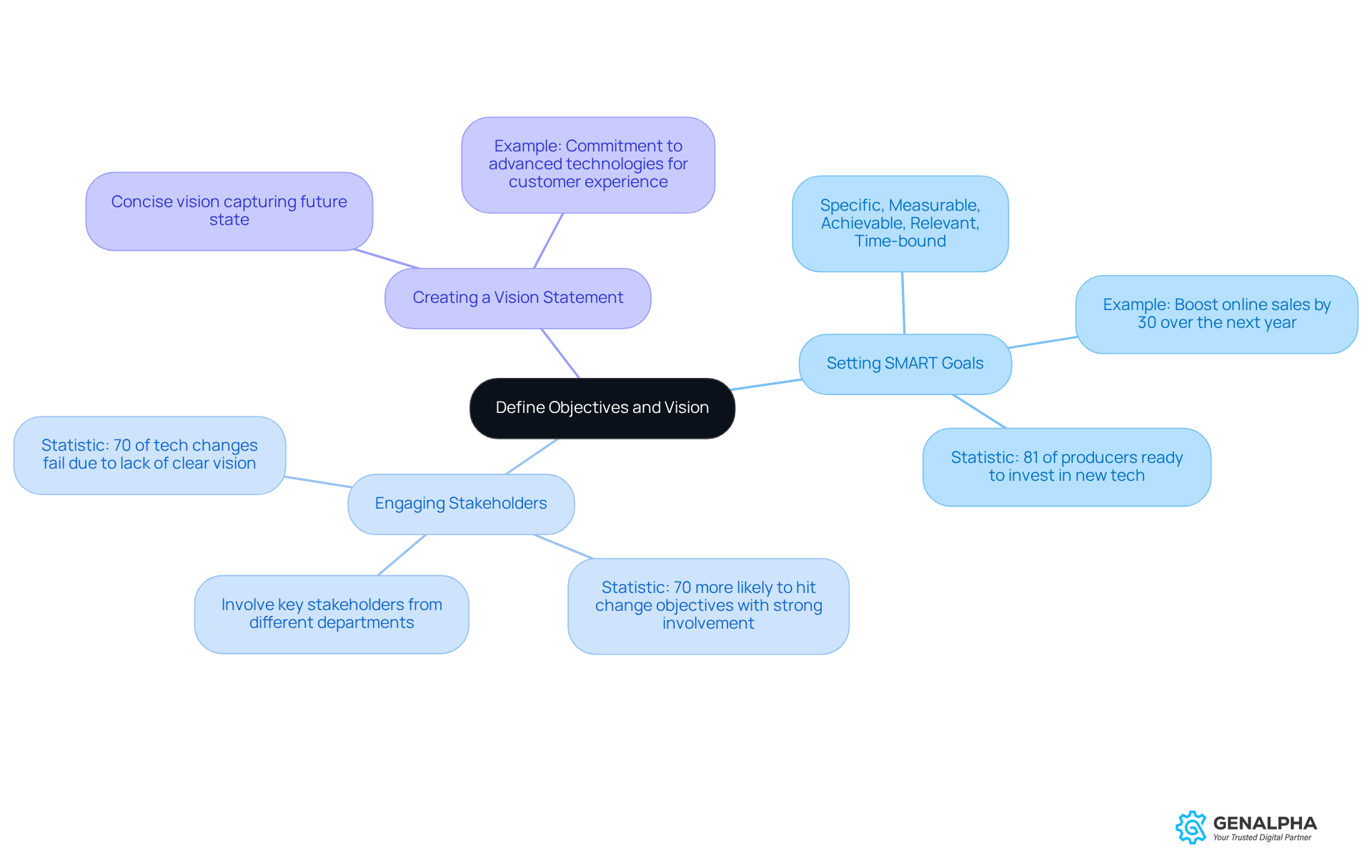

Once we evaluate the existing technological maturity, the next step is to set clear goals and a vision for the digital transformation roadmap for manufacturing. So, how do we go about this? Here are a few key steps:

-

Setting SMART Goals: It’s crucial to make sure our objectives are Specific, Measurable, Achievable, Relevant, and Time-bound. For example, a producer might aim to boost online sales by 30% over the next year. This goal is backed by the fact that 81% of producers are ready to invest in new tech to enhance productivity.

-

Engaging Stakeholders: Let’s not forget to involve key stakeholders from different departments. Gathering diverse perspectives helps foster buy-in. Did you know that organizations with strong stakeholder involvement in online projects are 70% more likely to hit their change objectives? Plus, around 70% of tech changes fail due to a lack of clear vision and resistance to change. This really highlights how important it is to set clear goals while engaging stakeholders.

-

Creating a Vision Statement: Next up, we need a concise vision statement that captures the future state we want for our organization after the transformation. This vision should resonate with both employees and customers, guiding all our actions. For instance, a vision might express a commitment to using advanced technologies to enhance customer experiences and operational efficiency, positioning the company as a leader in the online space.

By prioritizing these elements, we can lay a solid foundation for a successful digital transformation roadmap for manufacturing. This ensures our initiatives align well with organizational goals and stakeholder expectations. And let’s not forget, the global tech evolution market is projected to reach $3.4 trillion by 2026, which really emphasizes the urgency and importance of these initiatives.

Identify and Prioritize Digital Technologies

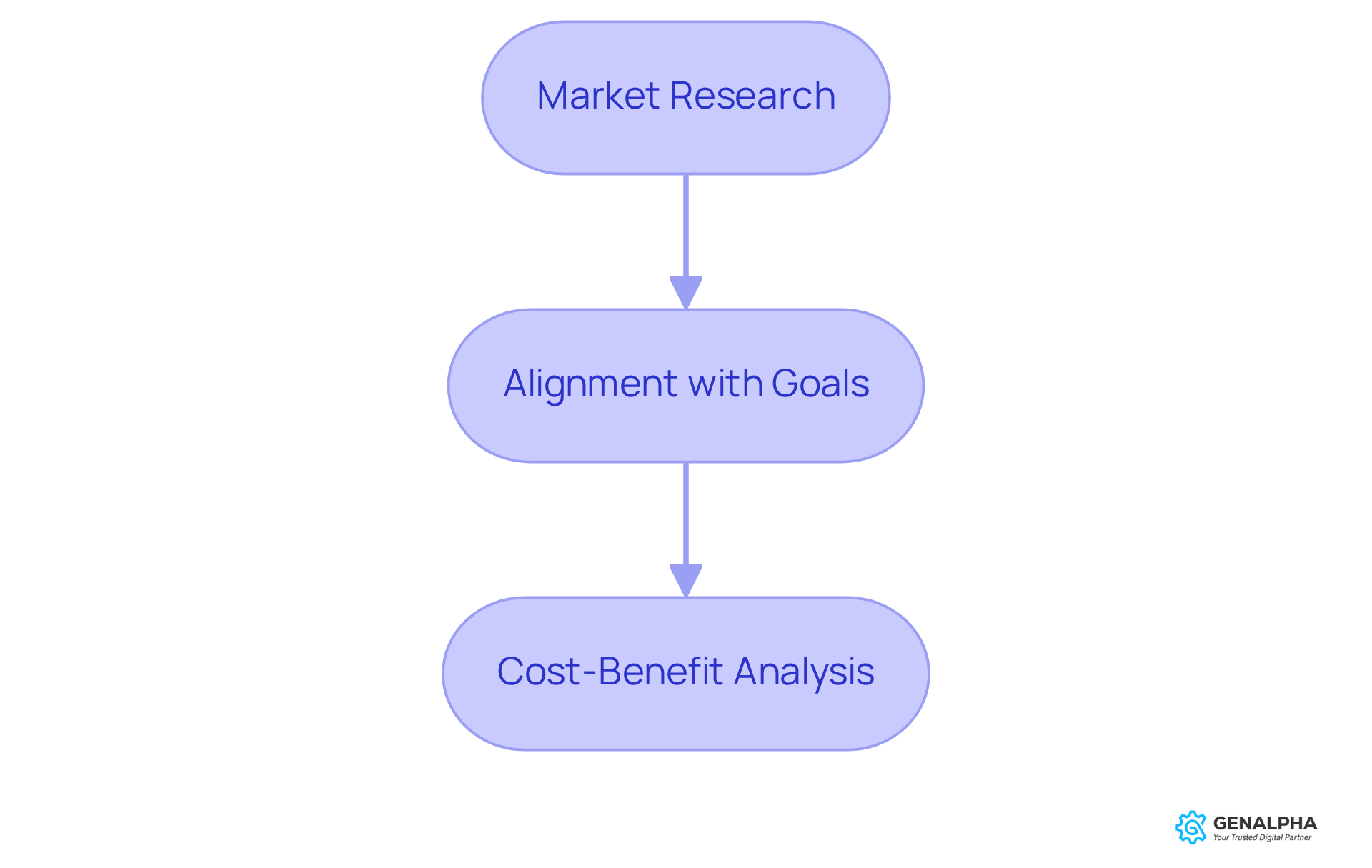

Now that we’ve got our goals and vision set, it’s time to determine which digital tools can assist us in following our digital transformation roadmap for manufacturing. So, how do we go about this? Here are a few steps to consider:

- Market Research: Let’s dive into the latest technologies that are shaking up the manufacturing world. Think about AI, IoT, and advanced analytics - these could be game-changers for us.

- Alignment with Goals: Next, we need to see how each tool fits with what we want to achieve. For example, if boosting customer engagement is on our list, investing in CRM systems or better eCommerce platforms might be the way to go.

- Cost-Benefit Analysis: Finally, it’s all about the numbers. We should run a cost-benefit analysis to figure out the potential ROI for each technology. Let’s prioritize the ones that promise the biggest bang for our buck, considering both cost and how complex they are to implement.

By following these steps, we can make informed decisions that align with our vision and drive our digital transformation roadmap for manufacturing forward!

Develop an Implementation Plan

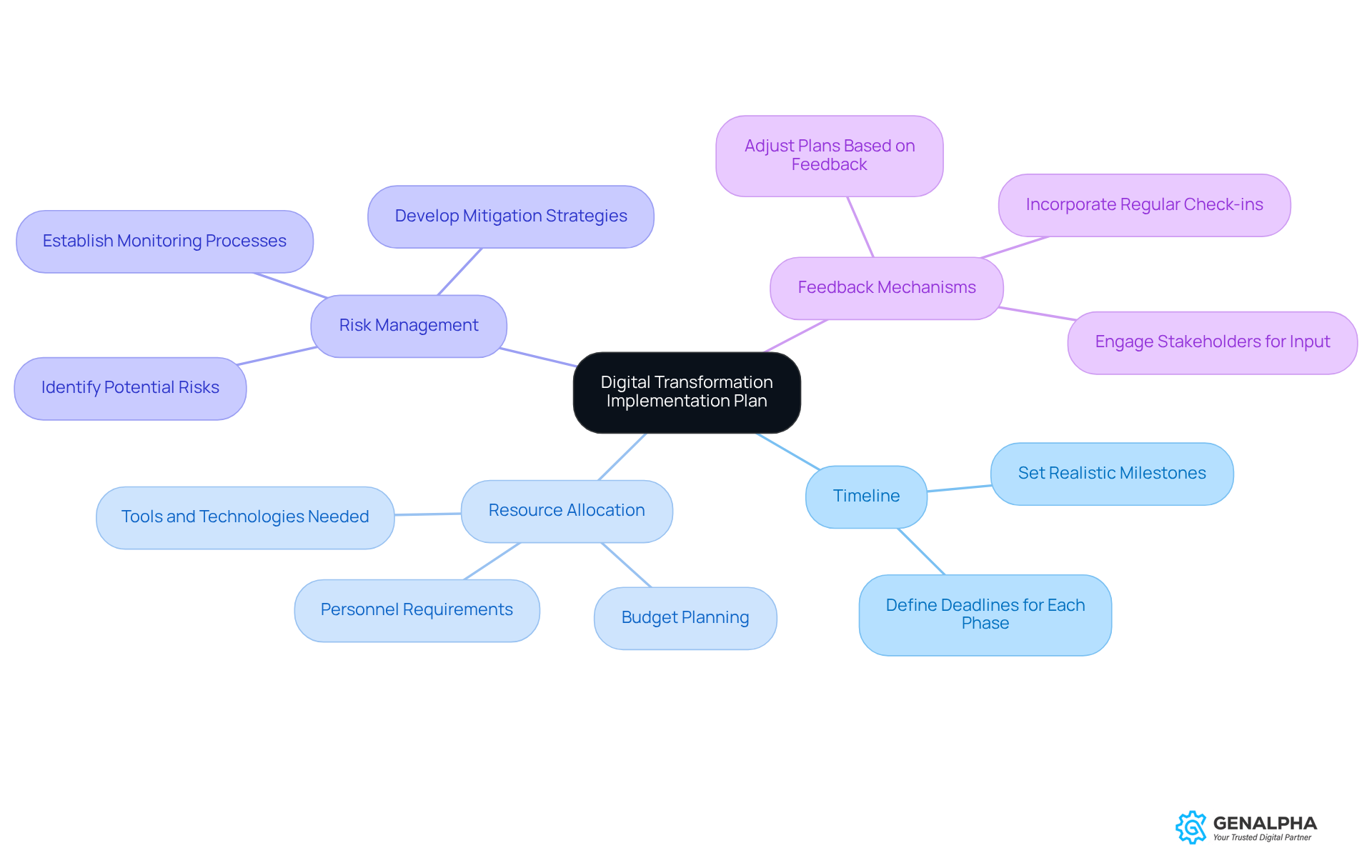

When it comes to successful digital change, having an effective digital transformation roadmap for manufacturing is key. So, what should this plan look like? Let’s break it down into some essential components:

- Timeline: First off, you’ll want to set a realistic timeline for each phase of your transformation. Think about milestones and deadlines that keep everyone on track.

- Resource Allocation: Next, consider what resources you’ll need for each phase. This includes your budget, personnel, and the tools that will help you along the way.

- Risk Management: Don’t forget about potential bumps in the road! Developing a risk management strategy can help you tackle challenges and obstacles that might pop up during implementation.

- Feedback Mechanisms: Lastly, it’s super important to incorporate feedback loops. These will help you assess progress and make any necessary adjustments as you go.

By keeping these elements in mind, you’ll be well on your way to confidently following the digital transformation roadmap for manufacturing. What do you think? Are there any other aspects you’d add to your plan?

Train and Upskill the Workforce

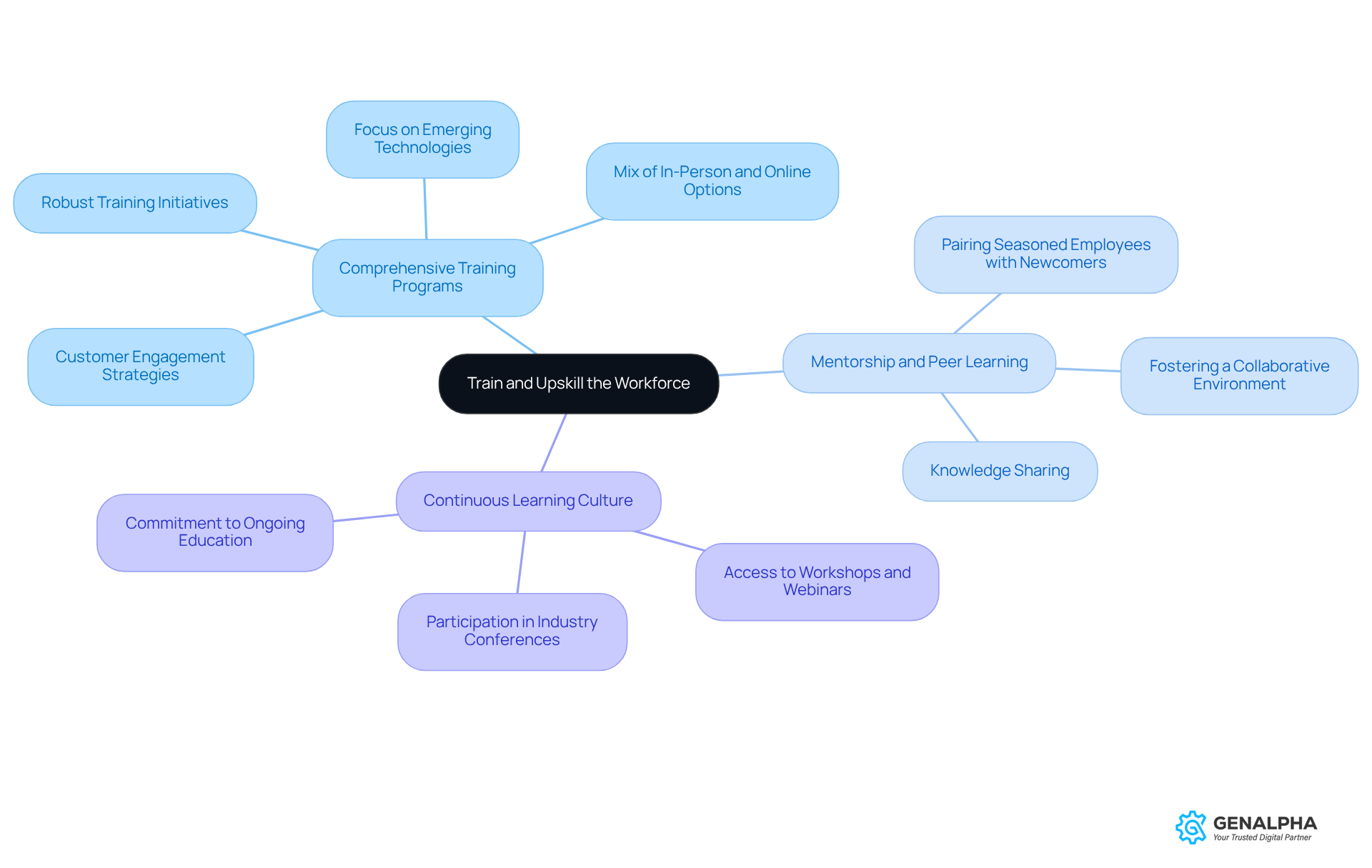

To really tap into the perks of technological transformation, manufacturers need to focus on training and upskilling their workforce. So, how can they do this effectively? Here are a few key strategies:

- Comprehensive Training Programs: Let’s kick things off with robust training initiatives that cover emerging technologies, innovative processes, and better customer engagement strategies. Mixing in-person and online training options can cater to different learning styles, making it accessible for everyone on the team.

- Mentorship and Peer Learning: How about pairing seasoned employees with newer team members? This mentorship approach not only helps newcomers adjust to electronic tools and procedures but also fosters a collaborative environment where knowledge flows freely.

- Continuous Learning Culture: It’s all about creating a culture of continuous learning! By giving employees access to workshops, webinars, and industry conferences, you’re showing a commitment to ongoing education. This way, your workforce stays in the loop with the latest trends and tech advancements.

Did you know that nearly 60% of employees will need training before 2030 due to rapid technological changes? That’s a wake-up call for manufacturers to invest in upskilling initiatives! Plus, 81% of manufacturers are ready to pour resources into new tech to boost productivity, which highlights just how crucial it is to equip the workforce with the right skills. And let’s not forget the skills gap-fewer than half of candidates have the high-demand tech skills needed today. By embracing these best practices, organizations can gear up their workforce for the challenges and opportunities outlined in the digital transformation roadmap for manufacturing. So, what’s the next step for your team?

Conclusion

Creating a digital transformation roadmap for manufacturing isn’t just a good idea; it’s essential for organizations that want to thrive in today’s competitive landscape. Have you taken a good look at your current digital maturity? By assessing where you stand, setting clear objectives, and pinpointing the right technologies, manufacturers can strategically position themselves for success. This structured approach not only sparks innovation but also aligns your initiatives with broader business goals and what your stakeholders expect.

Let’s dive into some key insights. It’s crucial to conduct a thorough evaluation of your existing technologies and processes. Establishing SMART goals is a game changer, and prioritizing the right digital tools can make all the difference. Plus, developing a solid implementation plan and investing in workforce training are vital steps that ensure your transformation initiatives run smoothly. Together, these steps lay a strong foundation for achieving your desired outcomes and boosting productivity in manufacturing.

As the manufacturing sector keeps evolving, embracing digital transformation isn’t just an option anymore; it’s a necessity. Organizations need to prioritize these strategies to stay competitive and agile in a fast-changing environment. By committing to this transformative journey, manufacturers can unlock new opportunities, enhance operational efficiency, and ultimately secure a leading position in the market. So, why wait? Now’s the time to take action and invest in the future of manufacturing with a well-crafted digital transformation roadmap.

Frequently Asked Questions

What is the first step in creating a digital transformation roadmap?

The first step is to assess the current digital maturity of your organization by evaluating existing technology, processes, and cultural readiness for change.

How can I evaluate my organization's technology?

Conduct a technology audit to take stock of the digital tools and platforms currently in use, including ERP systems, eCommerce solutions, and data analytics tools.

What should I look for in a process evaluation?

During a process evaluation, identify existing workflows and check for bottlenecks or areas that could be improved.

Why is cultural readiness important in digital transformation?

Cultural readiness is important because it reflects how open your organization is to change and how employees feel about adopting new technologies.

What are SMART goals?

SMART goals are objectives that are Specific, Measurable, Achievable, Relevant, and Time-bound, such as aiming to boost online sales by a certain percentage within a year.

Why is engaging stakeholders crucial in the transformation process?

Engaging stakeholders is crucial because it helps gather diverse perspectives and fosters buy-in, which increases the likelihood of successfully hitting change objectives.

What is the purpose of a vision statement in digital transformation?

A vision statement captures the desired future state of the organization post-transformation and guides actions to align with both employee and customer expectations.

What is the projected growth of the global tech evolution market?

The global tech evolution market is projected to reach $3.4 trillion by 2026, highlighting the urgency and importance of digital transformation initiatives.