Introduction

In a world where technology is changing the game, manufacturers are at a crucial crossroads. Digital transformation isn’t just a buzzword; it’s a major shift that can boost efficiency, enhance product quality, and ultimately drive profits. But as companies dive into the world of IoT, AI, and automation, you might wonder: how can manufacturers successfully navigate this complex journey to achieve lasting success in a competitive market?

Let’s think about it. Imagine a factory that’s just starting to embrace these new technologies. They’re excited about the possibilities, but they also face challenges. How do they integrate these tools without disrupting their current operations? This is where the real conversation begins.

As we explore this topic, we’ll uncover actionable insights and strategies that can help manufacturers not just survive but thrive in this digital age. So, are you ready to take the plunge into the future of manufacturing?

Define Digital Transformation in Manufacturing

The concept of digital transformation for manufacturers involves weaving digital tools into every part of the manufacturing process. Digital transformation for manufacturers is a game-changer for how companies operate and deliver value to their clients. Think about it: technologies like the Internet of Things (IoT), artificial intelligence (AI), and automation are stepping in to boost efficiency and improve product quality.

For instance, IoT devices let manufacturers keep an eye on equipment performance in real-time. This means they can tweak production processes and cut down on downtime. And let’s not forget AI-powered predictive maintenance solutions. They analyze data from sensors to predict equipment failures before they happen, helping manufacturers save on maintenance costs and avoid those pesky disruptions. Plus, automation takes care of repetitive tasks, allowing human workers to dive into more complex activities that need critical thinking and creativity.

Now, the shift from traditional manufacturing methods to data-driven decision-making is key to the digital transformation for manufacturers. By tapping into data analytics, manufacturers can uncover insights about operational efficiencies, customer preferences, and market trends. This agility is vital in today’s competitive landscape, where customer expectations are always changing.

It’s also crucial for manufacturers to align their overall business goals with their digital transformation for manufacturers efforts. They need to make sure their online strategies not only boost operational capabilities but also enhance customer experiences and drive profitability. This way, they can carve out a sustainable competitive edge in an increasingly digital marketplace. As Nancy White puts it, "To stay competitive, technological advancement for manufacturers is essential." And with global tech investment expected to exceed $3.4 trillion by 2027, the urgency of this change is clear.

Look at successful examples like Tesla’s automation achievements and BMW’s use of AI-driven solutions. They show just how beneficial embracing modern advancements can be.

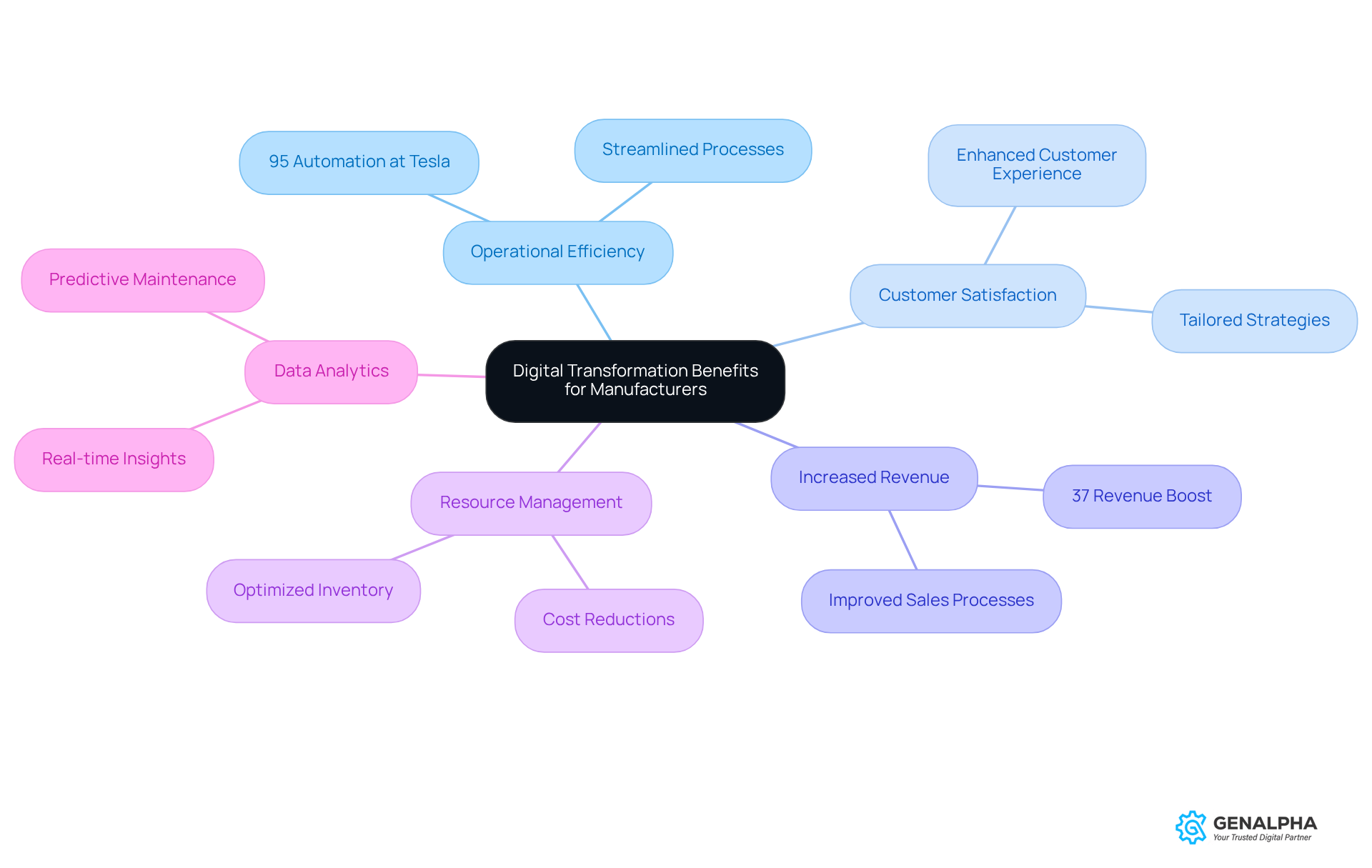

Identify Key Benefits of Digital Transformation

Digital transformation for manufacturers brings a ton of benefits! Think about it: improved operational efficiency, happier customers, and yes, even increased revenue. For instance, companies that have jumped on the tech bandwagon report an average sales revenue boost of 37%, according to a study by McKinsey. That’s a pretty compelling reason to embrace these technologies, right?

Now, here’s something interesting: 83% of producers believe that electronic solutions will revolutionize product creation in the next five years. Zvi Feuer, Senior Vice President of Digital Manufacturing Software Solutions at Siemens Digital Industries Software, backs this up. And it’s not just talk-case studies show that producers using data analytics and predictive maintenance can spot operational hiccups before they happen. Take Tesla’s Gigafactory in Shanghai, for example. With 95% automation, it cranks out a million cars a year, which is a game-changer for efficiency and lead times.

But wait, there’s more! Digital transformation for manufacturers also helps with resource management. By optimizing inventory and cutting operational costs, producers can achieve digital transformation for manufacturers to streamline their processes. Integrating technologies like AI and IoT gives them real-time insights into operations, leading to smarter decision-making and better resource allocation.

Data analytics plays a crucial role in the digital transformation for manufacturers. It allows producers to sift through massive amounts of data from production lines, boosting operational performance and enabling informed decisions. This data-driven approach not only ramps up efficiency but also fosters a culture of continuous improvement, helping producers stay competitive in a fast-paced market.

So, what do you think? Are you ready to embrace the digital shift and see how it can transform your operations?

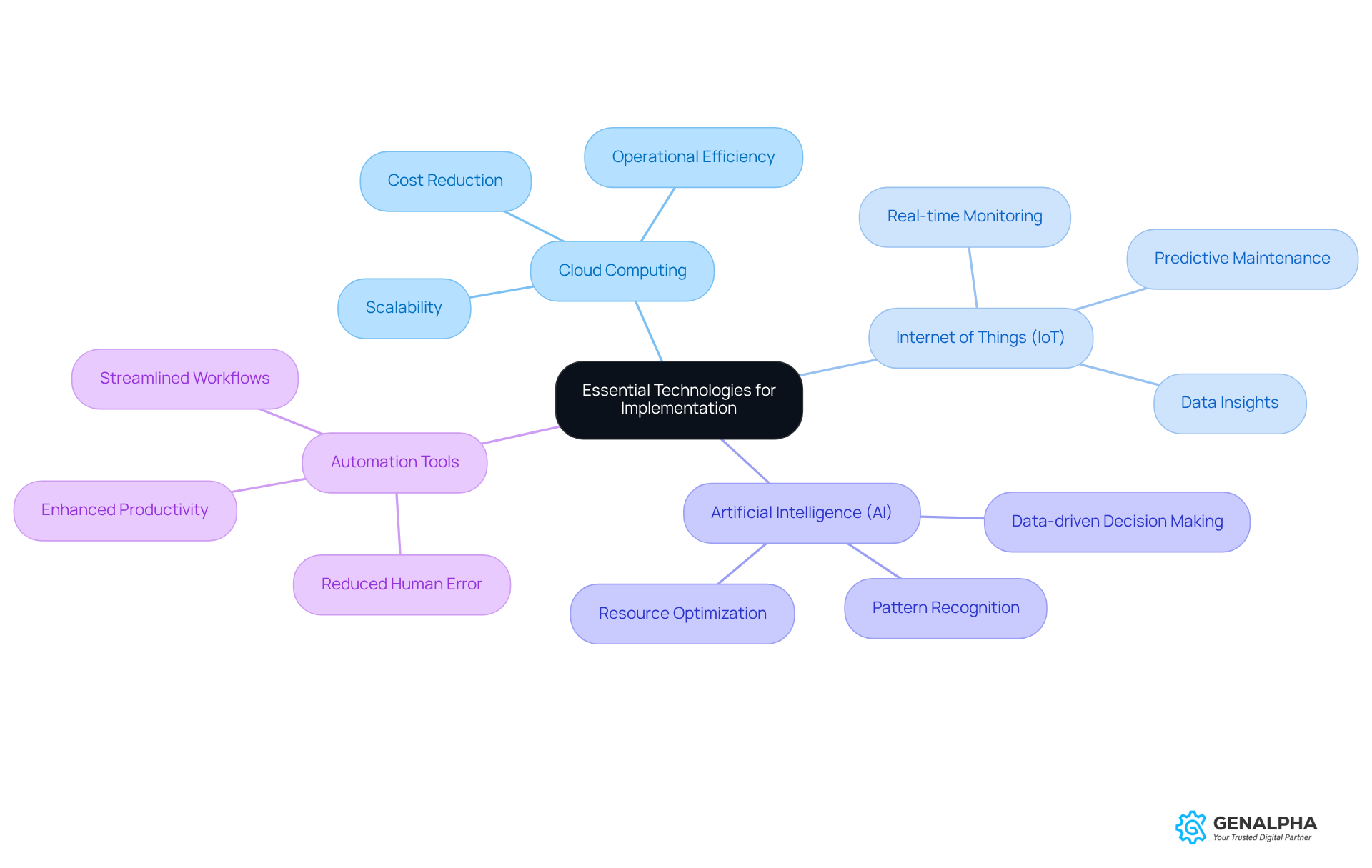

Explore Essential Technologies for Implementation

In the fast-paced world of manufacturing, keeping up with innovations like cloud computing, the Internet of Things (IoT), artificial intelligence (AI), and automation tools is key to driving digital transformation. Think about it: 87% of manufacturers are already using cloud solutions in their strategies. This shift not only makes operations smoother but also boosts data accessibility and teamwork across the board.

Now, when you combine IoT with cloud computing, you get real-time monitoring and management of production processes. IoT devices can offer valuable insights into how assets are performing, which means predictive maintenance becomes a reality, cutting down on downtime. For instance, companies leveraging IoT can catch temperature irregularities in machinery before they lead to failures. How cool is that? This proactive approach really ramps up operational efficiency and helps avoid those costly disruptions.

And let’s not forget about AI! It takes these benefits to the next level by enabling data-driven decision-making. By sifting through the massive amounts of data generated by IoT devices, AI can spot patterns and optimize production schedules. This leads to better resource allocation and lower operational costs. When you integrate AI with cloud computing and IoT, you’re creating smart manufacturing environments where automation tools can really shine, streamlining workflows and boosting productivity.

To make the most of these innovations, it’s crucial for producers to ensure a smooth integration with existing systems, especially Enterprise Resource Planning (ERP) systems. This integration creates a unified approach to data management, giving better visibility and control over operations. With 70% of CEOs seeing skill shortages as a major hurdle in digital transformation, investing in training and upskilling employees to navigate these integrated systems is a must.

When looking at service providers and their offerings, it’s important to consider your specific business needs and how scalable the solutions are. Emerging technologies, like low-code/no-code platforms, are also on the rise, allowing for quicker application development and deployment. By embracing these innovative tools, producers can enhance their agility and responsiveness to market demands, setting themselves up for success in this tech-driven era.

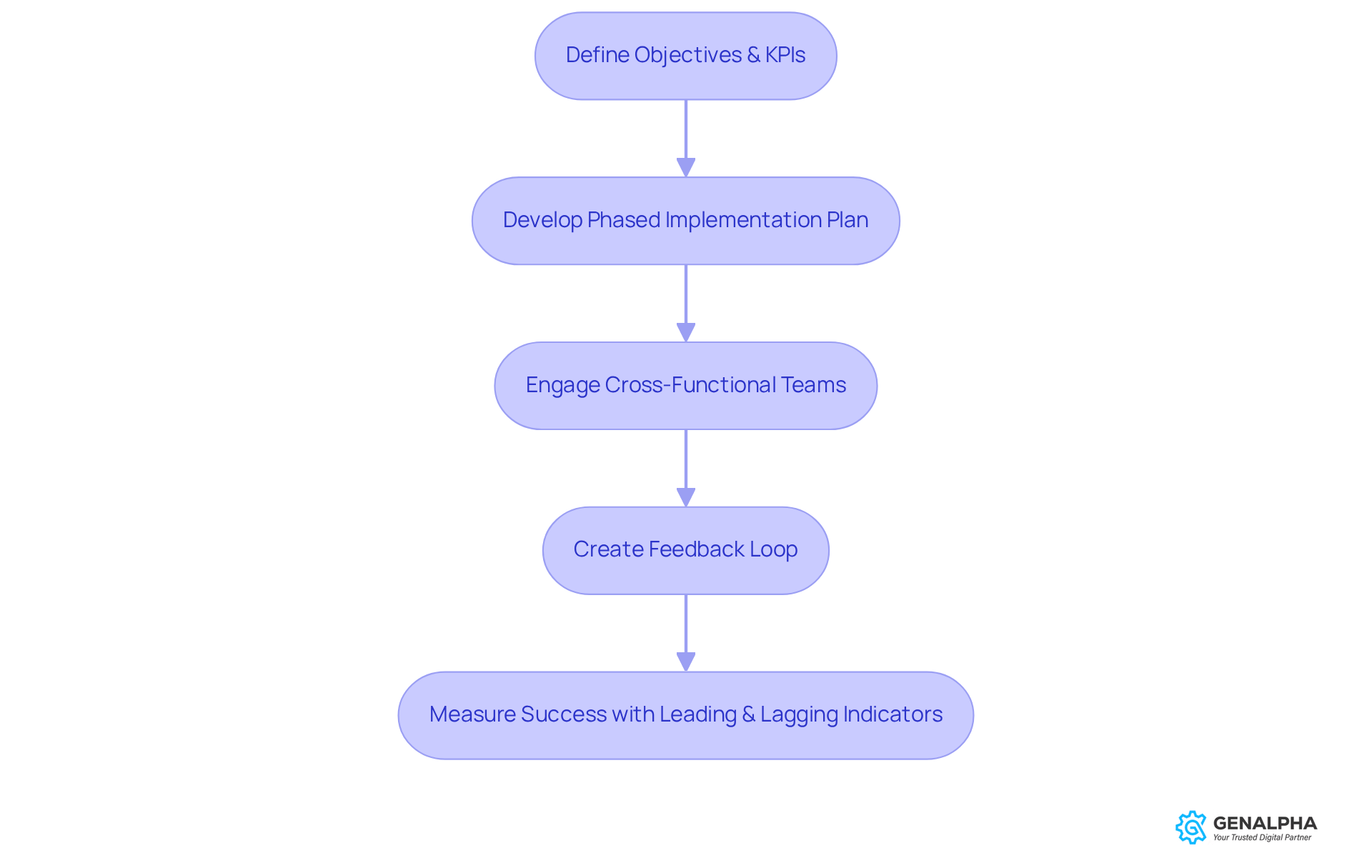

Develop a Strategic Plan for Digital Transformation

Navigating digital transformation for manufacturers can feel like a daunting task, but it doesn’t have to be! The first step is to define clear objectives and set up key performance indicators (KPIs) that align with your strategic goals. This foundational step is crucial because it ensures that all your initiatives are measurable and focused on driving meaningful outcomes.

Once you’ve got your objectives in place, it’s time to develop a phased implementation plan. Think of it as a roadmap that outlines both your short-term and long-term goals. This structured approach helps you prioritize initiatives, allocate resources effectively, and manage change incrementally. By doing this, you can reduce disruption to your ongoing operations, making the transition smoother for everyone involved.

Now, let’s talk about teamwork! Engaging cross-functional teams is essential to ensure that every aspect of your business is considered during the change process. This collaboration not only fosters a holistic view of your organization’s needs but also encourages buy-in from various departments. When everyone is on board, the likelihood of success skyrockets!

Creating a feedback loop is another key element for evaluating progress and making necessary adjustments along the way. Regularly assessing performance against your established KPIs will help you spot areas for improvement and keep your technological changes aligned with your organization’s evolving goals.

It’s also important to strike a balance between leading and lagging indicators when measuring success. This balance gives you a comprehensive view of your performance. As industry insights suggest, organizations that don’t experiment and adapt to disruption face significant risks. In fact, forecasts indicate that global technology spending is expected to hit $1.6 trillion in 2022 and double by 2023! This really highlights the urgency for manufacturers to embrace digital transformation through technological initiatives.

Moreover, as Pearl Zhu points out, executing a capability-based strategy is vital for the digital transformation for manufacturers. This reinforces the need for a strategic approach that not only addresses immediate challenges but also sets the stage for long-term success. So, are you ready to take the plunge into digital transformation?

Conclusion

Digital transformation is a game changer for manufacturers, bringing in advanced technologies that can boost every part of operations and customer interactions. Imagine using tools like IoT, AI, and automation - not just to streamline processes but to build a business model that’s quick on its feet and ready to meet changing market needs.

So, what does it take to successfully navigate this digital shift? The article lays out four key steps:

- Define what digital transformation means for you and the benefits it brings.

- Pinpoint the technologies you need to implement.

- Craft a strategic plan.

Each step underscores the need to align your digital efforts with your business goals, encourage teamwork across departments, and keep an eye on performance through established KPIs. These insights show that embracing digital transformation can lead to better efficiency, higher revenue, and a competitive edge that lasts.

But here’s the thing: the journey to digital transformation isn’t just about jumping on the latest tech bandwagon. It’s about rethinking and reshaping the entire manufacturing landscape. Manufacturers should take bold steps by prioritizing digital initiatives that fit their strategic goals, investing in employee training, and nurturing a culture of innovation. The time to act is now! The future of manufacturing depends on our ability to adapt and thrive in this fast-paced digital world. Are you ready to take the leap?

Frequently Asked Questions

What is digital transformation in manufacturing?

Digital transformation in manufacturing involves integrating digital tools into all aspects of the manufacturing process to enhance operations and deliver greater value to clients.

What technologies are involved in digital transformation for manufacturers?

Key technologies include the Internet of Things (IoT), artificial intelligence (AI), and automation, which help improve efficiency and product quality.

How do IoT devices benefit manufacturers?

IoT devices allow manufacturers to monitor equipment performance in real-time, enabling them to adjust production processes and reduce downtime.

What role does AI play in digital transformation for manufacturers?

AI-powered predictive maintenance solutions analyze sensor data to forecast equipment failures, helping manufacturers save on maintenance costs and avoid operational disruptions.

How does automation impact the manufacturing workforce?

Automation handles repetitive tasks, freeing up human workers to focus on more complex activities that require critical thinking and creativity.

Why is data-driven decision-making important in digital transformation?

Data-driven decision-making allows manufacturers to gain insights into operational efficiencies, customer preferences, and market trends, which is essential for remaining competitive.

How should manufacturers align their digital transformation efforts with business goals?

Manufacturers need to ensure that their digital strategies enhance operational capabilities, improve customer experiences, and drive profitability to maintain a competitive edge.

What is the expected global investment in technology by 2027?

Global tech investment is expected to exceed $3.4 trillion by 2027, highlighting the urgency for manufacturers to embrace digital transformation.

Can you provide examples of successful digital transformation in manufacturing?

Successful examples include Tesla's achievements in automation and BMW's use of AI-driven solutions, demonstrating the benefits of adopting modern technological advancements.