Overview

Managing bill of materials (BOM) software can feel overwhelming, right? But don’t worry! This article dives into some effective strategies that can make your life a lot easier. We’ll talk about the importance of:

- Setting clear objectives

- Getting everyone on board

- Providing comprehensive training

- Managing change effectively

- Continuously improving

These strategies aren't just buzzwords; they really enhance operational efficiency, cut down on errors, and boost collaboration. And in a competitive manufacturing world, that means better product management and happier customers!

So, why should you care? Well, think about it: when everyone understands the goals and feels involved, things just run smoother. Imagine a workplace where training sessions are engaging and everyone knows how to adapt to changes without a hitch. That’s the kind of environment that leads to success.

Ready to take action? Start by evaluating your current BOM management practices. Ask yourself:

- Are your objectives clear?

- Is your team fully trained?

By focusing on these areas, you’ll not only improve your processes but also create a culture of continuous improvement. Let’s work together to make BOM management a breeze!

Introduction

Managing a bill of materials (BOM) effectively is super important in today’s manufacturing world. Think about it: precision and efficiency can really make or break a product's success. As companies tackle the challenges of more complex product designs and the need for smooth collaboration, having the right BOM management software can truly be a game-changer.

But with so many options out there, how do manufacturers pick the best strategies for implementation? In this article, we’ll dive into some essential practices that not only boost operational efficiency but also help sidestep common pitfalls in BOM oversight. This way, you’ll pave the road for smoother production and happier customers. Ready to get started?

Understand the Fundamentals of Bill of Materials Management

Have you ever wondered what goes into making a product? A bill of materials management software is essentially a detailed list of all the components, parts, raw materials, and sub-assemblies needed for manufacturing. Think of it as your go-to plan for creation, ensuring that everything you need is on hand when it's time to get to work.

Understanding the structure of a BOM is key. It usually includes item numbers, descriptions, quantities, and units of measure. Plus, there are different types of BOMs, like the Engineering BOM (EBOM) and Manufacturing BOM (MBOM), each with its own unique role in the product lifecycle.

Now, why is this important? A well-organized bill of materials management software not only aids in production planning but also enhances inventory control and cost estimation. This can lead to improved operational efficiency and happier customers. But there's a catch! Manual oversight of BOMs can create disconnects between departments and cause delays in their creation. This highlights some real challenges in managing BOMs.

Additionally, if BOM data is fragmented, it can result in poor traceability and slow process cycles. So, what can we do about it? As the bill of materials management software market is expected to grow significantly—driven by increasingly complex product designs and the need for remote collaboration—manufacturers need to prioritize effective bill of materials management software to stay competitive in today’s fast-paced environment.

Michael Munsey reflects on this evolution in the industry, pointing out that embracing digital transformation in bill of materials management software is crucial. It fosters collaboration, cuts costs, and speeds up product development cycles, ensuring timely delivery and quality assurance. So, how are you planning to tackle BOM oversight in your organization?

Leverage BOM Management Software for Operational Efficiency

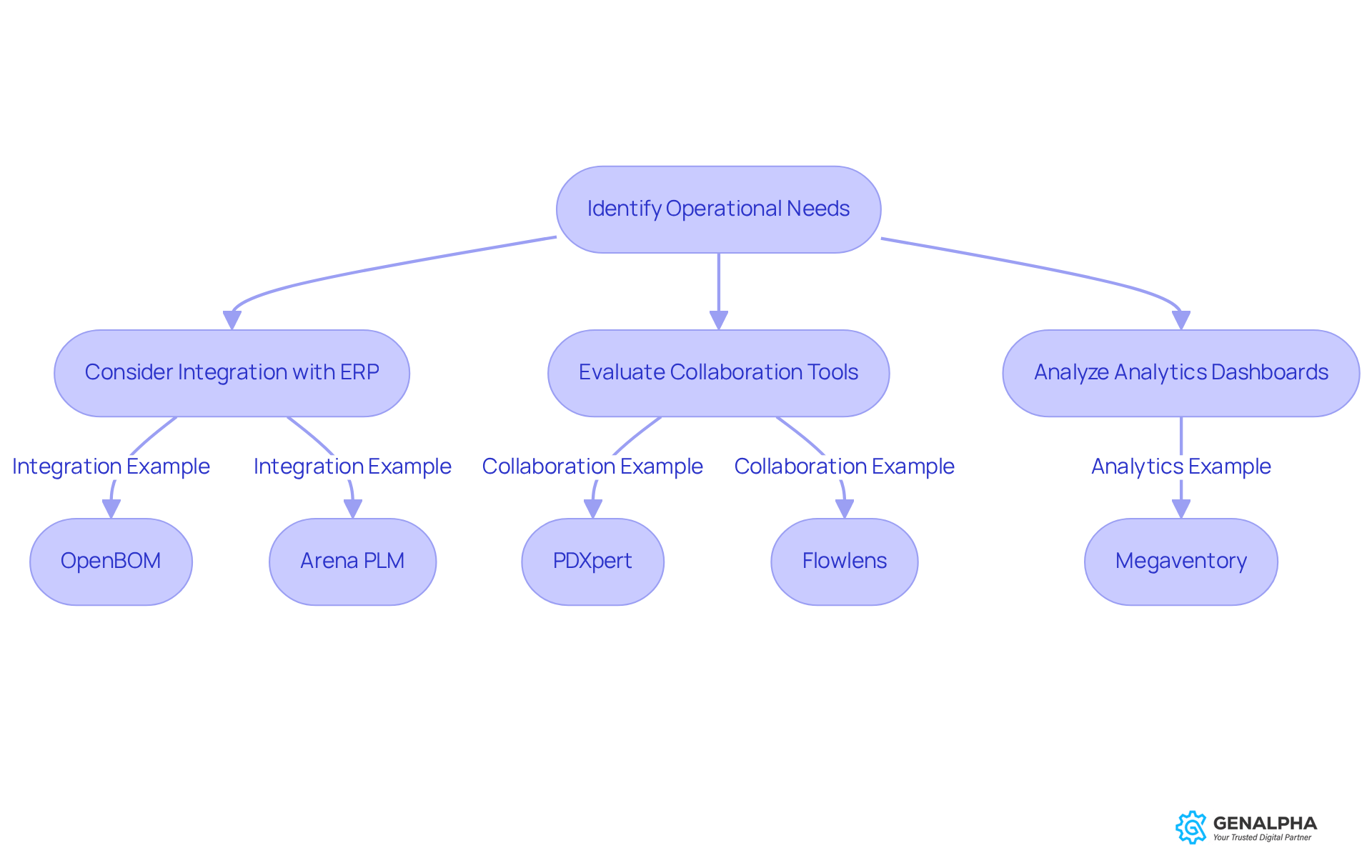

BOM control tools are essential for boosting operational efficiency. They automate key tasks like data entry, change tracking, and version control, making life a lot easier for teams. When you're on the hunt for bill of materials management software, consider what really matters: seamless integration with your current ERP systems, real-time collaboration tools, and comprehensive analytics dashboards that provide insights into inventory levels and scheduling.

For example, take a look at platforms like OpenBOM, which serves over 15,000 customers around the globe, and Arena PLM. These tools exemplify effective collaboration, helping teams document and communicate changes without a hitch. And guess what? Current market trends indicate there's a growing demand for these solutions. In fact, the BOM market is projected to grow from USD 8.20 Billion in 2023 to USD 25.69 Billion by 2033, with a CAGR of 12.10%. That's pretty impressive!

By leveraging bill of materials management software and other advanced tools, manufacturers can cut down on errors, shorten lead times, and boost overall efficiency—creating a more agile manufacturing environment. Plus, solutions like PDXpert, which comes in at $49 per month, show the kind of investment needed for these tools. So, it’s crucial for organizations to weigh their options carefully. What features will make the biggest difference for you? Let’s dive in and explore the possibilities together!

Adopt Best Practices for Successful BOM Software Implementation

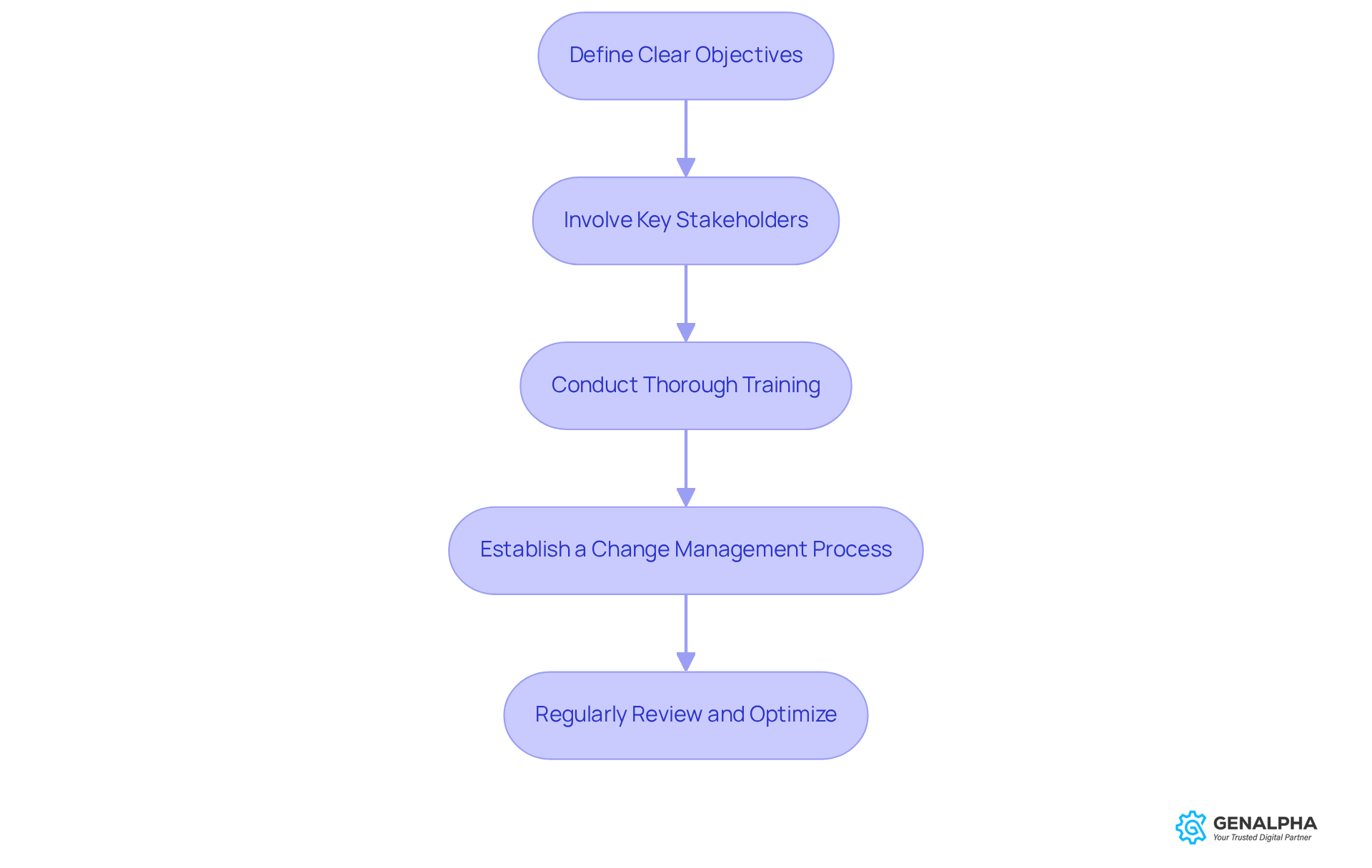

To make sure your organization successfully implements BOM management tools, let’s dive into some best practices that can really make a difference:

-

Define Clear Objectives: Start by setting specific goals for your system—think about reducing lead times or boosting accuracy. Remember what Antoine de Saint-Exupéry said: "A goal without a plan is just a wish." A well-defined objective serves as your guiding star throughout the implementation process.

-

Involve Key Stakeholders: Bring team members from different departments—engineering, production, and procurement—into the conversation. This not only gathers diverse insights but also helps everyone feel more invested in the process. When people collaborate, they’re more likely to see the application as relevant and feel a sense of ownership.

-

Conduct Thorough Training: It’s vital to provide comprehensive training for all users. This way, everyone feels comfortable with the new system and understands its features. Effective training can significantly reduce resistance to change and boost overall user satisfaction.

-

Establish a Change Management Process: Set up a structured method to manage changes in BOMs. This should include clear documentation and communication protocols. It’s crucial for maintaining data integrity and ensuring that everyone is in the loop about updates.

-

Regularly Review and Optimize: After you’ve implemented the system, make it a habit to assess its performance continuously. This will help you make necessary adjustments as your business needs evolve. Regular evaluations can uncover areas for improvement and ensure that the system remains a valuable asset in your operations.

By the way, did you know that industry projections suggest the BOM software market is set to grow significantly by 2025? This growth is driven by increased digital adoption and the rising demand for managing product complexity. So, by following these strategies, you can enhance your BOM oversight processes and drive greater efficiency in your manufacturing operations. Ready to take action?

Embrace Continuous Improvement in BOM Management

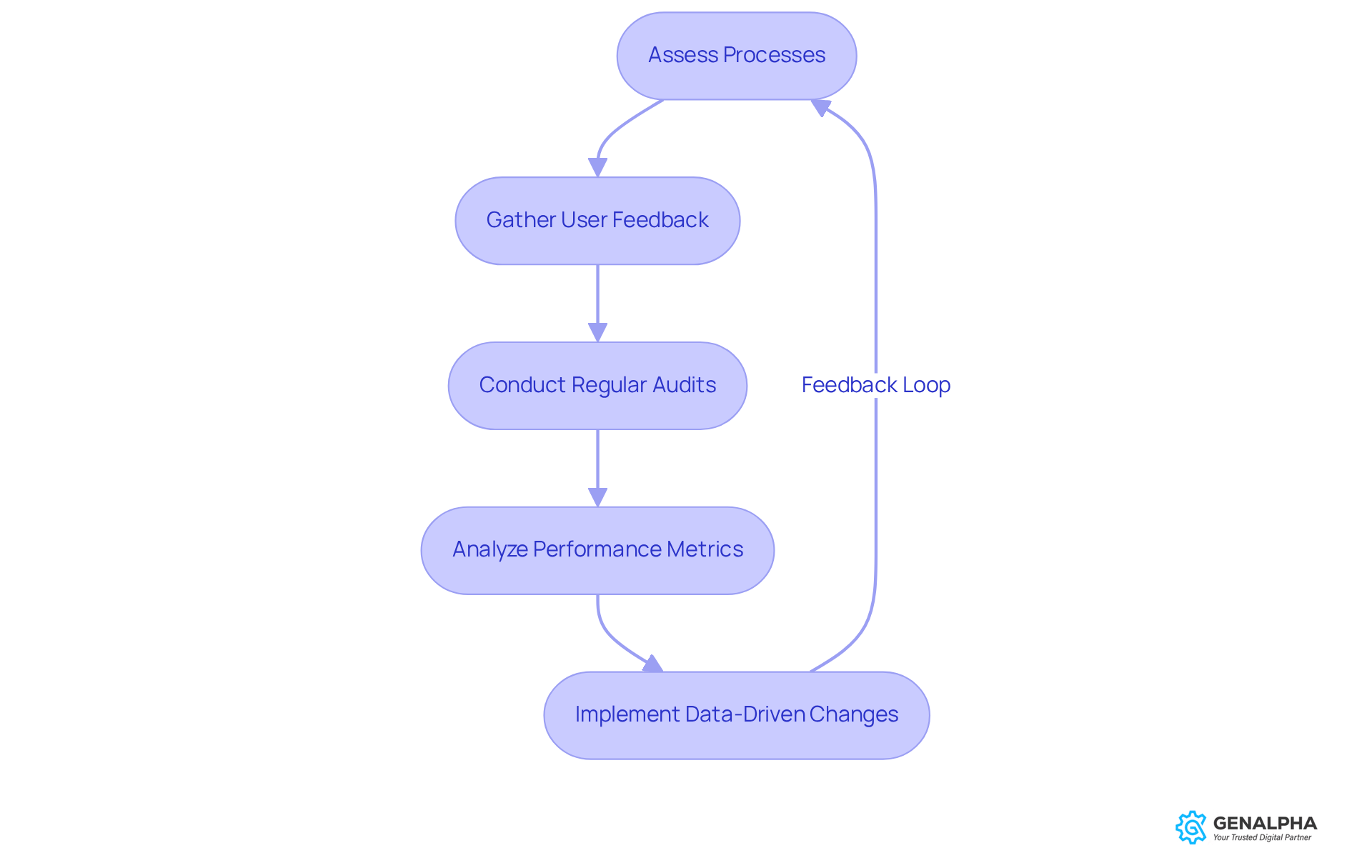

Embracing continuous improvement in bill of materials management software oversight is essential for taking a systematic approach. Have you ever thought about how assessing processes, gathering user feedback, and making data-driven changes can really make a difference? Establishing strong feedback loops between departments is key to spotting bottlenecks and identifying areas that could use a little TLC.

For example, conducting regular audits of BOM accuracy and completeness can reveal discrepancies that need fixing. Plus, using analytics tools helps organizations keep an eye on important performance metrics like operational efficiency and material costs. This way, decision-making becomes a breeze!

By fostering a culture of ongoing enhancement, we can significantly boost our BOM practices. Think about it: greater efficiency, lower costs, and happier customers! Manufacturing leaders often highlight that effective bill of materials management software not only streamlines production but also fosters a proactive approach to tackling challenges. This ultimately drives operational excellence. So, how can we start implementing these ideas today?

Conclusion

Managing your bill of materials (BOM) software effectively is key for any manufacturing organization looking to boost operational efficiency and streamline production processes. By grasping the basics of BOM management, utilizing advanced software tools, and following best practices for implementation, manufacturers can tackle challenges head-on and remain competitive in a complex landscape.

This article highlights how crucial BOM management software is for automating tasks, enhancing collaboration, and delivering valuable insights into inventory and production planning. You’ll find key strategies like:

- Setting clear objectives

- Involving stakeholders

- Providing thorough training

- Establishing change management processes

- Committing to continuous improvement

These practices not only improve accuracy and efficiency but also cultivate a culture of collaboration and accountability across departments.

So, as the demand for sophisticated BOM management solutions grows, organizations really need to focus on effective implementation and ongoing optimization of their systems. By embracing these strategies, manufacturers can cut costs and lead times while ensuring higher quality products and greater customer satisfaction. Taking proactive steps in BOM management today will set the stage for a more agile and resilient manufacturing future. What steps will you take to enhance your BOM management today?

Frequently Asked Questions

What is a bill of materials (BOM)?

A bill of materials is a detailed list of all the components, parts, raw materials, and sub-assemblies needed for manufacturing a product. It serves as a comprehensive plan for creation, ensuring that all necessary items are available when production begins.

What are the key components typically included in a BOM?

A BOM usually includes item numbers, descriptions, quantities, and units of measure.

What are the different types of BOMs?

The main types of BOMs are the Engineering BOM (EBOM) and the Manufacturing BOM (MBOM), each serving a unique role in the product lifecycle.

Why is effective BOM management important?

Effective BOM management aids in production planning, enhances inventory control, and improves cost estimation, leading to better operational efficiency and increased customer satisfaction.

What challenges can arise from manual oversight of BOMs?

Manual oversight can create disconnects between departments, cause delays in BOM creation, and lead to fragmented data, resulting in poor traceability and slow process cycles.

How is the market for BOM management software expected to change?

The market for BOM management software is expected to grow significantly due to increasingly complex product designs and the need for remote collaboration, making effective BOM management a priority for manufacturers.

What role does digital transformation play in BOM management?

Embracing digital transformation in BOM management fosters collaboration, reduces costs, and speeds up product development cycles, ensuring timely delivery and quality assurance.