Introduction

In today’s world of manufacturing, managing product data effectively is more important than ever. It’s a key factor that can really make or break operational success. Think about it: manufacturers can reap huge benefits by adopting best practices that not only streamline their processes but also boost data quality and accessibility. But let’s be real - the path to mastering product data management isn’t always smooth sailing. What common pitfalls might trip us up, and how can organizations steer clear of them to achieve lasting excellence?

As we dive into this topic, consider your own experiences. Have you faced challenges in managing product data? You’re not alone! Many organizations struggle with this, but understanding the hurdles is the first step toward overcoming them. So, let’s explore how we can navigate these challenges together and unlock the full potential of product data management.

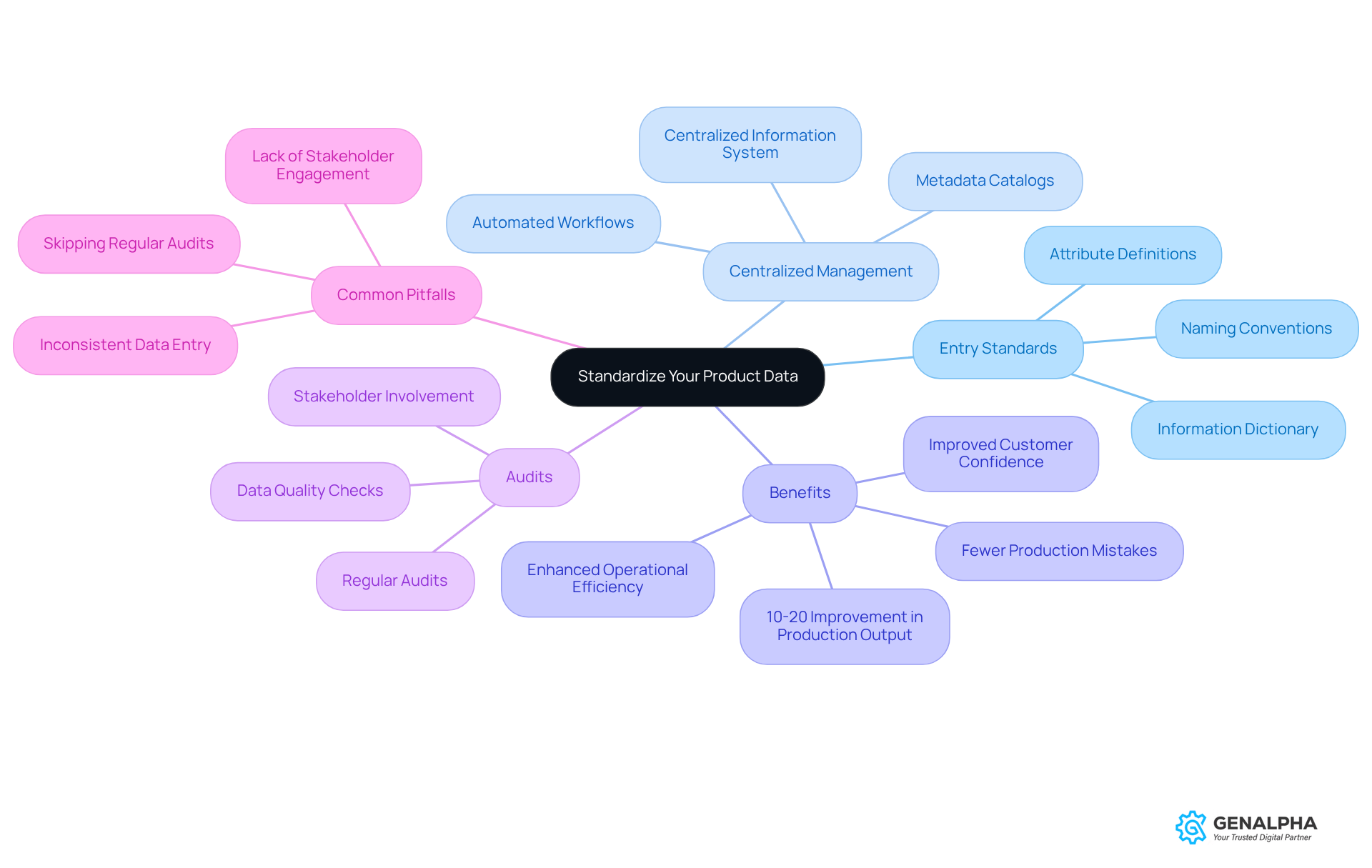

Standardize Your Product Data for Consistency

To keep item information consistent, manufacturers really need to set up solid entry standards and naming conventions. Think about it: clearly defining attributes like item descriptions, specifications, and categorization is key. A centralized information management system can make this whole process a breeze, letting all teams access the same standardized info.

For example, a manufacturer could whip up a detailed information dictionary that lays out the necessary fields and formats for product details. This would serve as a handy reference for all departments. Plus, regular audits are super important to spot and fix any inconsistencies, which helps keep information integrity intact.

By putting product data management best practices into action, you not only boost operational efficiency but also foster a culture of accountability and accuracy in information management. This, in turn, leads to happier customers and fewer production mistakes. Did you know that standardization can lead to a 10-20% improvement in production output? That’s what industry experts say, especially for companies diving into smart manufacturing initiatives.

And let’s not forget what Quinnox pointed out: 'Standardization not only prevents confusion but also guarantees that conclusions derived from information are valid.' Learning from successful case studies, like American Meat Companies, which improved their Overall Equipment Effectiveness (OEE) through the implementation of product data management best practices and smart information standardization, can really help manufacturers see the tangible benefits of these practices.

However, it’s crucial to steer clear of common pitfalls, like skipping regular audits or not involving all the right stakeholders in the standardization process. That way, you can truly reap the rewards of implementing those entry standards.

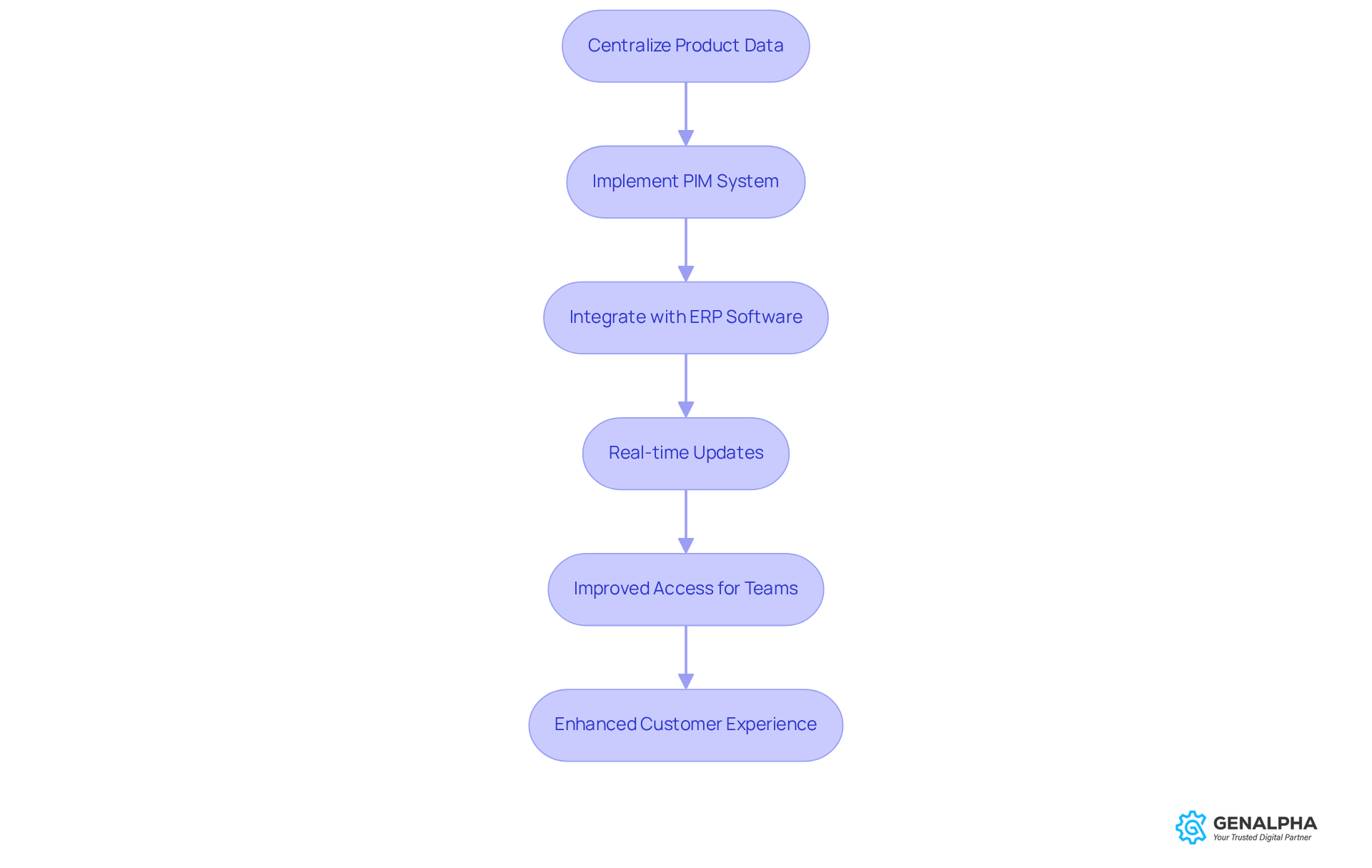

Centralize Your Product Data for Improved Access

Centralizing information is all about bringing all those item-related details into one easy-to-access spot, which is a key aspect of product data management best practices, like a Product Information Management (PIM) system. Imagine how much smoother things would be when everyone in your company can find what they need without digging through endless files! For example, manufacturers can set up a PIM system that works seamlessly with their existing ERP software. This means that all item information is updated in real-time, making it a breeze for sales, marketing, and customer service teams to access the latest data.

But why does this matter? Well, a centralized approach not only boosts the accuracy of your information but also exemplifies product data management best practices by speeding up how quickly you can respond to customer inquiries. Did you know that companies using PIM systems can cut their time to market by an average of 30%? That’s a game changer in the fast-paced world of manufacturing! Plus, when your item information is consistent and complete, it builds trust with your customers and enhances their experience. This can lead to higher conversion rates and greater customer satisfaction.

So, if you’re looking to stay ahead of the competition, consider how centralizing your information could transform your operations. What steps can you take today to start this journey?

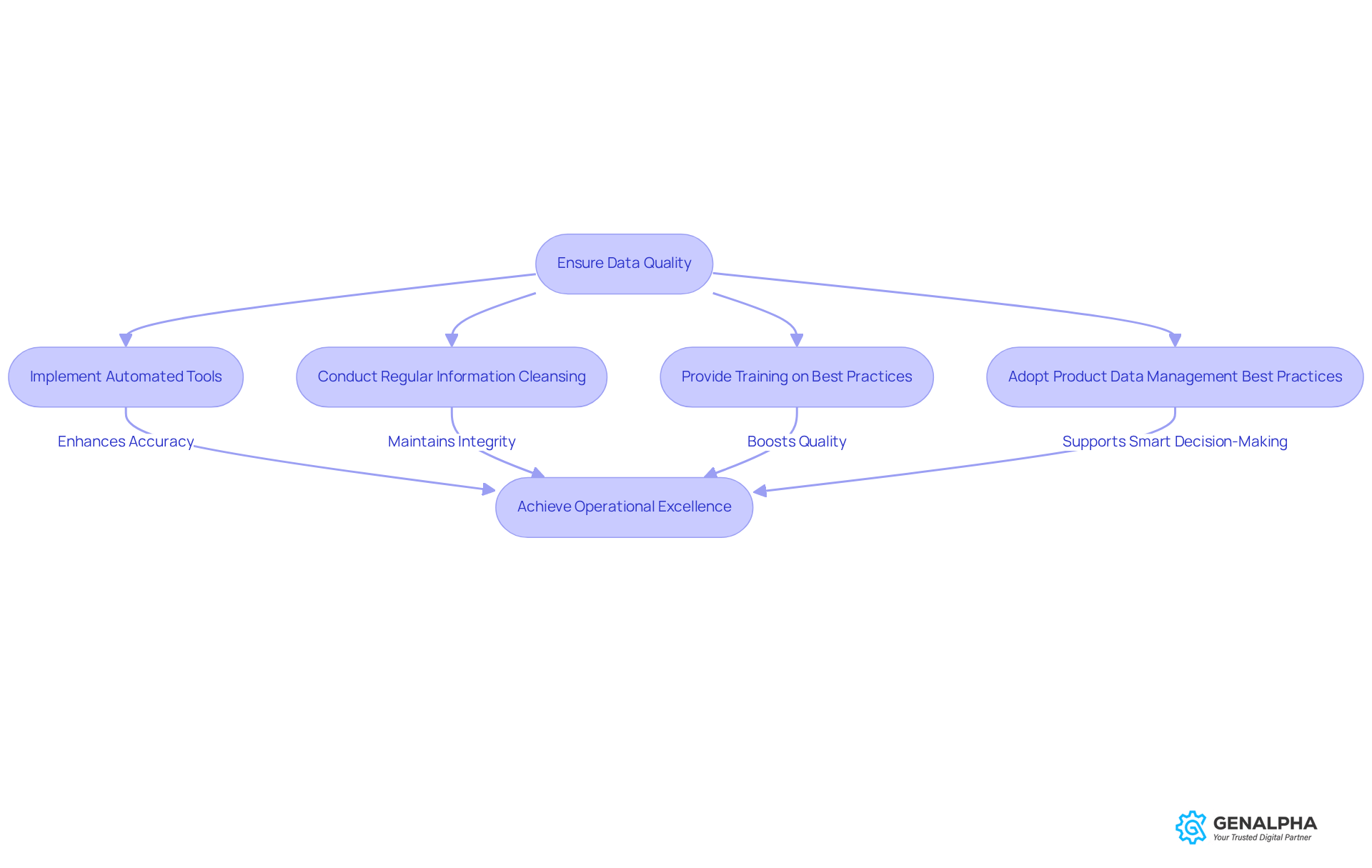

Ensure Data Quality to Drive Operational Excellence

To achieve operational excellence, manufacturers really need to focus on solid information validation processes right from the start. Think about it: implementing automated tools is crucial for spotting errors, duplicates, and inconsistencies as they happen. For example, advanced software can automatically flag discrepancies in product specs, allowing teams to fix issues before they mess with customer orders.

And let’s not forget about regular information cleansing activities! Integrating these into workflows helps maintain integrity over time. Plus, when you provide your team with training on product data management best practices for data entry, you significantly boost information quality. This ensures that the details used across the organization are accurate and reliable.

Did you know that a recent study found 93% of producers consider quality to be very or extremely important to their operations? This really highlights how vital information validation is for fostering operational excellence. As Tamas Cser puts it, "Information validation automation enhances accuracy, improves efficiency & streamlines management for businesses to ensure error-free information."

By adopting product data management best practices, manufacturers can create a culture of information excellence that drives efficiency and supports smart decision-making. Take Domino's, for instance; they effectively consolidated customer and order information through automated validation, which led to better delivery analytics and improved operational performance.

So, what steps can you take today to enhance your information validation processes?

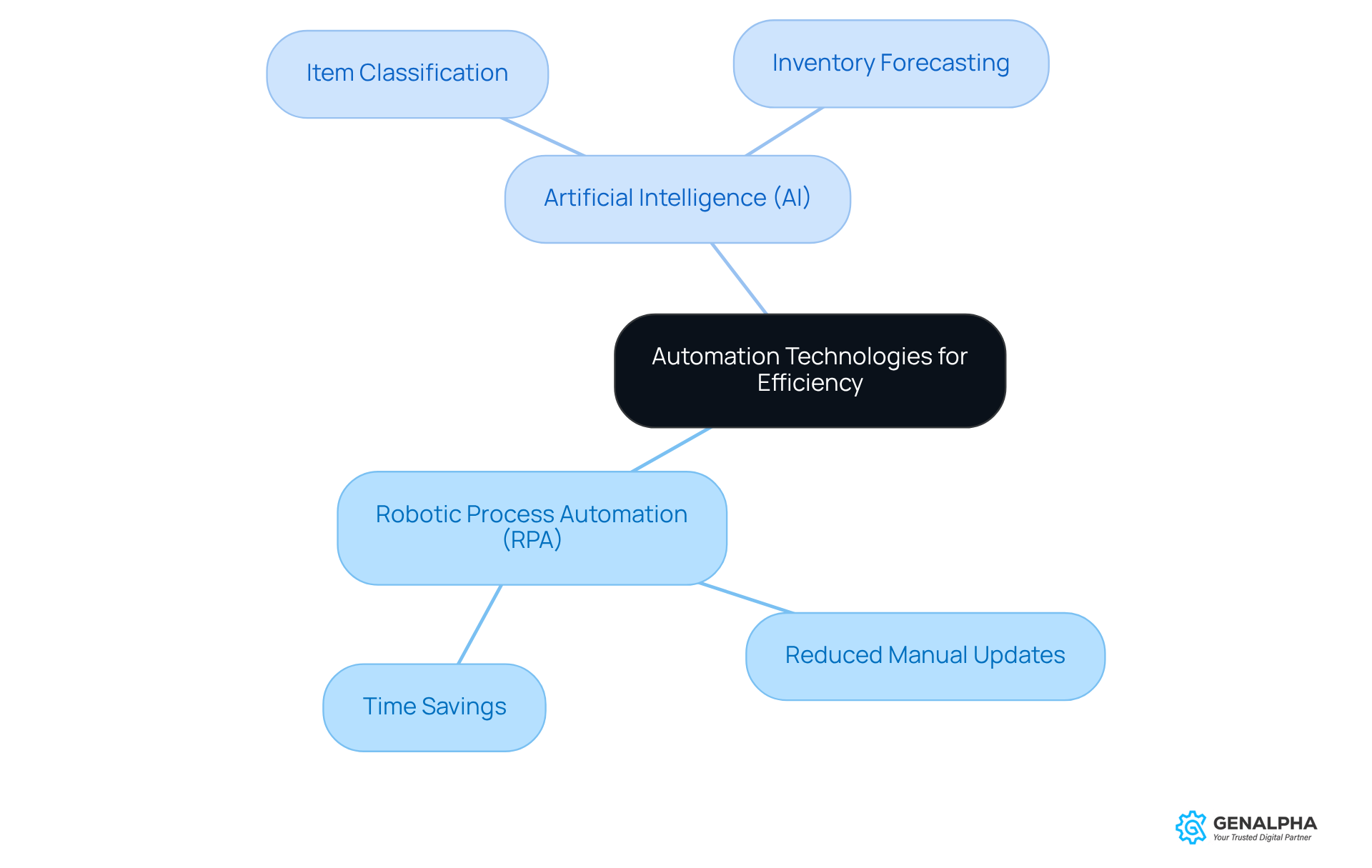

Leverage Automation Technologies for Efficiency

Have you ever thought about how manufacturers can make their lives easier with automation? Well, technologies like robotic process automation (RPA) and artificial intelligence (AI) are game-changers when it comes to managing information about goods. For instance, RPA can take over those tedious data entry tasks, which means less time spent on manual updates. Sounds great, right?

But that’s not all! AI steps in to help classify items and even forecast inventory needs based on past data. Imagine how much smoother operations could run with these tools in place! By embracing these technologies, producers can seriously boost their information handling processes. This leads to quicker response times and more accurate item details.

So, why not consider how these innovations could transform your operations? It’s time to explore the possibilities!

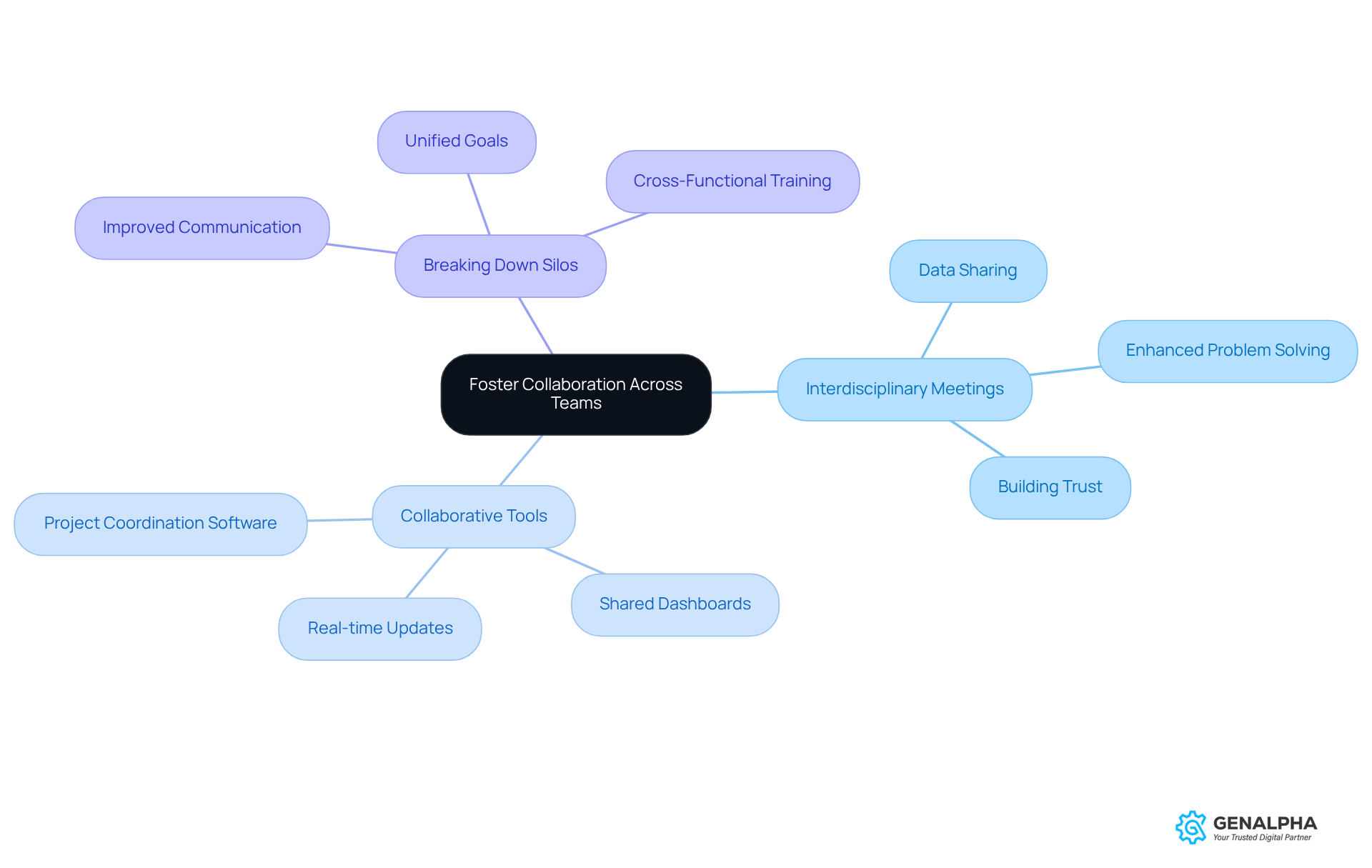

Foster Collaboration Across Teams for Better Outcomes

Want to boost collaboration? Let’s talk about how regular interdisciplinary meetings can really make a difference. These gatherings allow teams to dive into data issues and share those golden insights that can drive success. Plus, using collaborative tools like shared dashboards and project coordination software can seriously up your communication game.

For instance, imagine a manufacturer rolling out a platform where sales, marketing, and development teams can all access and update item information in real-time. Sounds great, right? This kind of teamwork not only sharpens information accuracy but also gets everyone on the same page, working together toward shared goals.

Research shows that companies that champion effective cross-functional collaboration are up to five times more likely to hit high performance. That’s a big deal! It really highlights how crucial these practices are for operational success. As Jill Romford puts it, "Breaking down silos is essential to building a culture of cross-functional coordination, where teams work in sync toward shared business outcomes."

So, how can you start breaking down those silos in your organization? Let’s get the conversation going!

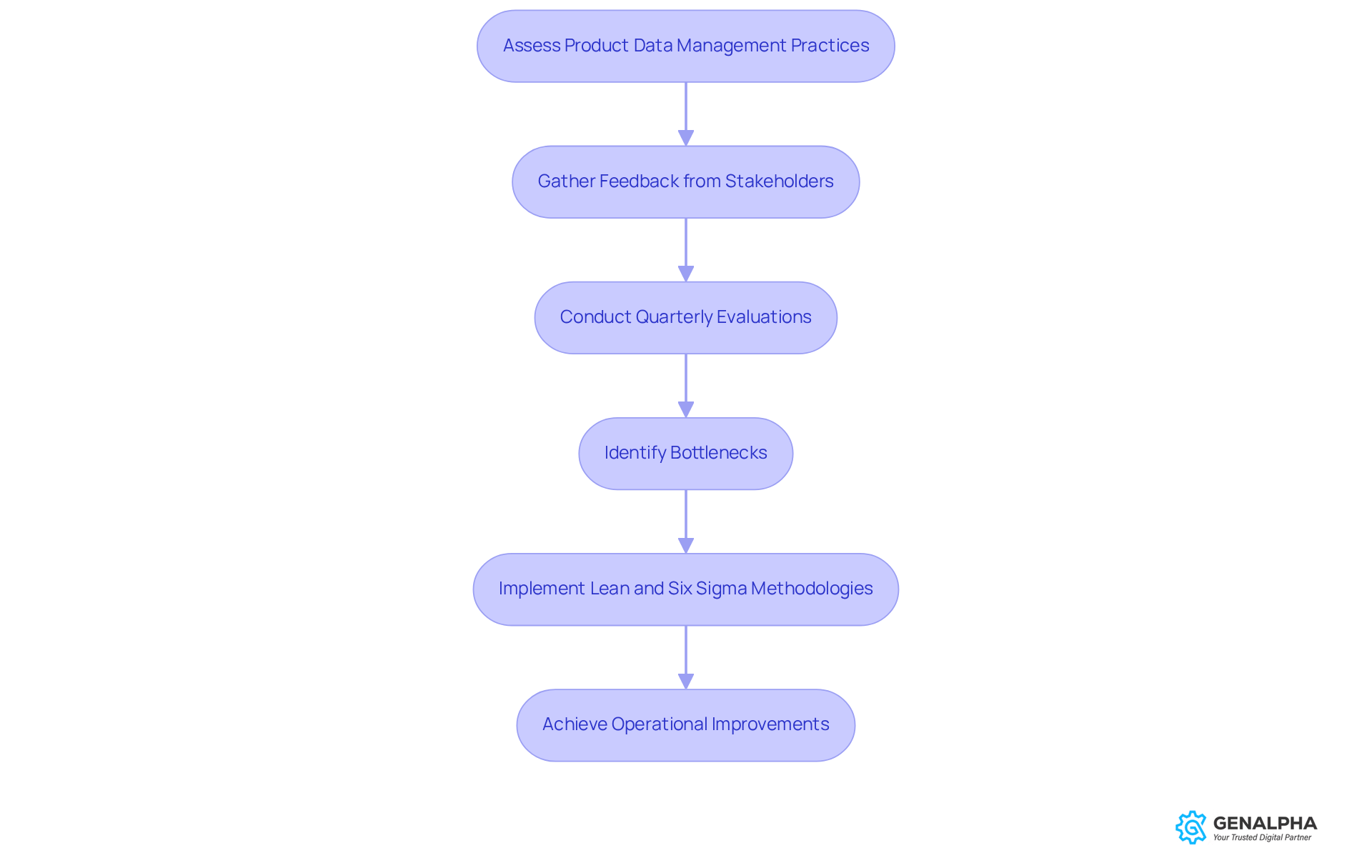

Continuously Improve Your Processes for Sustained Success

Producers, let’s talk about something crucial: the mindset of ongoing improvement. Have you ever considered how regularly assessing your product data management best practices can make a difference? By actively seeking feedback from your stakeholders, you can really enhance your processes.

For example, consider using methodologies like Lean and Six Sigma. These approaches can help you spot inefficiencies and areas that need a little TLC. Imagine conducting quarterly evaluations of your information handling techniques, focusing on performance metrics, and gathering insights from your team. This way, you can identify those pesky bottlenecks that slow you down.

This proactive approach not only helps you keep up with industry trends but also ensures you adhere to product data management best practices for maintaining high standards in information management. Lean principles focus on cutting out waste and optimizing processes, while Six Sigma zeroes in on quality control, boosting accuracy and reliability.

Did you know that many continuous improvement initiatives fall flat because of outdated practices and lack of engagement? That’s why it’s essential to adopt a robust approach. By integrating these methodologies based on product data management best practices, you can build a solid framework for continuous improvement, leading to better decision-making and increased operational efficiency.

As Ralf W. Seifert, Professor of Operations Management at IMD, puts it, "Each step offers a basis for ongoing enhancement, enabling producers to adjust and develop their strategies according to information and real-time feedback."

And here’s a real-world example: a case study involving Augmentir's AI-powered solutions shows how combining Lean and Six Sigma can lead to significant operational improvements. It’s a great reminder of the practical benefits these methodologies can bring to the table.

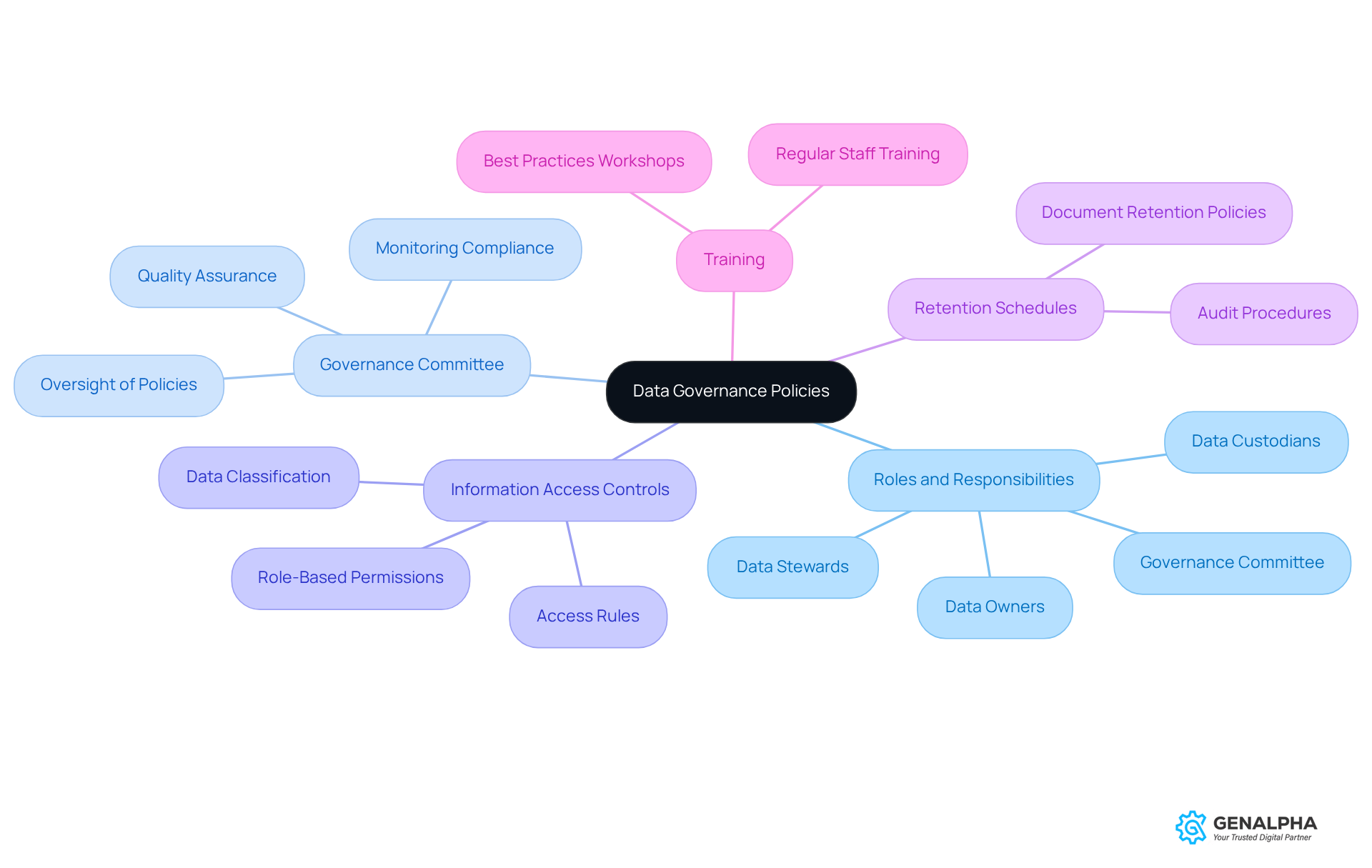

Establish Data Governance Policies for Compliance

When it comes to setting up effective information governance policies, manufacturers really need to nail down distinct roles and responsibilities for managing information within their organizations. Think about it: having a governance committee in place can make a world of difference. This committee would keep an eye on information quality, security, and compliance, ensuring everything runs smoothly.

Implementing comprehensive policies is key here. We're talking about clear information access controls, retention schedules, and audit procedures. For instance, imagine a producer creating a solid information governance framework that includes regular training for staff on best practices for handling information. This way, everyone on the team knows their role in keeping information integrity intact.

Did you know that a 2021 study found poor information quality costs organizations an average of $12.9 million each year? That’s a pretty strong financial reason to invest in governance! Plus, industry specialists point out that effective information governance not only helps with sticking to industry regulations but also fosters a culture of responsibility and continuous improvement in management practices.

So, how can manufacturers avoid common pitfalls like unclear roles and inadequate training? By doing so, they can significantly boost their operational efficiency and data reliability. It’s all about taking those actionable steps to create a better information governance environment.

Conclusion

To really boost operational efficiency and keep customers happy, manufacturers need to get serious about product data management. Think about it: when you standardize, centralize, and ensure the quality of your product data, you’re not just creating a solid framework; you’re also building trust with your customers. This approach streamlines your internal processes and gives you a competitive edge.

So, what are some key strategies to make this happen? Well, leveraging automation technologies can significantly cut down on manual errors and speed up data handling. Plus, when teams collaborate effectively, everyone works towards the same goals, making the whole operation more effective. And let’s not forget about data governance - it’s crucial for keeping your information accurate and compliant in today’s data-driven world.

Manufacturers, it’s time to take action! Embracing continuous improvement methodologies can help refine your processes, keeping you agile and ready for market changes. By prioritizing product data management, you’re not just enhancing your operational capabilities; you’re setting yourself up for long-term success in a competitive landscape. So, what steps will you take today to get started?

Frequently Asked Questions

Why is it important to standardize product data?

Standardizing product data is essential for maintaining consistency in item information, which improves operational efficiency, fosters accountability, and enhances customer satisfaction. It also helps prevent confusion and ensures that conclusions drawn from the data are valid.

What practices should manufacturers implement for effective product data management?

Manufacturers should establish solid entry standards and naming conventions, create a detailed information dictionary for product details, conduct regular audits to identify inconsistencies, and involve all relevant stakeholders in the standardization process.

How can a centralized information management system benefit manufacturers?

A centralized information management system, such as a Product Information Management (PIM) system, allows all teams to access updated item information in real-time, boosting accuracy and speeding up responses to customer inquiries.

What are the potential improvements in production output from standardization?

Standardization can lead to a 10-20% improvement in production output, particularly for companies engaged in smart manufacturing initiatives.

Can you provide an example of a successful implementation of product data management best practices?

American Meat Companies improved their Overall Equipment Effectiveness (OEE) by implementing product data management best practices and smart information standardization.

What are some common pitfalls to avoid in the standardization process?

Common pitfalls include skipping regular audits and failing to involve all the right stakeholders in the standardization process, which can hinder the effectiveness of the implemented standards.