Overview

Let’s talk about Product Data Management (PDM) and why it’s a game changer for manufacturers. Have you ever felt the frustration of errors slowing down your production? Well, PDM systems are here to help! They play a crucial role in boosting operational efficiency, enhancing collaboration, and ensuring compliance.

Imagine cutting down on mistakes and speeding up your time-to-market. Sounds great, right? With features like version control and integration capabilities, PDM systems make this possible. Companies like Nissan and HP have seen remarkable improvements in productivity and quality, proving that these systems really work.

So, what’s the takeaway? If you’re looking to streamline your processes and elevate your business, it might be time to consider implementing a PDM system. Why not explore how it can transform your operations? After all, who wouldn’t want to work smarter, not harder?

Introduction

Understanding the journey of product information from conception to market is super important for manufacturers looking to boost efficiency and collaboration. Think about it: Product Data Management (PDM) systems can really help here, making it easier to organize and share essential product details throughout their lifecycle. But as industries change and grow, a big question pops up: how can manufacturers truly make the most of PDM to tackle ongoing challenges and spark new opportunities for innovation and growth?

Let’s dive into this together!

Define Product Data Management (PDM)

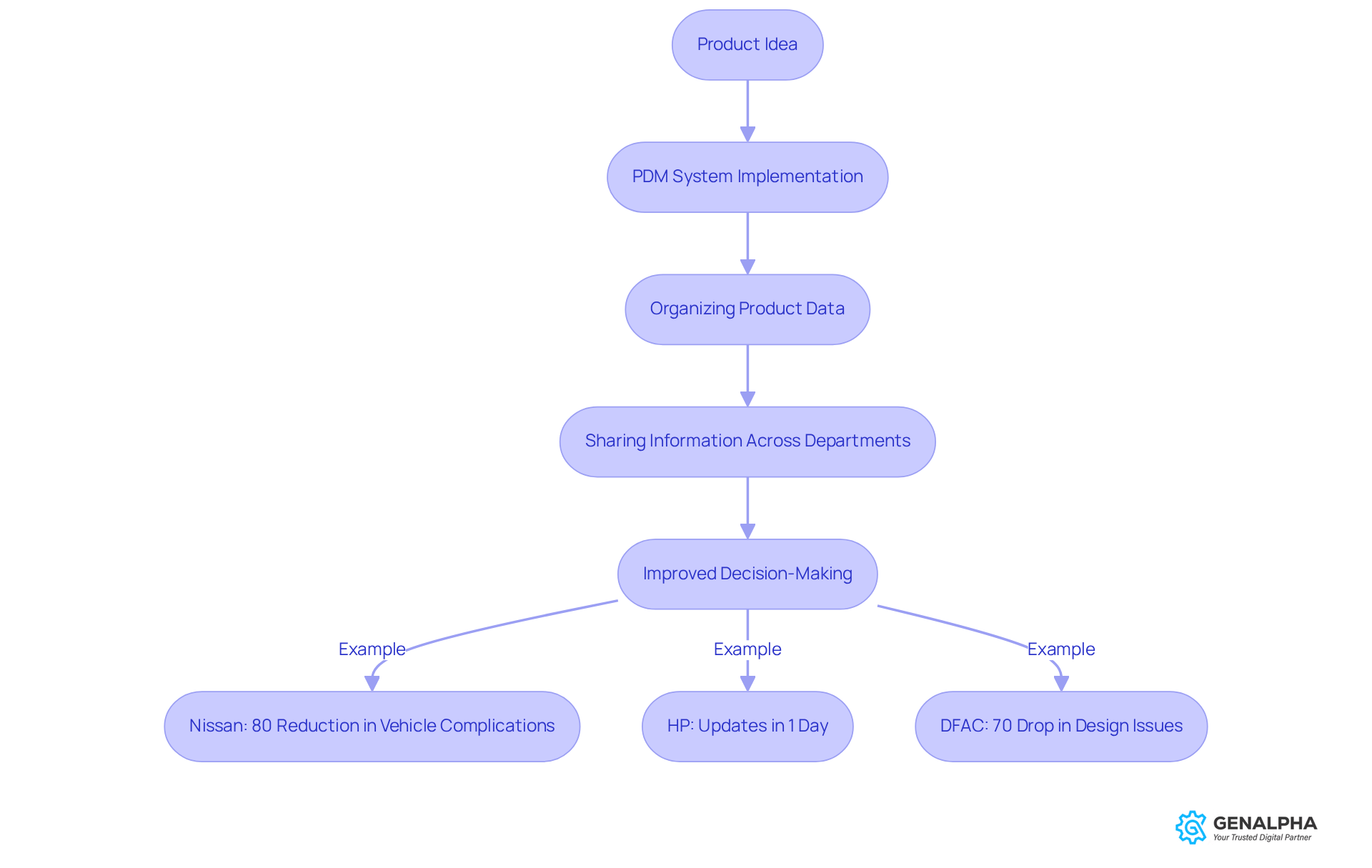

Have you ever thought about how product information travels from the drawing board to the market? That’s where Product Information Management (PIM) comes into play! It’s all about keeping track of product-related info throughout its entire lifecycle—from the moment an idea sparks to when it’s finally retired. This process involves organizing, storing, and sharing crucial details like specifications, designs, and compliance documents through PDM product data management.

PDM product data management solutions serve as a central hub, assisting manufacturers in maintaining accurate and up-to-date information. This is super important for fostering collaboration across different departments. By making it easier to access vital information, PDM product data management helps reduce errors and enhances decision-making.

For example, companies are really starting to see the benefits of PDM systems. Take Nissan, for instance—they’ve managed to reduce post-market vehicle complications by an impressive 80%! And they’ve also cut design time by 50%. How cool is that? HP has jumped on the bandwagon too, slashing the time it takes to share engineering updates from a week down to just one day. Talk about efficiency!

DFAC isn’t left out either; they’ve reported a 70% drop in design issues. These numbers really highlight how PDM product data management can transform operational efficiency and quality. It’s clear that PDM product data management is becoming essential in modern manufacturing strategies. By minimizing development errors, design changes, and unexpected delays, it ultimately helps lower costs.

So, if you’re in the manufacturing game, isn’t it time to consider how PDM could streamline your processes? Let’s chat about how you can implement these systems and reap the benefits!

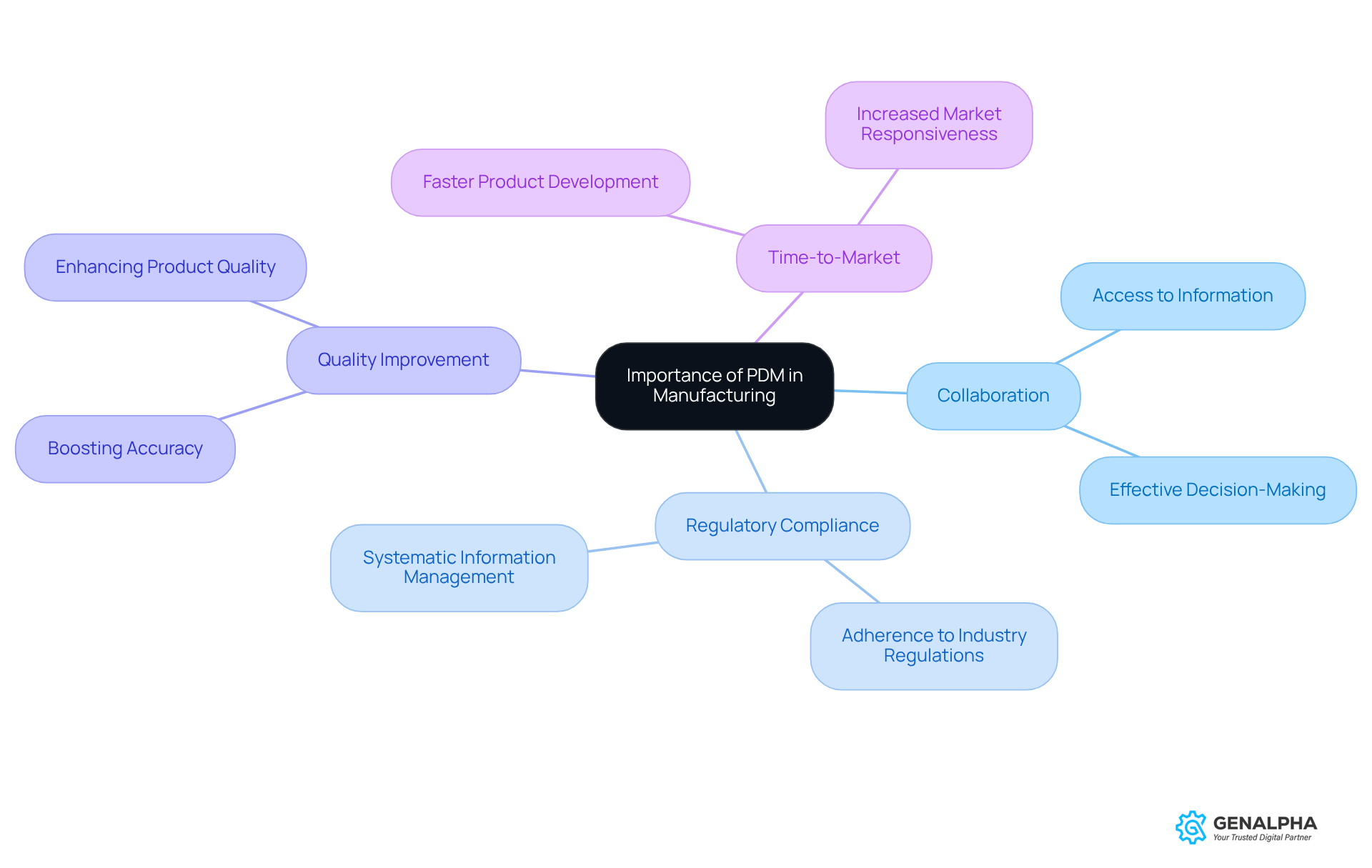

Explain the Importance of PDM in Manufacturing

You know, the importance of PDM (Product Data Management) in manufacturing really can’t be overstated. Imagine a world where everyone involved has access to the right information at the right time—sounds pretty essential for effective collaboration and decision-making, right? PDM solutions serve as the backbone for manufacturers, assisting them in adhering to industry regulations by providing a systematic way to manage all that information.

But it doesn’t stop there! By boosting the accuracy and availability of information, PDM not only improves quality but also speeds up time-to-market. And who doesn’t want happier customers? In today’s competitive landscape, having effective PDM can truly set a business apart and drive success.

So, how are you leveraging PDM in your operations? It might just be the game-changer you need!

Identify Key Features and Functions of PDM Systems

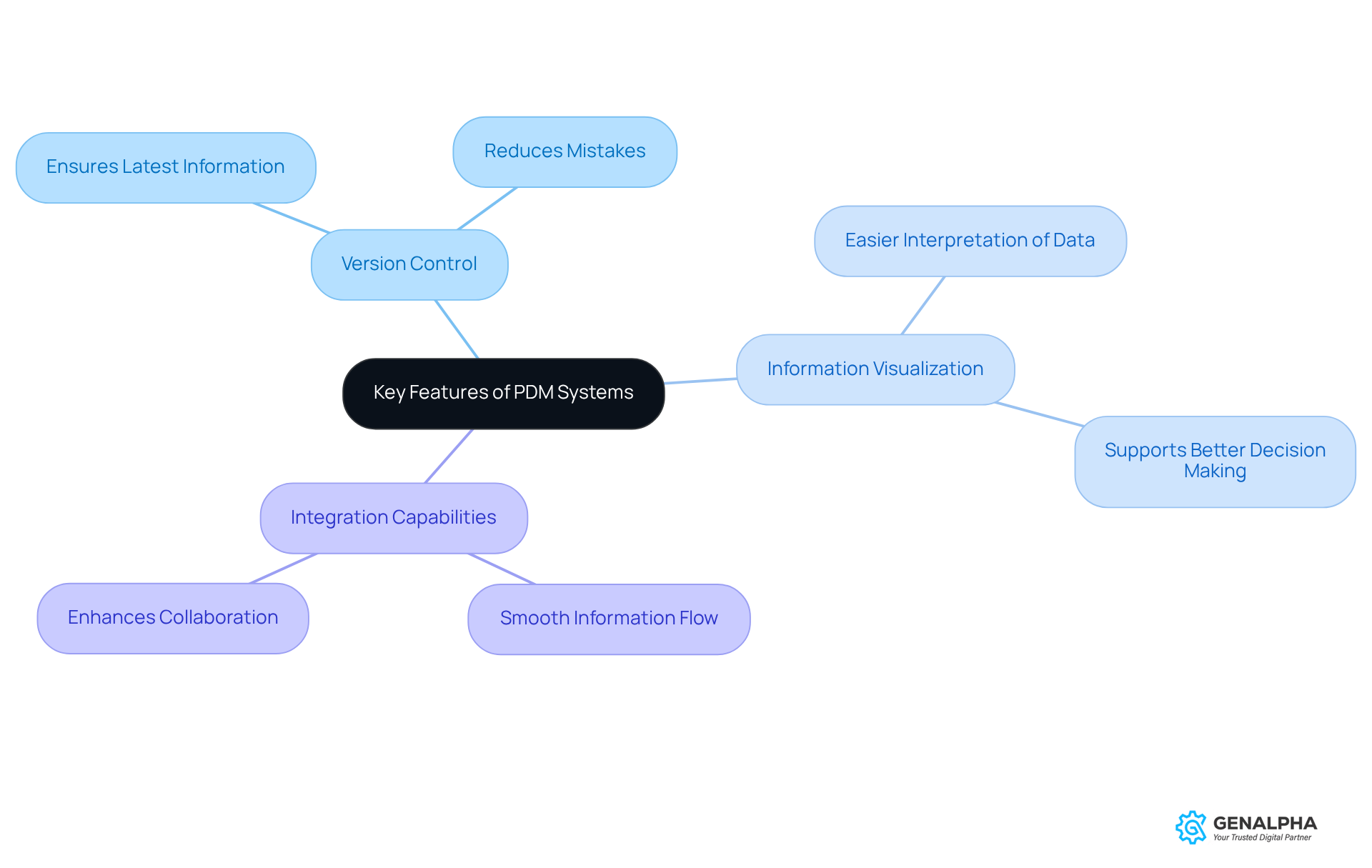

Have you ever wondered how teams keep everything organized when working on complex projects? That’s where pdm product data management systems come into play! They come packed with key features like version control, information visualization, and integration capabilities with other enterprise systems like ERP and CAD.

First off, version control is a game changer. It ensures that everyone on the team is using the latest product information, which really cuts down on mistakes. Imagine the chaos if everyone was working off different versions!

Then there are the visualization tools. These make it super easy to interpret complex sets of information, helping teams make better decisions. It’s like having a clear map when you’re navigating through a maze.

Additionally, the integration features allow for smooth information flow between various systems. This means better collaboration and efficiency all around. When these characteristics come together, manufacturers can leverage pdm product data management to manage item information more effectively and respond quickly to market changes.

So, if you’re looking to streamline your processes and enhance teamwork, consider how PDM systems can make a difference!

Discuss Challenges in Manufacturing Addressed by PDM

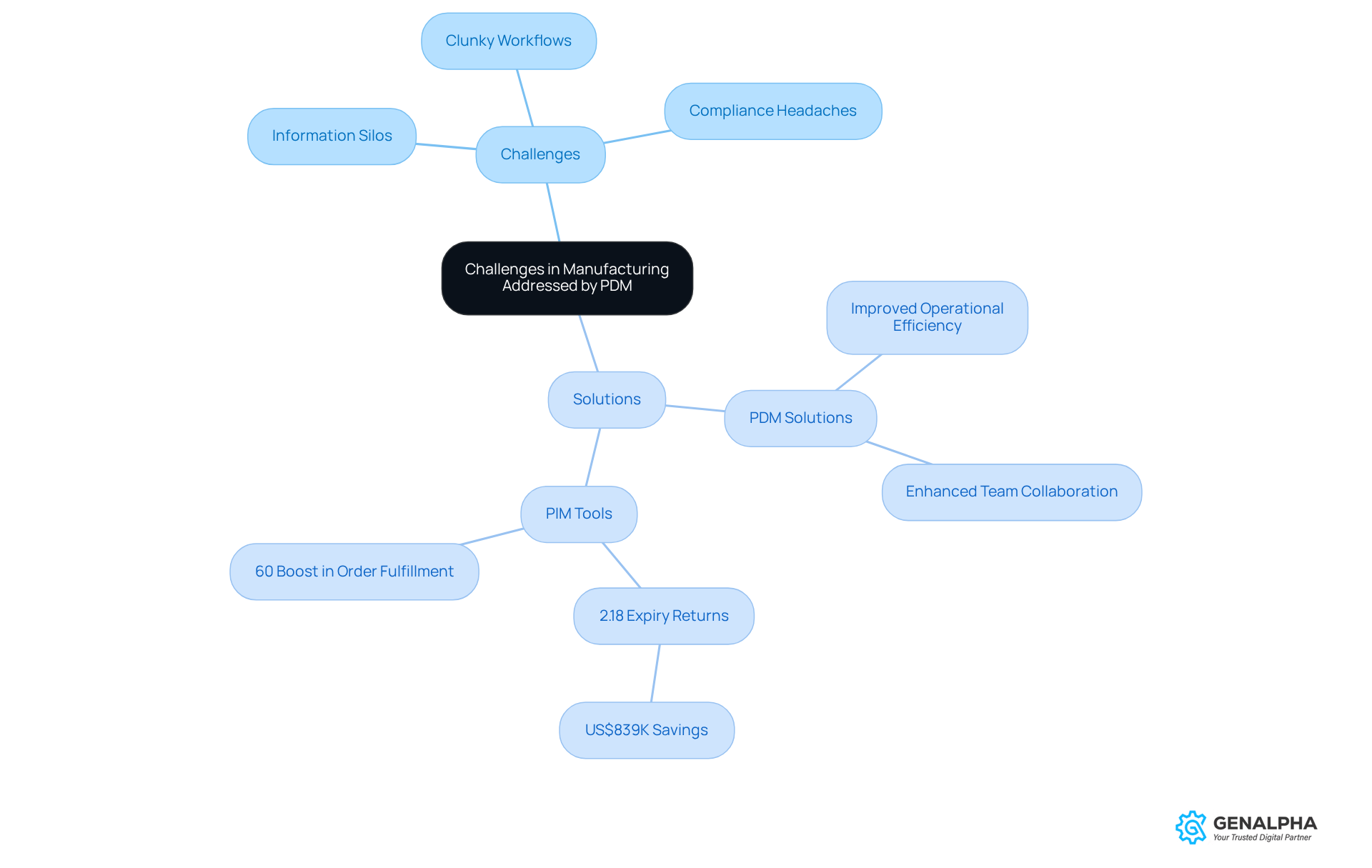

Producers often run into some pretty tough challenges, right? Think about information silos, clunky workflows, and compliance headaches that can really slow things down. That’s where PDM (Product Data Management) solutions become essential. They offer a centralized platform for managing product info, breaking down those silos and encouraging teamwork across different departments. By streamlining workflows, PDM solutions help cut down the time spent on data retrieval and management, allowing teams to focus on what really matters: innovation and improving quality.

But that’s not all! PIM (Product Information Management) tools are also key for keeping up with industry standards. They help maintain accurate records and make audits a breeze, which is essential for meeting regulatory requirements. For example:

- A food and beverage company in the Middle East managed to slash expiry returns to just 2.18%, saving a whopping US$839K thanks to better inventory management and operational efficiencies.

- An Indian food producer saw a fantastic 60% boost in order fulfillment by embracing PIM strategies.

It’s clear that these approaches can really amp up production efficiency.

On another note, a sanitation firm in South America cut down non-productive time by 33% after adopting management control frameworks. This just goes to show how PDM tools can enhance operational efficiency. By tackling these challenges head-on, PDM systems empower manufacturers to work smarter and more effectively in a fast-paced market, ultimately driving growth and boosting competitiveness. So, what’s holding you back from exploring PIM solutions for your operations?

Conclusion

Product Data Management (PDM) is a game-changer for manufacturers looking to boost their operational efficiency and product quality. Imagine having all your product information in one place, making it super easy for teams to collaborate and access accurate data whenever they need it. This kind of integration is crucial for cutting down on errors and speeding up decision-making, which is key to thriving in today’s competitive market.

Let’s look at some real-world examples. Companies like:

- Nissan

- HP

- DFAC

have seen impressive reductions in design time and fewer operational hiccups thanks to PDM systems. These success stories highlight just how beneficial it can be to implement PDM. Plus, features like version control, information visualization, and seamless integration with other enterprise systems really empower teams to tackle complex projects without breaking a sweat.

So, why should manufacturers embrace PDM? Well, it’s not just a smart move; it’s essential for staying ahead in a fast-paced market. By tackling common challenges like information silos and compliance issues, PDM systems help businesses innovate and improve quality while keeping their competitive edge. If you’re a manufacturer, consider how PDM could fit into your operations—it might just be the key to unlocking greater efficiency and success in the years ahead. What are you waiting for? Let’s explore the possibilities together!

Frequently Asked Questions

What is Product Data Management (PDM)?

Product Data Management (PDM) is the process of organizing, storing, and sharing product-related information throughout its entire lifecycle, from the initial idea to when the product is retired.

Why is PDM important for manufacturers?

PDM is important for manufacturers because it serves as a central hub for maintaining accurate and up-to-date product information, which fosters collaboration across different departments, reduces errors, and enhances decision-making.

Can you provide examples of companies benefiting from PDM?

Yes, Nissan has reduced post-market vehicle complications by 80% and cut design time by 50%. HP has decreased the time to share engineering updates from a week to one day, and DFAC reported a 70% drop in design issues.

How does PDM impact operational efficiency and quality?

PDM improves operational efficiency and quality by minimizing development errors, design changes, and unexpected delays, which ultimately helps lower costs.

Should manufacturers consider implementing PDM systems?

Yes, manufacturers should consider implementing PDM systems to streamline their processes and improve overall efficiency and product quality.