Introduction

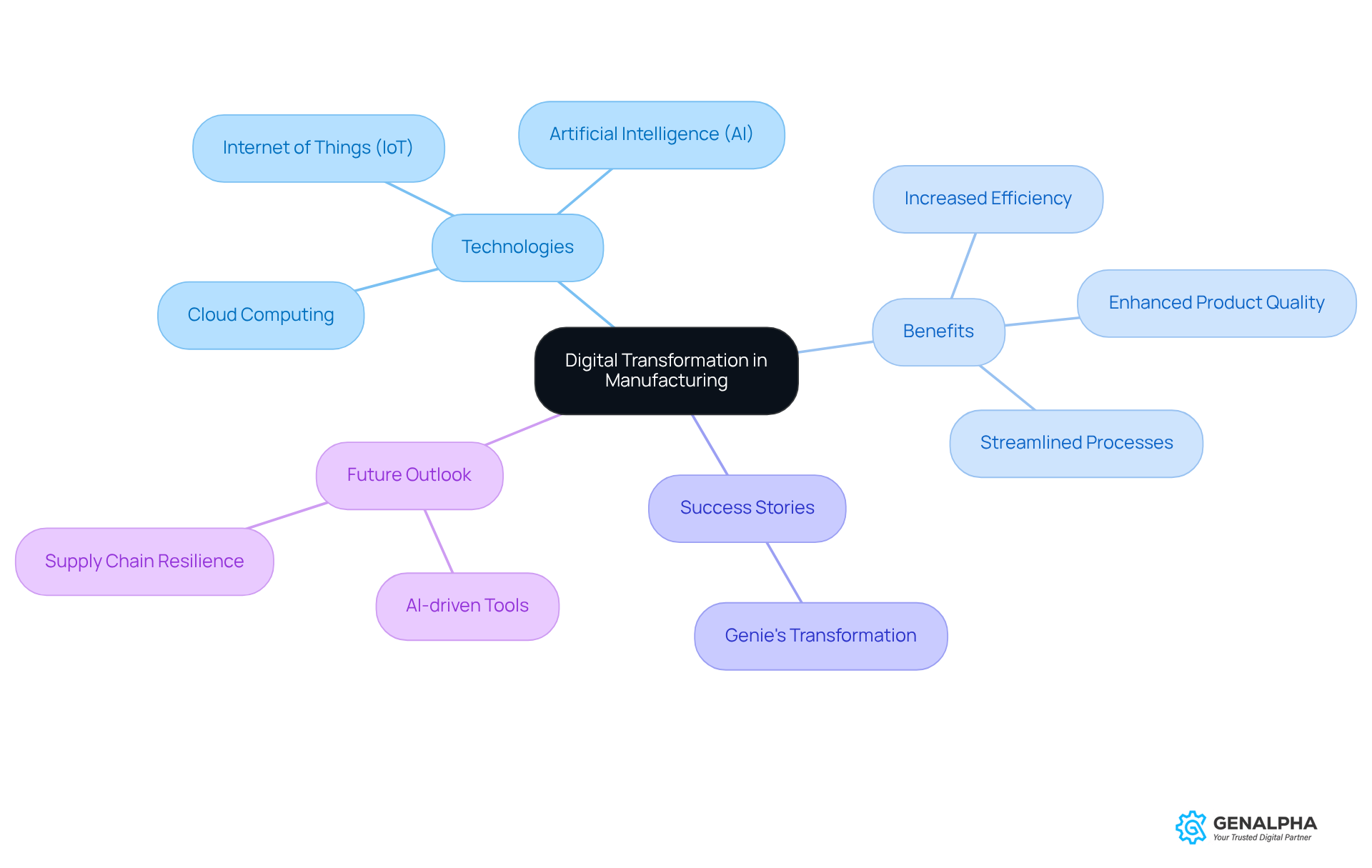

Digital transformation is shaking up the manufacturing world, right? With cool technologies like IoT, AI, and cloud computing, production processes and operational efficiencies are getting a serious makeover. As manufacturers face tougher competition, it’s crucial to get a grip on these digital tools to boost productivity and meet what the market demands.

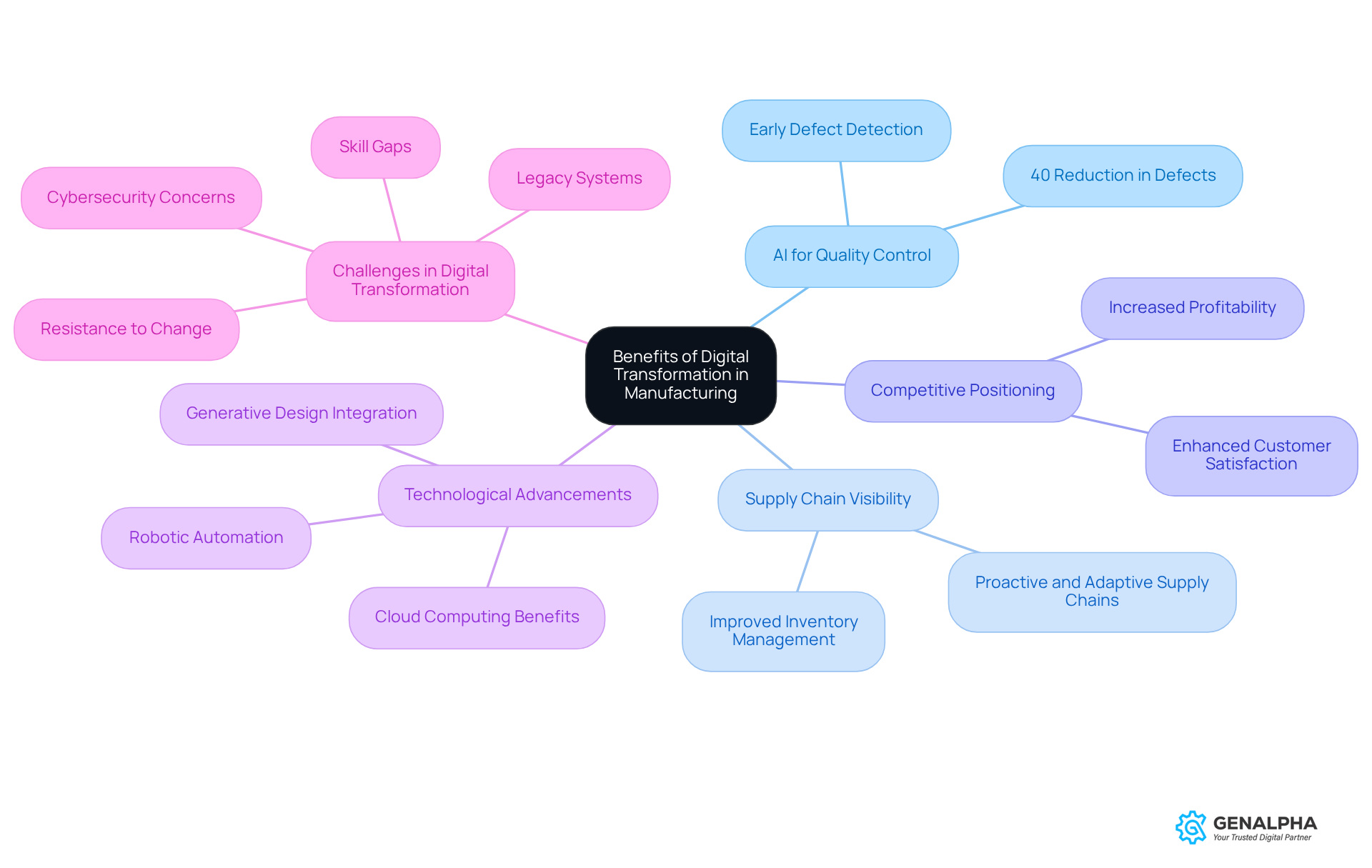

But let’s be real - the journey isn’t all smooth sailing. There are hurdles to jump over, like resistance to change and skill gaps. So, how can companies tap into digital transformation not just to tackle these challenges but also to discover amazing opportunities for growth and innovation?

Think about it: embracing these changes could be the key to unlocking your potential. Let’s dive into how we can make this transformation work for us!

Understand Digital Transformation in Manufacturing

The concept of digital transformation for manufacturing companies involves integrating digital tools into every nook and cranny of production and operations. Think about it: technologies like the Internet of Things (IoT), artificial intelligence (AI), and cloud computing are not just buzzwords; they’re game-changers that boost efficiency, enhance product quality, and streamline processes. As manufacturers face a tougher competitive landscape, understanding the digital transformation for manufacturing companies is crucial for meeting market demands and enhancing supply chains.

Did you know that companies undergoing digital transformation for manufacturing companies see major boosts in agility and productivity? For example, productivity gains in manufacturing have dropped from 2-3% in the early 2000s to under 1% today. This calls for a fresh workforce model that blends robots and AI systems. In fact, a whopping 93% of Chief Operating Officers at firms with revenues over $1 billion plan to ramp up investments in AI and tech advancements in the next five years. By 2026, the digital transformation for manufacturing companies will see them increasingly lean on AI-driven supply chain intelligence tools to explore scenarios and test assumptions, marking a strategic shift towards digital solutions.

There are plenty of success stories in the manufacturing world. Take Genie, for instance. They’ve made significant strides, leading to better operational efficiencies and improved customer service. Their global contact center revamp not only cut down call wait times but also laid the groundwork for integrating AI into their operations, proving the tangible benefits of tech initiatives.

Industry leaders are all in on this shift. As Greg Kaiser, Senior Director of Manufacturing at Slalom, puts it, "Entities that invest in robust data foundations and embrace virtual twins as a fundamental enterprise capability will be optimally positioned to lead by transforming how decisions are made and how producers compete in a swiftly changing market."

Looking ahead to 2026, the impact of digital transformation for manufacturing companies on manufacturing processes will be huge. Manufacturers will increasingly depend on AI-driven tools to boost supply chain resilience, automate tasks, and enhance decision-making. This evolution won’t just streamline operations; it’ll foster a culture of continuous improvement, helping producers thrive in a fast-paced environment.

Leverage Key Technologies for Transformation

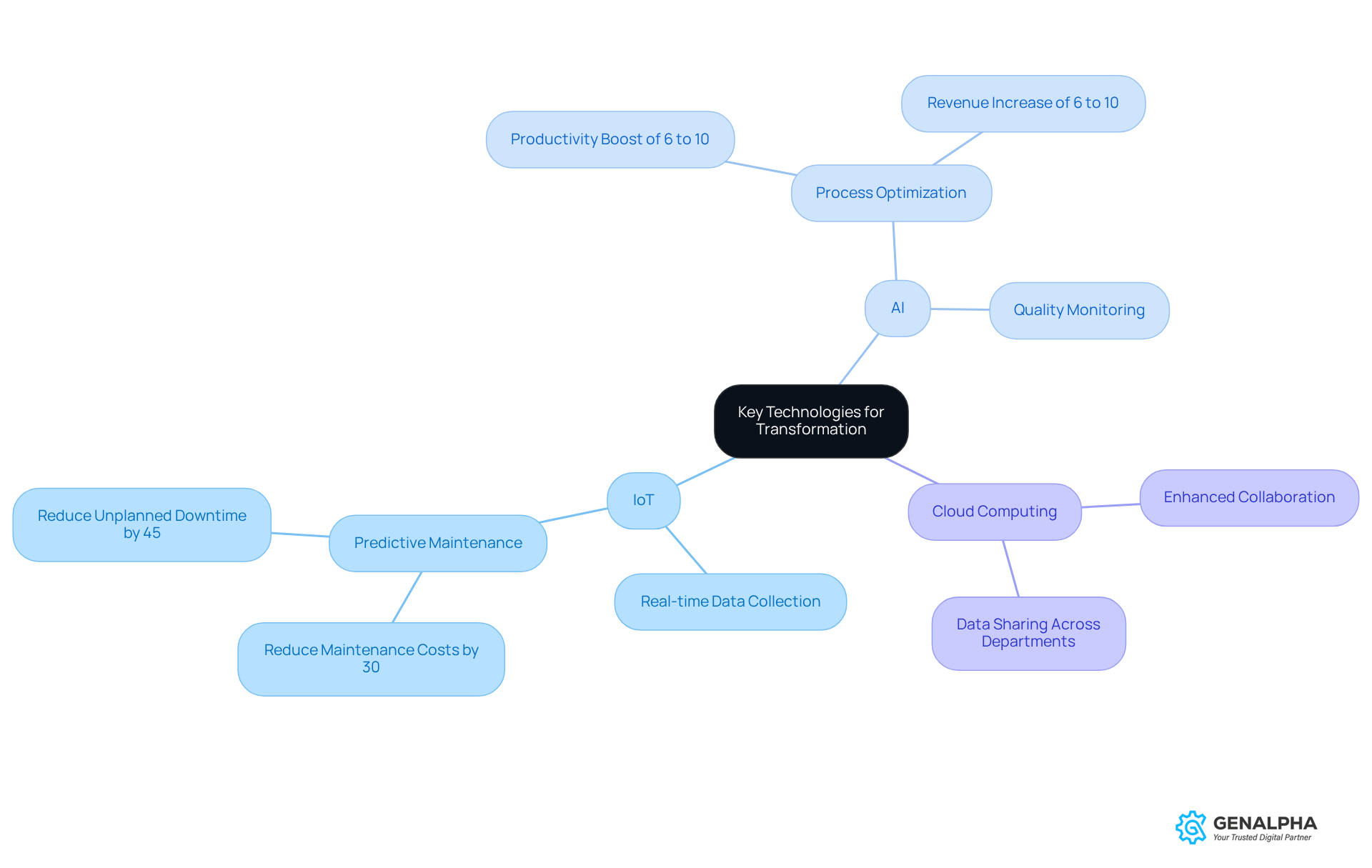

Managing changes in the online world can feel overwhelming, right? But here’s the good news: producers can tap into some pretty amazing innovations like IoT, AI, and cloud computing to make things easier. For instance, IoT devices are fantastic for real-time data collection. They help with predictive maintenance, which can cut maintenance costs by up to 30% and reduce unplanned downtime by 45%. That’s a big deal!

Now, let’s talk about AI. It takes things a step further by analyzing production data to optimize processes. Businesses that embrace these solutions often see productivity boosts of 6% to 10%. And guess what? They can also expect a revenue increase in that same ballpark. Pretty enticing, huh?

Additionally, cloud computing makes collaboration and data sharing a breeze across departments, which can significantly enhance operational efficiency. The trend is shifting from traditional automation to orchestration, allowing for a more dynamic and adaptive coordination of resources.

By incorporating these innovations, manufacturers can create a more agile and responsive production environment as part of their digital transformation for manufacturing companies. This positions them for success in a competitive landscape. Are you ready to embrace these changes and elevate your production game?

Identify and Overcome Transformation Challenges

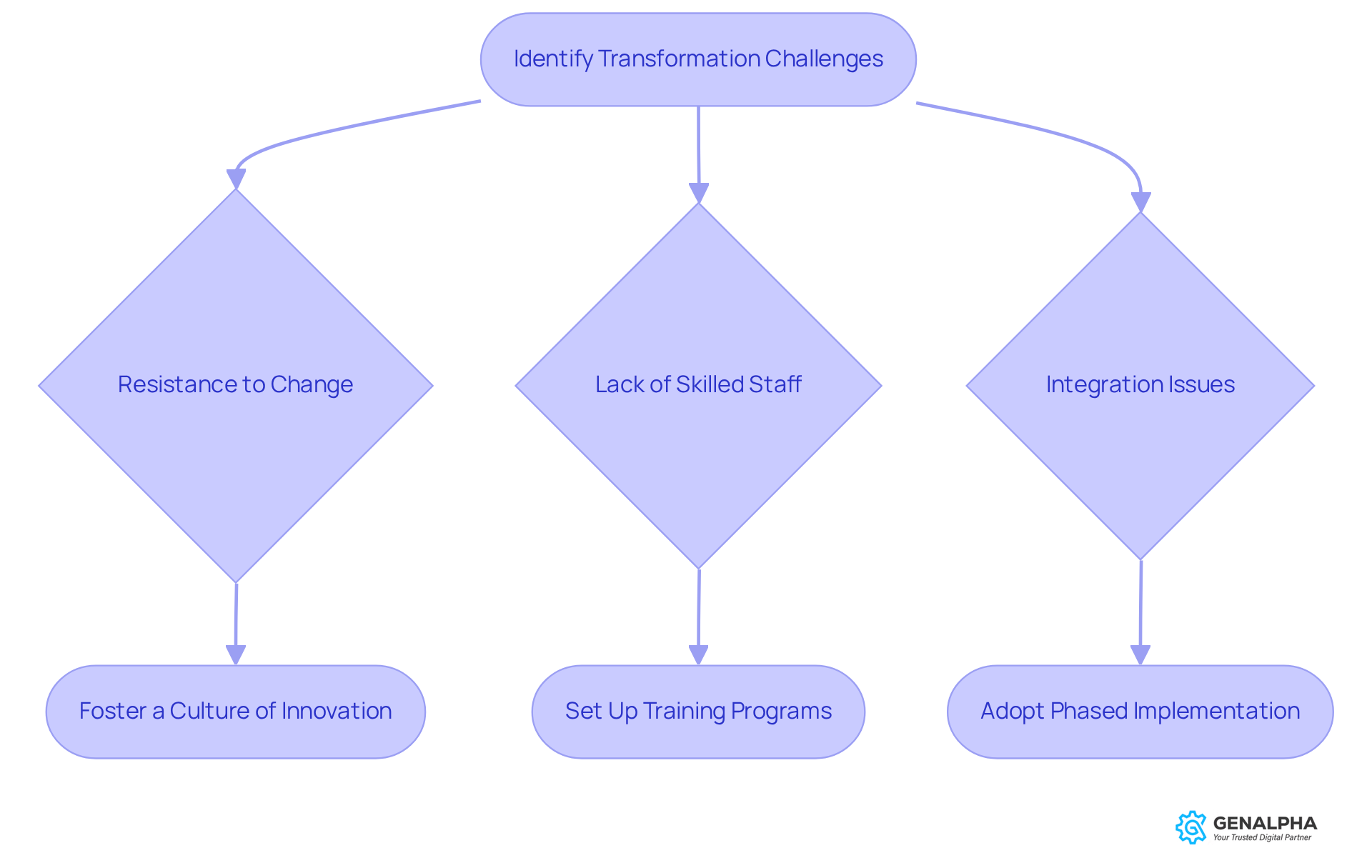

Producers often hit some pretty big roadblocks when it comes to tech advancements. You know, things like resistance to change, not having enough skilled staff, and the headaches that come with integrating old systems. So, how can organizations tackle these challenges? Well, it all starts with fostering a culture of innovation and continuous learning.

One key step is to set up strong training programs. These are essential for equipping employees with the skills they need to adapt to new technologies. Studies have shown that when organizations communicate openly about the benefits of change, they see less pushback. It really highlights how important it is to share the positive impacts of tech initiatives.

Additionally, adopting phased implementation strategies can make transitions smoother. By gradually integrating new systems, companies can minimize disruptions. For example, a producer might pilot a new innovation in one department before rolling it out company-wide. This way, staff can get the support they need and feel more prepared.

It's also worth noting that 37% of producers have pointed out a lack of internal knowledge as a barrier to tech advancement. This really underscores the need for effective training initiatives. As Donal Tobin puts it, 'Cultural and organizational barriers prevail over change challenges (surpassing technological obstacles).' So, tackling these issues head-on is crucial.

Develop a Strategic Digital Transformation Roadmap

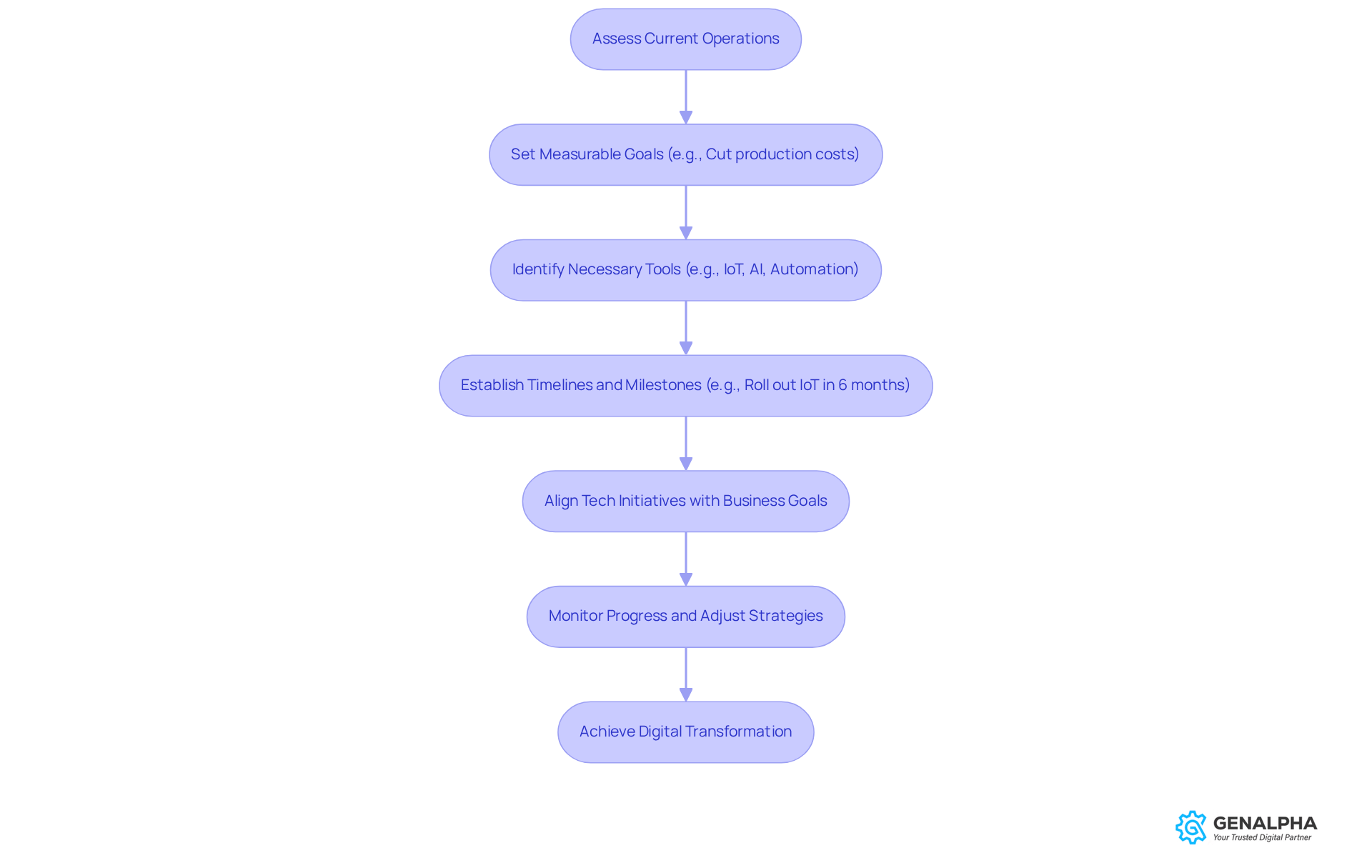

Creating a strategic roadmap for digital transformation for manufacturing companies is a must for manufacturers looking to thrive in today’s fast-paced world. It all kicks off with a solid look at current operations to spot inefficiencies and areas that could use a little TLC. From there, manufacturers should set clear, measurable goals - like cutting production costs by a certain percentage or speeding up delivery times. These goals not only give you a clear direction but also help keep everyone accountable.

So, what tools do you need to hit those targets? Think:

- IoT for real-time monitoring

- AI for predictive analytics

- Automation tools to make processes smoother

And don’t forget about timing! For instance, a manufacturer might aim to roll out IoT solutions in six months, followed by AI analytics in the next year.

To keep the roadmap effective, it’s smart to include milestones that let you track progress and tweak strategies as needed. Industry experts agree that aligning tech initiatives with business goals is key to success. Looking ahead to 2026, organizations will be all about becoming composable businesses, ready to adapt quickly to market shifts and customer needs. This proactive approach to digital transformation for manufacturing companies not only boosts operational efficiency but also opens the door to new opportunities.

So, are you ready to take the leap into digital transformation?

Realize the Benefits of Digital Transformation

Have you ever thought about how digital advancements are shaking up the manufacturing world? They’re not just a trend; they’re bringing some serious benefits to the table. Imagine this: manufacturers using AI for quality control can spot defects way earlier in the production process. This not only cuts down on waste but also keeps customers happy. In fact, studies show that AI-driven quality control can slash defects by up to 40%!

As we look ahead to 2026, we can expect even more exciting changes. Technological transformations are set to boost supply chain visibility, making inventory management smoother and allowing for quicker responses to market shifts. Supply chains are becoming more proactive and adaptive, thanks to AI and virtual twins that react to real-time data. This kind of agility is crucial in today’s fast-paced environment, where producers need to keep up with changing demands.

So, what does all this mean for manufacturers? These advancements not only help strengthen competitive positioning but also drive profitability. Embracing digital transformation for manufacturing companies isn’t just a nice-to-have; it’s a must for manufacturers who want to thrive in the modern landscape. Are you ready to jump on board?

Conclusion

Digital transformation in manufacturing isn’t just a passing trend; it’s a game changer for how companies operate. By tapping into advanced technologies like IoT, AI, and cloud computing, manufacturers can really shake up their production processes. This means they can meet market demands more effectively and create a culture of continuous improvement.

Throughout this article, we’ve highlighted some key practices for a successful digital transformation. It’s crucial to understand the importance of these technologies, tackle challenges with training and phased implementation, and develop a strategic roadmap. These steps are essential for manufacturers looking to thrive in a competitive landscape. Take Genie, for example; their success story shows the real benefits of embracing these innovations, leading to improved operational efficiencies and better customer service.

As the manufacturing sector continues to evolve, the need for digital transformation is becoming clearer by the day. Companies can’t just adopt new technologies; they also need to foster an environment that encourages innovation and adaptability. Embracing these changes is vital for manufacturers who want to boost their competitive edge and drive profitability in a fast-paced market. So, what are you waiting for? The time to act is now-transformative opportunities are out there for those ready to embrace the future of manufacturing!

Frequently Asked Questions

What is digital transformation in manufacturing?

Digital transformation in manufacturing involves integrating digital tools like IoT, AI, and cloud computing into all aspects of production and operations to enhance efficiency, product quality, and streamline processes.

Why is digital transformation important for manufacturing companies?

It is crucial for manufacturers to understand digital transformation to meet market demands, enhance supply chains, and remain competitive in a challenging landscape.

What productivity trends have been observed in manufacturing?

Productivity gains in manufacturing have decreased from 2-3% in the early 2000s to under 1% today, highlighting the need for a new workforce model that incorporates robots and AI systems.

How are companies planning to invest in technology for digital transformation?

A significant 93% of Chief Operating Officers at firms with revenues over $1 billion plan to increase investments in AI and technology advancements in the next five years.

What role will AI play in the future of manufacturing?

By 2026, manufacturers will increasingly rely on AI-driven supply chain intelligence tools to enhance decision-making, automate tasks, and improve supply chain resilience.

Can you provide an example of a successful digital transformation in manufacturing?

Genie is an example of a company that has improved operational efficiencies and customer service through digital transformation, including revamping their global contact center to integrate AI.

What does Greg Kaiser say about the future of manufacturing?

Greg Kaiser emphasizes that companies investing in robust data foundations and virtual twins will be better positioned to transform decision-making and compete effectively in a rapidly changing market.

What are some key technologies that can facilitate digital transformation in manufacturing?

Key technologies include IoT for real-time data collection, AI for process optimization, and cloud computing for enhanced collaboration and operational efficiency.

How can IoT benefit manufacturing processes?

IoT devices can facilitate predictive maintenance, potentially reducing maintenance costs by up to 30% and minimizing unplanned downtime by 45%.

What benefits can AI bring to manufacturing?

AI can analyze production data to optimize processes, leading to productivity boosts of 6% to 10% and corresponding revenue increases.

How does cloud computing impact manufacturing operations?

Cloud computing enhances collaboration and data sharing across departments, significantly improving operational efficiency.

What is the trend in automation within manufacturing?

The trend is shifting from traditional automation to orchestration, allowing for more dynamic and adaptive coordination of resources in manufacturing processes.