Introduction

Efficient order management is like the backbone of successful manufacturing. It influences everything from production planning to how happy customers are. Imagine this: you’ve got a structured order management guide in place. What happens? You streamline your processes, cut down on fulfillment errors, and build stronger relationships with your clients. Sounds great, right?

But here’s the kicker: nearly a quarter of customer requests get canceled because of inventory inaccuracies and delays. So, how can manufacturers tackle these challenges head-on? How can they optimize their order management to ensure a seamless experience for customers? Let’s dive into this together!

Define Order Management and Its Importance

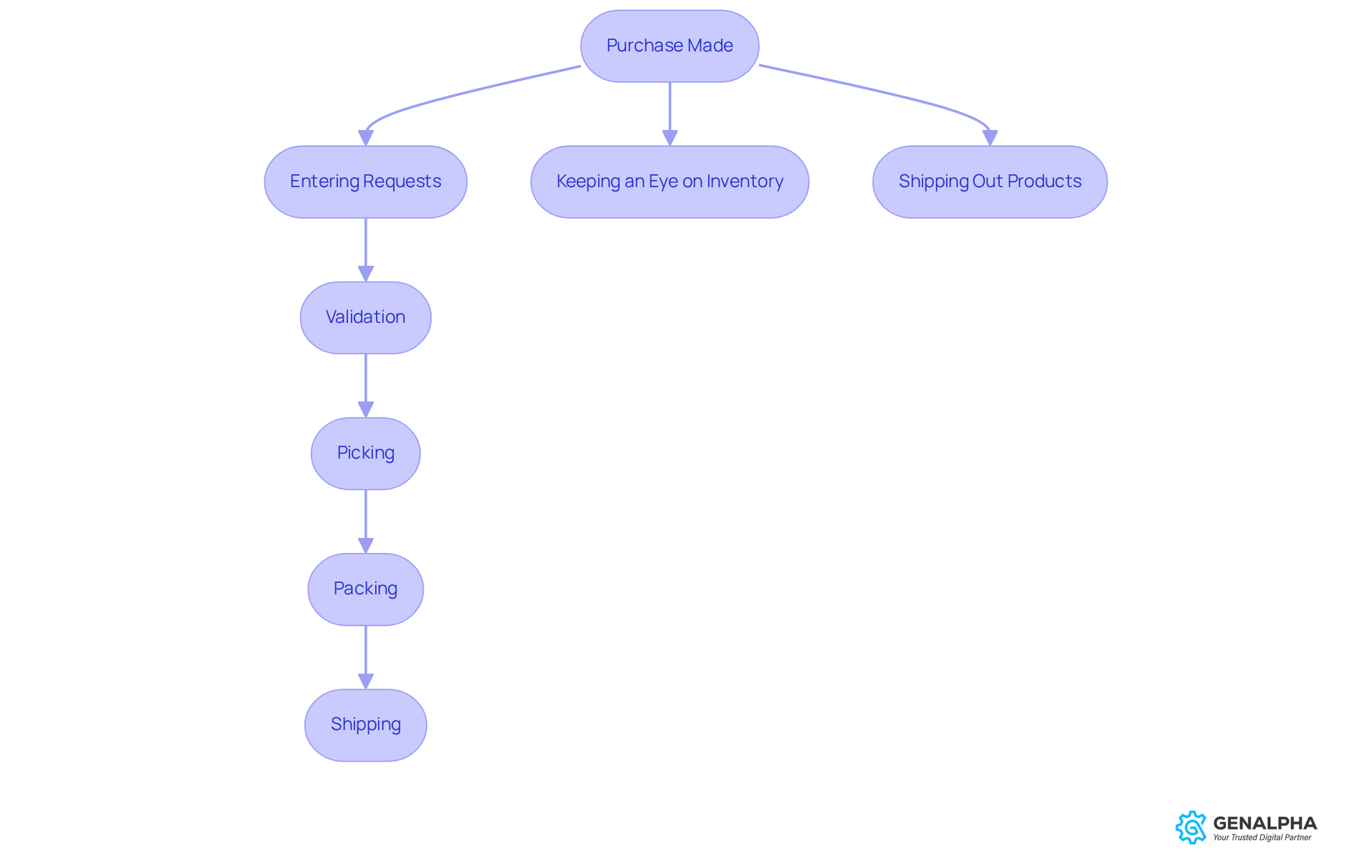

Handling requests is all about a smooth process that follows the order management guide, taking you from the moment a purchase is made all the way to delivery. It involves key steps like:

- Entering requests

- Keeping an eye on inventory

- Shipping out products

For producers, following an order management guide is super important as it really shapes production planning, inventory control, and, most importantly, customer satisfaction.

An efficient request handling system can cut down on fulfillment errors. By automating tasks like:

- Validation

- Picking

- Packing

- Shipping

you ensure that requests are processed quickly and accurately. Did you know that companies with better fulfillment practices can hit a delivery rate of around 90%? That’s a big deal when it comes to meeting customer expectations!

On the flip side, nearly 23% of customer requests get canceled due to incorrect inventory info and delayed restocking alerts. This really highlights how crucial it is to handle requests accurately to keep customers happy. By recognizing the importance of system oversight, manufacturers can refer to an order management guide to fine-tune their operations, boost efficiency, and build stronger relationships with their clients. This leads to greater loyalty and repeat business.

As Oliver Munro puts it, "Understanding your Rate of Returns will help you spot mistakes during production or fulfillment stages." So, let’s take a closer look at how we can improve our request handling and make things better for everyone!

Outline the Order Management Process Steps

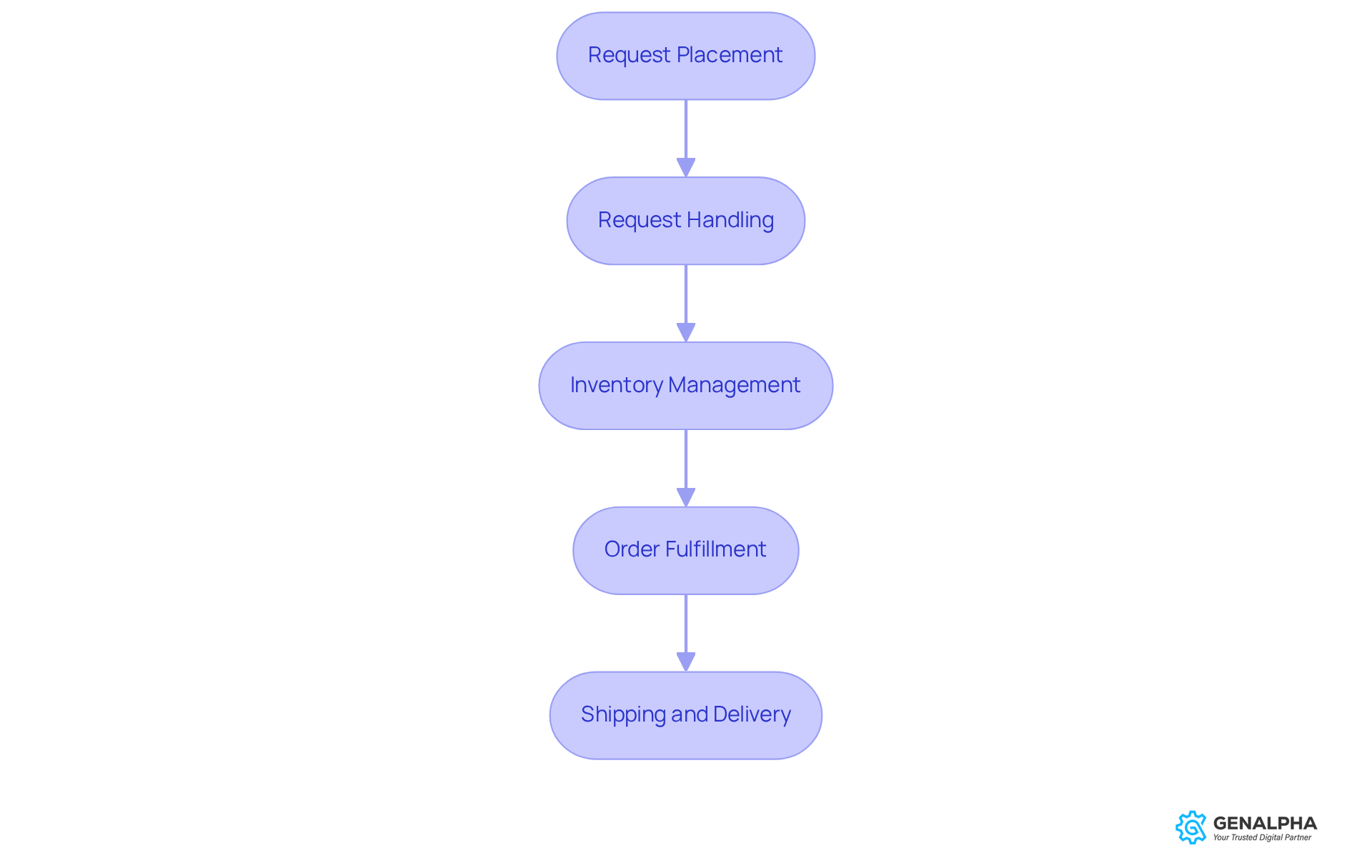

The order management guide for manufacturers focuses on ensuring efficiency and keeping customers happy. Let’s break it down into some key steps:

-

Request Placement: It all starts when customers place their requests. They can do this through various channels, like online platforms or sales reps. This step is super important because it sets the stage for everything that follows.

-

Request Handling: Once a request comes in, it needs to be validated. This means checking that the client’s info is correct and that what they want is actually in stock. Getting this right helps cut down on mistakes.

-

Inventory Management: Here’s where effective inventory management comes into play. Manufacturers need to check stock levels to make sure they can fulfill the orders. Keeping a close eye on inventory helps avoid stockouts and boosts fulfillment rates. Ideally, you want those rates to be above 90% - that’s the sweet spot for meeting customer expectations. After all, a perfect delivery rate means only 10% of requests might run into issues.

-

Order Fulfillment: Now we’re at the exciting part - fulfilling the order! This includes picking, packing, and shipping the request. Streamlining these processes can really cut down on internal cycle time. You can measure this by looking at the difference between the time shipped and the time placed. It’s a key metric for assessing how efficiently the warehouse is running.

-

Shipping and Delivery: Finally, the shipment heads out to the client. Providing tracking details is a great way to boost transparency and let clients keep an eye on their purchases. In today’s market, customers expect this level of service. Plus, tracking updates can really enhance the client experience.

By following these steps and sticking to best practices from the order management guide, manufacturers can really improve their request processing. This leads to better operational efficiency and happier clients. As Dr. Muddassir Ahmed points out, managing requests efficiently is crucial for achieving operational excellence and boosting customer satisfaction. So, what steps are you taking to enhance your order management process?

Identify Tools and Systems for Streamlined Order Management

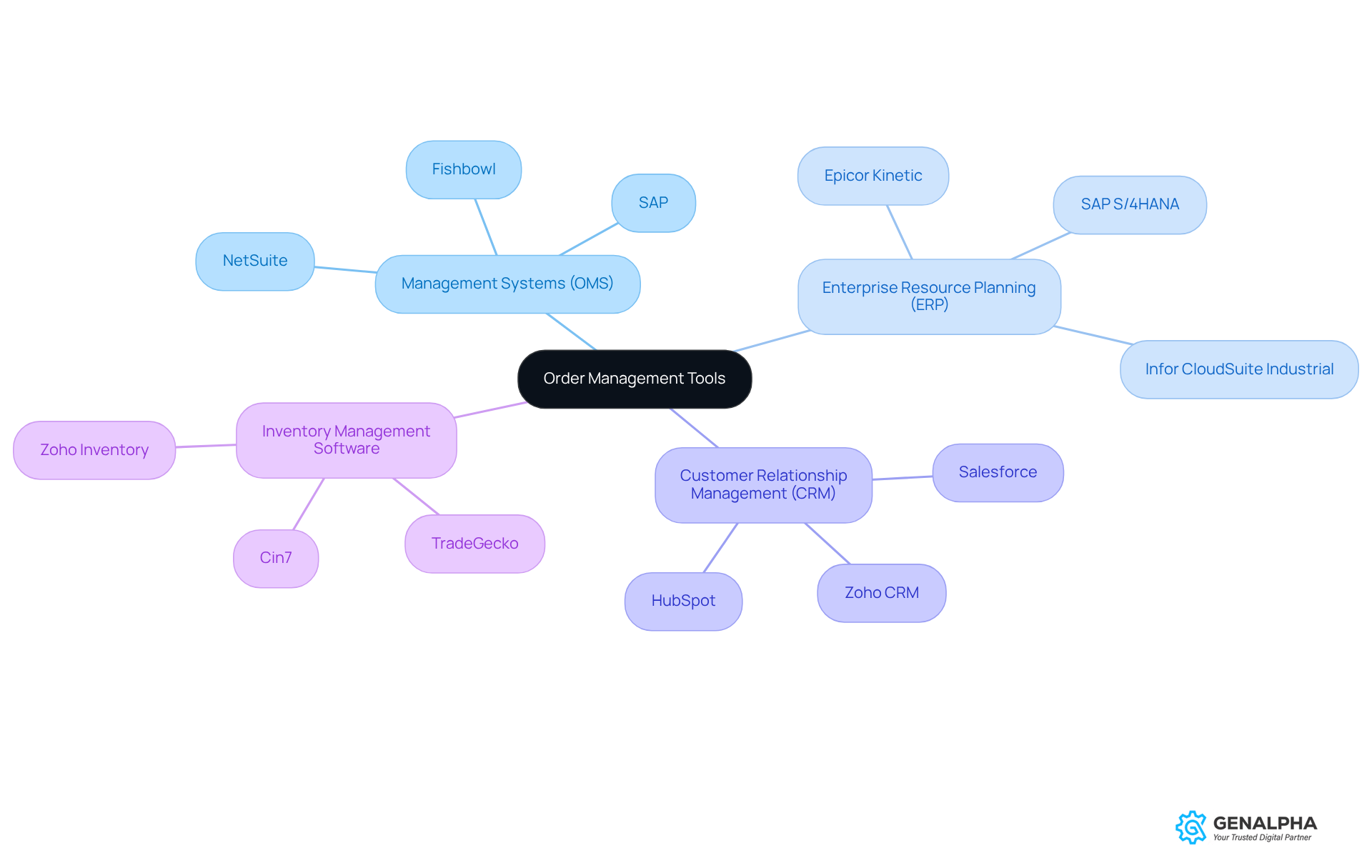

When it comes to managing orders, manufacturers can refer to an order management guide that includes a bunch of handy tools and systems at their disposal. Let’s take a look at a few that can really make a difference:

- Management Systems (OMS): Think of these as your order-processing superheroes! They automate everything from capturing orders to fulfilling them. Some popular choices are Fishbowl, NetSuite, and SAP.

- Enterprise Resource Planning (ERP) Systems: Ever feel like departments are speaking different languages? Integrating an ERP system can help sync up request data with inventory and financial info, giving you a clearer picture across the board.

- Customer Relationship Management (CRM) Tools: CRMs are like your trusty sidekick for customer interactions. They help manage engagements and provide valuable insights into what your customers like and their purchase history.

- Inventory Management Software: Tools like TradeGecko or Zoho Inventory are great for keeping an eye on stock levels and automating those pesky reordering tasks.

By utilizing the order management guide, manufacturers can streamline their order processing, cut down on errors, and really amp up efficiency. So, why not explore how these systems can work for you?

Address Common Challenges and Solutions in Order Management

Manufacturers often face a few bumps in the road when it comes to the order management guide. Let’s break down some common challenges and how to tackle them:

-

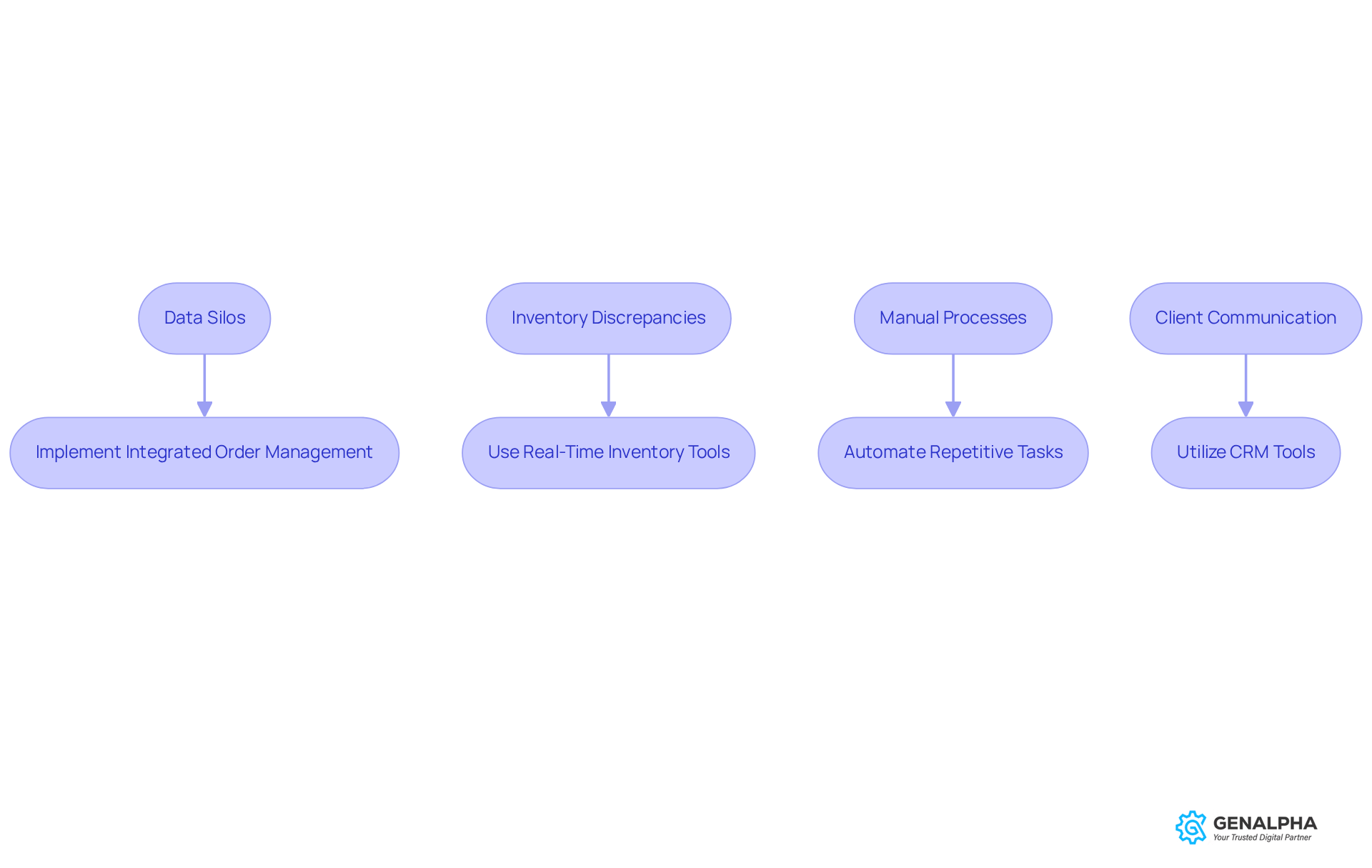

Data Silos: Ever feel like your systems are speaking different languages? Fragmented systems can lead to miscommunication and errors. Solution: Why not implement an integrated order management guide that brings all your data together?

-

Inventory Discrepancies: Nothing’s worse than thinking you have stock, only to find out you don’t. Inaccurate stock levels can really mess with order fulfillment. Solution: Consider using real-time inventory management tools to keep those stock counts spot on.

-

Manual Processes: Relying on manual entry? That can lead to errors and delays. Solution: Let’s use an order management guide to automate those repetitive tasks and boost efficiency.

-

Client Communication: Poor communication can leave clients feeling frustrated. Solution: Use CRM tools to keep your clients in the loop about their shipment status and any potential delays.

By tackling these challenges head-on with effective solutions, manufacturers can really enhance their order management guide processes. This not only leads to happier customers but also boosts operational efficiency. So, what’s stopping you from making these changes?

Conclusion

Mastering order management is crucial for manufacturers looking to boost efficiency and keep customers happy. By following a structured order management guide, manufacturers can simplify their processes from the first request all the way to the final delivery. This organized approach not only cuts down on errors but also builds stronger relationships with customers, leading to greater loyalty and repeat business.

Throughout this article, we’ve highlighted key steps in the order management process, like:

- Placing requests

- Validating them

- Managing inventory

- Fulfilling orders

- Shipping

Each of these stages is vital for meeting customer expectations, and using automation and effective tools can really ramp up operational efficiency. Plus, tackling common challenges such as data silos, inventory discrepancies, and communication gaps shows just how important a cohesive order management strategy is.

So, what’s the takeaway? Investing in a solid order management system and sticking to best practices can really change the game for manufacturers. By focusing on efficiency and accuracy, manufacturers can not only raise their service levels but also adapt to the ever-changing market demands. Embracing these strategies will set the stage for operational excellence and sustainable growth in the competitive manufacturing landscape. Ready to take the leap?

Frequently Asked Questions

What is order management?

Order management refers to the process of handling requests from the moment a purchase is made until the product is delivered. It includes key steps such as entering requests, monitoring inventory, and shipping products.

Why is order management important for producers?

Order management is crucial for producers as it shapes production planning, inventory control, and customer satisfaction. An efficient order management system can reduce fulfillment errors and enhance overall operational efficiency.

How does automating order management tasks benefit companies?

Automating tasks such as validation, picking, packing, and shipping ensures that requests are processed quickly and accurately, which can lead to a higher delivery rate and improved customer satisfaction.

What impact do fulfillment practices have on delivery rates?

Companies with better fulfillment practices can achieve a delivery rate of around 90%, which is significant for meeting customer expectations.

What are the consequences of poor order management?

Poor order management can lead to issues such as incorrect inventory information and delayed restocking alerts, resulting in nearly 23% of customer requests being canceled.

How can manufacturers improve their request handling?

Manufacturers can improve request handling by following an order management guide, which helps fine-tune operations, boost efficiency, and strengthen relationships with clients, ultimately leading to greater customer loyalty and repeat business.

What role does understanding the Rate of Returns play in order management?

Understanding the Rate of Returns helps identify mistakes during production or fulfillment stages, allowing companies to address issues and improve their order management processes.