Introduction

Navigating the world of custom manufacturing can feel like a daunting task, right? It’s packed with unique challenges that businesses face as they strive to stay ahead of the competition. Enter engineer to order (ETO) manufacturing software - a game changer that streamlines processes and boosts operational efficiency.

As companies wrestle with the urgent need for customization and quick turnaround times, it begs the question: how can they harness these advanced tools to not just meet, but truly exceed client expectations? And let’s not forget about minimizing waste and maximizing productivity along the way.

So, what’s the secret sauce? Let’s dive in and explore how ETO software can transform your manufacturing game!

GenAlpha Technologies: Streamline Operations with ETO Software

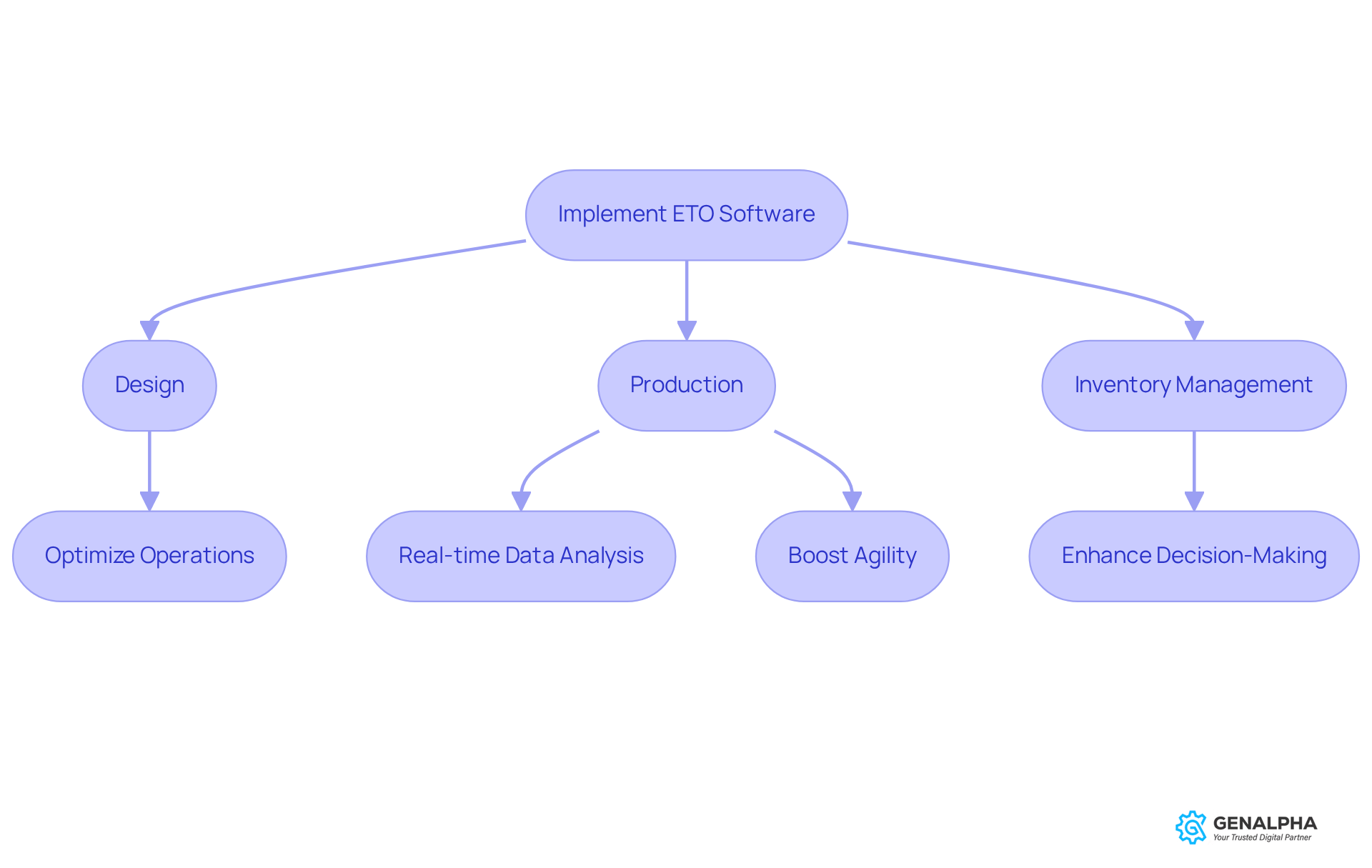

Have you ever felt overwhelmed by the complexities of custom manufacturing? Well, GenAlpha Technologies has got your back with their specialized engineer to order manufacturing software solutions. These tools are designed to optimize manufacturing operations by bringing together key functions like design, production, and inventory management. Imagine a workflow that’s not just cohesive but also simplifies the chaos of custom manufacturing. Sounds good, right?

This streamlined approach allows manufacturers to quickly respond to customer demands, boosting agility in today’s competitive landscape. Plus, with real-time data analysis features, companies can gain actionable insights that lead to smarter decision-making. As Tom Peters wisely said, 'An enterprise is only as strong as the efficiency of its processes.'

Industry leaders are on the same page, stressing that effective integration of ETO systems can cut down on operational bottlenecks and nurture a culture of continuous improvement. This is crucial for thriving in our fast-paced market. Did you know that it’s projected that at least 40% of all businesses might struggle in the next decade if they don’t embrace new technologies? That really highlights the urgent need for robust engineer to order manufacturing software solutions. So, what are you waiting for? Let’s dive into the future of manufacturing together!

Enhance Customization for Unique Client Needs

Have you ever thought about how important customization is in today’s fast-paced market? GenAlpha's ETO platform really shines when it comes to enhancing product customization, which is essential for engineer to order manufacturing software these days. Clients are looking for tailored solutions, and the engineer to order manufacturing software allows manufacturers to tweak designs and adjust production schedules on the fly. This means they can meet specific client needs without those annoying delays.

Such flexibility not only boosts customer satisfaction but also contributes to building lasting relationships with the help of engineer to order manufacturing software. After all, who doesn’t want to feel valued and understood? One manufacturer put it perfectly: 'Customization is key to our success; it allows us to meet our clients' unique needs effectively through engineer to order manufacturing software.'

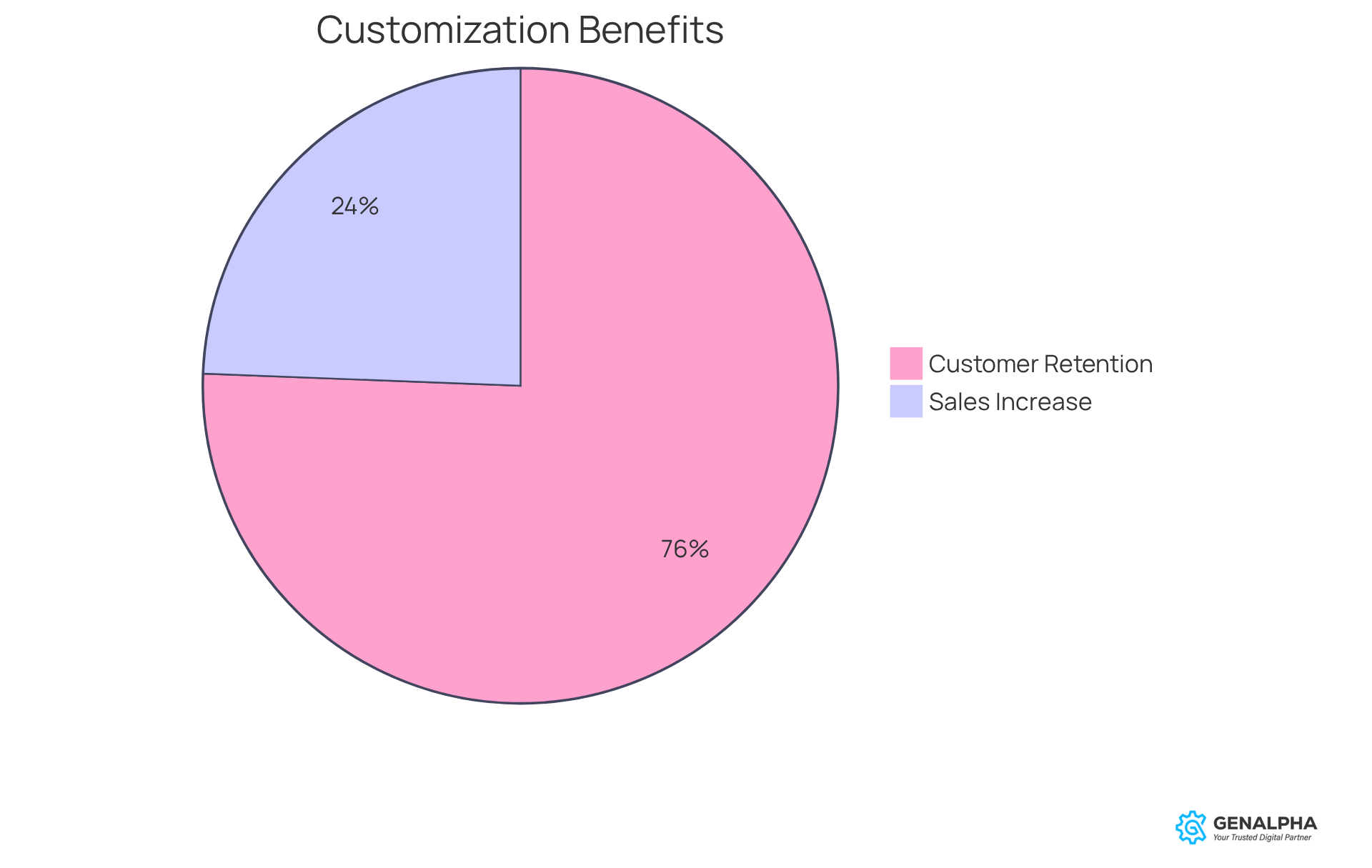

But wait, there’s more! Companies utilizing engineer to order manufacturing software from GenAlpha can implement effective personalization strategies that lead to a whopping 20% increase in sales. That really shows how crucial customization is for driving revenue. Plus, 62% of business leaders have noticed better customer retention thanks to personalized experiences. So, it’s clear that engineer to order manufacturing software isn’t just a nice-to-have; it’s essential for success in the manufacturing world.

What do you think? Are you ready to embrace customization in your business?

Increase Production Efficiency and Reduce Lead Times

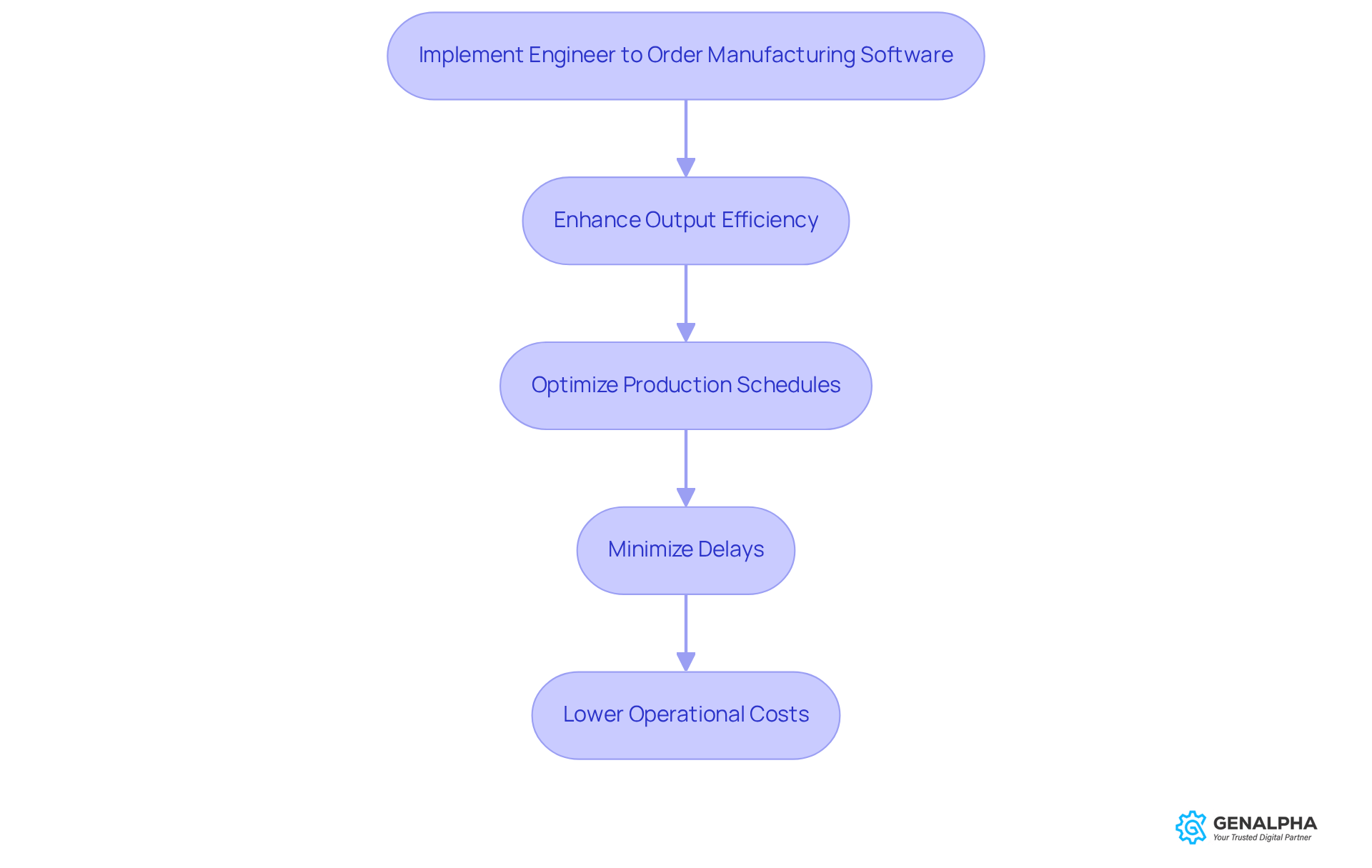

Have you ever thought about how much time and effort could be saved with the right tools? Implementing GenAlpha's engineer to order manufacturing software can significantly enhance output efficiency by automating various processes and reducing manual work. Imagine production schedules that are optimized to ensure resources are allocated just right, making everything run smoothly.

By minimizing delays and streamlining workflows with engineer to order manufacturing software, manufacturers can enjoy faster turnaround times. And let’s be honest, in today’s fast-paced world, meeting customer expectations is crucial. This kind of efficiency doesn’t just ramp up productivity; it also helps lower operational costs. That means organizations can allocate their resources more effectively.

So, why not consider how this application could transform your operations? It might just be the game-changer you’ve been looking for!

Optimize Inventory Management and Reduce Waste

Have you ever faced the frustration of overstocking or running out of materials just when you need them? Well, GenAlpha's engineer to order manufacturing software is designed to help! It offers some pretty robust inventory management tools that let manufacturers track materials in real-time. This means you can minimize those pesky stockouts and overstock situations.

By tapping into data analytics, this application helps businesses forecast demand accurately and adjust inventory levels accordingly. Imagine cutting down on waste and ensuring that production runs smoothly without interruptions due to material shortages. Sounds great, right?

Plus, the engineer to order manufacturing software integrates seamlessly with existing ERP systems, ensuring that information flows effortlessly. As Bryant Jones, a manufacturing and construction expert, puts it, "Data-driven decisions are essential for efficient inventory management, as they assist organizations in avoiding costly errors and enhancing productivity."

And here’s a staggering fact: 35% of businesses have shipped an order late because of stock issues. This really highlights how crucial real-time inventory tracking is in reducing waste and keeping operations running smoothly. So, why not consider how this could benefit your business?

![]()

Conclusion

Implementing engineer to order (ETO) manufacturing software is a game changer for operational efficiency in the manufacturing world. Imagine being able to seamlessly integrate design, production, and inventory management. This software doesn’t just simplify complex processes; it also helps companies respond quickly to what customers want. In today’s competitive landscape, shifting to ETO solutions isn’t just a nice-to-have; it’s essential for businesses that want to thrive.

Throughout this article, we’ve highlighted some key benefits of ETO manufacturing software. For instance, it enhances product customization, allowing you to meet unique client needs and build stronger relationships. Plus, it significantly boosts production efficiency by automating processes and cutting down lead times. And let’s not forget about inventory management - it optimizes it to minimize waste. These insights really show how ETO systems can drive operational success.

In a fast-paced market, embracing engineer to order manufacturing software isn’t just a smart move; it’s a must for any organization looking to boost efficiency and customer satisfaction. As companies face mounting pressure to innovate and adapt, integrating ETO solutions could be the key to their future success. So, why wait? Investing in ETO software now can set the stage for a more agile, responsive, and efficient manufacturing operation.

Frequently Asked Questions

What is GenAlpha Technologies known for?

GenAlpha Technologies specializes in engineer to order (ETO) manufacturing software solutions that optimize operations in custom manufacturing.

How does ETO software benefit manufacturing operations?

ETO software streamlines key functions such as design, production, and inventory management, allowing manufacturers to respond quickly to customer demands and improve operational efficiency.

What features do GenAlpha's ETO software solutions offer?

The software includes real-time data analysis features that provide actionable insights for smarter decision-making.

Why is it important for businesses to integrate ETO systems?

Effective integration of ETO systems can reduce operational bottlenecks and foster a culture of continuous improvement, which is essential for success in a competitive market.

What is the potential risk for businesses that do not adopt new technologies?

It is projected that at least 40% of all businesses may struggle in the next decade if they fail to embrace new technologies, highlighting the need for robust ETO manufacturing solutions.