Overview

Have you ever thought about how an online order management system could transform a manufacturing business? Well, let me share with you seven key benefits that could really make a difference!

- Increased efficiency—who doesn’t want to streamline operations?

- Real-time inventory management, which means you always know what’s in stock.

- Centralized data access allows everyone on your team to stay in the loop, enhancing collaboration.

- Enhanced customer engagement is a game changer, helping you connect with your clients like never before.

- Scalable systems, which means they grow with your business.

- Seamless ERP integration makes everything work together smoothly.

- Improved data-driven insights to make smarter decisions.

Collectively, these benefits lead to operational improvements and cost reductions, ultimately boosting customer satisfaction. Companies that have adopted such systems often report higher fulfillment rates and shorter processing times. So, why not consider taking the leap? It could be the change your business needs!

Introduction

The manufacturing landscape is changing fast, and the need for efficient order management has never been more important. Have you ever thought about how online order management systems, like Equip360 by GenAlpha Technologies, could completely change the way manufacturers manage inventory and interact with clients? They promise to enhance operational efficiency in a big way! But with so many options out there, how do businesses figure out the best strategies to make the most of these systems? In this article, we’ll dive into seven key advantages of adopting an online order management system. You’ll see how manufacturers can streamline their processes, boost customer satisfaction, and get ready for future growth.

Equip360 by GenAlpha Technologies: Streamline Your Order Management Process

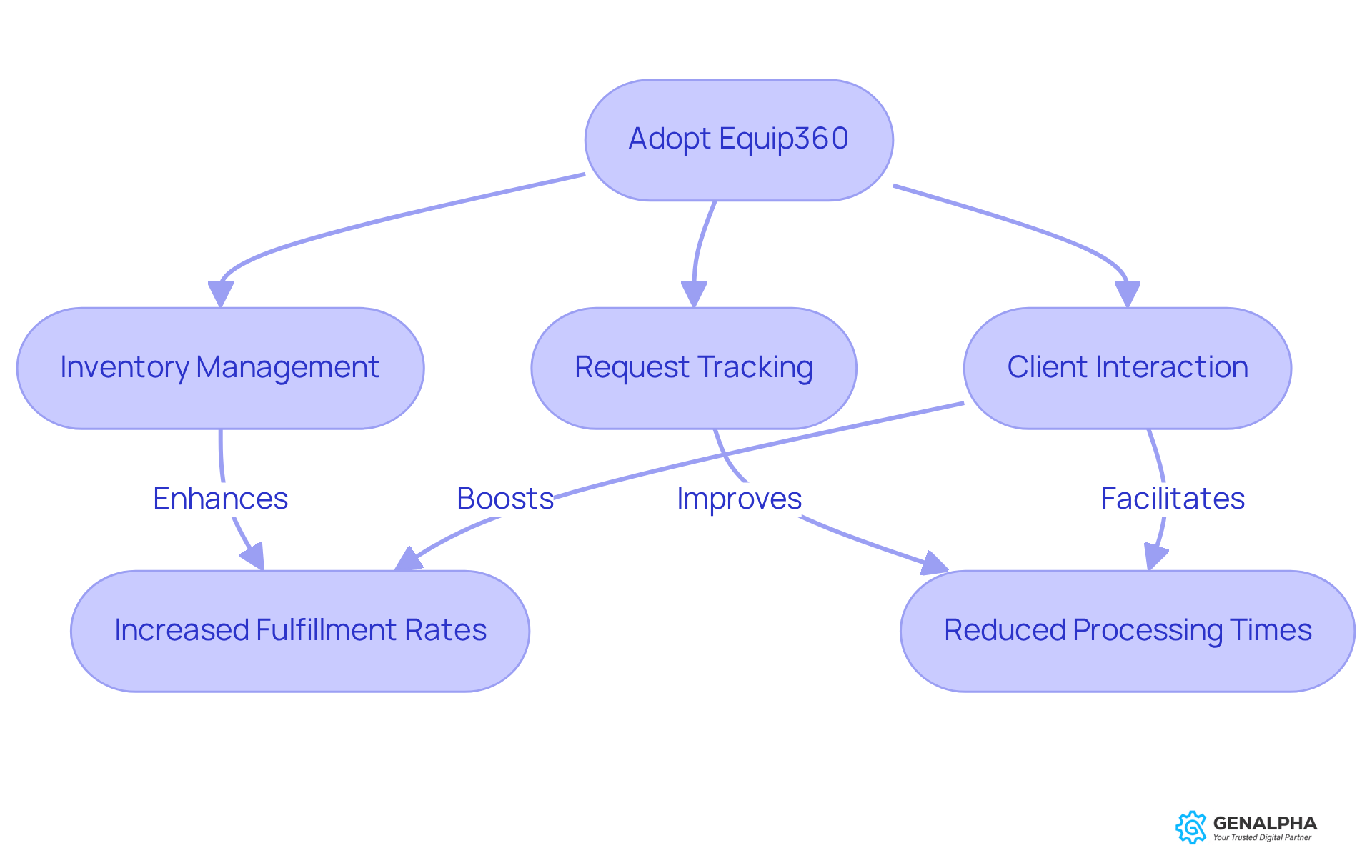

Have you ever felt overwhelmed by managing inventory and client requests? Equip360 is here to change that! This platform is specifically designed to make life easier for manufacturers and distributors. With essential features like inventory management, request tracking, and client interaction, Equip360 offers a comprehensive online order management system that enhances operational efficiency.

Imagine a user-friendly interface where handling requests is a breeze. Companies using Equip360 have found they can significantly cut down on the time spent on manual tasks and reduce errors. This streamlined approach not only simplifies processing requests but also enhances the overall client experience by utilizing an online order management system to ensure timely and accurate fulfillment.

Manufacturers who have adopted Equip360 report impressive gains in their operational metrics. For instance, many have seen a 30% increase in fulfillment rates and a noticeable drop in processing times. This leads to happier customers and stronger loyalty.

So, why not take it a step further? We encourage producers to consider integrating Equip360 with their existing online order management system. This could be the key to unlocking even greater operational efficiency. Are you ready to elevate your management process?

Increased Efficiency: Automate Your Order Processing

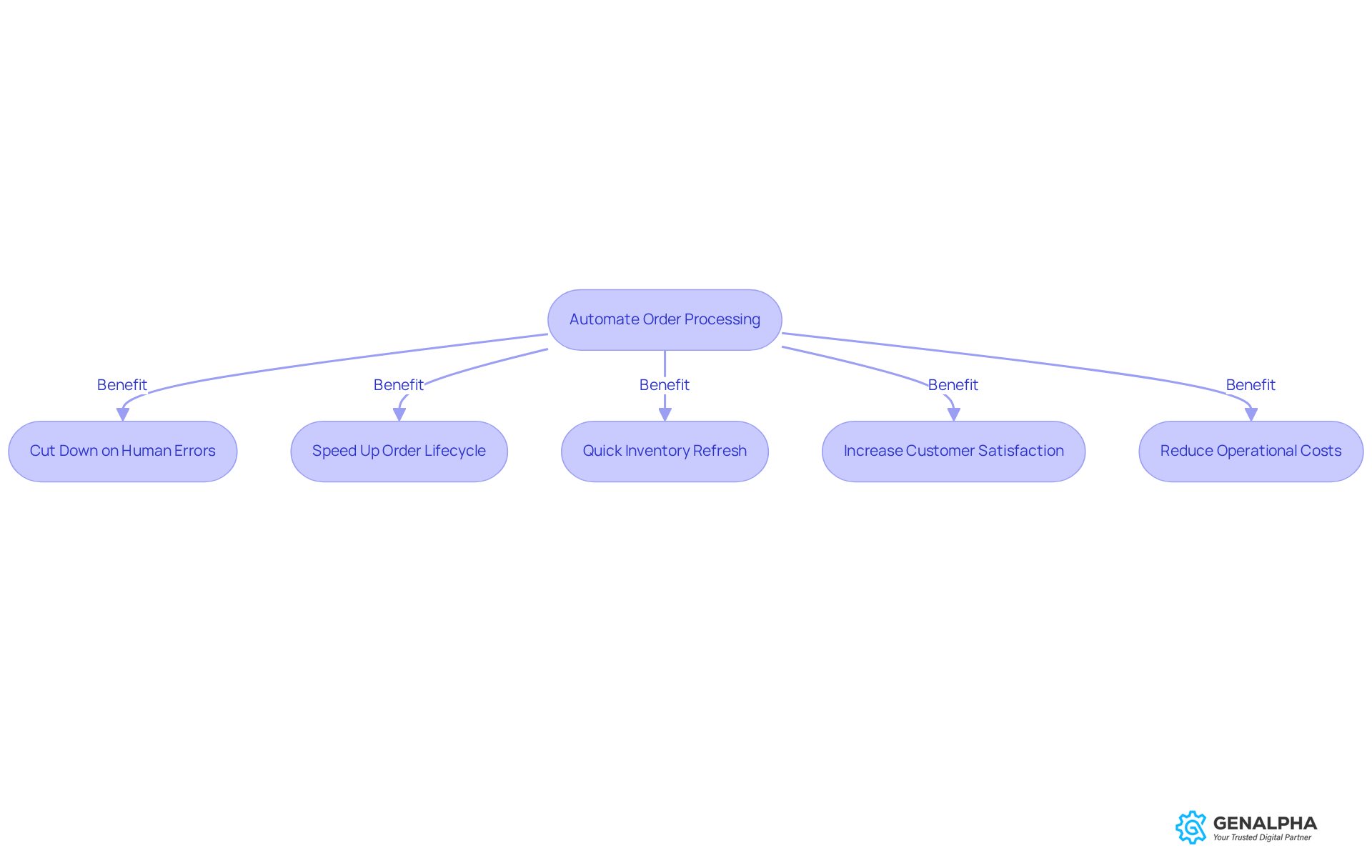

Automating transaction processing is a game changer for online order management systems! Imagine how much easier it would be if essential tasks like entry, invoicing, and shipping notifications were handled automatically. This shift not only cuts down on human errors—thanks to the precision that automation brings—but it also speeds up the entire lifecycle of requests. For example, automated processes can quickly refresh inventory levels, which helps avoid overselling and ensures that customers get timely updates about their purchases.

This capability can lead to happier customers who feel valued, and let’s be honest, who doesn’t want to keep clients satisfied and loyal? By processing requests swiftly and accurately, the online order management system really boosts customer contentment. Plus, businesses that embrace automation in their order management often see operational costs drop by 10-15%, especially in areas like procurement and accounts payable. This means they can use their resources more efficiently and focus on growth initiatives.

So, it’s no wonder that more manufacturers are recognizing how vital automation is for enhancing their operations and improving overall efficiency. Have you thought about how automation could transform your processes? It might just be the boost your business needs!

Real-Time Inventory Management: Optimize Stock Levels

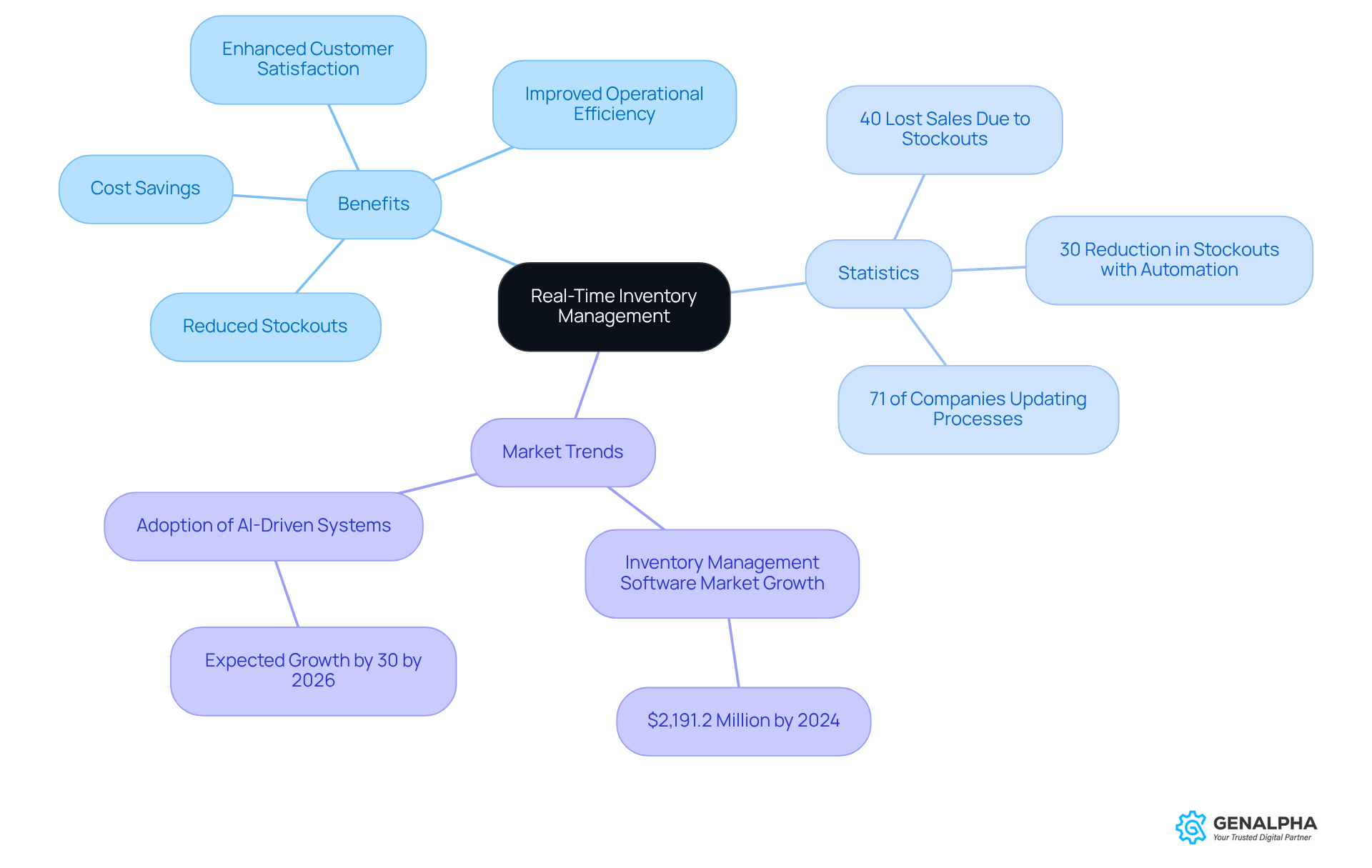

Have you ever thought about how real-time inventory management can change the game for manufacturers? It’s all about keeping stock levels just right, striking a balance between what customers want and what resources are available. By weaving real-time data into their online order management system, businesses can see what's happening across various locations and sales channels. This kind of oversight is a lifesaver—nobody wants to deal with stockouts, which account for a whopping 40% of lost sales! Plus, it helps cut down on excess inventory, leading to big cost savings and better service.

Imagine this: when the stock of a particular item dips below a certain point, the system automatically triggers a reorder. This way, inventory remains steady. This proactive strategy is essential because nearly 40% of retailers face stockouts that result in lost sales, highlighting the need for an online order management system to ensure effective inventory management. And here’s a cool fact: companies that use real-time data have found that automated systems can reduce stockouts by 30% through real-time tracking. That’s a clear win!

Additionally, a significant 71% of companies are planning to update their planning processes and governance within the next three years to boost supply chain visibility. This shows just how much people are starting to recognize the value of real-time data. By fine-tuning stock levels with real-time monitoring, producers can not only enhance operational efficiency but also improve client satisfaction, ultimately driving profitability.

The inventory management software market is set to hit $2,191.2 million by the end of 2024. This really reflects how crucial these solutions are becoming in the industry. So, what are you waiting for? It might be time to consider how real-time inventory management could benefit your business!

Centralized Data Access: Enhance Operational Consistency

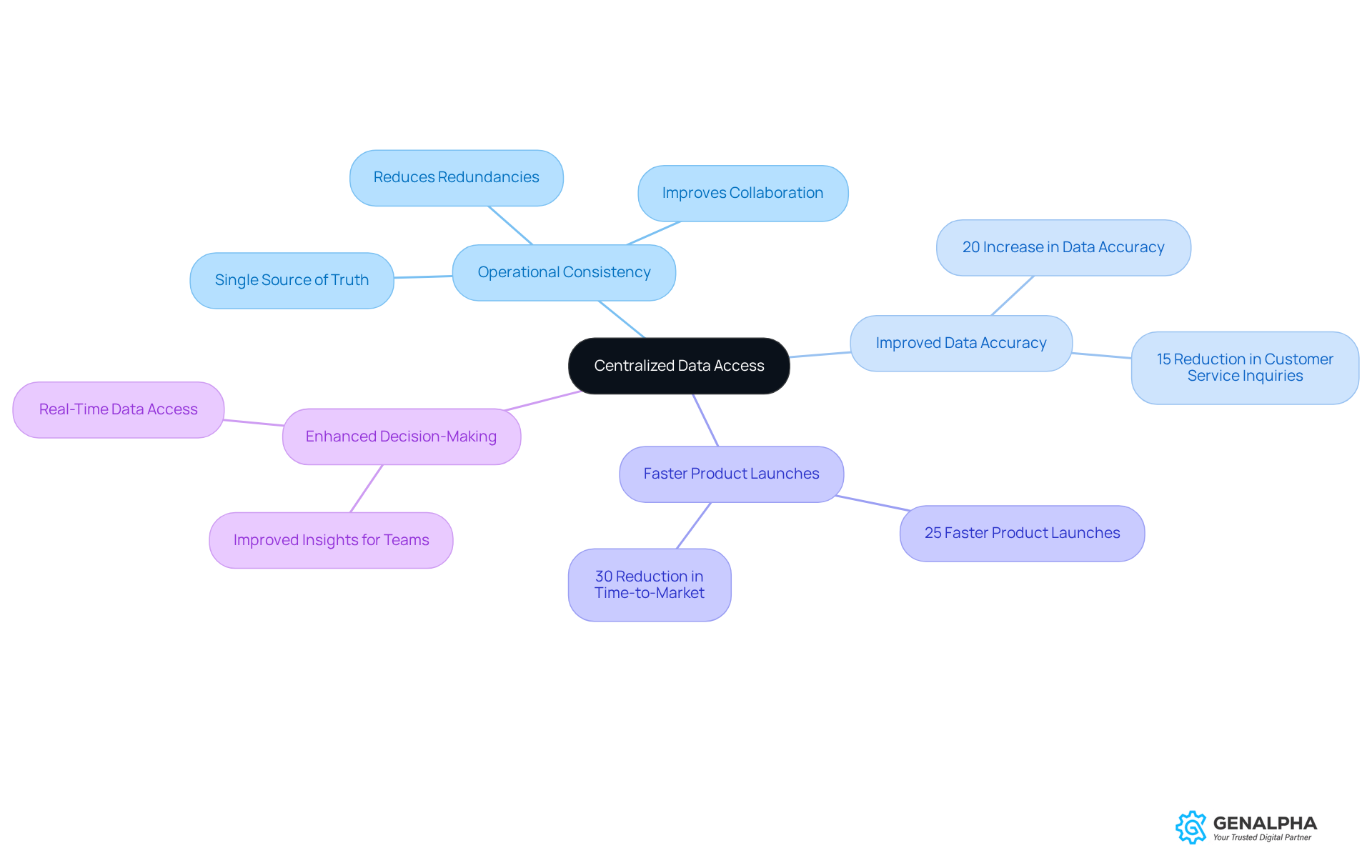

Imagine a world where manufacturers can access all their data in one place. Centralized data access is doing just that, revolutionizing operational consistency by bringing together information from various sources into a single platform. This means every team is on the same page, which cuts down on discrepancies and miscommunication. When teams have the same data, decision-making becomes not just easier, but way more efficient.

For example, think about sales teams using a centralized Product Information Management (PIM) platform. They can tap into real-time inventory data, enabling them to provide accurate delivery timelines. This not only boosts client trust but also enhances satisfaction. And here’s a fun fact: companies that embrace centralized PIM solutions see a 20% increase in data accuracy and a 15% drop in customer service inquiries related to incorrect product information.

But that’s not all! Producers who centralize their data can launch new products 25% faster. This really highlights how crucial data consolidation is for improving operational efficiency and consistency. So, if you’re a manufacturer looking to step up your game, it’s time to evaluate your current data management practices. Consider investing in a robust PIM solution that aligns with your operational needs. Ready to take the plunge?

Enhanced Customer Engagement: Foster Stronger Relationships

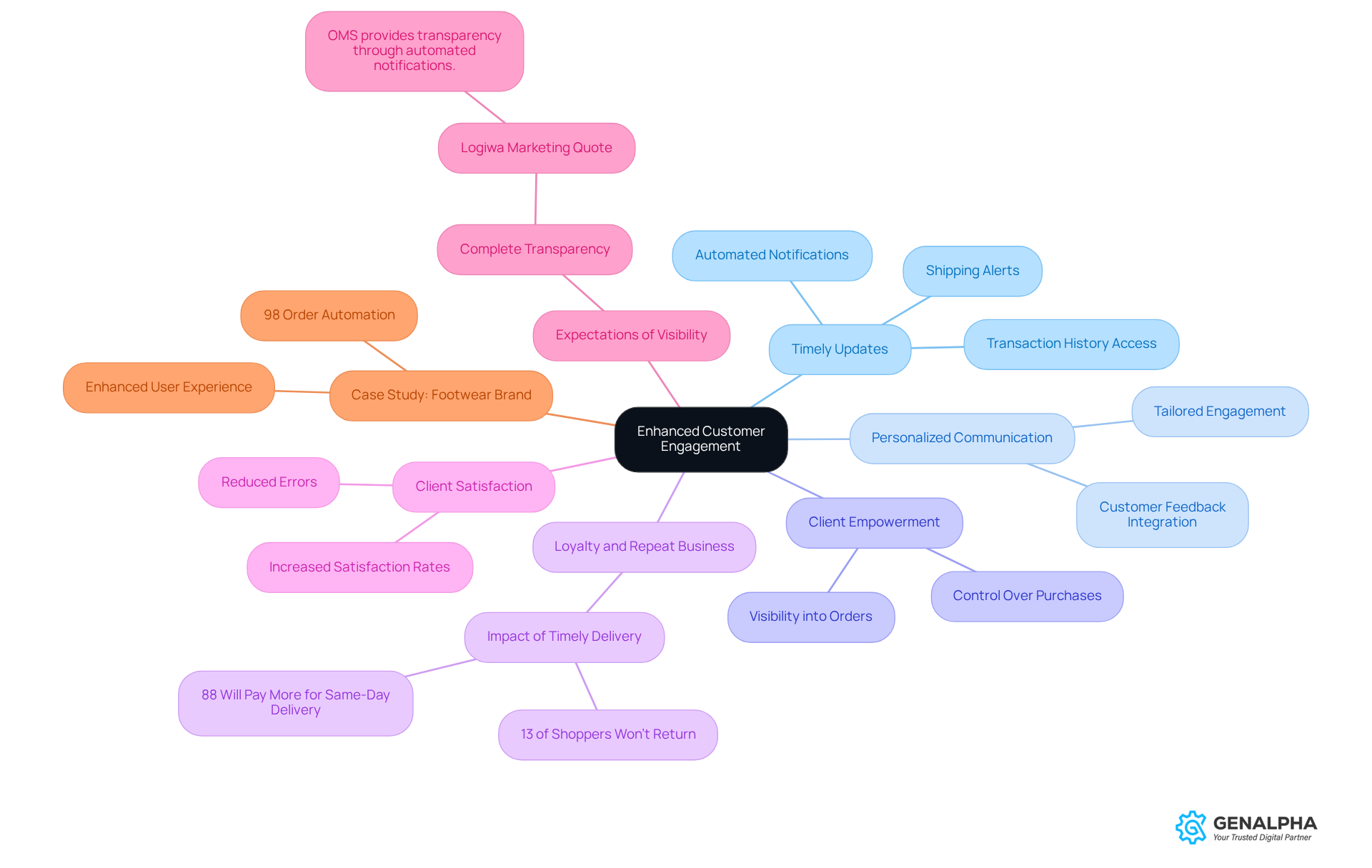

Imagine this: you’re eagerly waiting for a package, and you just want to know when it’s arriving. An efficient online order management system can make all the difference here! By providing timely updates and personalized communication, it keeps clients engaged and informed throughout their buying journey. Think about it—automated purchase confirmations, shipping alerts, and easy access to transaction history empower clients, making them feel in control.

This proactive communication doesn’t just keep clients informed; it builds stronger connections between producers and their clients, leading to enhanced loyalty and repeat business. Did you know that studies show 13% of shoppers won’t return for another purchase if their delivery doesn’t arrive on time? And get this—88% of consumers are willing to pay more for same-day delivery services! This really highlights the value of timely updates.

Additionally, companies that embrace an online order management system often report increased client satisfaction. Take a worldwide footwear brand, for example, which automated 98% of its requests. This not only reduced errors but also enhanced user experiences. By offering proactive alerts about status updates, producers can significantly elevate the client experience, ensuring that patrons feel appreciated and informed every step of the way.

As Logiwa Marketing puts it, "Today’s customers anticipate complete visibility into their purchases." Isn’t that a telling statement? It really emphasizes how crucial the online order management system is in fulfilling these expectations. So, how are you planning to enhance your client engagement today?

Scalability: Support Business Growth Effortlessly

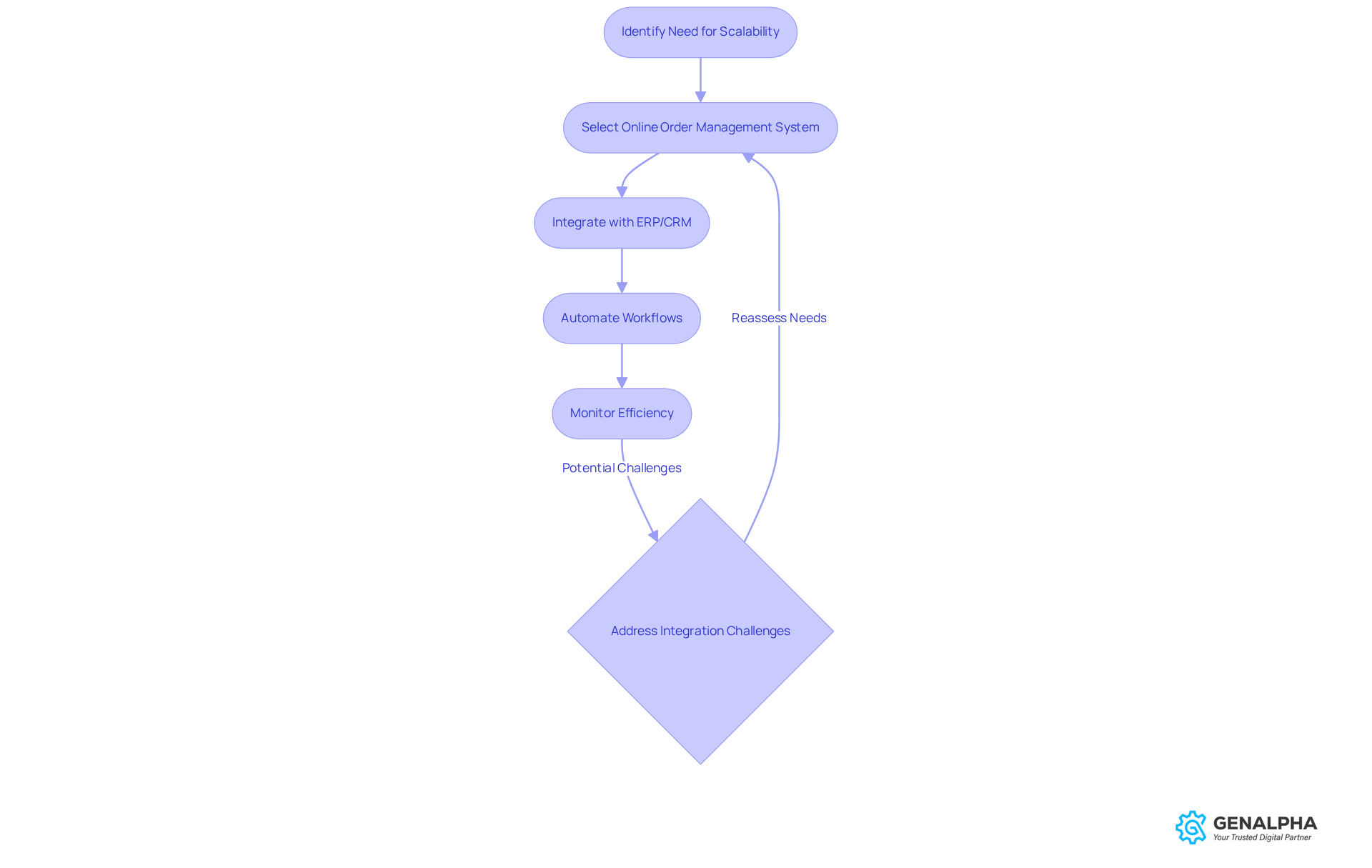

Scalability is super important in today’s management frameworks, allowing manufacturers to grow without getting bogged down by their processes. As companies expand, they often face higher demand and increased complexity. That’s where a smart online order management system comes in—it automates workflows and connects seamlessly with key systems like ERP and CRM platforms. This flexibility helps producers scale their operations efficiently, meeting market demands while keeping service quality high.

For example, companies using an online order management system have seen big boosts in operational efficiency and customer satisfaction. It’s a clear demonstration of how scalable solutions can really drive business growth. Plus, incorporating AI and machine learning into these frameworks enhances predictive capabilities, allowing producers to anticipate demand shifts and improve inventory control.

This strategic approach doesn’t just tackle immediate needs; it also sets manufacturers up for long-term success in a competitive market. Did you know that, according to Grand View Research, the global market for management solutions is projected to reach USD 3.17 billion by 2025? That really highlights how crucial these solutions are becoming in the manufacturing sector.

Additionally, Fluent Management handles over 100 billion API calls every month, showcasing its ability to efficiently manage increased transaction volumes. However, it’s important for producers to consider the potential challenges of integrating these frameworks with legacy systems, as that can complicate the scaling process. What strategies do you think could help overcome these hurdles?

Seamless ERP Integration: Connect Your Systems

Incorporating ERP platforms seamlessly is a game changer for efficient management solutions. Imagine linking your management processes with ERP—suddenly, data flows effortlessly between departments, reducing mistakes and boosting overall efficiency. This integration means real-time updates on inventory, requests, and customer info, leading to better decision-making and faster responses. For instance, when a request comes in, the platform can instantly refresh inventory levels in the ERP, keeping everyone in sync.

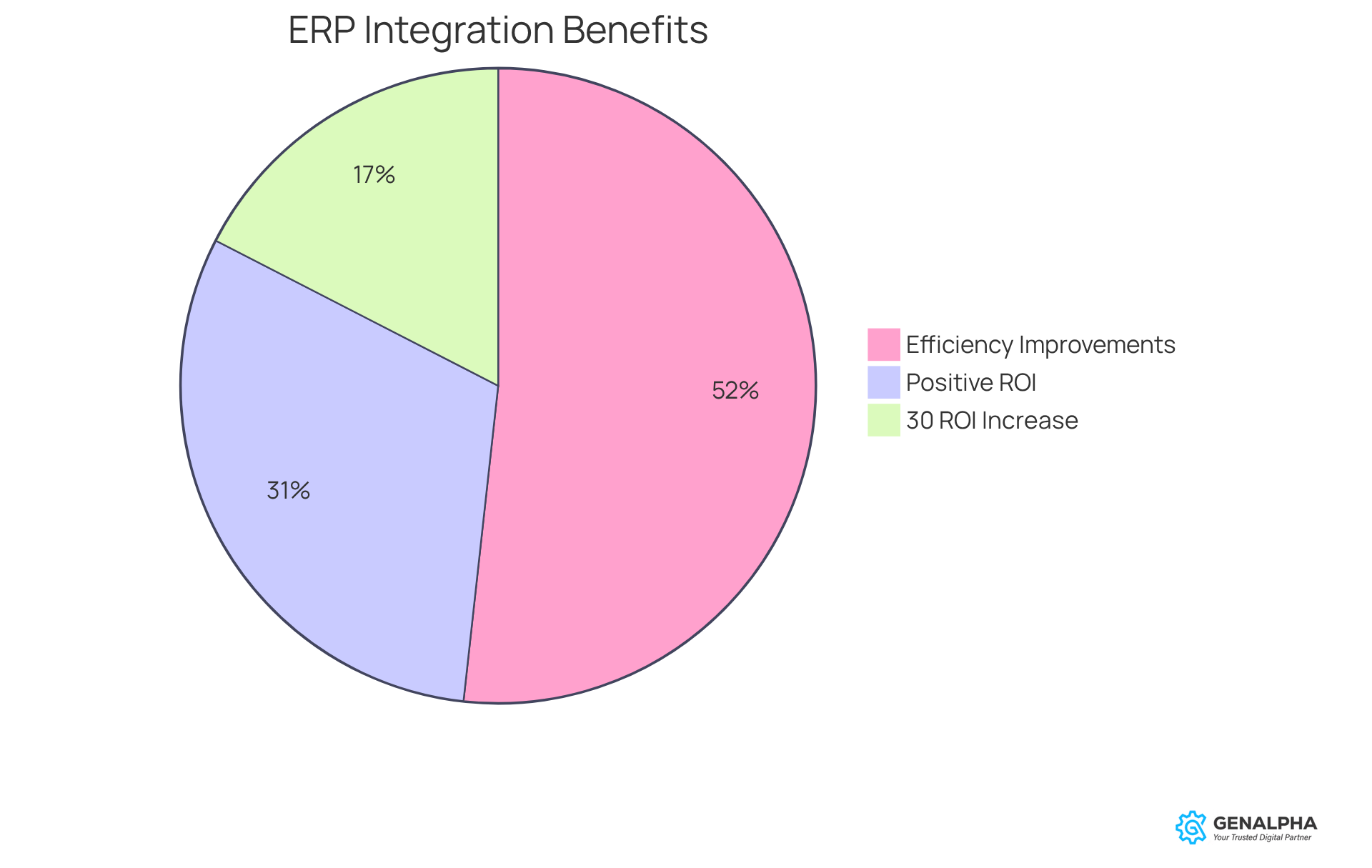

Did you know that 89% of ERP users highlight efficiency improvements as a top benefit? Plus, 53% of organizations see a positive ROI from their ERP implementations. That’s impressive! And for those manufacturers who’ve jumped on the ERP bandwagon, there’s a reported 30% rise in ROI within just three years. This really underscores the financial perks of enhanced management efficiency through ERP connectivity.

But wait, there’s more! ERP solutions also break down data silos, offering a single source of truth for all departments—talk about enhancing operational accuracy. Not to mention, ERP reduces manual errors by a whopping 70%. That’s a significant transformation! So, are you ready to explore how ERP can elevate your operations?

24/7 Access: Manage Orders Anytime, Anywhere

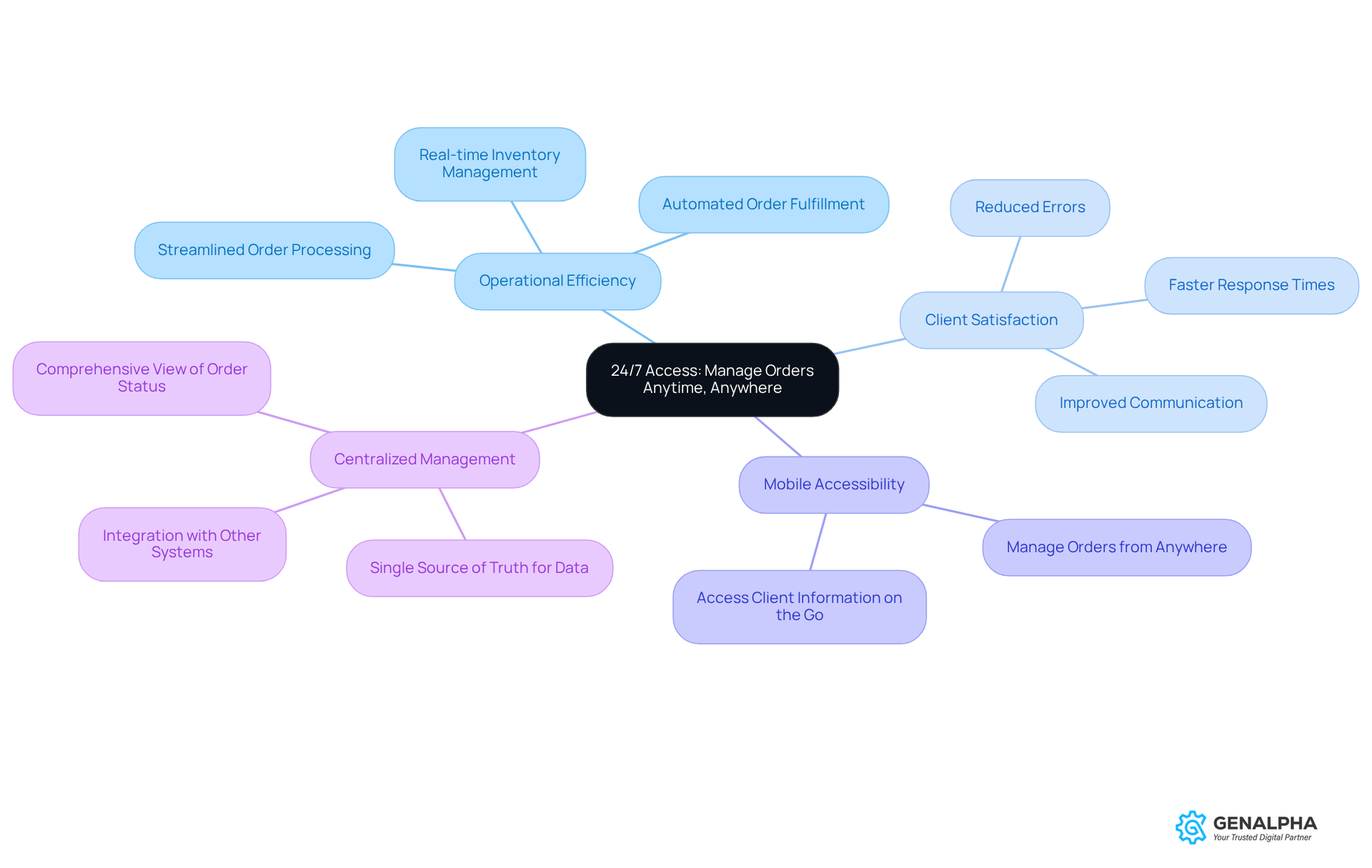

One of the coolest features of an online order management system is that you can access it anytime, anywhere—24/7! This flexibility is a game-changer for manufacturers with global operations or those who need to quickly respond to client inquiries. Imagine being able to manage orders, track shipments, and access client information via an online order management system right from your phone or laptop, no matter where you are. Pretty neat, right?

This capability not only boosts operational efficiency but also enhances service. Businesses can respond swiftly to inquiries and issues, regardless of time zones. As Caitlin Engelhardt pointed out, utilizing an online order management system significantly reduces the chance of errors, which is crucial for maintaining client satisfaction. Plus, producers who use mobile-friendly management platforms have noticed better response times and increased client satisfaction. It really shows the tangible benefits of this technology in today's fast-paced market.

By combining sales channels and centralizing request management through an online order management system, these solutions simplify operations and provide a complete view of status updates. Ultimately, this leads to improved client experiences. So, why not consider how these tools could work for you? They might just transform the way you do business!

Data-Driven Insights: Leverage Analytics for Better Decisions

Have you ever thought about how data-driven insights can really transform modern management systems? By tapping into analytics, producers can uncover valuable insights about consumer behavior, purchasing trends, and stock performance. This kind of intelligence is a game changer for strategic decision-making, allowing businesses to optimize stock levels, spot emerging trends, and fine-tune marketing strategies.

For instance, by examining sales data, producers can pinpoint peak buying times, which means they can adjust staffing and inventory ahead of time. This proactive approach not only boosts customer satisfaction but also enhances overall operational efficiency. Plus, organizations that put robust analytics frameworks in place often see improved inventory performance since they can manage stock fluctuations better and cut down on carrying costs.

Experts suggest that effectively leveraging analytics can lead to a more agile manufacturing process, ultimately driving profitability and giving businesses a competitive edge in a fast-paced market. As Shruti Bhat puts it, an online order management system enables companies to optimize their supply chain activities by providing improved visibility, which decreases lead times and enhances the accuracy of requests.

Looking ahead, the online order management system market is projected to grow significantly, with a compound annual growth rate (CAGR) of about 9.2% from 2025 to 2033, fueled by the rising demand for streamlined operations. However, it’s important for producers to navigate challenges like integration difficulties and the need for substantial upfront investment, which can sometimes slow down the adoption of advanced analytics.

So, what do you think? Are you ready to embrace the power of analytics in your operations?

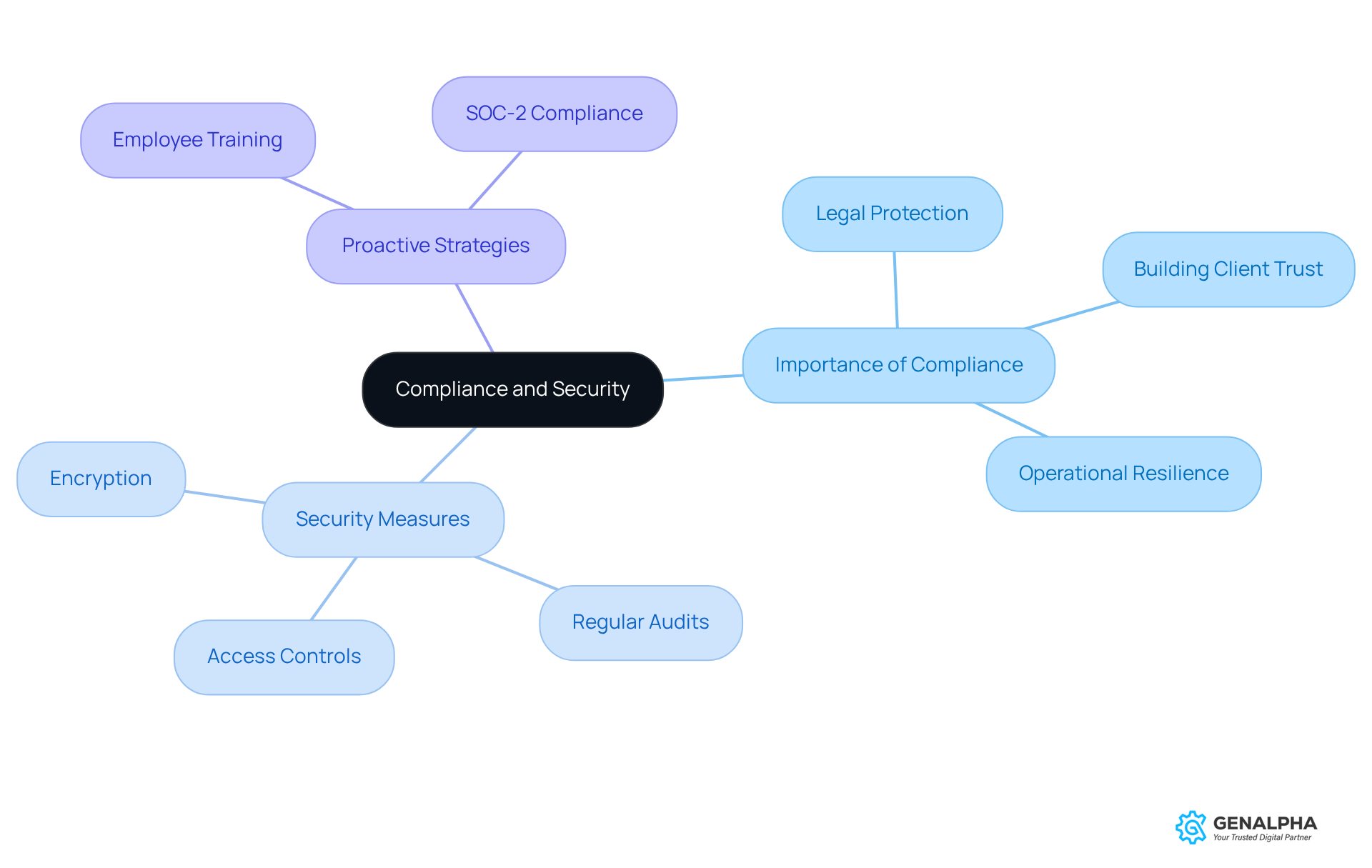

Compliance and Security: Safeguard Your Operations

For producers using an online order management system, it’s super important to keep compliance and security top of mind. The online order management system must meet strict industry regulations while also safeguarding sensitive client information. Implementing strong security measures, like encryption and regular audits, is key to protecting your operations from data breaches and cyber threats. Did you know that a 2020 report by Deloitte found that 39% of manufacturing companies faced a data breach? That really highlights the need for proactive security protocols.

As Rob Janes points out, producers can lower these risks by embracing both physical and cybersecurity strategies, such as:

- Access controls

- Employee training

Following these guidelines not only shields your business from potential legal issues but also builds trust with your clients. By adopting comprehensive security strategies, including SOC-2 compliance, manufacturers can boost their operational resilience and enhance their reputation in the marketplace. This, in turn, leads to improved customer loyalty and business growth. So, what steps will you take to secure your operations today?

Conclusion

The advantages of implementing an online order management system for manufacturers are pretty clear and compelling. By leveraging tools like Equip360, businesses can streamline their operations, boost efficiency, and ultimately enhance customer satisfaction. With automation, real-time inventory management, and centralized data access, not only do we reduce errors, but we also build stronger relationships with clients. This is crucial for manufacturers looking to stay competitive in a fast-paced market.

As we dive deeper, some key insights pop up. Think about the significant operational improvements that automation can drive, the critical need for real-time inventory oversight, and the seamless benefits of ERP integration. These elements come together to create a more agile and responsive manufacturing process, allowing companies to meet customer demands better and adapt to ever-changing market conditions. Plus, having access to data anytime and anywhere means teams can make quick, informed decisions, driving efficiency and growth.

So, in conclusion, embracing an online order management system isn’t just a passing trend; it’s a strategic move that can redefine how manufacturers operate. As the industry evolves, focusing on automation, data-driven insights, and solid security measures will be key to sustaining success. Manufacturers should definitely explore these technologies and consider how they can transform operations, leading to greater profitability and customer loyalty. The future of manufacturing lies in harnessing these advancements, and the time to act is now. What steps will you take to embrace this change?

Frequently Asked Questions

What is Equip360 by GenAlpha Technologies?

Equip360 is an online order management system designed for manufacturers and distributors to streamline their order management process, featuring inventory management, request tracking, and client interaction.

How does Equip360 improve operational efficiency?

Equip360 enhances operational efficiency by reducing the time spent on manual tasks, minimizing errors, and simplifying the processing of requests, which leads to a better client experience.

What operational gains have manufacturers reported after using Equip360?

Manufacturers using Equip360 have reported a 30% increase in fulfillment rates and a noticeable decrease in processing times, resulting in happier customers and stronger loyalty.

How does automation benefit order processing in online order management systems?

Automation in order processing reduces human errors, speeds up the lifecycle of requests, refreshes inventory levels quickly, and ensures timely updates for customers, leading to increased customer satisfaction.

What financial benefits can businesses expect from automating their order management?

Businesses that embrace automation often see operational costs decrease by 10-15%, particularly in procurement and accounts payable, allowing for more efficient resource use and a focus on growth.

What is the significance of real-time inventory management for manufacturers?

Real-time inventory management helps manufacturers maintain optimal stock levels, avoid stockouts—which account for 40% of lost sales—and reduce excess inventory, leading to cost savings and improved service.

How does real-time data help in inventory management?

By integrating real-time data into their systems, businesses can monitor stock levels across locations and trigger automatic reorders when inventory dips below a certain point, reducing stockouts by up to 30%.

What trends are emerging in the inventory management software market?

The inventory management software market is projected to reach $2,191.2 million by the end of 2024, indicating a growing recognition of the importance of real-time data and effective inventory management solutions.