Introduction

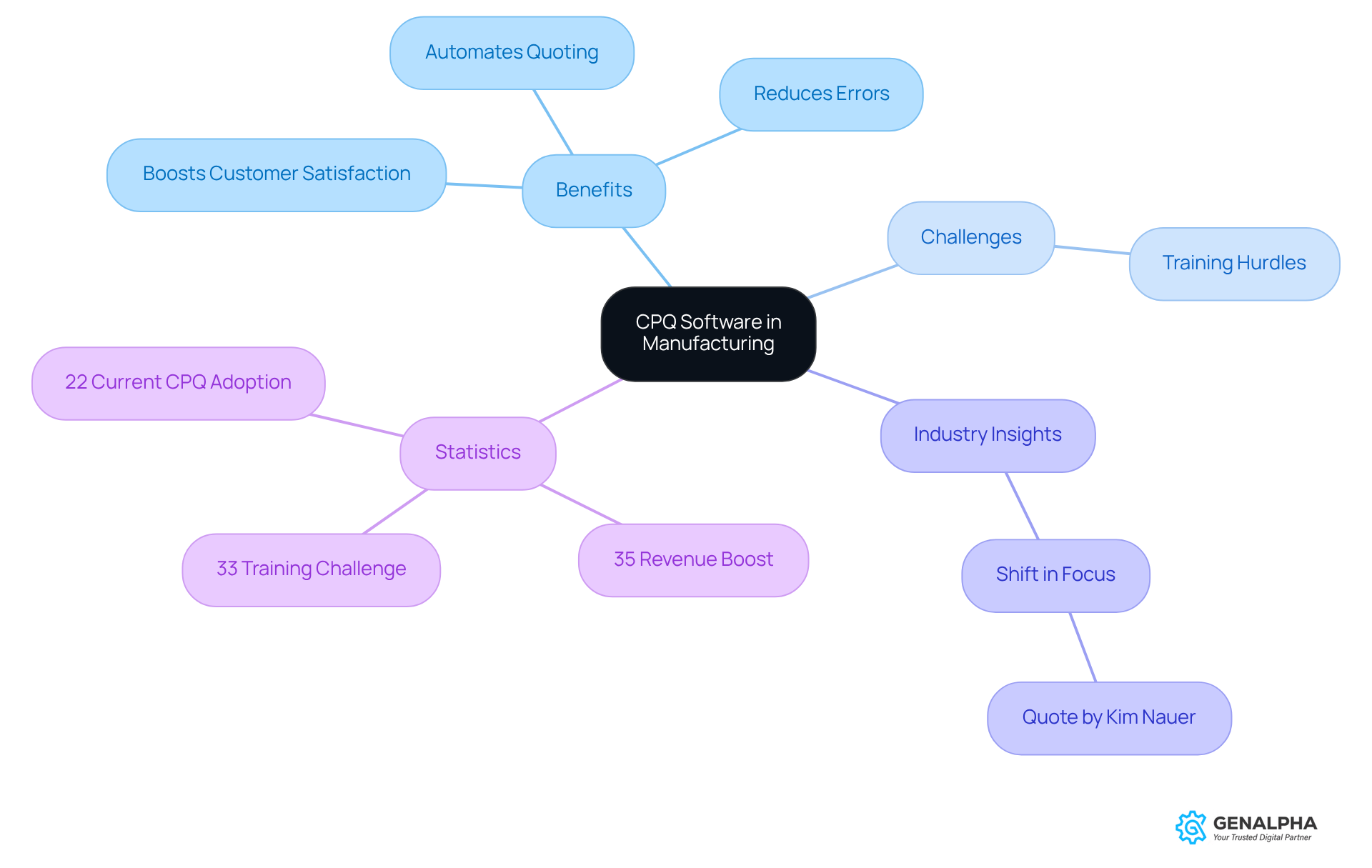

The manufacturing landscape is changing fast, and with competition heating up, the need for efficiency and accuracy in pricing is more important than ever. Have you ever felt overwhelmed by the quoting process? That’s where Configure, Price, Quote (CPQ) software comes in. It’s a game-changer for manufacturers, helping to streamline quoting processes and boost customer satisfaction.

But let’s be real: adopting CPQ isn’t always a walk in the park. There are challenges, like training staff and integrating new systems. So, how can manufacturers tackle these hurdles? What steps can you take to fully harness the benefits of CPQ technology and gain that competitive edge in the market?

Let’s dive into this together!

Understand CPQ Software and Its Role in Manufacturing

CPQ technology, or Configure, Price, Quote application, is a game-changer for manufacturers. It automates the often tedious process of generating quotes for complex products. Imagine a sales team that can quickly configure products based on what clients want, calculate accurate pricing, and whip up quotes in no time. In the manufacturing world, where products can come with a myriad of configurations and pricing variables, CPQ solutions really simplify things. They help cut down on errors and speed up responses to client inquiries. Plus, when these tools integrate with existing ERP systems, sales teams get access to real-time data. This means they can provide precise and prompt quotes, boosting customer satisfaction and driving sales efficiency.

Industry leaders are really excited about the potential of CPQ tools. As Kim Nauer puts it, "Manufacturers are entering 2026 with a clear shift in focus, prioritizing predictable and stable operations over rapid experimentation." This shift highlights just how important it is to adopt technologies like CPQ if you want to stay competitive. And here’s a stat that might catch your attention: producers using CPQ applications often see a revenue boost of 35% within the first year. That’s a pretty compelling reason to consider it!

But it’s not all smooth sailing. A significant 33% of producers say that training team members on new CPQ tools is a major hurdle during implementation. Tackling these challenges is key to making sure CPQ adoption is successful.

So, what’s the takeaway? Embracing CPQ software is becoming essential for producers who want to stay competitive and meet the needs of today’s buyers. By leveraging this technology, manufacturers can not only streamline their quoting processes but also set themselves up for continued growth in a fast-paced market. Are you ready to take the plunge?

Identify Key Benefits of CPQ Tools for Enhanced Efficiency

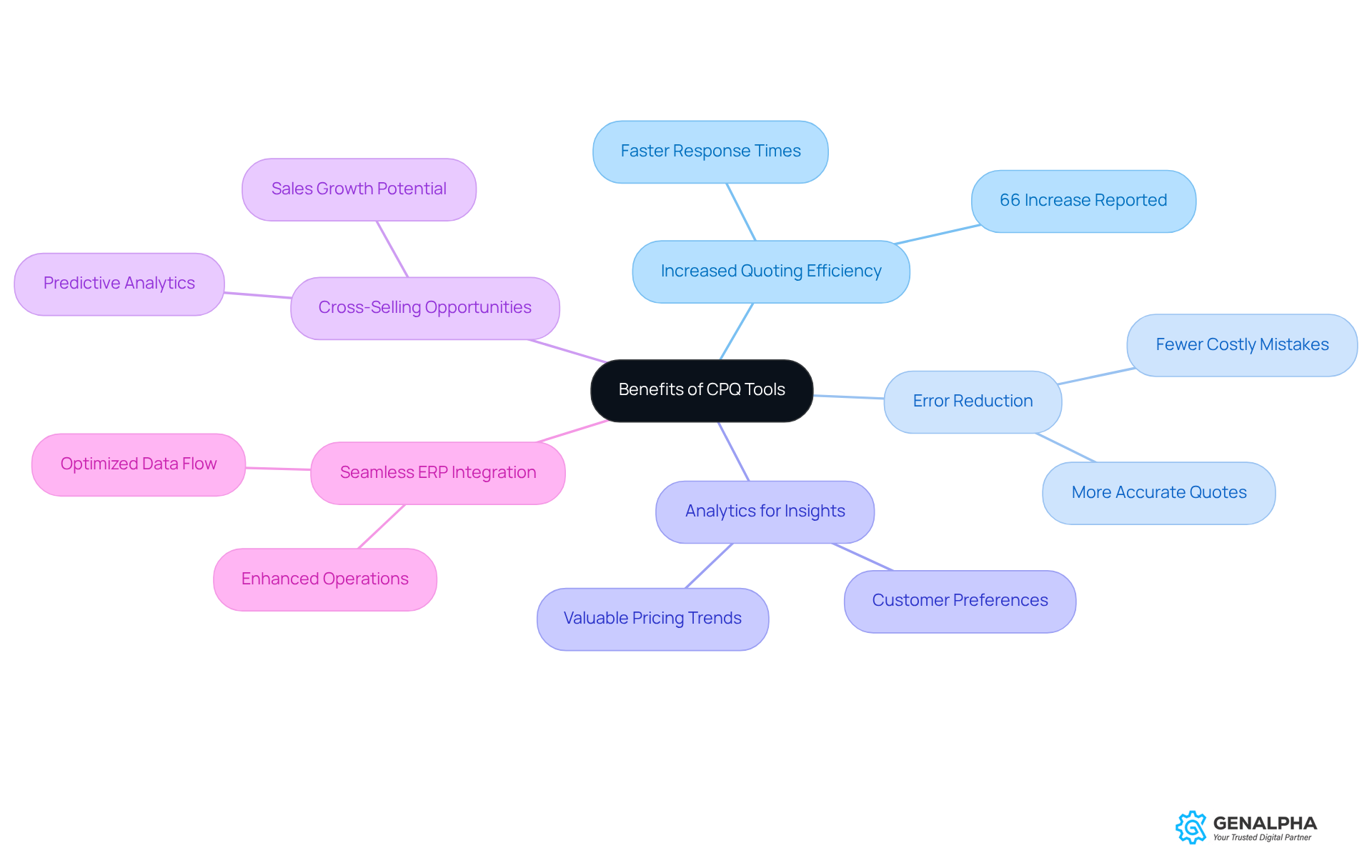

CPQ tools are game-changers for manufacturers, bringing some serious benefits that can really boost efficiency. Imagine cutting down the time it takes to create quotes-this means sales teams can respond to client inquiries faster. In a competitive market, that speed can make all the difference in securing sales. For instance, manufacturers using CPQ tools have reported a whopping 66% increase in quoting efficiency, leading to significant time savings and happier clients.

But that’s not all. CPQ software also helps reduce errors in pricing and product configurations, which means more accurate quotes and fewer costly mistakes. This reduction in errors is crucial because it directly impacts profit margins and builds client trust. Plus, these tools leverage analytics to provide valuable insights into pricing trends and customer preferences, paving the way for smarter decision-making.

Have you ever thought about how predictive analytics in CPQ platforms can uncover cross-selling and upselling opportunities? This can really drive sales growth! And when CPQ solutions integrate seamlessly with existing ERP systems, they enhance operations and optimize data flow. This means producers can tailor solutions to meet specific customer needs.

In the end, this comprehensive approach not only strengthens relationships but also fosters loyalty, setting producers up for long-term success in the market. So, why not consider how CPQ tools could transform your business?

Implement Effective Strategies for Integrating CPQ Software

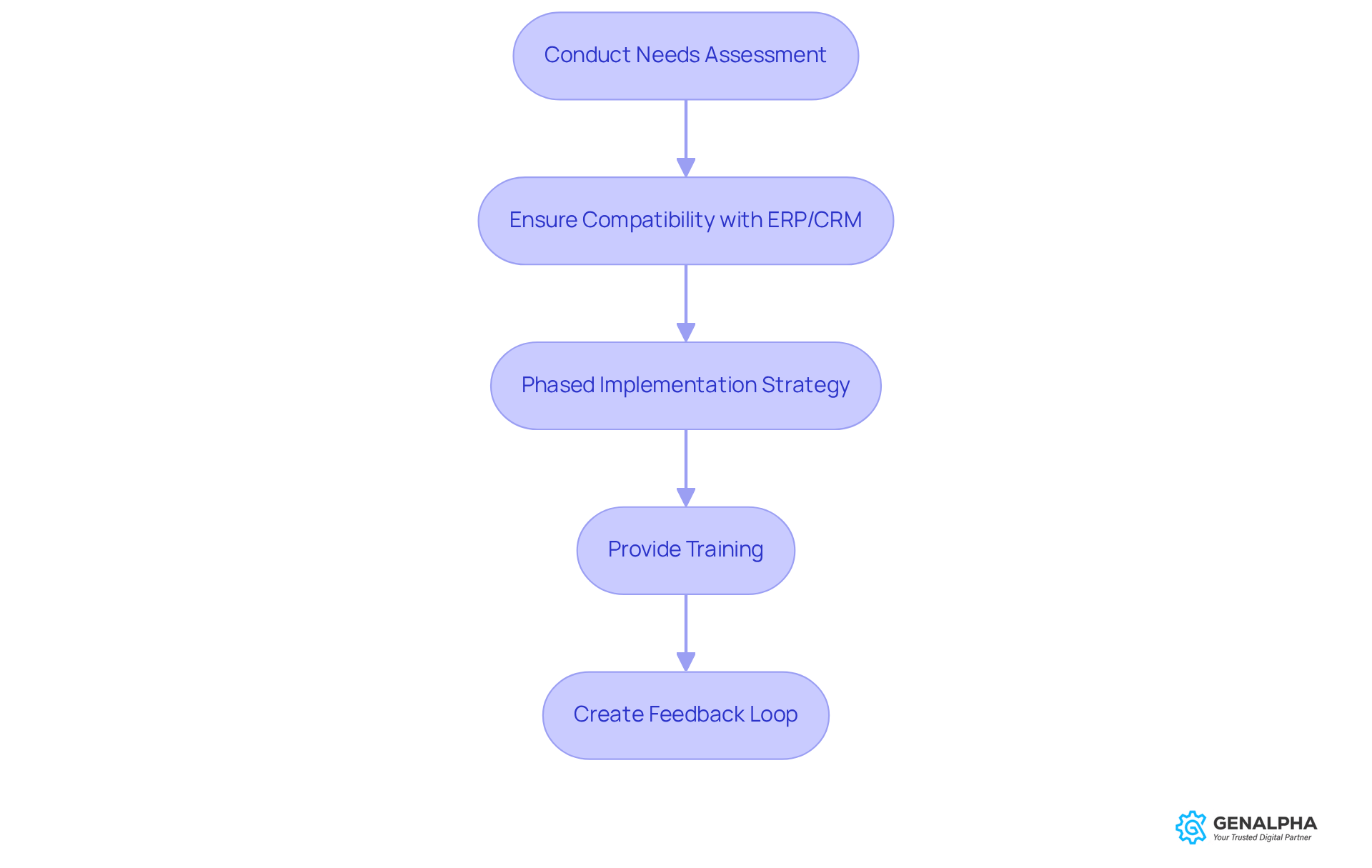

Integrating CPQ tools effectively can really transform how manufacturers operate. Have you ever thought about what it takes to get the most out of these tools? First off, conducting a thorough needs assessment is key. This step helps pinpoint your specific organizational requirements and challenges, guiding you to choose a CPQ solution that truly aligns with your business goals.

Now, let’s talk about compatibility. Ensuring that your CPQ tools work seamlessly with existing ERP and CRM systems is crucial. Why? Because it facilitates smooth data flow, which can significantly cut down on errors and boost operational efficiency. Plus, consider a phased implementation strategy. This approach allows businesses to gradually integrate CPQ tools, minimizing disruption and building user confidence along the way.

Training is another essential piece of the puzzle. Providing thorough instruction for your sales and support teams means they can use the system efficiently, which ultimately boosts overall productivity. And don’t forget about creating a feedback loop! This is vital for continuously enhancing the CPQ process, allowing producers to adapt to user experiences and shifting market needs.

By following these best practices, like the insights gained from Brother Industries' successful integration of CPQ with Salesforce and SAP, you can really optimize the benefits of CPQ tools. Imagine quicker, more accurate quoting and happier clients! And let’s not overlook critical concerns like data privacy and accuracy - addressing these will ensure a stronger implementation process. So, are you ready to take the plunge into CPQ integration?

Overcome Challenges in CPQ Adoption for Seamless Integration

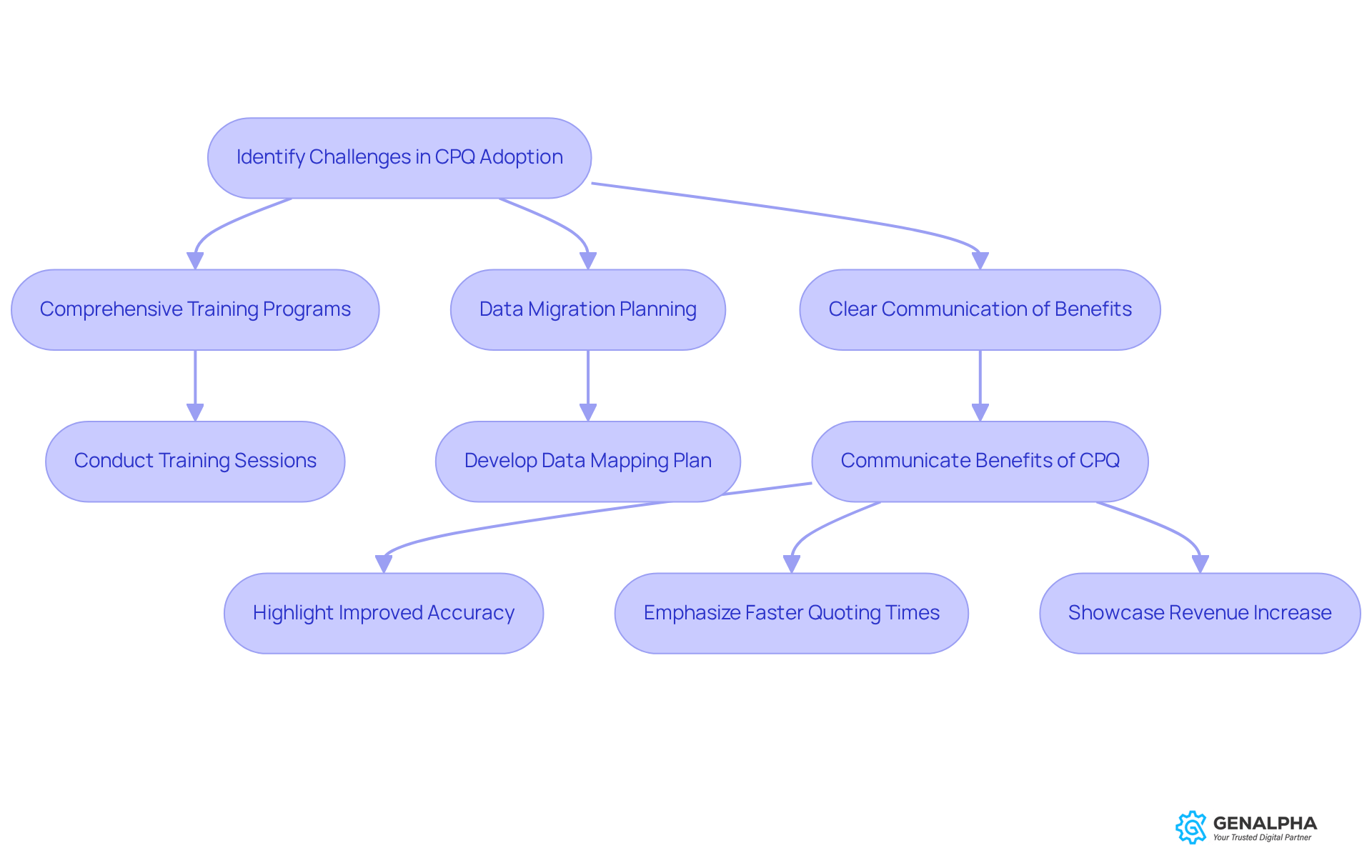

Implementing CPQ software in manufacturing can be a bit tricky, especially when it comes to getting employees on board. Have you ever faced resistance to change? It’s pretty common! That’s why having comprehensive training programs is so important. They help equip your team with the knowledge and skills they need to embrace the new system. Plus, clear communication about the benefits of CPQ - like improved accuracy, faster quoting times, and even a reported 35% increase in revenue within the first year - can really help ease those worries. For instance, many producers who have tackled these challenges report significant boosts in efficiency and customer satisfaction.

Now, let’s talk about data migration from legacy systems. That’s another hurdle to jump over! Developing a detailed data mapping plan is crucial for a smooth transition. And don’t forget about aligning the CPQ system with your existing sales workflows. This requires collaboration among sales, IT, and management teams to ensure the CPQ tool meets your organization’s specific needs, ultimately enhancing productivity. A phased implementation strategy can also help ease the transition.

By proactively addressing these challenges, manufacturers can not only make CPQ implementation a success but also significantly improve their overall operational efficiency and the software price quote processes. Did you know that organizations adopting CPQ software can cut quote completion times by over 50%? That really highlights the potential of these solutions! However, it’s also important to consider the upfront costs associated with CPQ implementation, as this gives a more balanced view of the challenges involved.

Conclusion

Embracing CPQ software is a game-changer for manufacturers aiming to boost efficiency and stay competitive in today’s complex market. Imagine automating your quoting process-suddenly, operations become smoother, errors drop, and you can respond to customer inquiries faster. This not only enhances customer satisfaction but can also lead to a nice bump in revenue.

Throughout this article, we’ve explored the perks of CPQ tools. Think about the significant improvements in quoting efficiency and pricing accuracy, plus the power of analytics for smarter decision-making. We also touched on effective strategies for integrating CPQ software, highlighting the need for thorough training, ensuring compatibility with your existing systems, and taking a phased approach to implementation. This way, the transition feels seamless.

Now, let’s be real-the journey to adopting CPQ technology isn’t always smooth sailing. There are challenges, like team resistance and data migration, but the rewards can be huge. By tackling these common hurdles, manufacturers can truly unlock the full potential of CPQ tools. So, why not consider how these innovative solutions can reshape your business operations and fuel sustainable growth? Embracing CPQ software isn’t just a passing trend; it’s a strategic move that could redefine success in the manufacturing industry. Ready to take the leap?

Frequently Asked Questions

What is CPQ software and what role does it play in manufacturing?

CPQ software, or Configure, Price, Quote application, automates the process of generating quotes for complex products in manufacturing. It allows sales teams to quickly configure products, calculate accurate pricing, and create quotes efficiently.

How does CPQ software benefit manufacturers?

CPQ solutions simplify the quoting process, reduce errors, speed up responses to client inquiries, and provide access to real-time data when integrated with existing ERP systems. This leads to precise and prompt quotes, enhancing customer satisfaction and sales efficiency.

What shift are manufacturers experiencing regarding CPQ technology?

Manufacturers are focusing on predictable and stable operations rather than rapid experimentation, highlighting the importance of adopting technologies like CPQ to remain competitive in the industry.

What is the potential revenue increase for producers using CPQ applications?

Producers using CPQ applications often experience a revenue boost of 35% within the first year of implementation.

What challenges do manufacturers face when implementing CPQ software?

A significant challenge is training team members on new CPQ tools, with 33% of producers citing it as a major hurdle during implementation.

Why is embracing CPQ software becoming essential for manufacturers?

Embracing CPQ software is essential for manufacturers to stay competitive and meet the needs of today’s buyers, enabling streamlined quoting processes and opportunities for continued growth in a fast-paced market.