Introduction

The sales landscape for equipment manufacturers is changing fast, right? With the push for efficiency and accuracy in a more complex market, it’s no surprise that Configure, Price, Quote (CPQ) software is becoming a hot topic. Manufacturers are finding that automating their quoting processes not only saves time but also boosts customer engagement. But here’s the kicker: as they shift away from traditional sales methods - often bogged down by delays and inaccuracies - they’re left wondering: how can embracing CPQ technology not just streamline operations but also redefine what success looks like in this competitive environment?

Let’s think about it. Imagine a world where quoting is quick and accurate, where you can focus more on building relationships with your customers rather than getting lost in paperwork. Sounds appealing, right? That’s the promise of CPQ technology. It’s not just about making things easier; it’s about transforming the way we do business. So, how can we take that leap? Let’s explore!

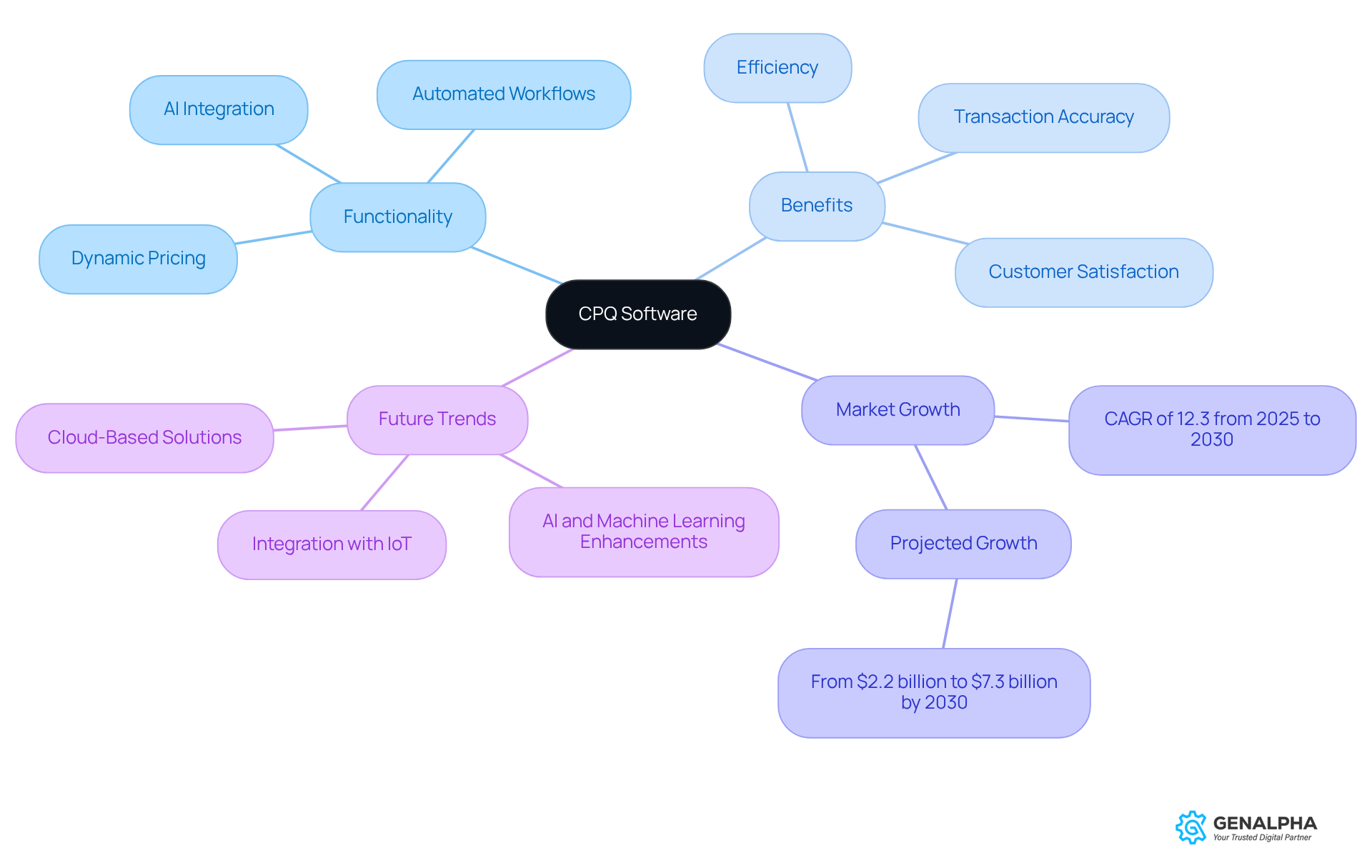

Define CPQ Software and Its Functionality

Have you ever found yourself bogged down in the details of creating quotes for complex products? That’s where the CPQ market, which includes Configure, Price, Quote applications, comes into play. These tools are game-changers for companies, allowing them to whip up accurate estimates for intricate products in no time. By automating everything from product configuration to pricing calculations and quote generation, CPQ systems empower teams to respond to customer inquiries with impressive speed and precision. This is especially beneficial for equipment manufacturers, who often juggle customizable products that require exact specifications. With built-in product rules and pricing frameworks, CPQ tools help cut down on mistakes and boost the overall efficiency of the sales process.

Looking ahead to 2026, the advantages of CPQ software for equipment manufacturers are clearer than ever. The CPQ market is projected to skyrocket from $2.2 billion to $7.3 billion by 2030, growing at a compound annual growth rate of 12.3% from 2025 to 2030. Manufacturers are starting to realize just how vital these tools are for streamlining operations and improving transaction accuracy. For instance, companies that have embraced CPQ automation report transaction cycle reductions of 10-15% and deal sizes increasing by up to 20%. That’s a significant impact!

So, what exactly can CPQ tools do? They offer dynamic pricing that updates in real-time based on the configurations you select, along with automated workflows that speed up the approval process for quotes. These features not only quicken transactions but also ensure compliance with pricing regulations and internal business rules. Plus, the latest trends in CPQ software are all about integrating AI and machine learning, which provide smart recommendations and predictive insights to further optimize the sales process.

As Nicole Epstein puts it, "CPQ (Configure, Price, Quote) tools have revolutionized the commercial sector." Real-world examples back this up, showing how CPQ tools enhance transaction accuracy. Manufacturers dealing with complex product configurations have used CPQ automation to streamline product setup, integrate real-time data, and boost quote accuracy, leading to better operational efficiency. And let’s not forget about customer-facing portals - they enhance satisfaction by allowing real-time updates and customization. As commerce automation continues to evolve, CPQ software is becoming a must-have for equipment producers looking to thrive in the CPQ market.

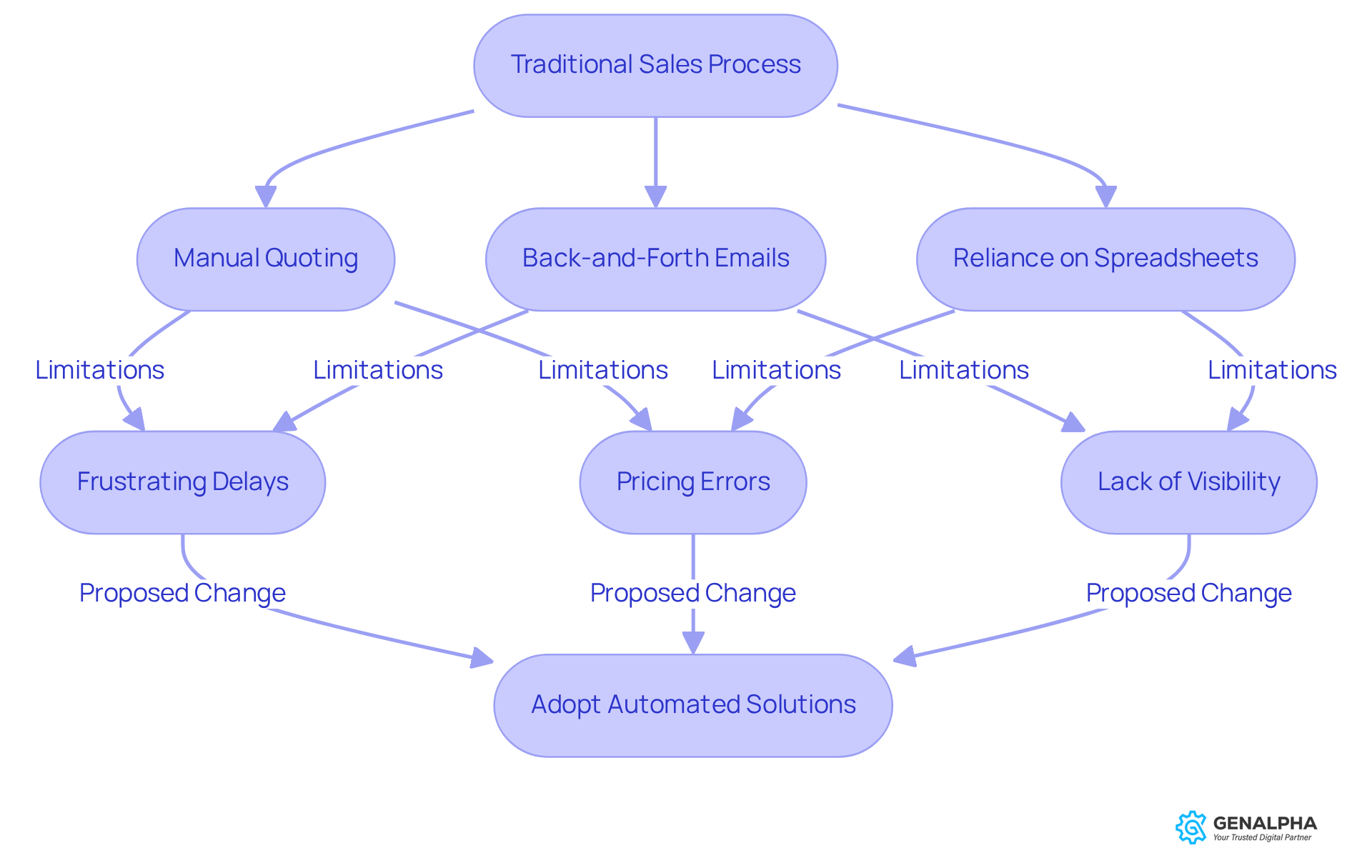

Explore Traditional Sales Processes and Their Limitations

Have you ever felt bogged down by the lengthy processes in equipment production? Conventional methods often involve tedious manual quoting, endless back-and-forth emails, and a heavy reliance on spreadsheets. This can lead to frustrating delays, pricing errors, and a lack of visibility into what’s really happening with inventory and customer needs. It’s no wonder that sales agents struggle to provide quick responses to customer inquiries, which can mean missed opportunities and unhappy clients.

Looking ahead, the average sales cycle for equipment manufacturers in 2026 is expected to be heavily influenced by these inefficiencies. Many deals could stretch beyond six months, especially those larger transactions over USD 250,000. In fact, 58% of companies say they lose sales deals due to project funding being pulled, which really highlights how crucial timely quoting is.

So, what’s the solution? The limitations of these outdated processes make a strong case for adopting a more efficient and automated approach, particularly within the cpq market. By embracing these tools, manufacturers can not only improve their revenue efficiency in the cpq market but also enhance overall client engagement. Why not take that step towards a smoother, more effective sales process?

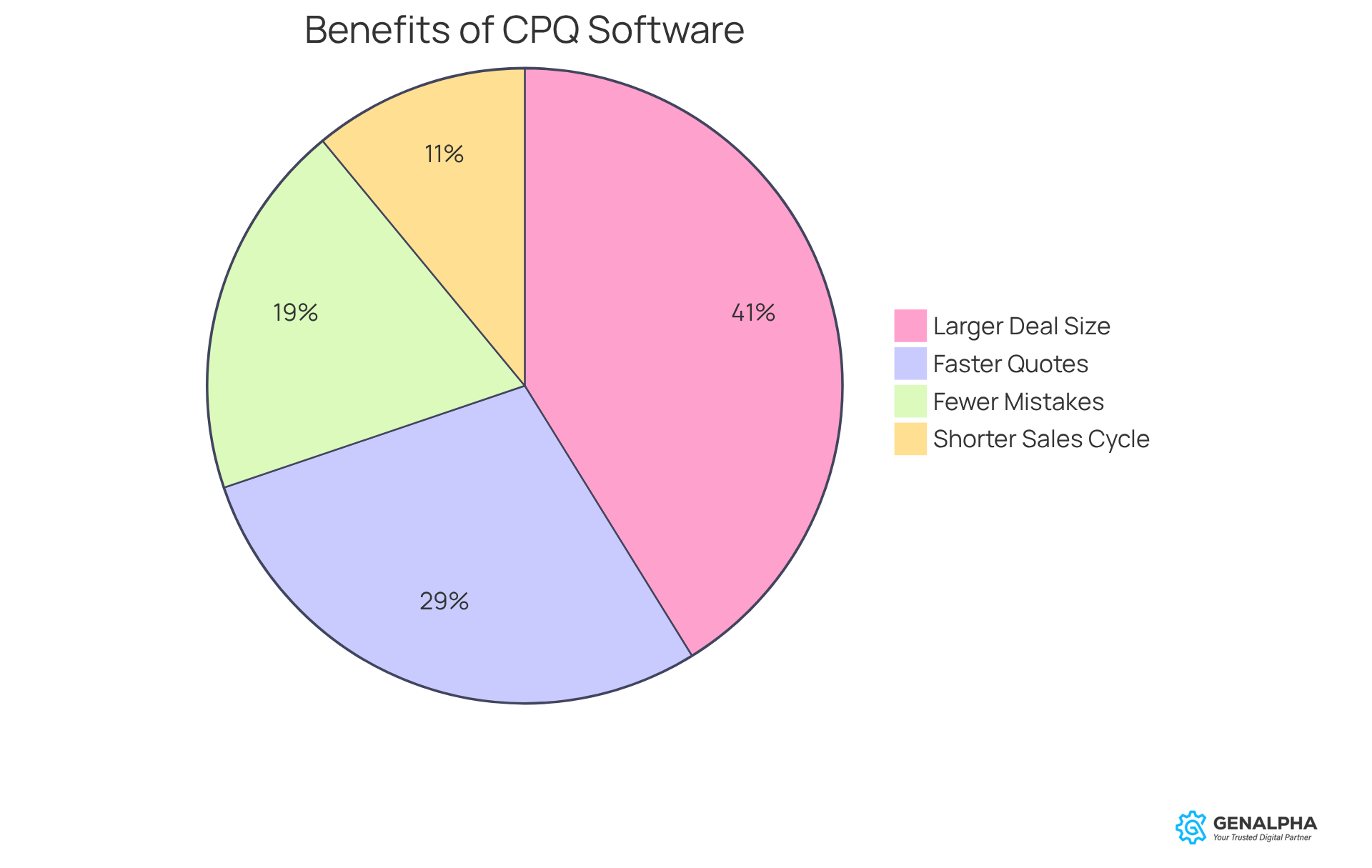

Compare Benefits of CPQ Software vs. Traditional Sales Methods

Have you ever felt bogged down by the slow process of generating quotes? Well, the CPQ market is set to change that for equipment manufacturers! Imagine cutting down quote generation time by a whopping 73%. That’s right - teams can respond to inquiries with impressive speed, making a real difference in how they engage with customers.

But it doesn’t stop there. With CPQ, pricing and configuration tasks are automated, which means fewer mistakes and more accurate quotes. Plus, real-time data insights allow sales teams to make informed decisions based on current inventory and pricing strategies. How cool is that?

Organizations that embrace CPQ software also see a 28% reduction in their sales cycle length. This gives sales teams more time to focus on what really matters: building relationships with customers and strategizing for success. On the flip side, traditional sales methods can lead to inconsistencies and delays, which can hurt customer satisfaction and overall sales performance.

By streamlining these processes, CPQ applications not only enhance operational efficiency but also elevate the customer experience in the CPQ market. And here’s a stat that might surprise you: companies using CPQ solutions often see a 105% increase in their average deal size. That’s a significant boost to revenue!

So, why stick with outdated methods like spreadsheets? In today’s competitive landscape, investing in the CPQ market isn’t just smart - it’s essential. Ready to take your sales process to the next level?

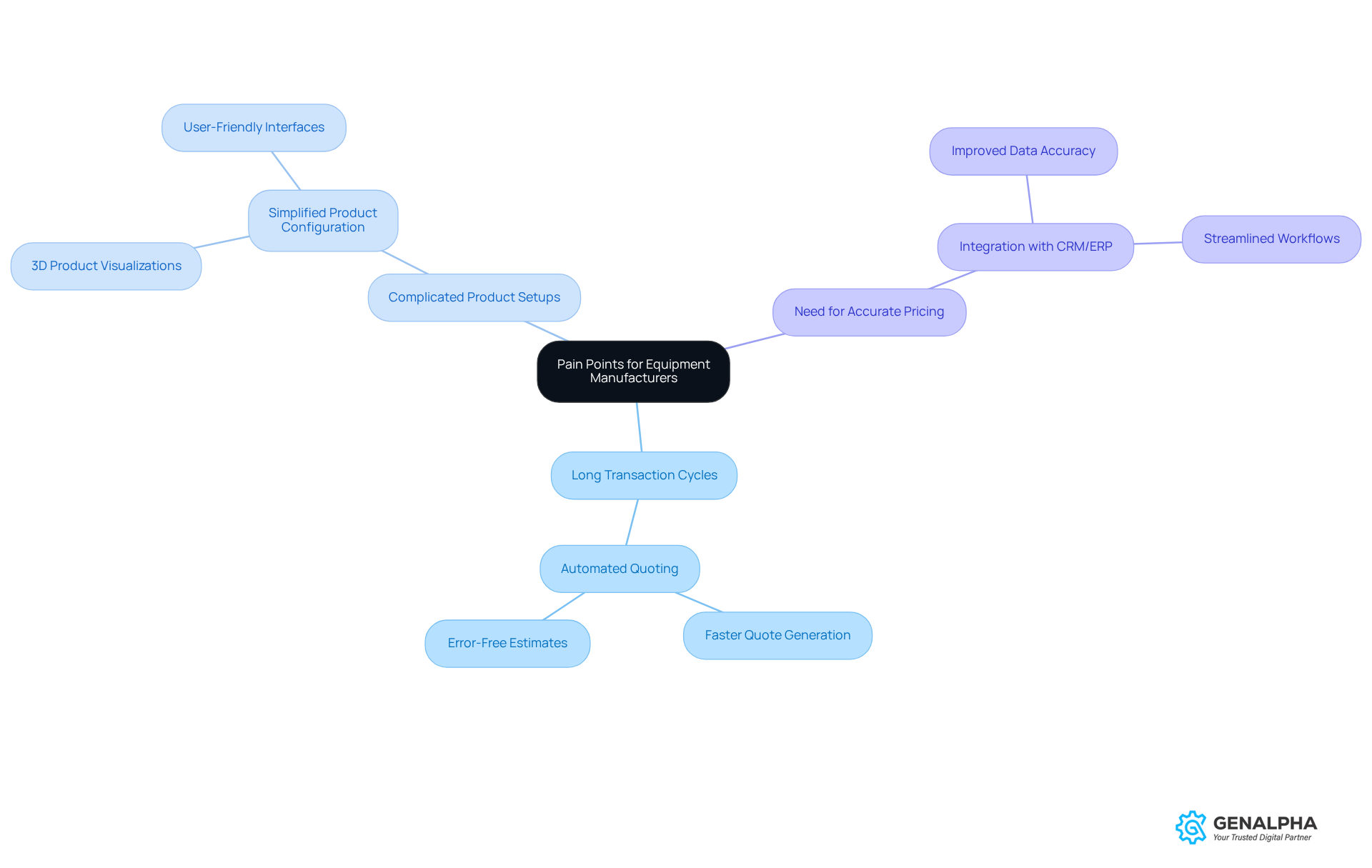

Identify Pain Points for Equipment Manufacturers and CPQ Solutions

Equipment producers often run into some pretty big hurdles. Think about it: long transaction cycles, complicated product setups, and the need for spot-on pricing. These issues can leave clients feeling frustrated and lead to missed business opportunities. Plus, with economic uncertainty looming, demand for manufactured products is likely to take a hit, making the market even trickier to navigate.

So, how can solutions in the CPQ market assist? They tackle these challenges head-on by automating the quoting process. This means that sales reps can whip up accurate estimates tailored to client needs in no time. And let’s not forget about the importance of integrating CPQ with CRM and ERP systems. This integration is key to boosting data accuracy and streamlining workflows.

But that’s not all! CPQ systems also make product configuration a breeze. Users can visualize their options and make informed choices, which is a game-changer. By simplifying the sales process, CPQ not only ramps up customer satisfaction but also enhances sales efficiency. In a competitive market, that’s a win-win!

Here’s a striking fact: CPQ applications can cut quote completion times by over 50%! That’s why the CPQ market is becoming essential for manufacturers looking to sharpen their sales strategies. So, why not consider how CPQ could transform your approach?

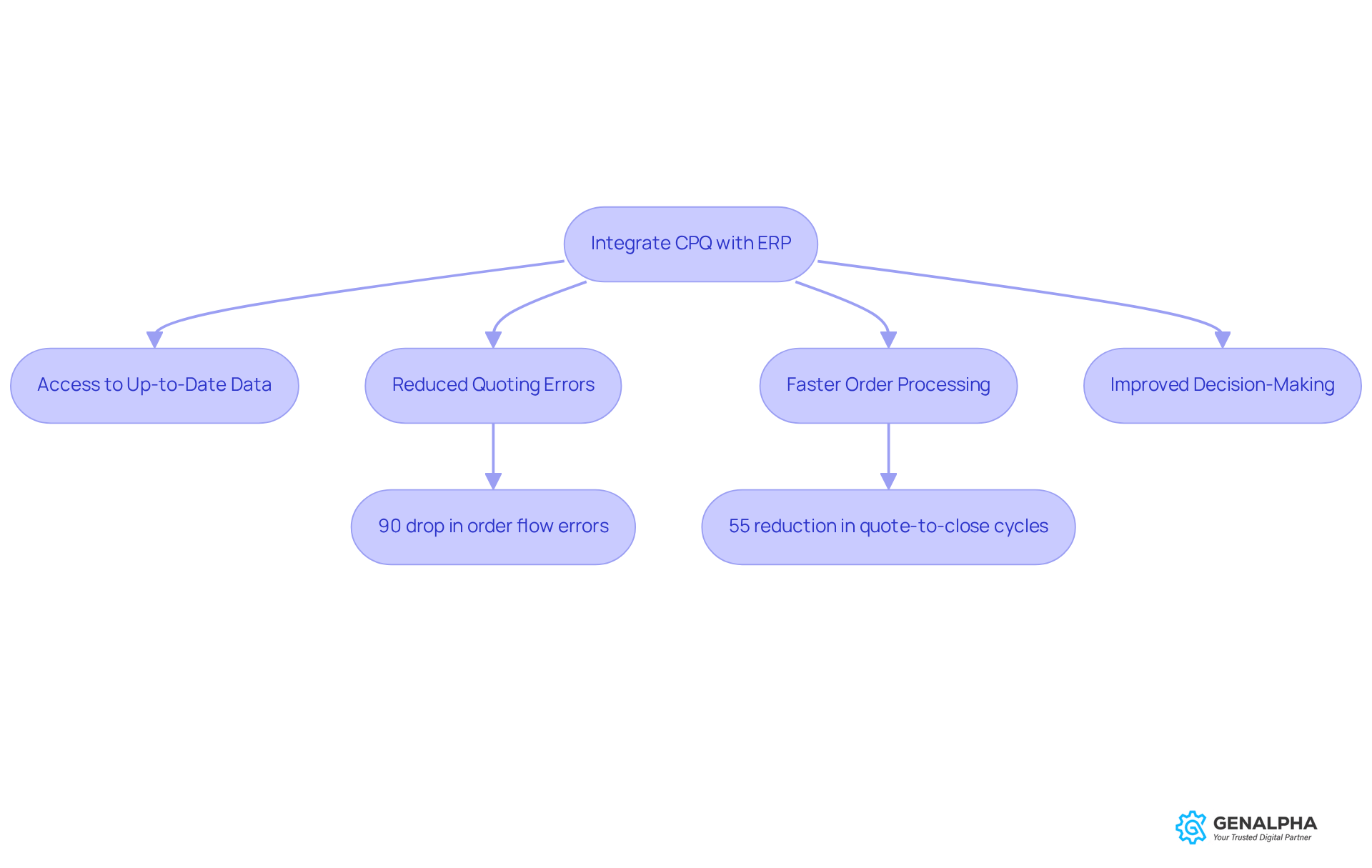

Examine Integration of CPQ with ERP Systems

Integrating CPQ software with ERP systems is a game-changer for equipment manufacturing. Imagine having a seamless flow of data between your marketing and operational teams - sounds great, right? This integration means your reps can instantly access up-to-date inventory levels, pricing, and client info. By syncing these systems, manufacturers can cut down on quoting and order processing errors, leading to quicker turnaround times and happier customers.

For example, companies that have made this leap report up to a 90% drop in order flow errors and a 55% reduction in quote-to-close cycles. That’s impressive! Plus, this integration boosts visibility across departments, which helps sales and production teams make better decisions together.

Current trends show that more businesses are jumping on board with cloud-based solutions like Salesforce CPQ and ERP systems. These tools not only streamline operations but also ramp up efficiency. As industry experts point out, organizations within the CPQ market that have integrated CPQ-ERP ecosystems consistently outperform their competitors, enjoying higher win rates and better profit margins.

So, if you’re looking to accelerate revenue and stay competitive in a fast-paced market, it’s time to consider this strategic transformation. What are you waiting for?

Conclusion

The power of CPQ (Configure, Price, Quote) software is really changing the game for equipment manufacturers. It offers a smoother way to handle sales, tackling the tricky parts of product customization and pricing. By automating the quoting process, CPQ tools boost efficiency and cut down transaction times, letting manufacturers respond to customer inquiries with impressive speed and accuracy. In a market that craves quick and precise service, this shift is essential for staying competitive.

As we’ve seen, traditional sales methods often come with their own set of challenges - delays, errors, and unhappy customers. But the perks of adopting CPQ solutions are hard to ignore. They lead to better quote accuracy, shorter sales cycles, and improved customer engagement. Plus, when CPQ integrates with ERP systems, it takes these benefits to the next level, creating a smooth flow of information that helps with decision-making and operational efficiency.

In today’s fast-paced market, using CPQ software isn’t just a nice-to-have; it’s a must for equipment manufacturers who want to succeed. Embracing these innovative tools can really boost sales performance and customer satisfaction. So, why not take proactive steps to integrate CPQ solutions into your sales processes? This way, you can stay agile and responsive in an increasingly competitive environment. The future of sales in equipment manufacturing is here, and it’s time to tap into the full potential of CPQ technology!

Frequently Asked Questions

What is CPQ software and what functionality does it provide?

CPQ software, which stands for Configure, Price, Quote, helps companies create accurate estimates for complex products quickly. It automates product configuration, pricing calculations, and quote generation, enabling teams to respond to customer inquiries with speed and precision.

How does CPQ software benefit equipment manufacturers?

CPQ software is particularly beneficial for equipment manufacturers as it helps manage customizable products that require specific configurations. It reduces mistakes, enhances efficiency, and can lead to transaction cycle reductions of 10-15% and deal sizes increasing by up to 20%.

What are some key features of CPQ tools?

Key features of CPQ tools include dynamic pricing that updates in real-time based on selected configurations, automated workflows for faster quote approvals, compliance with pricing regulations, and integration of AI and machine learning for smart recommendations and predictive insights.

How is the CPQ market expected to grow in the coming years?

The CPQ market is projected to grow from $2.2 billion to $7.3 billion by 2030, with a compound annual growth rate of 12.3% from 2025 to 2030, indicating a rising recognition of its importance for streamlining operations and improving transaction accuracy.

What are the limitations of traditional sales processes in equipment production?

Traditional sales processes often involve manual quoting, extensive email exchanges, and reliance on spreadsheets, leading to delays, pricing errors, and a lack of visibility into inventory and customer needs. This can result in missed opportunities and dissatisfied clients.

What impact do inefficiencies in traditional sales processes have on sales cycles?

Inefficiencies in traditional sales processes can extend the average sales cycle for equipment manufacturers beyond six months, especially for larger transactions over USD 250,000. Additionally, 58% of companies report losing sales deals due to project funding being pulled, highlighting the need for timely quoting.

How can manufacturers improve their sales processes?

Manufacturers can improve their sales processes by adopting automated CPQ tools, which enhance revenue efficiency and client engagement, ultimately leading to a smoother and more effective sales process.