Introduction

The manufacturing landscape is changing fast, and with that change, the need for efficiency and accuracy in quoting processes is more important than ever. Have you ever felt overwhelmed by the quoting process? Well, that’s where Configure, Price, Quote (CPQ) software comes in. It’s a game-changer for manufacturers, helping to streamline operations and boost customer satisfaction with quicker, more accurate quotes.

But let’s be real - implementing CPQ isn’t always a walk in the park. There are challenges to tackle, like integrating with existing systems and ensuring data accuracy. So, how can manufacturers navigate these hurdles to truly reap the benefits of CPQ software?

By understanding these complexities, we can unlock the full potential of CPQ and make quoting a breeze. Let’s dive in!

Define CPQ Software and Its Role in Manufacturing

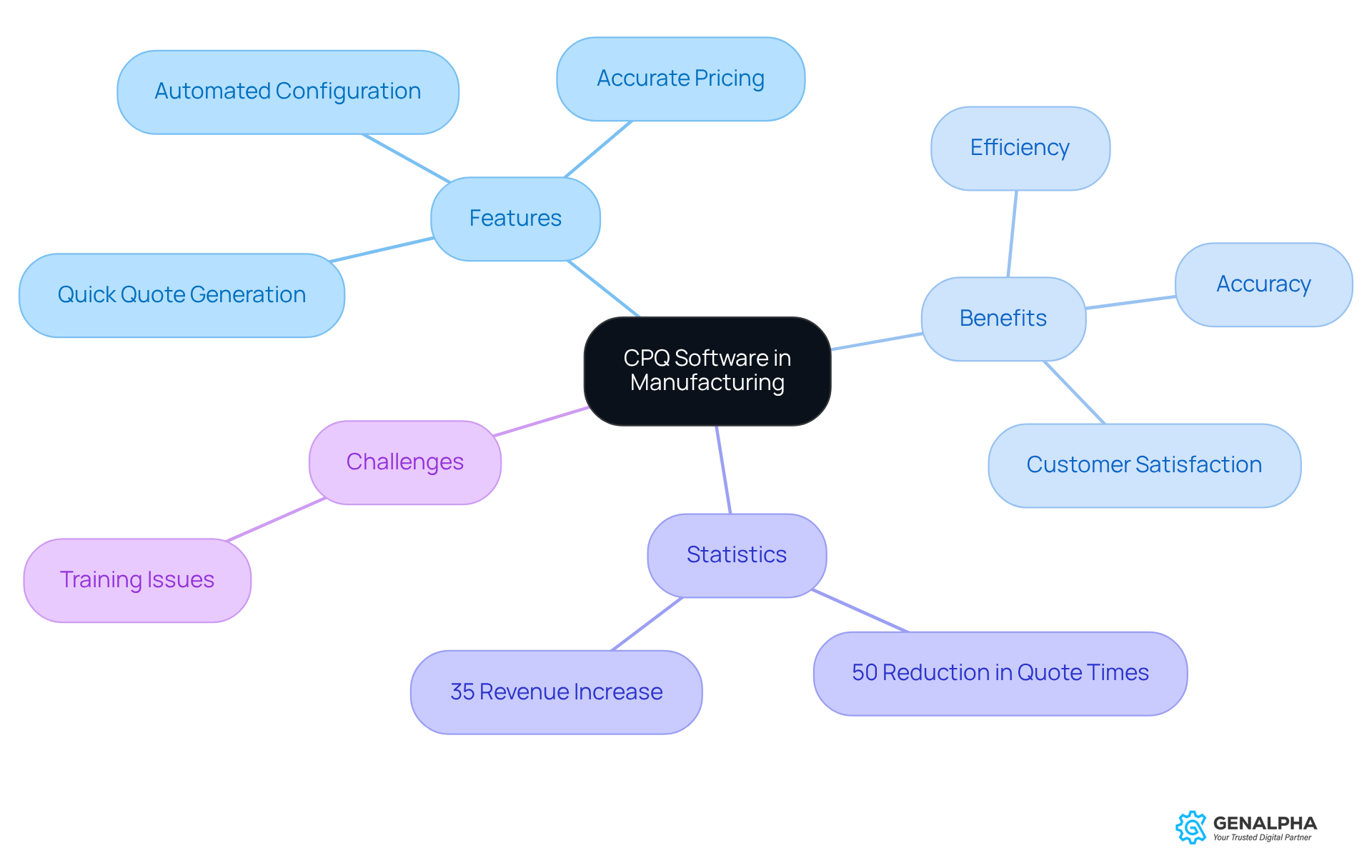

Have you ever found yourself tangled in the complexities of quoting for a custom product? That’s where Configure, Price, Quote (CPQ) applications come into play! These tools are game-changers for manufacturers, designed to streamline the quoting process by automating the configuration of intricate products, ensuring accurate pricing, and whipping up quotes in no time.

In an industry filled with diverse product configurations and tricky pricing variables, industrial CPQ software truly stands out. It boosts efficiency and accuracy in transactions, making life easier for everyone involved. Imagine this: a commercial team can easily pull together product specs, pricing guidelines, and discount frameworks to generate quotes that reflect real-time information. This not only cuts down on mistakes but also keeps customers happy. For instance, a manufacturer using CPQ can quickly create a quote for a customized piece of machinery, ensuring that every detail is spot on. How cool is that?

This capability doesn’t just speed up sales cycles; it also builds stronger relationships with customers. When clients receive timely and reliable information tailored to their needs, it makes a world of difference. In fact, CPQ tools can slash quote completion times by over 50%! That’s a huge win for efficiency.

But wait, there’s more! Manufacturers adopting CPQ tools are seeing some impressive results, with reports of up to a 35% increase in revenue within the first year. And the future looks bright for CPQ technology, with the market projected to grow to USD 3.92 billion by 2026 and around USD 10.84 billion by 2035. Clearly, industrial CPQ software solutions are becoming essential in the manufacturing sector.

However, it’s not all smooth sailing. Organizations need to be mindful of common pitfalls in CPQ implementation, like training challenges that can slow down effective adoption. By integrating insights from industry leaders, we can better understand the advantages of CPQ tools and how they can enhance efficiency in selling. So, are you ready to explore the benefits of CPQ for your business?

Integrate CPQ with ERP Systems for Enhanced Efficiency

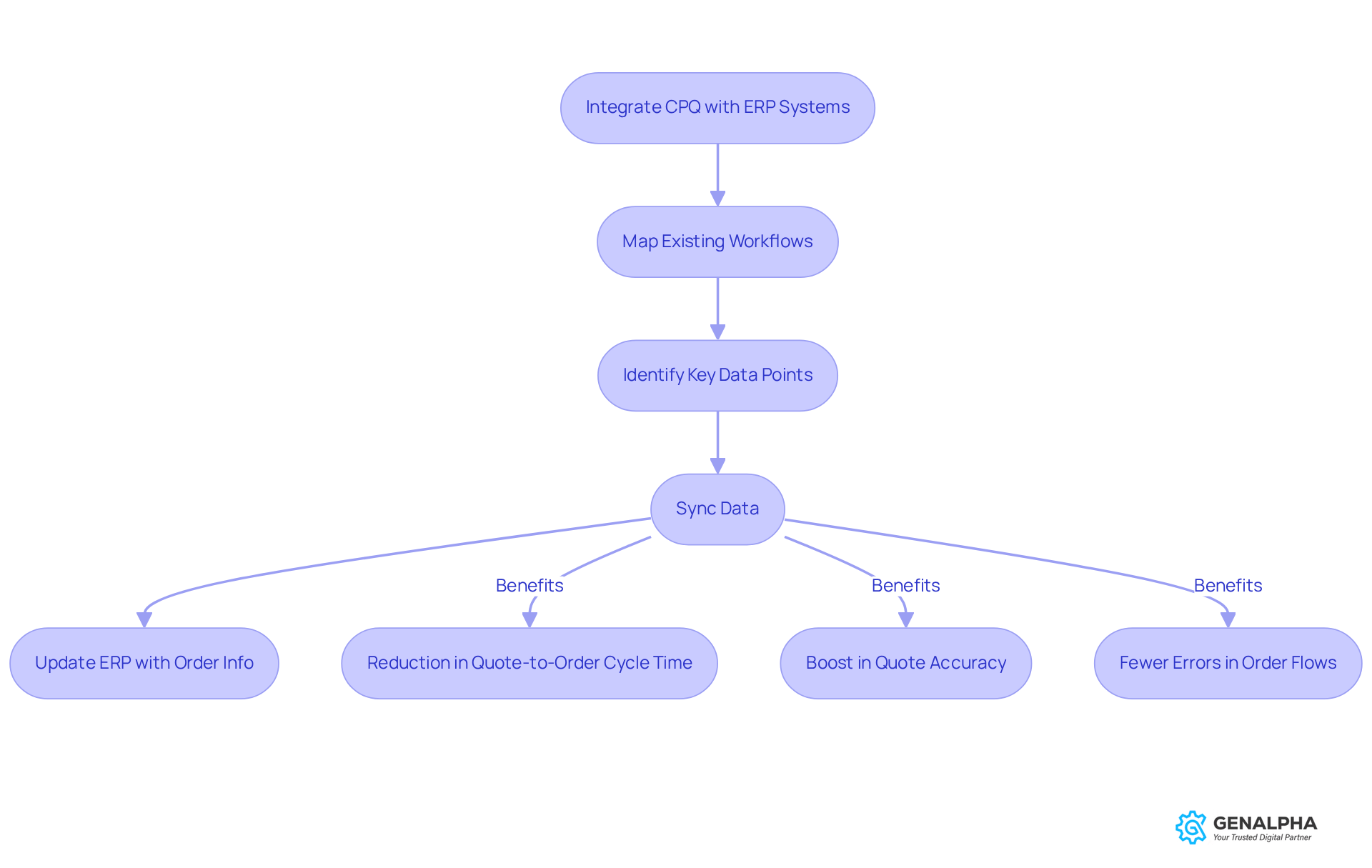

Integrating industrial cpq software with Enterprise Resource Planning (ERP) systems is a game-changer for enhancing operational efficiency in manufacturing. Imagine this: your sales team has real-time access to the latest product details, pricing, and inventory levels. Sounds great, right? This integration makes that possible by allowing seamless information sharing between marketing and production.

So, how does it work? It all starts with mapping out your existing workflows and pinpointing key data points that need to sync up. For instance, when a sales rep creates a quote using CPQ, the system can automatically update the ERP with the relevant order info. This not only cuts down on manual entry mistakes but also speeds up the order fulfillment process. Plus, it helps with inventory management. By aligning sales forecasts with production schedules, you can allocate resources better and reduce lead times.

Organizations that embrace industrial cpq software along with ERP integration often see impressive results, including:

- A 40-60% reduction in quote-to-order cycle time

- A 25-35% boost in quote accuracy

And get this: companies with integrated systems report up to 90% fewer errors in order flows. That’s a huge win for operational efficiency! Not to mention, businesses with integrated quote-to-cash processes tend to win 34% more competitive deals thanks to their superior responsiveness and pricing accuracy.

Take SportSafe, for example. They managed to cut their quote generation time by a whopping 80% after implementing an integrated platform. But it’s not all smooth sailing. Manufacturers need to be cautious about potential pitfalls during the integration process. Careful assessment of application choices and aligning internal processes are crucial to avoid complications.

So, are you ready to explore how CPQ-ERP integration can transform your operations? Let’s dive in!

Implement Effective Training and Change Management Strategies

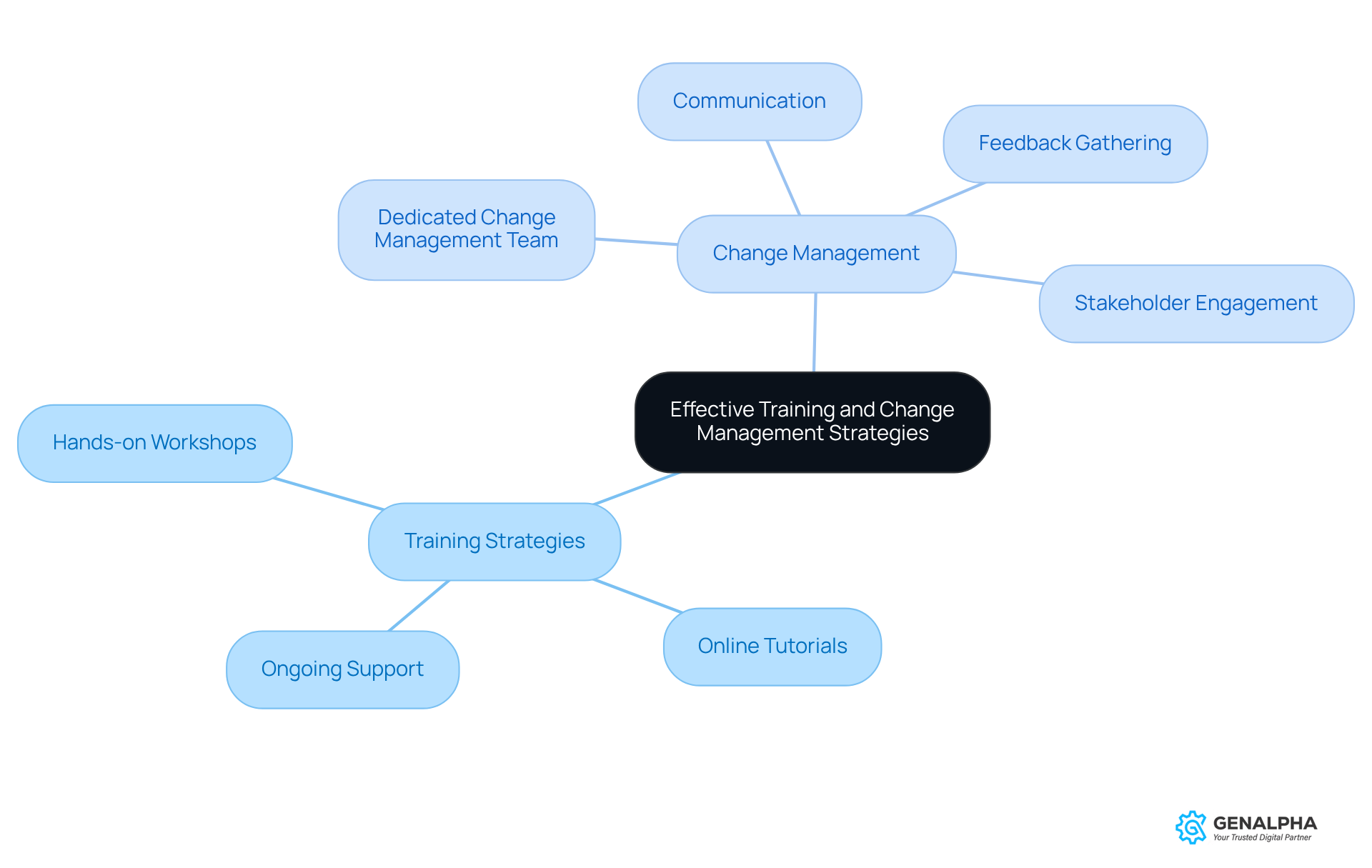

To make CPQ software implementation a success, manufacturers really need to focus on solid training and change management strategies. Have you ever thought about how a thorough needs evaluation can help? It’s all about figuring out what different user groups - like sales teams, customer service folks, and management - actually need. A well-rounded training program should include:

- Hands-on workshops

- Online tutorials

- Ongoing support to tackle user questions and challenges effectively

For instance, role-playing scenarios can give sales teams a chance to practice using the CPQ system in real-life situations, boosting their confidence and skills.

Now, let’s talk about the importance of having a dedicated change management team. This team plays a key role in keeping communication flowing across the organization. They can tackle concerns head-on and gather feedback throughout the transition, which is crucial for overcoming any resistance to change. Engaging stakeholders at all levels helps create a culture of continuous improvement. This not only enhances user satisfaction but also optimizes how the CPQ system is used. Good change management aligns the implementation with organizational goals and ensures that employees feel supported and ready to adapt to new processes. This leads to a smoother transition and better operational efficiency.

So, what do you think? Are you ready to prioritize training and change management for your CPQ implementation?

Ensure Data Accuracy and Maintenance for Optimal Performance

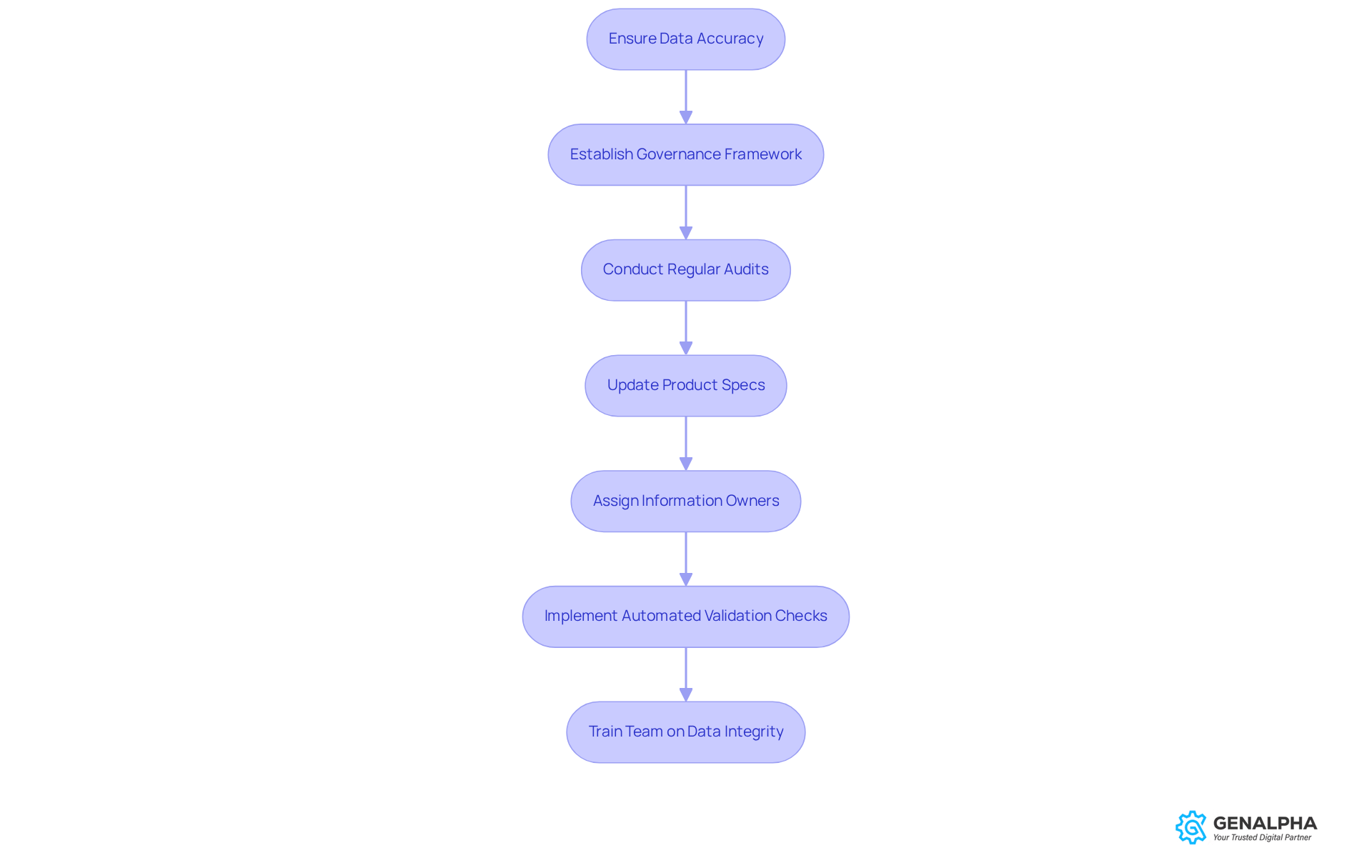

When it comes to CPQ software in manufacturing, ensuring information accuracy is absolutely crucial. Think about it: without a solid governance framework, things can quickly go off the rails. Regular audits and updates of product specs, pricing structures, and discount rules are a must. Plus, assigning information owners to keep an eye on specific datasets helps ensure that any changes are carefully tracked and communicated among the right teams.

For example, imagine if a product's price changes. Wouldn't it be a hassle if existing quotes weren't updated? That's where automated information validation checks come in handy. They can flag any quotes that might be affected, allowing for timely adjustments. And let’s not forget about training your team on the importance of information integrity. Providing them with the right tools fosters a culture of responsibility, leading to more accurate quotes and, ultimately, greater customer trust.

Industry leaders emphasize that effective information governance not only minimizes risks related to inaccuracies but also boosts overall operational efficiency. This makes it a vital part of successful CPQ implementation. Did you know that companies using CPQ applications see an average increase of 17% in conversion rates? That’s a pretty compelling reason to prioritize information accuracy!

As Cincom puts it, 'Industrial CPQ software for manufacturing addresses these challenges by automating quoting processes and integrating seamlessly with industrial operations.' This really highlights how important data governance is for achieving operational success. So, what steps are you taking to ensure your information is accurate?

Conclusion

Implementing industrial CPQ software in manufacturing isn’t just about upgrading technology; it’s a strategic move that can really boost your operational efficiency and customer satisfaction. Imagine automating those complex quoting processes-suddenly, workflows become smoother, errors drop, and your bottom line starts to look a lot healthier. Plus, when you integrate CPQ with ERP systems, you’re not just amplifying these benefits; you’re gaining real-time access to crucial information that aligns your sales efforts with what your production can actually handle.

Now, let’s talk about some key insights. Effective training and change management strategies are vital for a successful CPQ implementation. Organizations that focus on user training and foster a supportive environment for change tend to see significant improvements in quoting accuracy and speed. And don’t forget about data integrity! Regular audits and governance practices are essential for getting the most out of your CPQ systems, leading to higher conversion rates and building trust with your customers.

So, what’s the takeaway? The journey to successful CPQ implementation in manufacturing is complex, but with careful planning and execution, it’s totally achievable. By embracing these best practices, you’re not just positioning yourself to meet the challenges of a competitive market; you’re also nurturing a culture of continuous improvement. As the industry evolves, leveraging CPQ technology effectively will be key to staying ahead. So, why wait? Now’s the perfect time to take action and explore how these tools can truly transform your operations!

Frequently Asked Questions

What is CPQ software and what role does it play in manufacturing?

CPQ software, or Configure, Price, Quote software, is designed to streamline the quoting process for manufacturers by automating product configuration, ensuring accurate pricing, and generating quotes quickly.

How does CPQ software improve efficiency and accuracy in transactions?

CPQ software boosts efficiency by allowing commercial teams to easily access product specifications, pricing guidelines, and discount frameworks, which helps in generating accurate quotes and reducing mistakes.

What benefits do manufacturers experience by using CPQ tools?

Manufacturers using CPQ tools can expect to see a reduction in quote completion times by over 50% and an increase in revenue by up to 35% within the first year of adoption.

How does CPQ software impact customer relationships?

CPQ software enhances customer relationships by providing timely and reliable information tailored to client needs, which improves customer satisfaction and trust.

What is the projected market growth for CPQ technology?

The CPQ technology market is projected to grow to USD 3.92 billion by 2026 and around USD 10.84 billion by 2035.

What challenges might organizations face when implementing CPQ software?

Organizations may encounter challenges such as training difficulties that can hinder effective adoption of CPQ tools.

Why is CPQ software becoming essential in the manufacturing sector?

CPQ software is becoming essential in manufacturing due to its ability to enhance efficiency in selling, improve accuracy in quotes, and drive revenue growth.