Overview

Have you ever thought about how the Bill of Materials (BOM) management process could be more efficient? This article dives into just that, exploring some fantastic strategies that can really boost efficiency, accuracy, and collaboration in manufacturing operations. It’s all about making things work better for you!

So, what’s the secret sauce? Well, it starts with integrating BOM with ERP systems. Imagine having all your data in one place—that’s a game changer! Maintaining accurate data is another key piece of the puzzle. When you get this right, you’ll see fewer errors and a smoother workflow.

But wait, there’s more! Leveraging technology can further enhance your operations. Think about improved communication and how it can lead to better operational performance in manufacturing. Who wouldn’t want that?

In conclusion, optimizing your BOM management process isn’t just a nice-to-have; it’s essential for success. So, why not take the first step today? Let’s make your manufacturing operations the best they can be!

Introduction

Navigating the complexities of Bill of Materials (BOM) management can often feel like a daunting task for manufacturers, can't it? But here's the good news: with the right strategies in place, organizations can turn this critical process into a streamlined operation that boosts efficiency and accuracy. In this article, we're diving into nine powerful strategies designed to optimize BOM management. These insights into best practices can lead to significant improvements in production workflows and overall business performance.

So, what happens when traditional methods fall short? How can manufacturers tap into innovative solutions to not just keep up with industry demands but also gain a competitive edge? Let's explore together!

GenAlpha Technologies Equip360: Streamline BOM Management for Manufacturers

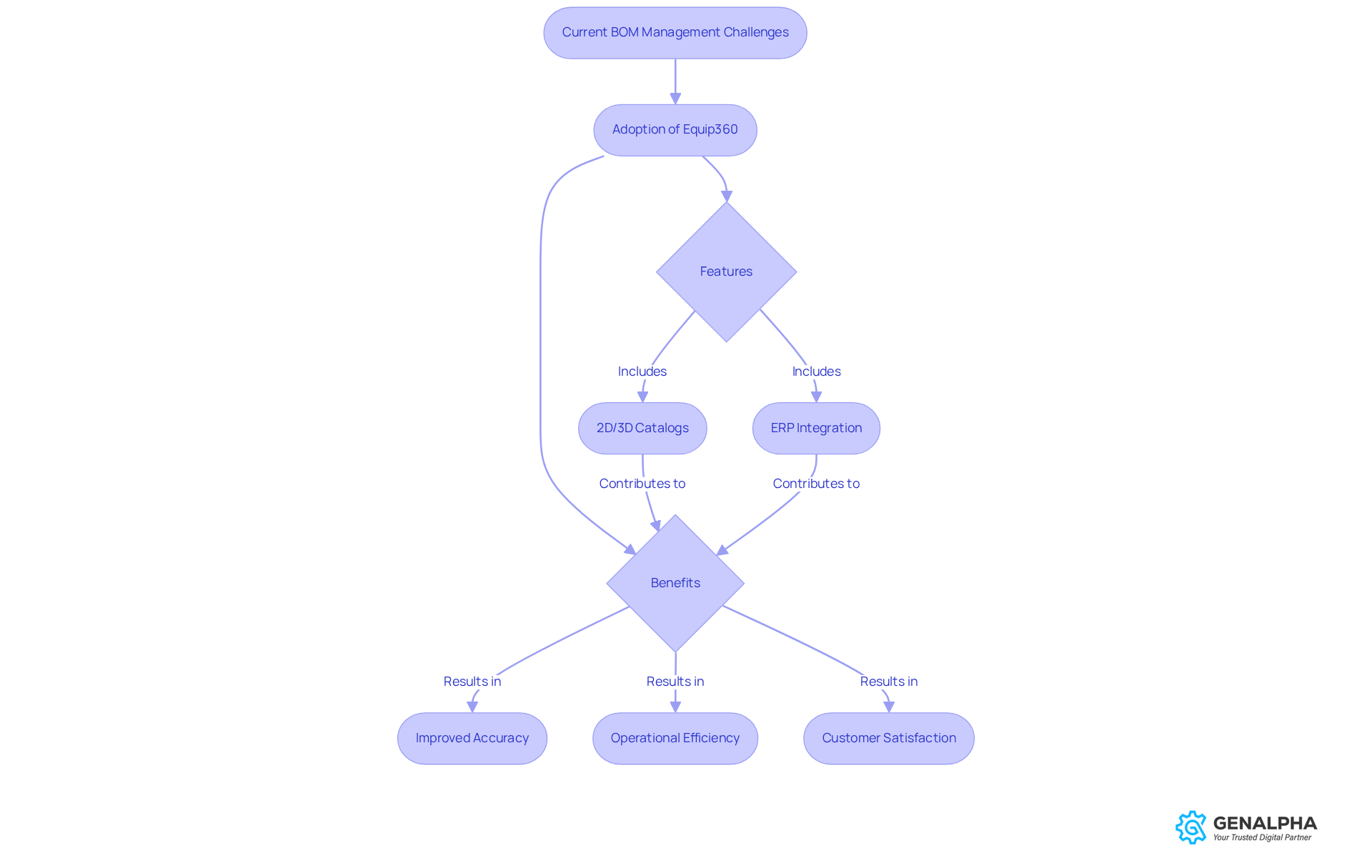

Have you ever found yourself tangled in the complexities of the BOM management process? Well, Equip360 is here to change that! Designed specifically for manufacturers and distributors, this platform offers a powerful solution that transforms how you handle your BOM. With its interactive 2D and 3D catalogs, you can quickly find parts, access manuals, and manage your inventory like a pro.

But that’s not all—Equip360 seamlessly integrates with ERP systems, ensuring your BOM data is always up-to-date. This means fewer errors and a boost in operational efficiency. Imagine how much smoother your BOM management process could be, which would also positively impact customer satisfaction with accurate and timely information.

Success stories from manufacturers who have embraced Equip360 speak volumes. They’ve experienced improved accuracy and shorter lead times, proving just how effective this platform can be in enhancing the BOM management process. As we navigate the ever-evolving digital landscape, Equip360 stands out as a must-have resource for manufacturers eager to adapt to the latest technological advancements.

So, why wait? Implementing the digital thread into your BOM management process can create a significant impact for all stakeholders involved. With predictions suggesting that at least 40% of businesses might not survive the next decade without transformation, it’s clear that adopting digital solutions like Equip360 is not just beneficial—it’s essential. Are you ready to take the leap and revolutionize your BOM management process?

Define a Clear BOM Structure: Establishing the Foundation for Effective Management

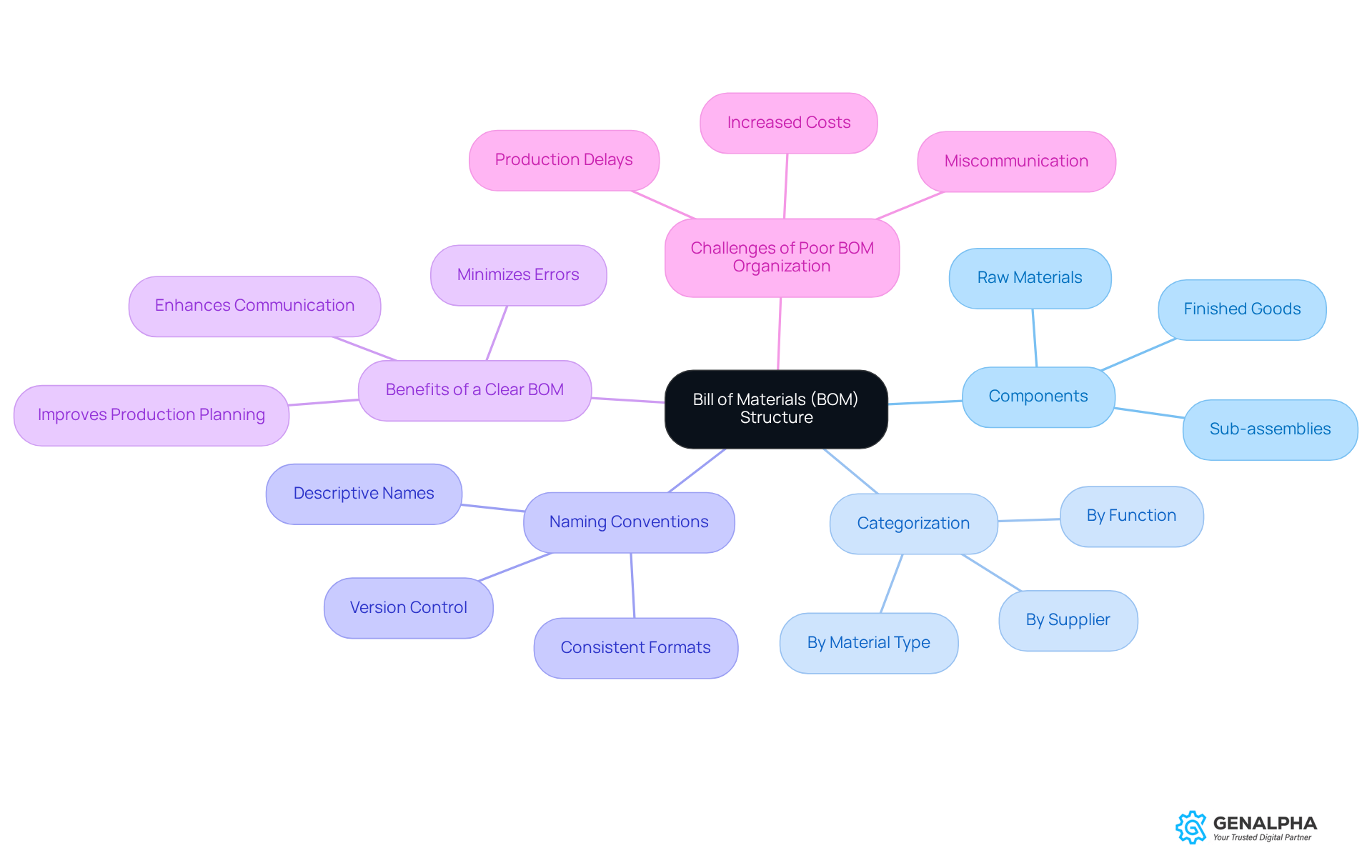

Have you ever thought about how a well-defined Bill of Materials (BOM) can make a world of difference in manufacturing? Organizing components hierarchically, categorizing parts, and sticking to consistent naming conventions are not just good practices; they’re essential for clarity. This organized approach helps teams quickly locate crucial materials and grasp their relationships within the assembly.

Research shows that poor BOM organization can lead to significant errors. In fact, studies reveal that up to 30% of production delays are tied to BOM-related issues. As Stephen Covey wisely said, "Once you have a clear idea of your priorities, organize around them." By setting up a clear BOM structure, manufacturers can enhance production planning and improve communication across departments. This, in turn, minimizes the risk of miscommunication and errors.

Industry specialists emphasize that a well-structured BOM not only streamlines operations but also lays the groundwork for continuous improvement in manufacturing methods. So, why not take a moment to reflect on how you can implement a clear BOM structure in your own processes? It could be the key to unlocking smoother operations and better teamwork!

Select the Right BOM Type: Tailoring to Operational Needs

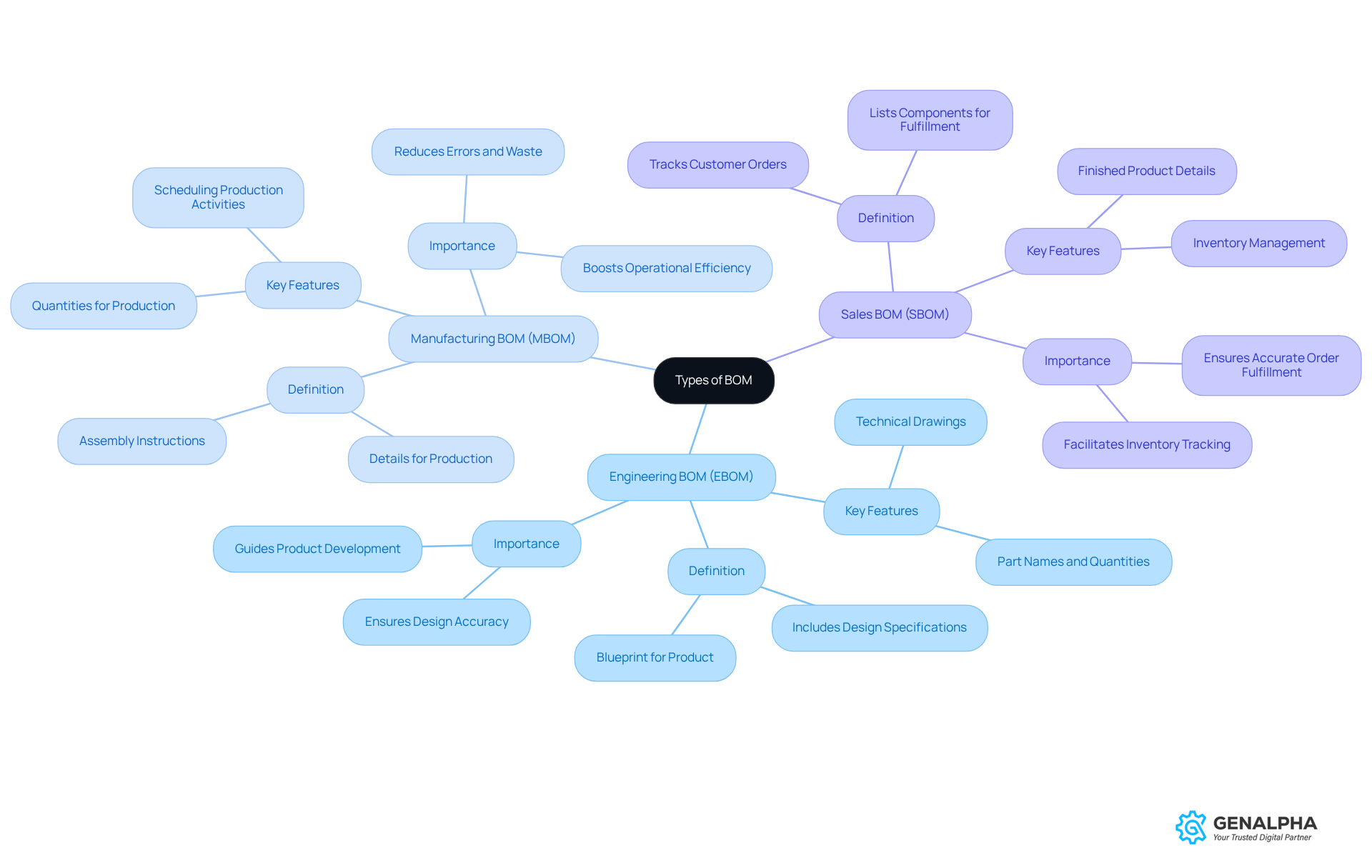

When it comes to equipment manufacturing, picking the right type of Bill of Materials (BOM) is key to keeping things running smoothly. There are three main types you should know about: Engineering BOM (EBOM), Manufacturing BOM (MBOM), and Sales BOM (SBOM), and each one has its own special role.

-

Engineering BOM (EBOM): Think of this as the blueprint for your product. It lays out all the design specifications, detailing every component, material, and subassembly needed during the design phase. This is crucial for making sure the product is built just as intended, often paired with technical drawings. As Michelle Adams puts it, "Each item listed in the BOM comes with specific information, including part names, quantities, costs, and instructions on how they should be used or assembled."

-

Manufacturing BOM (MBOM): Now, the MBOM is all about the actual manufacturing process. It provides the quantities and assembly instructions needed to create the final product. This type is super important for scheduling production activities and ensuring that all materials are on hand, which helps to cut down on errors and waste. A well-organized MBOM can really boost operational efficiency.

-

Sales BOM (SBOM): This one is primarily for sales and keeping track of inventory. The SBOM lists all the components needed to fulfill customer orders, including both the finished product and its individual parts. This makes it easier to ensure accurate order fulfillment and inventory management.

So, how do you choose the right BOM type? It’s all about aligning with your operational needs. Companies that manage their BOMs effectively through the BOM management process are 50% more likely to launch products on time, which really underscores the importance of making the right choice. The BOM management process ensures that a well-structured BOM not only improves communication among teams but also provides everyone with access to the essential information needed for efficient manufacturing. By tapping into the unique strengths of EBOM, MBOM, and SBOM, manufacturers can enhance their operational efficiency, cut costs, and elevate overall product quality. What are you waiting for? Let’s optimize those production workflows!

Integrate BOM with ERP Systems: Ensuring Seamless Data Flow

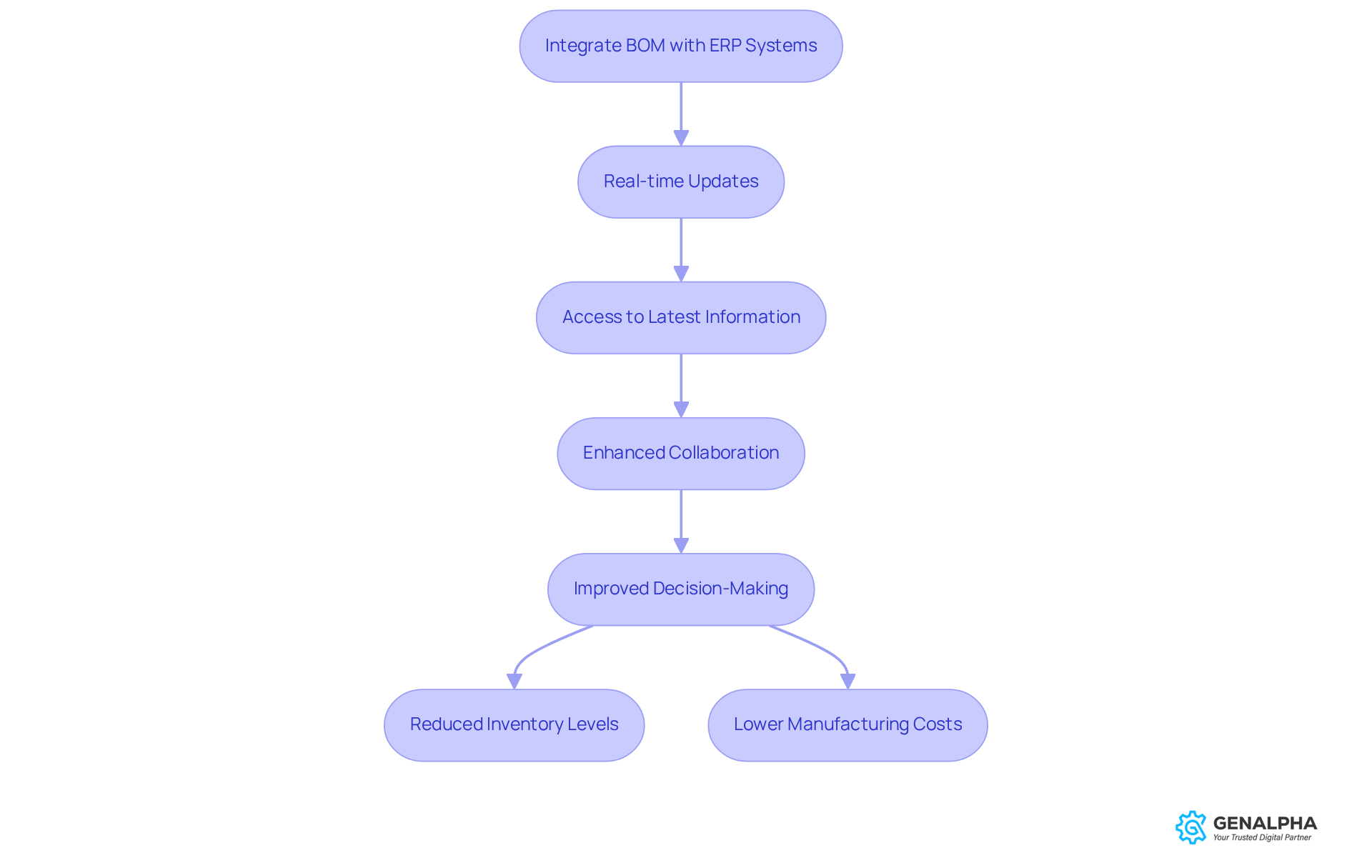

Integrating Bill of Materials (BOM) with ERP systems is crucial for keeping everyone on the same page with real-time updates and smooth information flow across departments. Imagine how much easier it is for teams to access the latest information—this is vital for tracking inventory levels, managing procurement processes, and streamlining production planning. By breaking down those pesky information silos, organizations can enhance collaboration and improve decision-making, leading to more efficient operations.

For example, Kellogg's SAP implementation not only boosted operational efficiency but also cut costs, showcasing the real benefits of effective ERP integration. Companies that have successfully merged BOM with ERP systems often report significant improvements in how they operate. With real-time information flowing seamlessly, keeping an eye on inventory becomes a breeze, reducing the chances of stockouts or excess stock. Research even suggests that an ERP system can potentially cut inventory levels by 20%, which directly helps lower manufacturing costs by 5% to 10%.

Plus, the accuracy of BOM information sees a major boost through ERP integration. This means that all the components needed for production are accounted for, which helps minimize errors and delays. As industry specialists point out, the BOM management process through ERP systems not only ramps up productivity but also aligns manufacturing processes with business objectives, ultimately driving profitability.

In the words of a leading expert, "Real-time information synchronization in manufacturing is not merely a luxury; it's essential for sustaining competitive advantage in today's fast-paced market." This really highlights how integrated systems are vital in modern manufacturing environments, where being agile and responsive is key. So, how can your organization leverage this integration to stay ahead?

Maintain Accurate BOM Data: Essential for Inventory Management

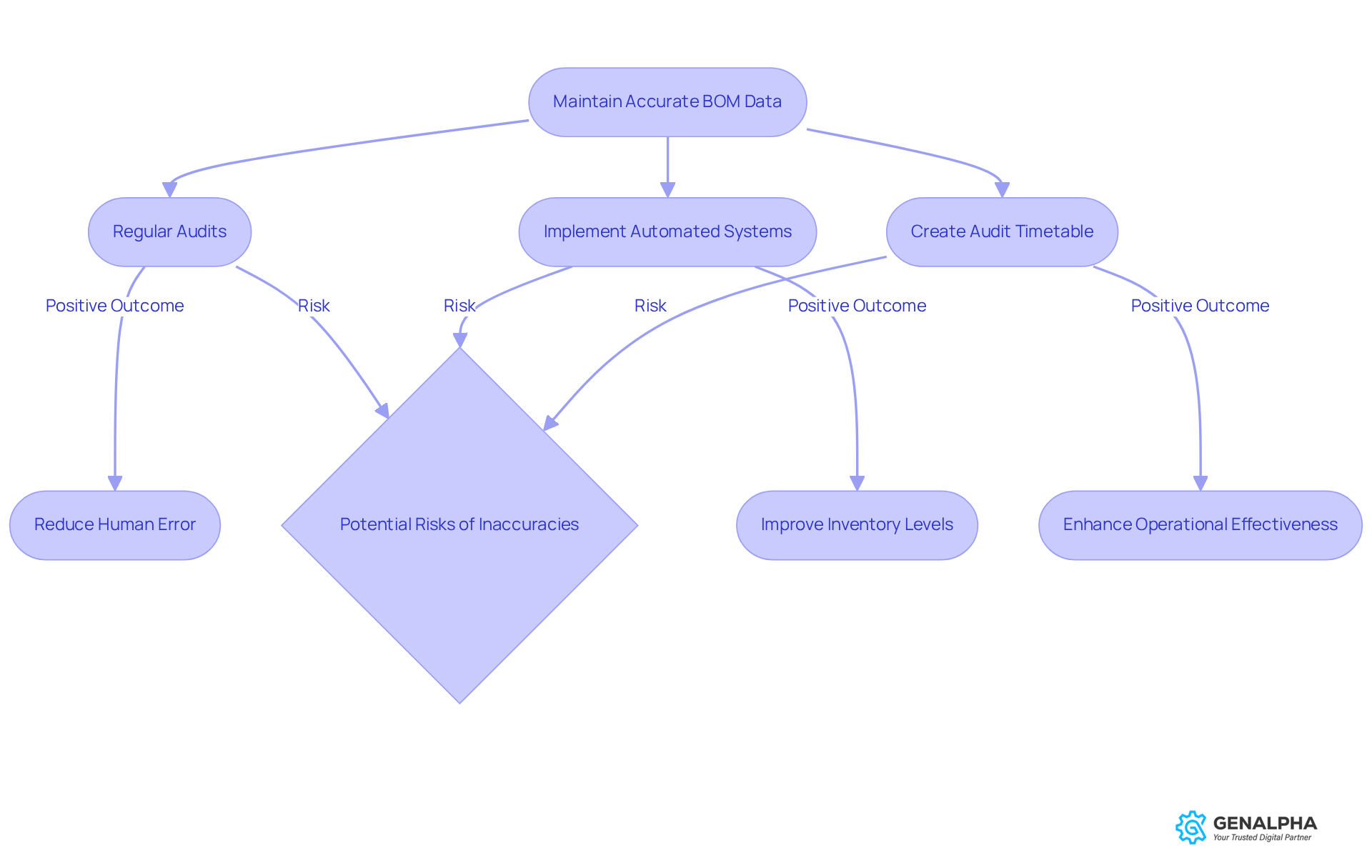

Maintaining accurate Bill of Materials (BOM) information is essential for the BOM management process in effective inventory management. Why? Because it ensures that we have the right quantities of materials on hand when we need them. Regular audits are key to reflecting any changes in materials, components, and production processes. They help us spot discrepancies that could lead to costly production delays. Just think about it: errors in BOM information can lead to serious financial consequences, like increased holding costs and potential stockouts, which can disrupt operations and hurt customer satisfaction. In fact, did you know that 62% of business finances are affected by failures in inventory tracking? This really highlights how crucial precision in the BOM management process is.

So, how can we mitigate these risks? Implementing automated systems for data entry and updates can be a game changer. These systems can drastically reduce human error, making sure our inventory levels are reliable and boosting production efficiency. For instance, tools like Prediko offer integrated BOM oversight features that simplify updates and maintain a single source of truth across departments. Plus, regular audits of the BOM management process can lead to fewer production disruptions, reinforcing their importance. By automating change notifications and scheduling routine BOM reviews, we can keep everyone in the loop about updates, which ultimately enhances our operational effectiveness. And let’s not forget, creating a solid audit timetable and using integrated inventory control software can provide a practical framework for maintaining BOM precision.

Foster Team Collaboration: Aligning Stakeholders in BOM Management

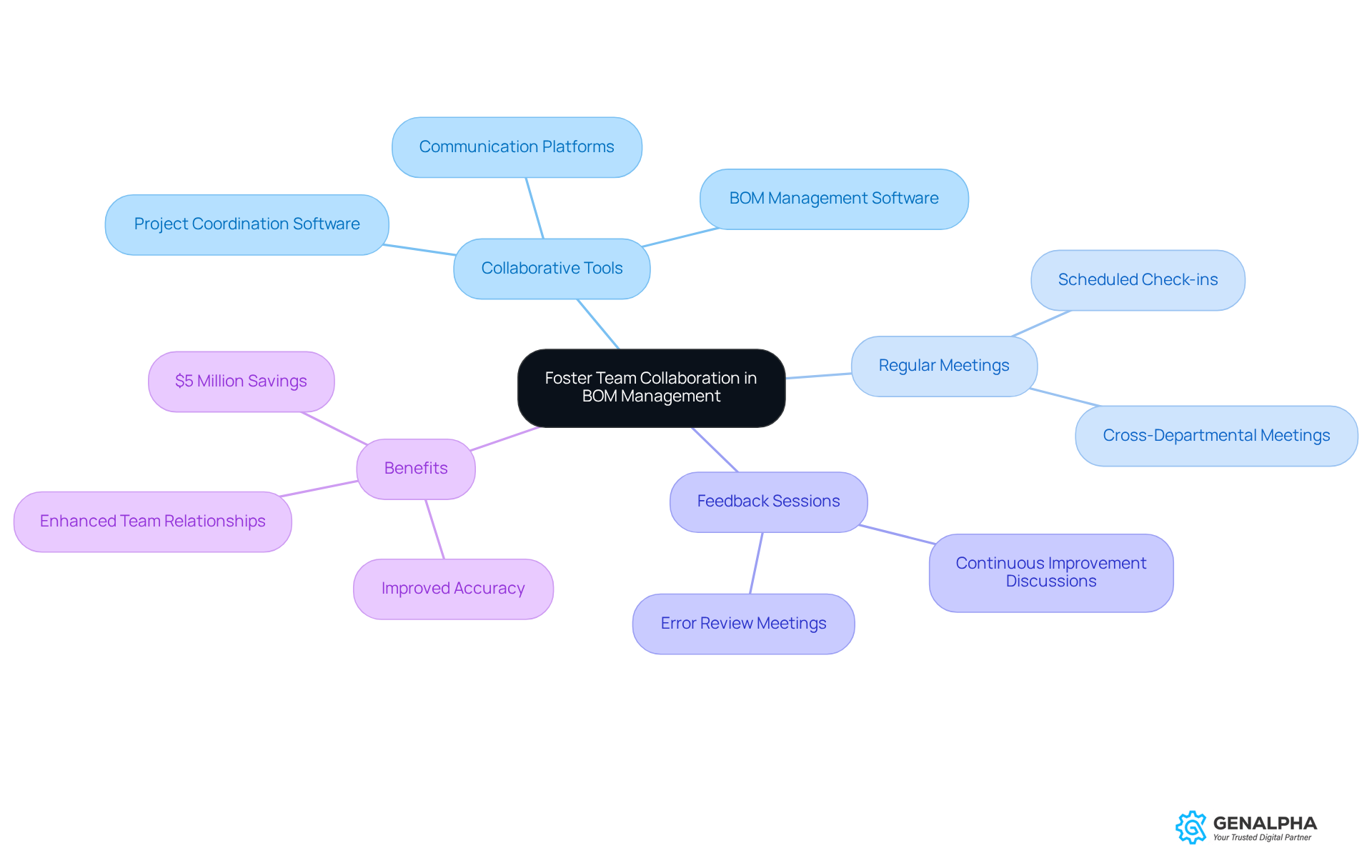

Encouraging team collaboration in the BOM management process is essential for building a culture of open communication and shared responsibility. Have you ever thought about how using collaborative tools, like project coordination software, can assist teams in the BOM management process to stay aligned on updates and changes? It really can improve overall accuracy! For instance, a global life sciences producer found $5 million in savings by centralizing BOM data and optimizing inventory. That's a clear win for efficient BOM oversight!

Regular meetings and feedback sessions are key to sparking discussions about the BOM management process improvements. They ensure that everyone involved stays informed and engaged. As Oliver Munro points out, the BOM management process assists various groups engaged in manufacturing, fostering efficient communication and cooperation among teams - while also decreasing the likelihood of mistakes and misinterpretations. This proactive approach not only minimizes errors but also strengthens relationships among teams. Ultimately, it leads to a more efficient BOM management process and improved production outcomes.

So, how can your team start implementing these strategies today? Let's make BOM oversight a collaborative effort!

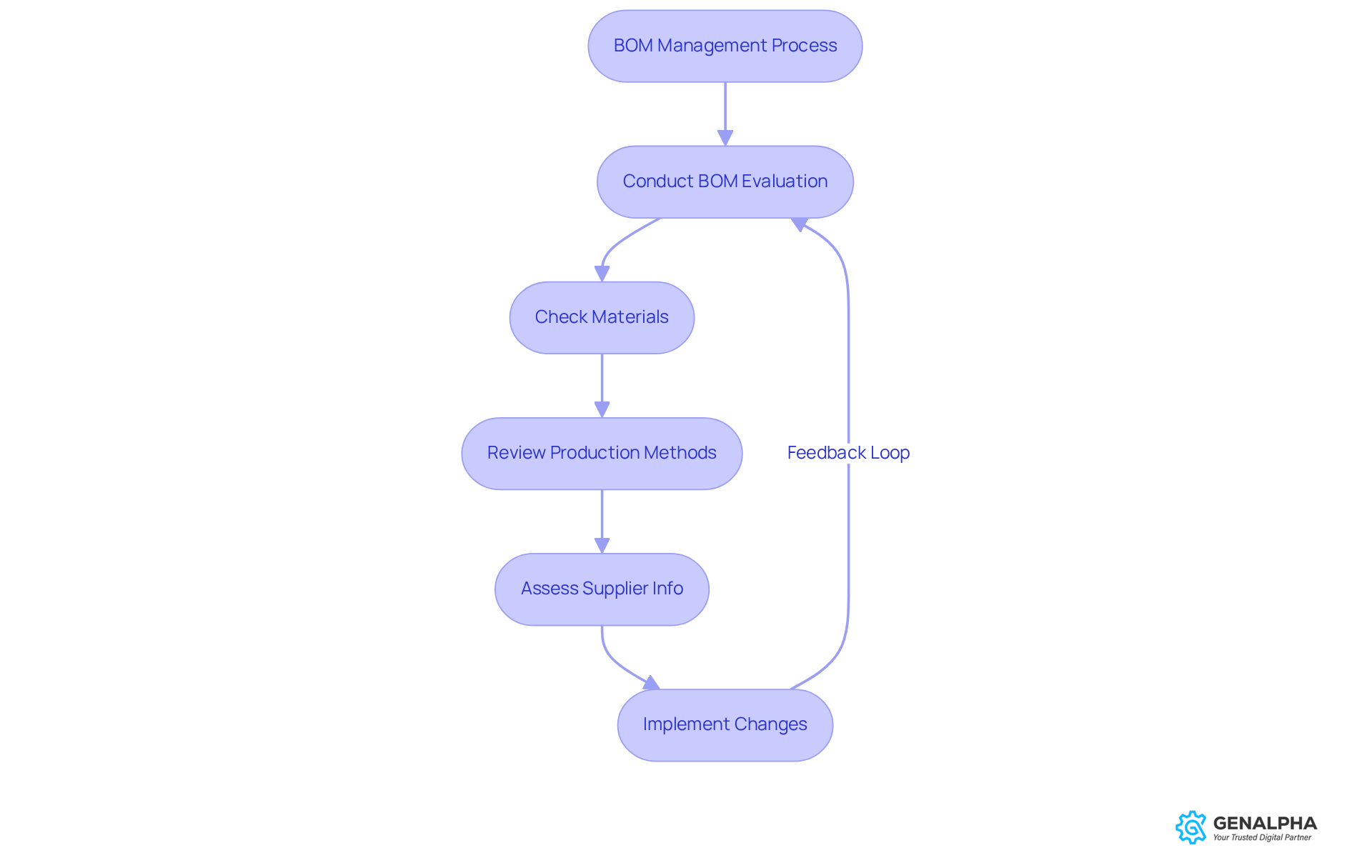

Conduct Regular BOM Reviews: Adapting to Changes in Production

You know, consistently performing BOM evaluations is super important for keeping things precise and relevant in manufacturing. Think about it: the BOM management process involves a thorough check of materials, production methods, and supplier info. For instance, a global life sciences producer managed to save $5 million just by centralizing its BOM information and improving inventory control. That really shows the tangible benefits of effective BOM management!

By staying on top of the BOM management process, organizations can quickly adapt to changes in production demands. This means fewer disruptions and a boost in operational efficiency. Experts point out that a well-maintained BOM management process is a vital tool in Product Lifecycle Management. It helps track changes and ensures everyone is on the same page across departments.

As one expert put it, 'The BOM management process is not a one-time event but rather an ongoing endeavor.' This really highlights the need for continuous reviews. Plus, this collaborative approach not only streamlines production but also builds resilience against supply chain fluctuations. In the end, it supports sustained growth and keeps companies competitive in the market. So, how are you managing your BOM today?

Train Staff on BOM Management: Maximizing Effectiveness

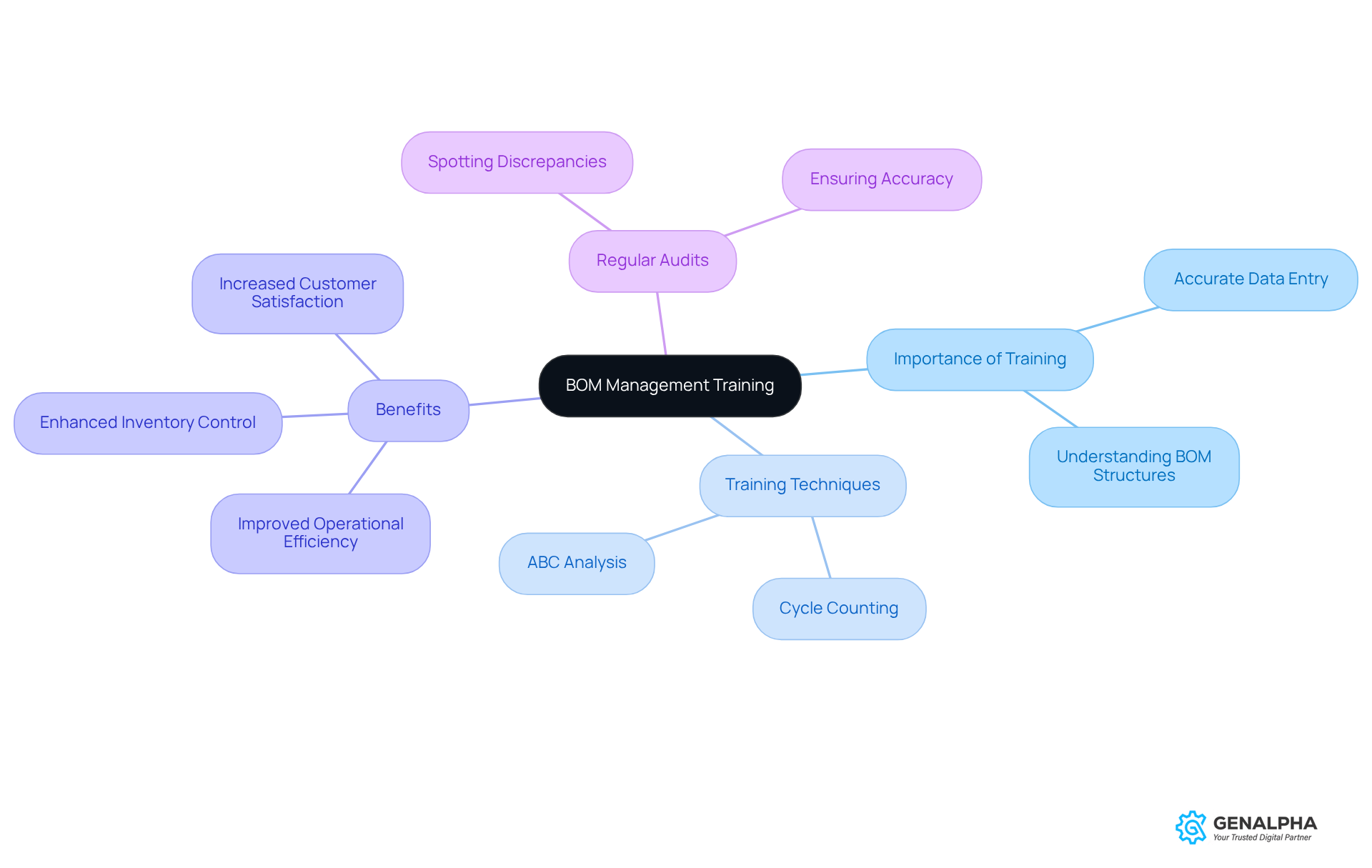

Effective training in the bom management process is crucial for ensuring accurate data entry and a solid grasp of BOM structures. Have you ever thought about how vital this is for your organization? By prioritizing comprehensive educational programs that delve into the nuances of the bom management process and the savvy use of software tools, companies can really make a difference.

Frequent workshops and training sessions not only reinforce best practices but also keep everyone in the loop about changes in procedures and technology. For example, techniques like cycle counting and ABC analysis can significantly boost BOM data accuracy, leading to better operational efficiency. Plus, regular audits can help spot discrepancies caused by theft, damage, or misplacement, which further highlights the importance of effective training.

So, why not invest in staff training? By doing so, manufacturers can enhance their bom management process, which ultimately improves inventory control and elevates customer satisfaction. It’s a win-win situation that everyone can benefit from!

Utilize Analytics Tools: Monitoring BOM Performance for Improvement

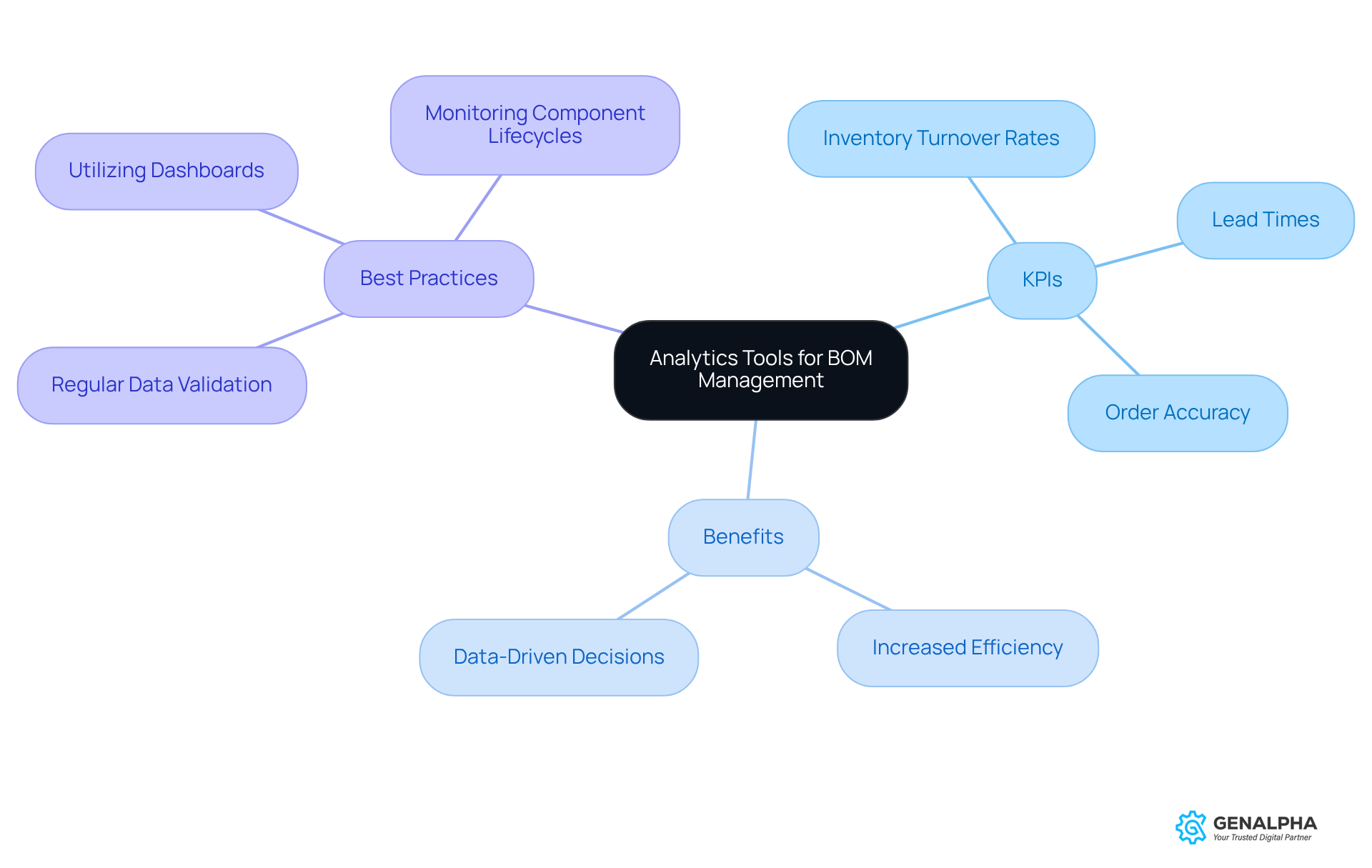

Have you ever thought about how crucial analytics tools are in managing your BOM management process? They’re essential for keeping an eye on key performance indicators (KPIs) like inventory turnover rates, lead times, and order accuracy. Surprisingly, engineers can spend up to 159 hours a year just dealing with administrative tasks related to procurement and BOM oversight. This highlights just how important analytics tools can be in lifting that burden and boosting efficiency.

By diving into this data, organizations can uncover trends and pinpoint areas that need improvement. This proactive approach allows for adjustments to the BOM workflow before issues arise. Plus, integrating dashboards and reporting tools gives teams real-time insights. Take the BOM Portal, for example—it provides live updates on component lifecycles, empowering teams to make informed decisions that can dramatically enhance overall efficiency and effectiveness.

And here's a fun fact: companies using advanced analytics have reported a 45% improvement in their quoting processes. This really shows the tangible benefits of data-driven decision-making in refining the BOM management process. As Geoffrey Moore wisely said, "information is entirely vital for making intelligent business choices." This really strengthens the argument for using analytics tools in the BOM management process.

Lastly, don’t forget about the importance of regular information validation and cleanup policies. They’re key to keeping your BOM integrity intact. So, what steps are you taking to leverage these tools in your organization?

Leverage Technology for BOM Management: Enhancing Efficiency and Accuracy

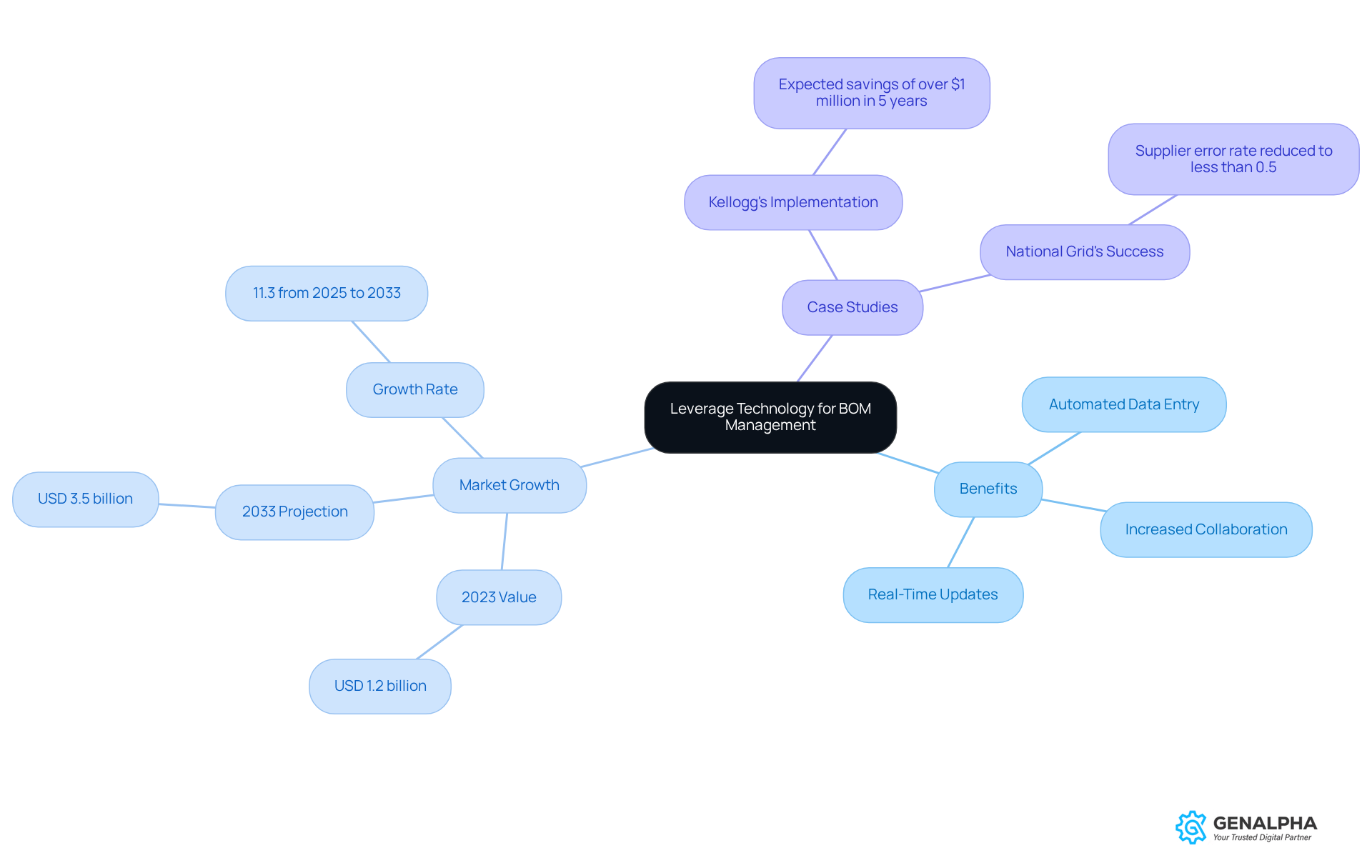

Have you ever thought about how cloud-based systems can totally change the game for organizations through the BOM management process? These systems not only automate data entry but also boost collaboration and provide real-time updates, so everyone involved has instant access to the latest information. The perks of this technology are huge! Companies can streamline their BOM processes, cut down on errors, and really amp up production efficiency.

For example, the global BOM Management Software market, which was valued at around USD 1.2 billion in 2023, is set to skyrocket to USD 3.5 billion by 2033. That's a growth rate of 11.3% from 2025 to 2033! This surge is driven by the increasing complexity of product designs and the rise of Industry 4.0 technologies. And guess what? This shift towards cloud solutions is especially beneficial for small and medium-sized enterprises (SMEs). In fact, SMEs make up 99% of all businesses in the EU and are starting to realize how vital BOM software is for staying competitive.

A great example is Kellogg's, which has successfully implemented SAP's ERP system. This move has led to improved operational efficiency, with expected savings of over $1 million in just five years. It really shows the tangible benefits of bringing cloud-based solutions into the BOM management process. Additionally, National Grid managed to slash their supplier error rate from 10-50% down to less than half a percent after adopting SAP. This further demonstrates just how effective cloud-based BOM management systems can be.

By embracing these advanced systems, organizations can boost their BOM management process and set themselves up for future growth in our increasingly digital world. So, why not consider making the switch? It could be the key to unlocking your organization’s potential!

Conclusion

Optimizing the Bill of Materials (BOM) management process is crucial for manufacturers aiming for efficiency and accuracy in their operations. Have you ever thought about how advanced technology, accurate data, and team collaboration can really transform your BOM practices? By embracing these strategies, organizations can significantly enhance their BOM management. Throughout this article, we’ve highlighted the importance of a well-structured BOM, the necessity for continuous reviews, and the benefits of using analytics tools to keep tabs on performance.

So, what are the key takeaways?

- Defining a clear BOM structure helps minimize errors.

- Selecting the right BOM types to meet your operational needs is essential.

- Implementing ERP systems for seamless data flow is important.

- Regular training and collaboration among stakeholders are vital for maintaining accuracy and adapting to shifts in production demands.

As the manufacturing landscape continues to evolve, these strategies will empower organizations to stay competitive and responsive.

The call to action is simple: embracing these strategies and leveraging innovative solutions like GenAlpha Technologies Equip360 can truly revolutionize your BOM management process. With businesses facing increasing pressures to adapt and thrive, investing in effective BOM management practices isn’t just a choice—it’s a necessity for future success. So, why wait? The time to optimize is now! Take the steps to transform your BOM management and unlock new levels of operational excellence.

Frequently Asked Questions

What is Equip360 and how does it help manufacturers?

Equip360 is a platform designed specifically for manufacturers and distributors to streamline Bill of Materials (BOM) management. It offers interactive 2D and 3D catalogs that allow users to quickly find parts, access manuals, and manage inventory efficiently.

How does Equip360 integrate with existing systems?

Equip360 seamlessly integrates with ERP systems, ensuring that BOM data is always up-to-date, which reduces errors and enhances operational efficiency.

What benefits have manufacturers experienced by using Equip360?

Manufacturers using Equip360 have reported improved accuracy, shorter lead times, and enhanced customer satisfaction due to more accurate and timely information.

Why is a clear BOM structure important for manufacturers?

A well-defined BOM structure helps organize components hierarchically and categorizes parts, which is essential for clarity. This organization minimizes errors and production delays, improving communication and production planning.

What are the consequences of poor BOM organization?

Poor BOM organization can lead to significant errors, with studies indicating that up to 30% of production delays are related to BOM issues.

What are the different types of BOMs and their roles?

There are three main types of BOMs: Engineering BOM (EBOM): Details all design specifications and components needed during the design phase. Manufacturing BOM (MBOM): Focuses on the quantities and assembly instructions needed for the actual manufacturing process. Sales BOM (SBOM): Used for sales and inventory tracking, listing components needed to fulfill customer orders.

How can selecting the right BOM type impact manufacturing operations?

Choosing the appropriate BOM type aligns with operational needs and can significantly enhance efficiency. Companies that manage their BOMs effectively are 50% more likely to launch products on time.

What is the overall importance of implementing digital solutions like Equip360 in BOM management?

Implementing digital solutions like Equip360 is essential for manufacturers to adapt to technological advancements and improve BOM management, ultimately leading to better operational efficiency and competitiveness in the market.