Introduction

In today’s fast-paced manufacturing world, digital transformation isn’t just a buzzword - it’s a must for companies that want to succeed. Think about it: having a solid digital transformation roadmap can really boost your operational efficiency and help you tap into the latest technologies for growth. But here’s the kicker: the journey can be pretty tricky.

How do manufacturers figure out where they stand in terms of digital maturity? What steps should they take to set clear goals and choose the right tech to make it all happen?

This article is here to help! We’ll walk you through a structured approach to creating a personalized roadmap that tackles these challenges head-on. By the end, you’ll feel empowered to navigate your digital transformation journey with confidence. So, let’s dive in!

Define Your Current Digital Maturity

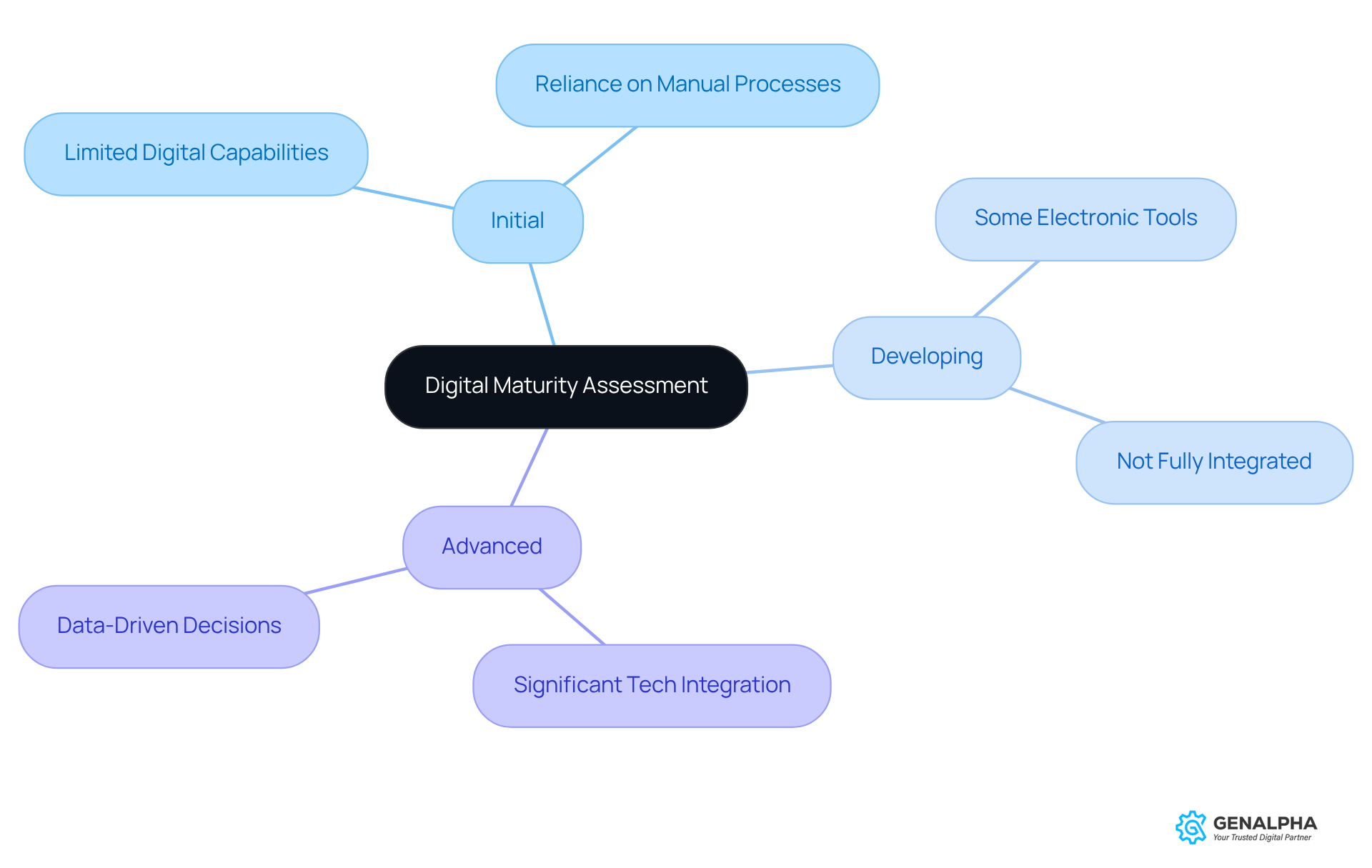

Are you ready to kick off your manufacturing digital transformation roadmap? First things first: let’s take a good look at where you stand with your current tech setup. This means evaluating your existing technologies, processes, and the skills of your workforce. A digital maturity model can help you categorize your organization into levels, like:

- Initial: You’ve got limited digital capabilities, mostly relying on manual processes.

- Developing: Some electronic tools are in place, but they’re not fully integrated yet.

- Advanced: You’re seeing significant tech integration, with decisions driven by data.

Now, it’s super important to gather input from different departments. This way, you’ll get a well-rounded view of your current state. Tools like surveys or workshops can really help with this assessment. Make sure to jot down your findings! This will give you a clear picture of your starting point, which is crucial for guiding your next steps in the manufacturing digital transformation roadmap.

So, what do you think? Are you ready to dive into this assessment?

Set Clear Objectives and Vision

After evaluating your current tech maturity, it’s time to outline clear goals and a vision for your manufacturing digital transformation roadmap. Let’s break it down into a few steps:

-

Engage Stakeholders: Get key players from different departments involved. Their diverse perspectives can really shape what your organization aims to achieve. As Kathryn Doyle puts it, "Stakeholder engagement is an ongoing dialogue and relationship that should be meaningful, inclusive, and transparent."

-

Define Specific Goals: It’s crucial to set specific, measurable, achievable, relevant, and time-bound (SMART) goals. For instance, how about aiming to boost online sales by 30% in the next year? This kind of clarity helps you track progress on your manufacturing digital transformation roadmap and stay focused.

-

Articulate a Vision: Craft a vision statement that captures the future you want for your organization after the transformation. This vision should inspire and motivate your team, acting as a guiding light throughout the change journey.

-

Align with Business Strategy: Make sure your tech evolution goals align with your overall business strategy. This alignment is key to maximizing impact and ensuring that the manufacturing digital transformation roadmap is effectively implemented. Plus, it’s essential for getting executive support and driving successful outcomes.

Don’t forget to jot down these goals and your vision clearly. They’ll serve as a guiding framework throughout the change process. Interestingly, organizations that involve stakeholders in their tech advancement efforts are statistically more likely to hit their targets. In fact, projects with high stakeholder involvement are 21% more likely to be successfully completed. And let’s not overlook the importance of addressing issues like reliance on outdated systems and trade uncertainties - these are vital for a balanced approach to tech advancement.

Identify Key Digital Technologies

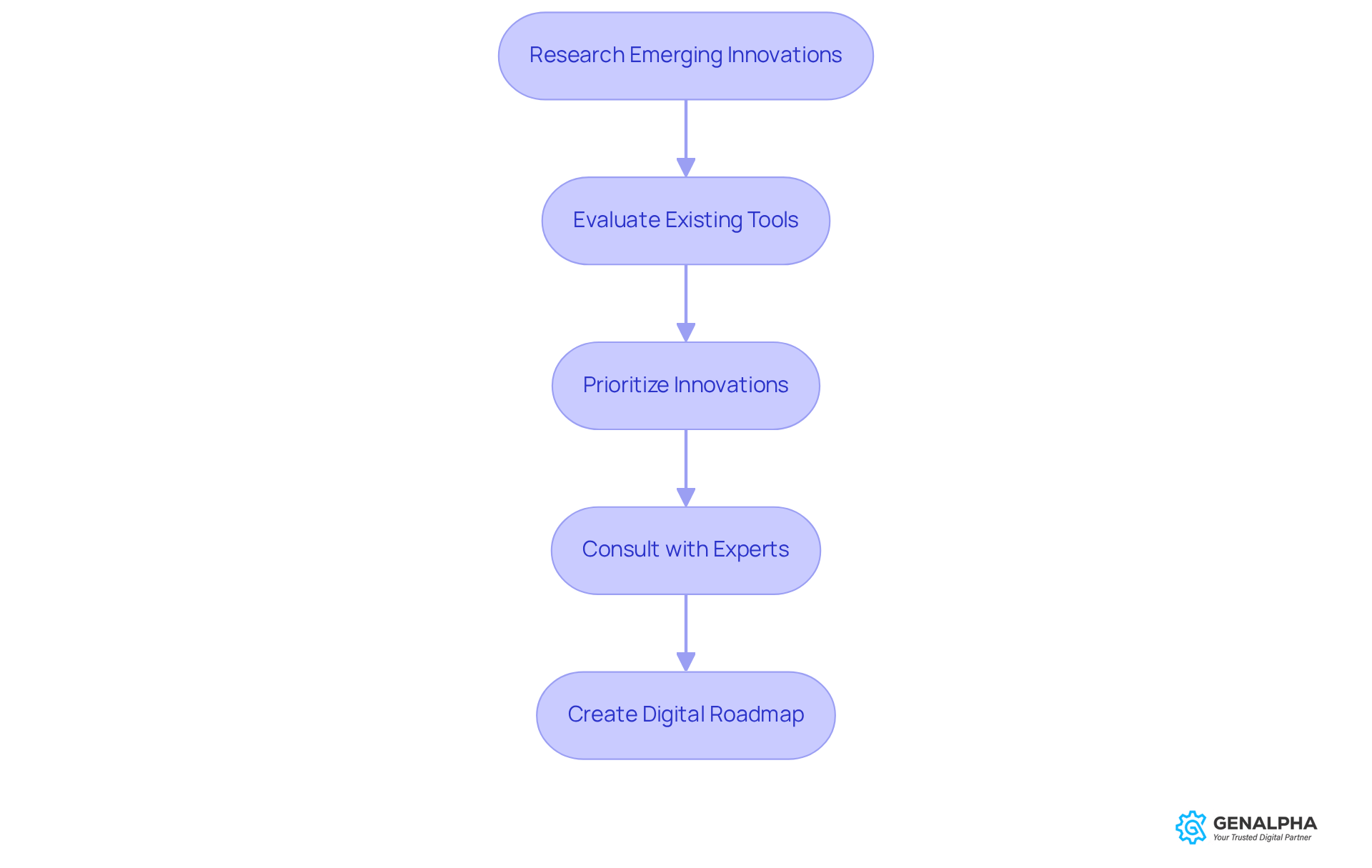

Now that you’ve set your clear objectives, it’s time to pinpoint the digital tools that will help you transform. Let’s break it down:

- Research Emerging Innovations: Keep your finger on the pulse of the latest trends in manufacturing, like AI, IoT, and cloud computing. Dive into industry reports and tech blogs - they’re goldmines for insights!

- Evaluate Existing Tools: Take a good look at what you already have. Are there tools that could use an upgrade or could be integrated into new systems? Think about your eCommerce platforms, CRM systems, and data analytics tools.

- Prioritize Innovations: With your objectives in mind, focus on the innovations that will make the biggest splash. For instance, if enhancing customer experience is on your list, consider investing in advanced CRM systems or electronic warranty management solutions.

- Consult with Experts: Don’t hesitate to reach out to vendors or consultants who specialize in manufacturing digital solutions. They can provide valuable insights into the best options for your organization.

Finally, create a digital roadmap that outlines the tools you’ve selected, their implementation timelines, and how they align with your transformation goals. Ready to get started?

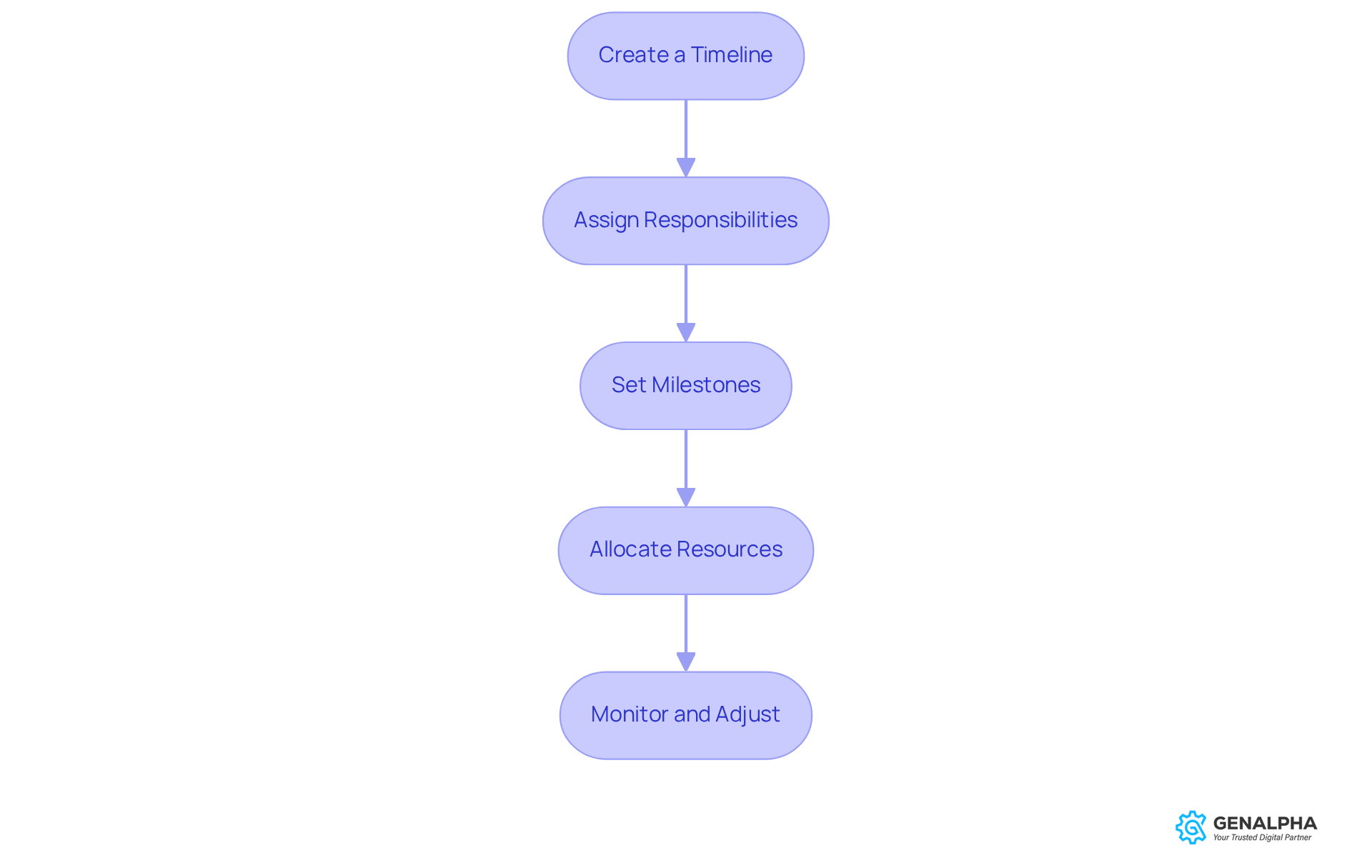

Develop a Strategic Implementation Plan

Once you've spotted those key innovations, the next step is to whip up a strategic implementation plan. Given the pressures manufacturing leaders are facing, including global supply chain hiccups and unpredictable energy markets, a structured manufacturing digital transformation roadmap is essential. So, let’s break it down:

- Create a Timeline: Start by setting a realistic schedule for rolling out each system. Keep in mind dependencies and resource availability. This timeline is key to managing expectations and keeping everyone on the same page.

- Assign Responsibilities: It’s time to designate team members or departments to take charge of each part of the implementation. Clear accountability is crucial for success, especially in a tech-driven world where agility and efficiency are the name of the game.

- Set Milestones: Define some key milestones to keep track of progress and ensure the project stays on track. Think phases like pilot testing, full deployment, and post-implementation review. This way, you can assess success in a timely manner.

- Allocate Resources: Figure out the budget and resources you’ll need for each phase. Make sure you have the backing from leadership to secure funding, as this support is vital for navigating the twists and turns of the manufacturing digital transformation roadmap.

- Monitor and Adjust: Set up a system to keep an eye on how things are going and make adjustments as needed. Regular check-ins with stakeholders can help spot challenges early. Plus, getting employees involved from the get-go is key to reducing resistance and helping everyone embrace new technologies.

Make sure to document your implementation strategy in detail. This will guide your team through the change process and keep everyone focused on the goals. For instance, case studies show that when employees are involved early on, it can really boost acceptance of new systems, leading to smoother transitions and better outcomes.

Plan Workforce Training and Upskilling

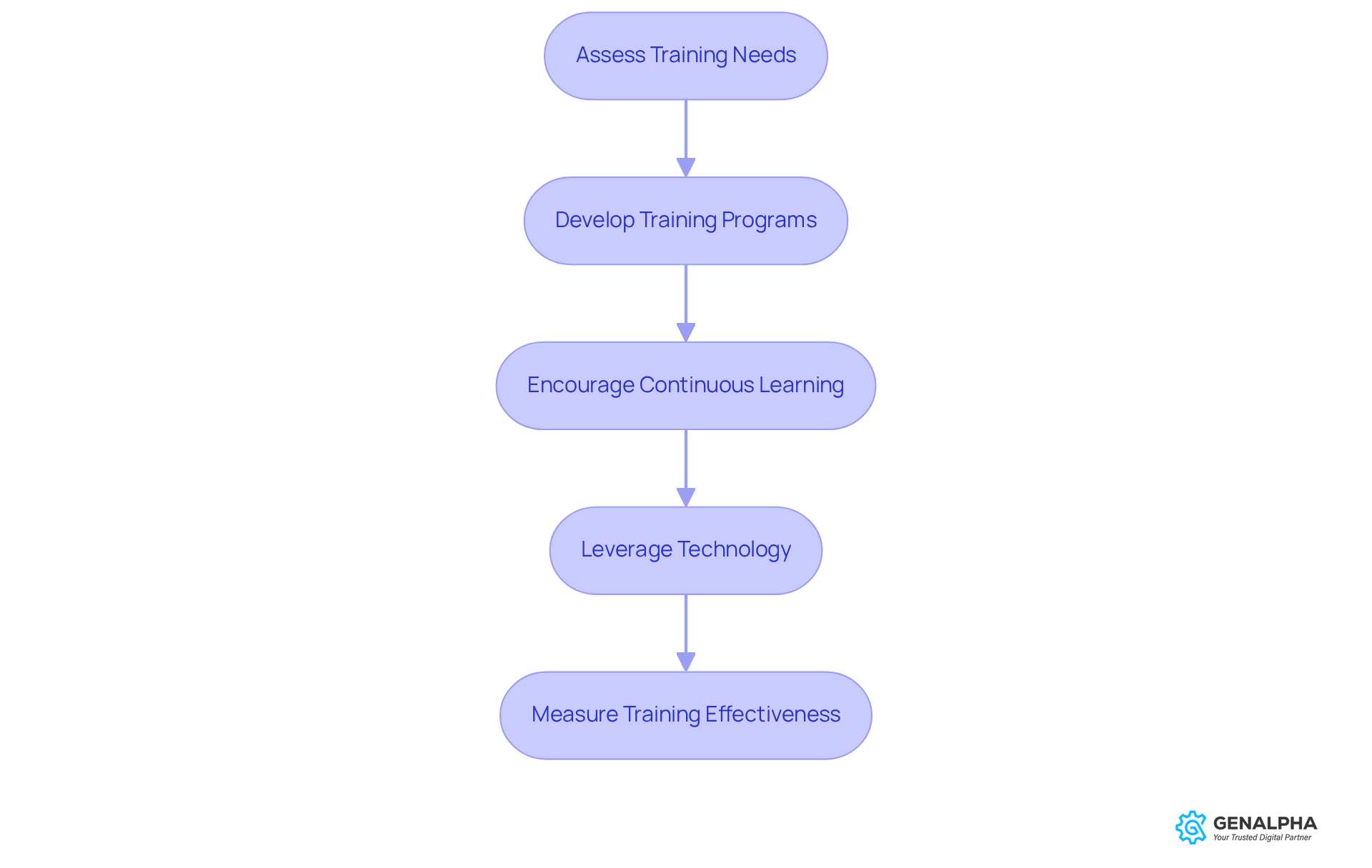

The last step in crafting your transformation roadmap? Planning for workforce training and upskilling! Let’s break it down:

- Assess Training Needs: Start by figuring out what skills your team is missing when it comes to the new tech you’re rolling out. A needs assessment can really help here.

- Develop Training Programs: Next, create training programs that are tailored to fill those gaps. Think workshops, online courses, or even hands-on training sessions that get everyone involved.

- Encourage Continuous Learning: It’s all about fostering a culture of continuous learning. Provide ongoing training opportunities and resources so your employees can keep enhancing their skills over time.

- Leverage Technology: Don’t forget to use tech for training! E-learning platforms or virtual reality simulations can make the learning process way more engaging and effective.

- Measure Training Effectiveness: Finally, set up some metrics to see how well your training programs are working. Gather feedback from participants and tweak the programs as needed to improve outcomes.

By investing in workforce training and upskilling, you’re not just preparing your employees for the changes that come with the manufacturing digital transformation roadmap; you’re also setting the stage for a successful implementation. So, what are you waiting for? Let’s get started!

Conclusion

Creating a successful digital transformation roadmap for manufacturing isn’t just a nice-to-have; it’s essential if you want to thrive in today’s competitive landscape. Think about it: by taking a good look at where you currently stand in terms of digital maturity, setting clear goals, pinpointing the right technologies, and crafting a solid implementation plan, you can set your organization on a path to transformation that boosts both efficiency and innovation.

Each step in this journey is crucial. Knowing your starting point helps you set realistic goals. Plus, getting everyone on board - stakeholders, employees, and tech experts - means you’ll gather diverse insights that shape a vision everyone can rally behind. And let’s not forget about the tech! Identifying the right tools and creating a structured plan makes the transition smoother. Finally, investing in training ensures your team has the skills they need to thrive in this new digital landscape.

The importance of digital transformation in manufacturing really can’t be overstated. As industries evolve, embracing these changes isn’t just a smart move; it’s vital for survival and growth. So, why not take those proactive steps in your digital journey? Use the insights shared here to create a roadmap that not only tackles today’s challenges but also anticipates tomorrow’s opportunities. Embracing this transformation will lead to better operational efficiency, improved customer experiences, and ultimately, a more resilient manufacturing sector. Ready to get started?

Frequently Asked Questions

What is the first step in initiating a manufacturing digital transformation roadmap?

The first step is to evaluate your current digital maturity by assessing existing technologies, processes, and workforce skills.

How can a digital maturity model help organizations?

A digital maturity model categorizes organizations into levels such as Initial, Developing, and Advanced, helping to understand their current digital capabilities.

What methods can be used to gather input from different departments during the assessment?

Tools like surveys or workshops can be utilized to gather input and provide a well-rounded view of the current state.

What should organizations do after evaluating their current tech maturity?

Organizations should outline clear goals and a vision for their digital transformation roadmap.

Why is stakeholder engagement important in the digital transformation process?

Engaging stakeholders from different departments provides diverse perspectives that shape the organization’s goals, fostering meaningful and transparent dialogue.

What does SMART stand for in goal-setting?

SMART stands for Specific, Measurable, Achievable, Relevant, and Time-bound, which helps in defining clear and trackable goals.

How should organizations articulate their vision for digital transformation?

Organizations should craft a vision statement that captures the future they want after the transformation, inspiring and motivating the team throughout the change journey.

Why is it important to align tech evolution goals with the overall business strategy?

Aligning tech evolution goals with the business strategy maximizes impact, ensures effective implementation, and secures executive support for successful outcomes.

What is the significance of documenting goals and the vision?

Documenting goals and the vision provides a guiding framework throughout the change process and helps track progress.

How does stakeholder involvement affect the success of tech advancement projects?

Organizations that involve stakeholders in their tech advancement efforts are statistically more likely to successfully complete projects, with a 21% higher likelihood of success.