Introduction

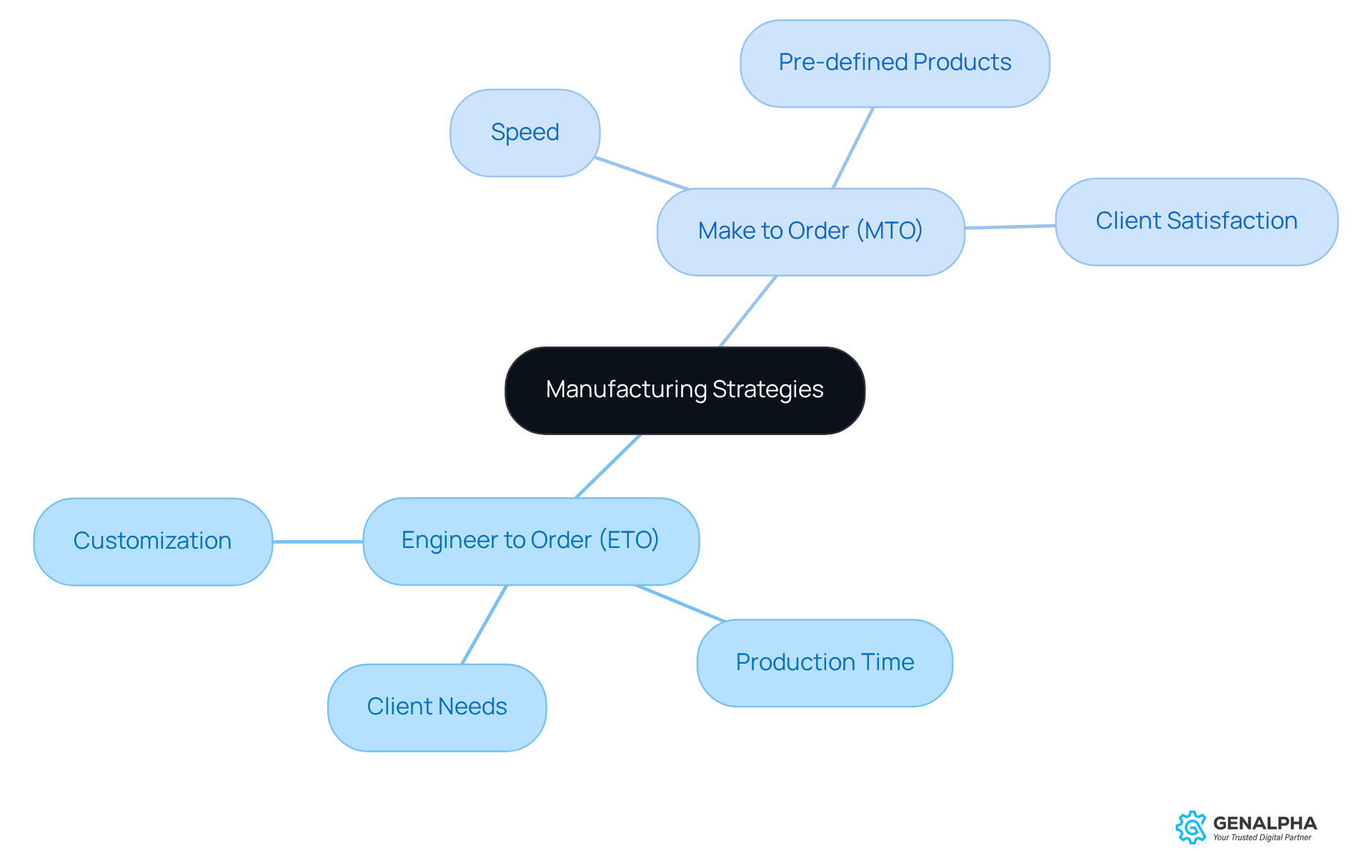

The manufacturing landscape is changing, and it’s important to understand the differences between Engineer to Order (ETO) and Make to Order (MTO) strategies if you want to keep your business competitive. Think about it: ETO is all about creating highly customized products that meet specific client needs. This often means longer production times and higher costs. On the flip side, MTO offers quicker turnarounds by using pre-defined products that can still be customized a bit.

As manufacturers face the growing demand for speed and efficiency, a question pops up: which approach really meets the diverse needs of today’s market? Is it the intricate, bespoke design of ETO, or the streamlined, efficient solution of MTO? Let’s dive into this together and explore what might work best for you!

Define Engineer to Order and Make to Order Manufacturing Strategies

Have you ever wondered how some manufacturers seem to get products out the door faster than others? Well, that’s where the distinction between engineer to order vs make to order becomes significant. ETO is all about crafting products tailored to specific client needs, which sounds great, right? But it often means a lot of engineering work and customization, leading to longer production times. On the flip side, MTO kicks into gear only after a customer places an order, using pre-defined products that can still be customized a bit. This usually means quicker turnaround times since the designs are already set, although it might not offer the same level of customization as ETO.

Current stats show that MTO can really speed things up, with some companies reporting a drop of up to 30% in production time compared to ETO. In today’s fast-paced market, that kind of efficiency is key-after all, speed is often what keeps businesses competitive. As one industry leader put it, 'Speed is everything.'

Lately, there’s been a noticeable shift towards MTO strategies among manufacturers. Why? Because there’s a growing demand for faster delivery and the ability to meet client needs without the hassle of excess inventory. Case studies have shown that companies embracing MTO have not only boosted client satisfaction but also improved their operational efficiency. It’s clear that the discussion of engineer to order vs make to order is making waves in modern manufacturing.

So, in a nutshell, while ETO offers a high degree of customization, MTO strikes a balance between efficiency and flexibility. If you’re a manufacturer looking to adapt to your clients’ ever-changing needs, MTO might just be the way to go!

Compare Key Characteristics of ETO and MTO

Have you ever thought about how products are made just for you? That’s where the distinction between engineer to order vs make to order comes in! ETO is all about high customization, extensive engineering involvement, and yes, longer delivery times. Imagine ordering something that’s uniquely designed just for your needs - sounds exciting, right? These products often require detailed specifications tailored to each client, making them one-of-a-kind.

Now, let’s switch gears and talk about engineer to order vs make to order (MTO). This approach is a bit quicker since production kicks off only after an order is placed. However, it usually relies on a catalog of pre-defined products. While MTO does allow for some customization, it’s generally less complex than ETO. Think of it like choosing from a menu rather than having a dish specially prepared just for you.

Additionally, there’s a financial angle to consider. ETO might come with higher costs due to those engineering requirements, but MTO can help keep inventory costs down since products aren’t made until someone orders them. So, whether you’re looking for something custom-made or a quicker option, the comparison of engineer to order vs make to order shows that both have their perks. Which one do you think suits your needs better?

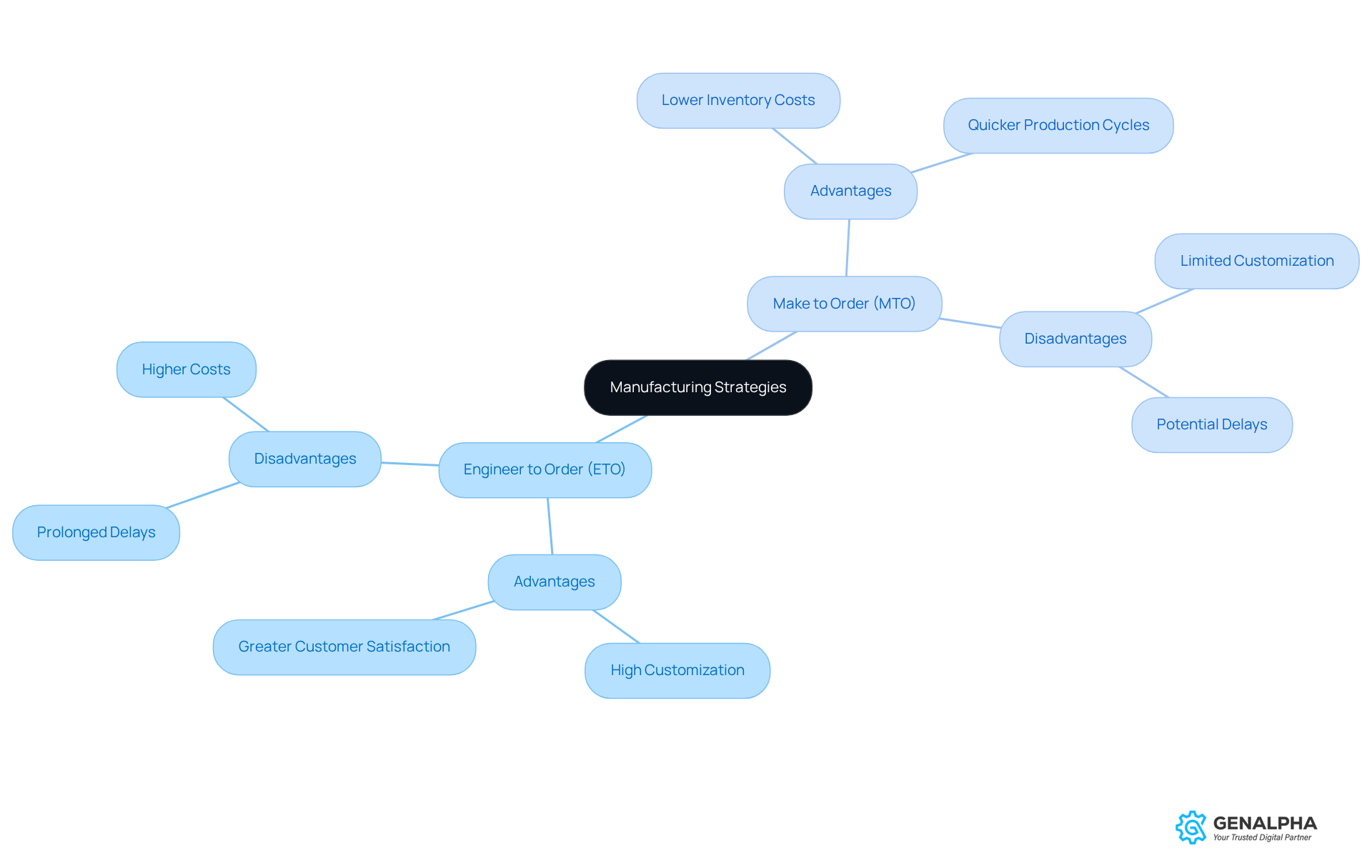

Evaluate Advantages and Disadvantages of Each Strategy

When it comes to manufacturing, the comparison of engineer to order vs make to order really highlights how Engineer to Order (ETO) excels in delivering products that are highly customized to meet specific customer needs. This approach can lead to greater satisfaction and loyalty among clients. But let’s be real - there are some significant downsides. ETO often comes with prolonged delays and higher costs due to the complex engineering and design processes involved. For instance, ETO projects usually require longer preparation times compared to standardized production methods, which can slow down how quickly a company can respond to market demands.

On the flip side, we have the comparison of engineer to order vs make to order manufacturing. This method has its perks, like lower inventory costs and quicker production cycles since items are made only after receiving customer orders. It’s a smart way to align production with actual demand, helping to minimize the risk of excess inventory. However, MTO isn’t without its challenges. It often offers limited customization options and can lead to delays if demand shifts unexpectedly. While MTO allows for some level of customization, it typically comes with higher costs and longer wait times compared to Make to Stock (MTS) approaches, which can impact customer satisfaction.

So, what’s the takeaway? The unique pros and cons of engineer to order vs make to order strategies are evident in their application. It’s crucial for producers to carefully evaluate their operational capabilities and customer expectations to figure out which method aligns best with their business goals. What do you think would work better for your needs?

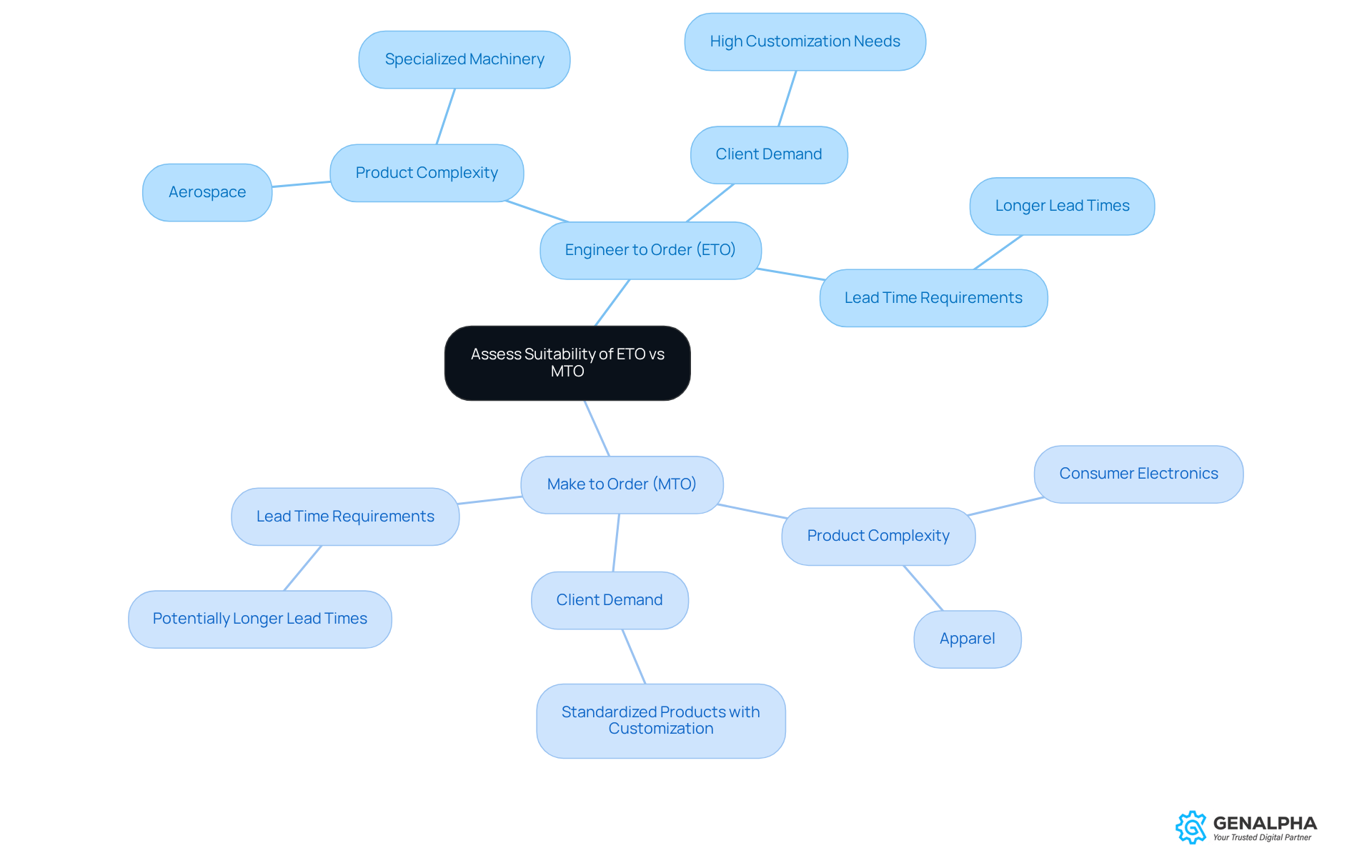

Assess Suitability of ETO vs MTO for Various Manufacturing Needs

When considering the pros and cons of engineer to order vs make to order, it’s essential to think about several key factors:

- Product complexity

- Client demand

- Lead time requirements

For instance, ETO shines in industries where customization is key - think aerospace or specialized machinery. Each product is unique and often needs a lot of engineering input.

On the flip side, MTO works best in industries with more standardized products that still allow for some customization, like consumer electronics or apparel.

So, how do you decide which strategy fits your business? It all comes down to evaluating your operational capabilities and what your customers expect.

Have you considered what your customers really want? Understanding their needs can help you choose the right approach that not only meets their expectations but also aligns with your business goals.

Conclusion

Understanding the differences between Engineer to Order (ETO) and Make to Order (MTO) manufacturing strategies is crucial for manufacturers who want to align their production methods with what customers really need. Think about it: ETO is all about creating highly customized products tailored to specific client requirements. This often means longer lead times and higher costs. On the flip side, MTO focuses on efficiency and speed, producing items based on predefined designs only after an order is placed. This generally leads to quicker turnaround times and lower inventory costs.

So, what are the key distinctions between these two approaches? ETO allows for extensive customization, making it perfect for complex industries like aerospace. Meanwhile, MTO fits well in sectors where standardization meets customer preferences, like consumer electronics. Both strategies come with their own set of pros and cons, so it’s important to consider product complexity, client demand, and lead time requirements carefully.

Ultimately, the choice between ETO and MTO should be guided by a solid understanding of your operational capabilities and what your customers expect. Embracing the right strategy not only boosts production efficiency but also enhances customer satisfaction and loyalty. So, take a moment to assess your unique circumstances. What will drive your success in this competitive market? Let's make informed decisions together!

Frequently Asked Questions

What is Engineer to Order (ETO) manufacturing?

Engineer to Order (ETO) manufacturing involves crafting products tailored to specific client needs, requiring significant engineering work and customization, which often leads to longer production times.

What is Make to Order (MTO) manufacturing?

Make to Order (MTO) manufacturing starts only after a customer places an order, using pre-defined products that can be customized to some extent, typically resulting in quicker turnaround times compared to ETO.

How do production times compare between ETO and MTO?

MTO can reduce production times by up to 30% compared to ETO, making it a more efficient option in many cases.

Why are manufacturers shifting towards MTO strategies?

Manufacturers are shifting towards MTO strategies due to growing demand for faster delivery and the ability to meet client needs without maintaining excess inventory.

What are the benefits of adopting MTO manufacturing?

Companies adopting MTO strategies have reported increased client satisfaction and improved operational efficiency, making it a desirable approach in modern manufacturing.

What are the trade-offs between ETO and MTO?

ETO offers a high degree of customization, while MTO strikes a balance between efficiency and flexibility, making it more suitable for manufacturers looking to adapt to changing client needs.