Introduction

The equipment manufacturing industry is facing a growing demand for customization, and let’s be honest, that can really complicate things. As producers work hard to meet client needs while juggling complex pricing structures and keeping up with rapid market changes, the integration of custom Configure, Price, Quote (CPQ) software stands out as a crucial solution. But here’s the big question: can embracing this technology really transform operations and boost customer satisfaction? Or will manufacturers find themselves lagging behind in a competitive landscape?

Think about it - how often do we hear about companies struggling to keep up with what their customers want? It’s a tough spot to be in. On one hand, you want to deliver exactly what your clients are asking for, but on the other, you’ve got to manage all those moving parts. That’s where CPQ software comes into play. It’s not just about making things easier; it’s about staying relevant and competitive. So, what’s your take? Are you ready to explore how this technology could change the game for your operations?

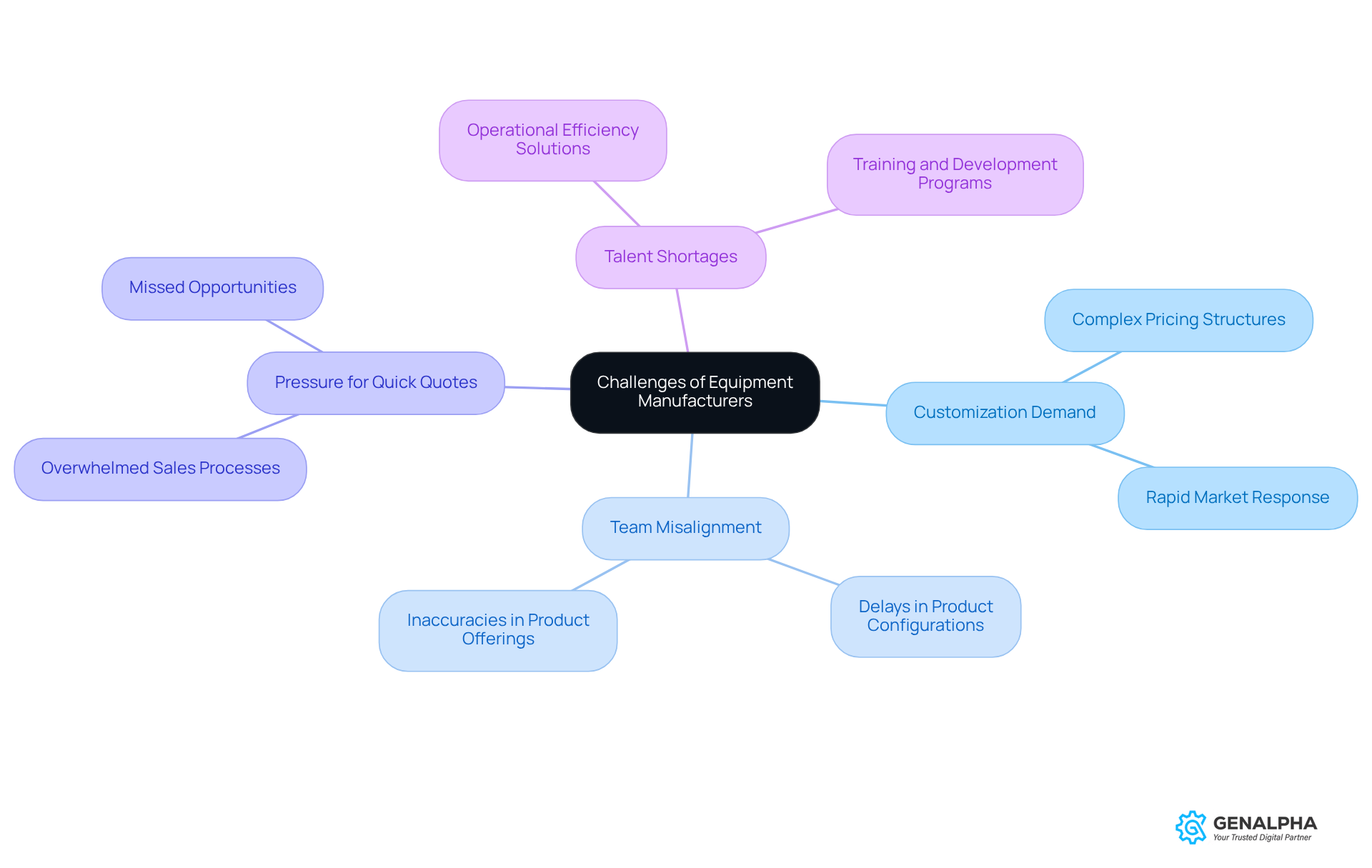

Understand the Unique Challenges of Equipment Manufacturers

Equipment producers face a bunch of challenges that can really complicate operations and hold back growth. One big issue? The rising demand for customization. This need pushes producers to create complex pricing structures and respond quickly to market changes. Have you ever noticed how often marketing and engineering teams seem out of sync? This misalignment can lead to delays and inaccuracies in product configurations, which isn’t great for anyone involved. It can stretch lead times and drive up costs, something industry leaders often highlight when they talk about the importance of teamwork for operational excellence.

And let’s not forget the pressure to provide quick and accurate quotes. It can really overwhelm traditional sales processes, leading to missed opportunities and unhappy clients. In fact, 53% of manufacturing leaders see talent shortages as a major hurdle. This really underscores the need for effective solutions that boost operational efficiency and keep clients satisfied.

As Hamdi Ulukaya wisely pointed out, focusing on long-term value creation instead of quick exits is key to tackling these unique challenges. Recognizing these issues is crucial for understanding the value of custom CPQ software. Custom CPQ software can streamline operations, enhance collaboration, and ultimately improve customer satisfaction in the competitive world of equipment manufacturing.

What do you think? Could embracing such solutions be the way forward?

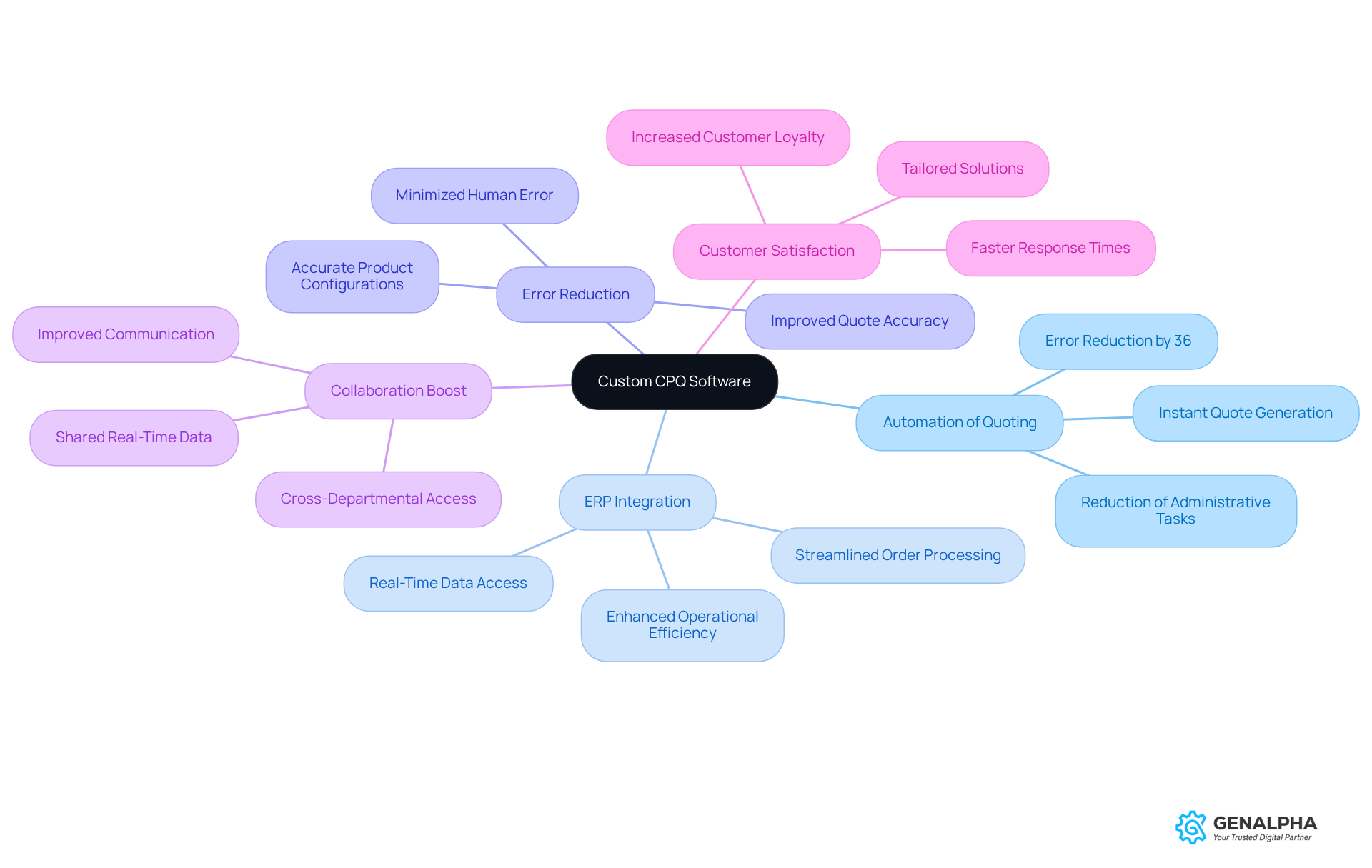

Explore How Custom CPQ Software Solves Industry-Specific Pain Points

Custom CPQ software is specifically created to address the unique challenges that equipment producers encounter. Have you ever wondered how sales teams can whip up accurate quotes in a flash? Well, that’s exactly what CPQ software does! It automates the configuration process, making it a breeze for teams to generate quotes quickly-super important in today’s fast-paced market.

But wait, there’s more! This software doesn’t just stop at quoting. It integrates seamlessly with existing ERP systems, which means everyone in the company can access real-time data. This not only cuts down on errors but also boosts collaboration across departments. Imagine how much smoother things could run when everyone’s on the same page!

By enabling producers to offer tailored solutions that meet client needs, custom CPQ software goes beyond merely streamlining operations. It also ramps up customer satisfaction and loyalty. So, if you’re looking to enhance your business processes and keep your clients happy, it might be time to consider implementing CPQ software. What do you think?

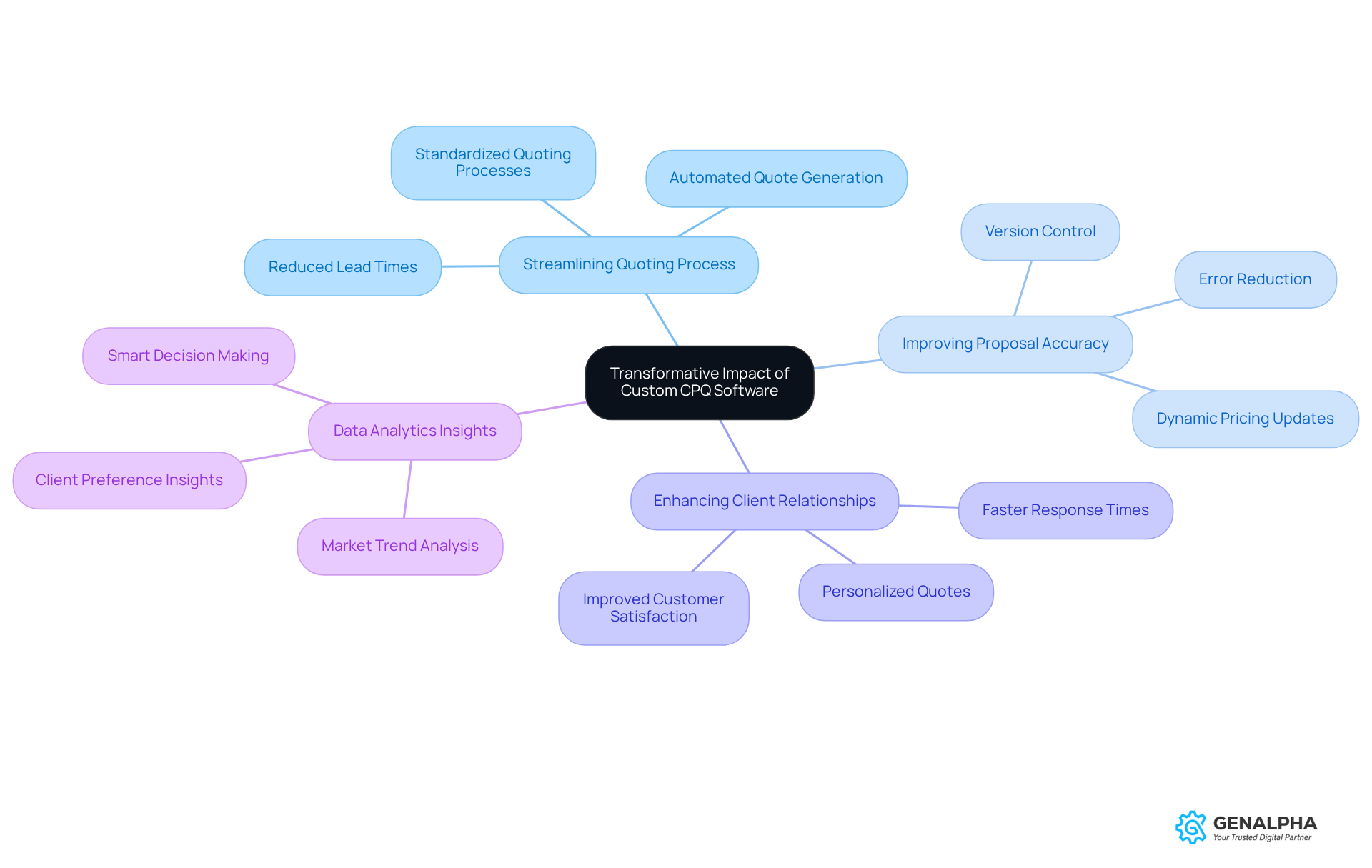

Analyze the Transformative Impact of Custom CPQ Software on Operations

Have you ever considered how custom cpq software could truly revolutionize operations for equipment producers? By streamlining the quoting process, these producers can cut down on lead times and boost the accuracy of their proposals. This not only makes life easier for clients but also frees up commercial teams to focus on building relationships instead of drowning in paperwork.

Additionally, the data analytics features of custom cpq software provide producers with insights into client preferences and market trends. This means they can make smart decisions that drive growth. As a result, businesses that embrace custom cpq software often see improved revenue efficiency and better profit margins.

So, why not consider how CPQ could transform your operations? It might just be the game-changer you’ve been looking for!

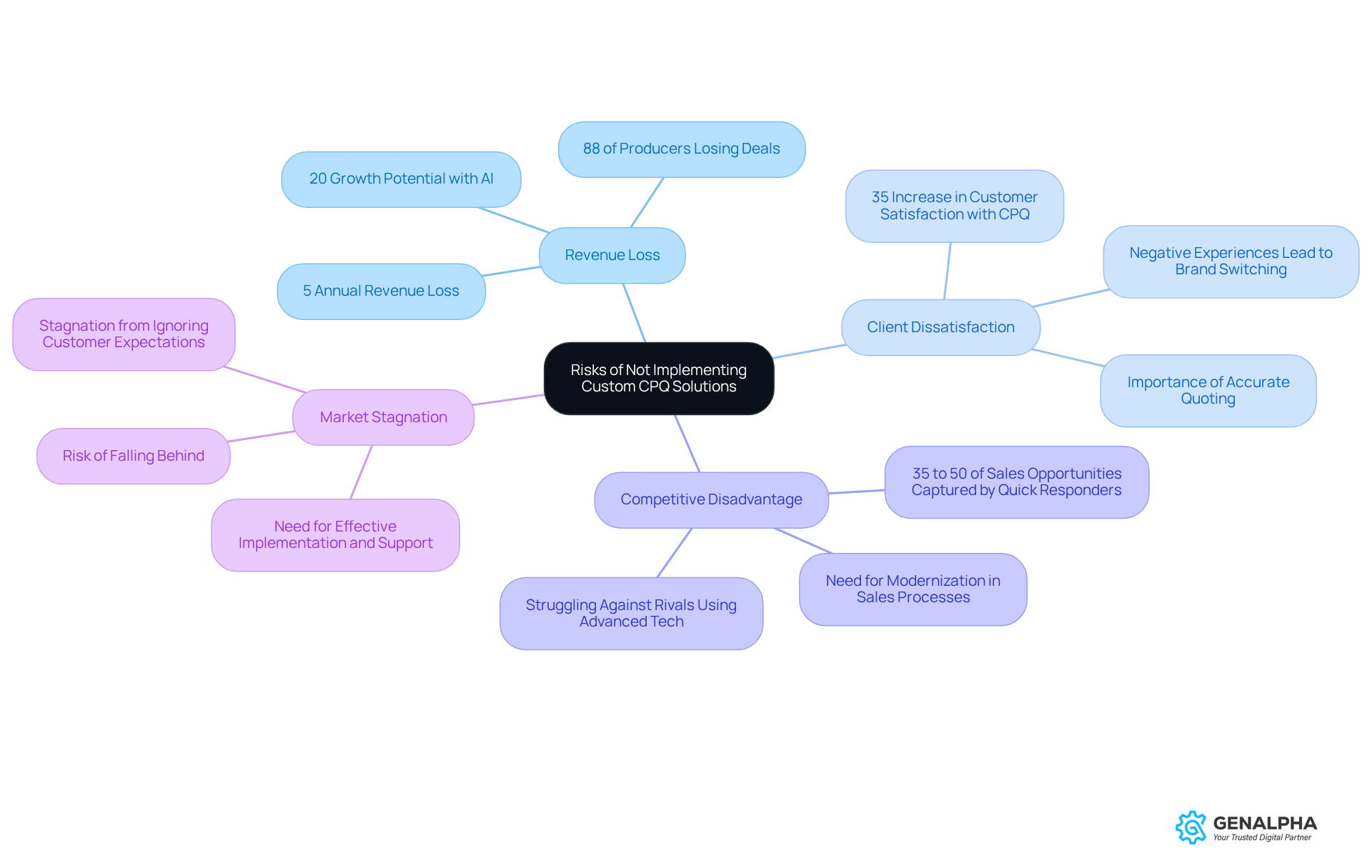

Consider the Risks of Not Implementing Custom CPQ Solutions

Not utilizing custom cpq software can really put equipment manufacturers at risk. Think about it: missing out on revenue and disappointing clients can be a tough pill to swallow. In today’s competitive landscape, those sticking with old quoting methods might struggle to keep pace with rivals who are leveraging advanced tech to streamline their sales processes. When quotes aren’t precise or timely, it not only frustrates clients but can also damage those all-important relationships.

As customer expectations shift, it’s crucial for producers to realize that ignoring custom cpq software solutions can lead to stagnation, jeopardizing their market position. Did you know that 88% of producers report losing deals because of slow or manual quoting processes? That’s a wake-up call for anyone still relying on outdated methods! Plus, companies that respond to leads quickly can snag 35% to 50% of sales opportunities. Clearly, efficient quoting is key to maximizing revenue potential.

As the Missoun Team points out, "The automated configuration process inherent in CPQ software significantly diminishes the risk of quoting errors, protecting producers against expensive mistakes." Without embracing custom CPQ software, manufacturers risk falling behind, resulting in a loss of both market share and customer loyalty. Andrew Parker puts it succinctly: "If you want to maximize your ROI from CPQ investment, you need your team to use it properly." This really drives home the importance of effective implementation and ongoing support.

Conclusion

Custom CPQ software is becoming essential for equipment manufacturers facing the unique challenges of their industry. It tackles the complexities of customization, pricing, and collaboration, making operations smoother and boosting customer satisfaction. In today’s fast-paced world, having accurate and quick quoting processes is crucial, and custom CPQ software is a powerful ally in meeting these demands.

Let’s think about it: these systems provide real-time data access, cut down on errors, and promote better teamwork across departments. This all leads to improved revenue efficiency and profit margins. Plus, the risks of not adopting such technology - like losing deals because of outdated quoting methods - highlight just how urgent it is for manufacturers to innovate and adapt.

In a market that’s always changing, embracing custom CPQ software isn’t just a choice; it’s a must for staying competitive and ensuring long-term success. Equipment manufacturers that invest in these tailored solutions are better positioned to meet customer expectations, optimize their operations, and secure their spot in the industry. So, what’s the takeaway? Leveraging custom CPQ solutions could be the game-changer that drives growth and boosts customer loyalty in the equipment manufacturing sector.

Frequently Asked Questions

What are the main challenges faced by equipment manufacturers?

Equipment manufacturers face challenges such as rising demand for customization, misalignment between marketing and engineering teams, pressure for quick and accurate quotes, and talent shortages.

How does the demand for customization affect equipment manufacturers?

The demand for customization complicates operations by requiring complex pricing structures and quick responses to market changes, which can lead to delays and increased costs.

What issues arise from the misalignment between marketing and engineering teams?

Misalignment can result in delays and inaccuracies in product configurations, stretching lead times and driving up costs.

What impact does the pressure for quick and accurate quotes have on sales processes?

It can overwhelm traditional sales processes, leading to missed opportunities and dissatisfied clients.

What percentage of manufacturing leaders see talent shortages as a significant challenge?

53% of manufacturing leaders identify talent shortages as a major hurdle.

What is the importance of focusing on long-term value creation in equipment manufacturing?

Focusing on long-term value creation, as emphasized by Hamdi Ulukaya, is key to addressing the unique challenges faced by manufacturers rather than seeking quick exits.

How can custom CPQ software benefit equipment manufacturers?

Custom CPQ software can streamline operations, enhance collaboration, and improve customer satisfaction, making it a valuable solution in the competitive equipment manufacturing sector.