Introduction

Digitalization in manufacturing has shifted from just a buzzword to a must-have strategy for success in the industry. Think about it: with the power to boost operational efficiency, cut costs, and enhance product quality, the pressure on manufacturers to adapt is at an all-time high. But let’s be real - the road to digital transformation isn’t all smooth sailing. From employee pushback to the tricky task of integrating new technologies, there are plenty of bumps along the way. So, what can manufacturers do to not just tackle these challenges but also flourish in this digital era? Let's dive in!

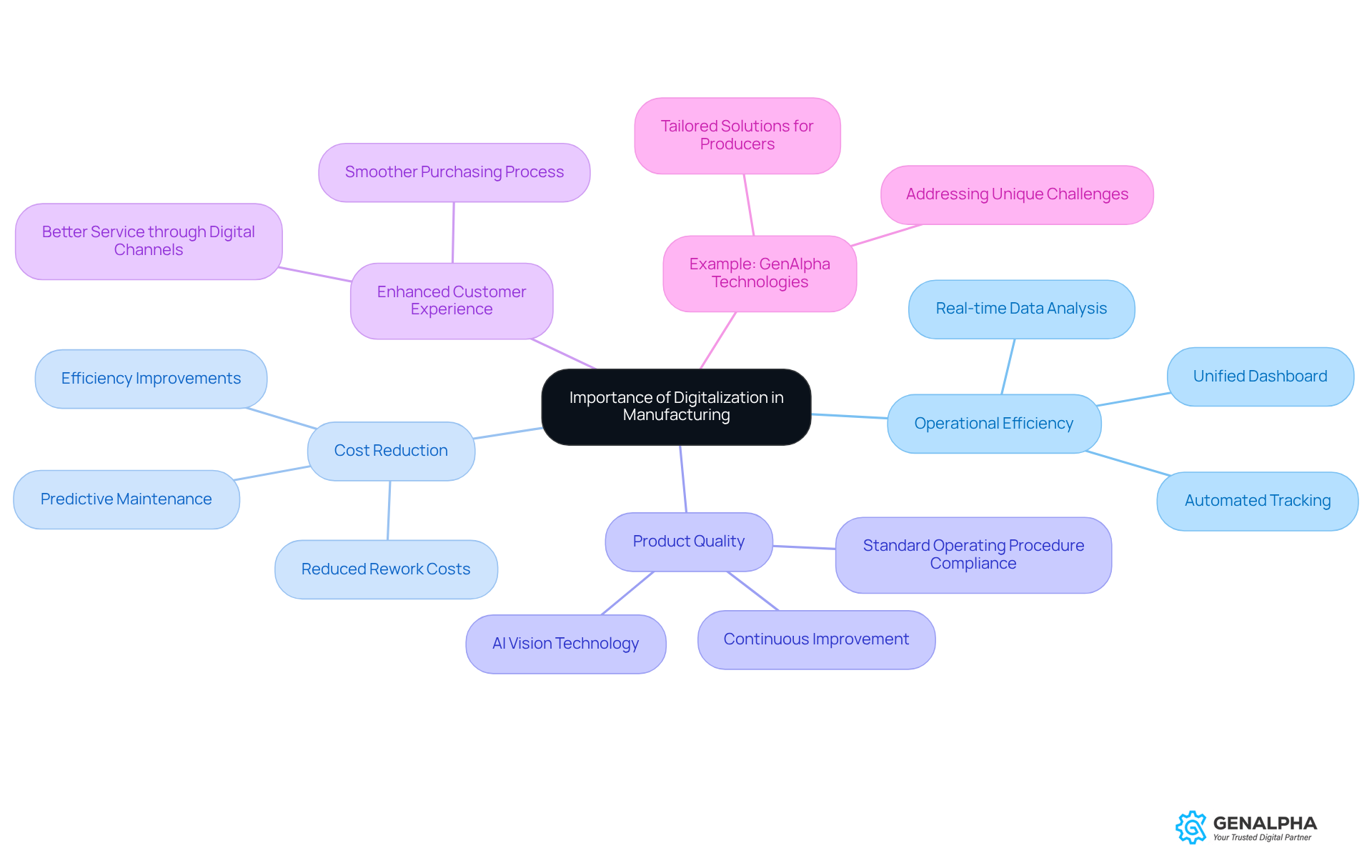

Understand the Importance of Digitalization in Manufacturing

Manufacturing digitalization is no longer just a nice-to-have; it has become a necessity! Think about it: it boosts operational efficiency, cuts costs, and elevates product quality. A Deloitte survey even shows that manufacturers embracing tech transformations see a real jump in productivity and agility.

So, how does this work? Well, digitalization allows for real-time data analysis, which means producers can make quick, informed decisions. Plus, it really enhances customer experiences by making purchasing smoother and offering better service through digital channels.

Take GenAlpha Technologies, for instance. They’re leading the charge by providing tailored solutions that address the unique challenges faced by producers and distributors. Isn’t it exciting to see how technology is reshaping the industry?

If you’re in manufacturing, now’s the time to consider how digitalization can work for you. What steps can you take today to start this journey?

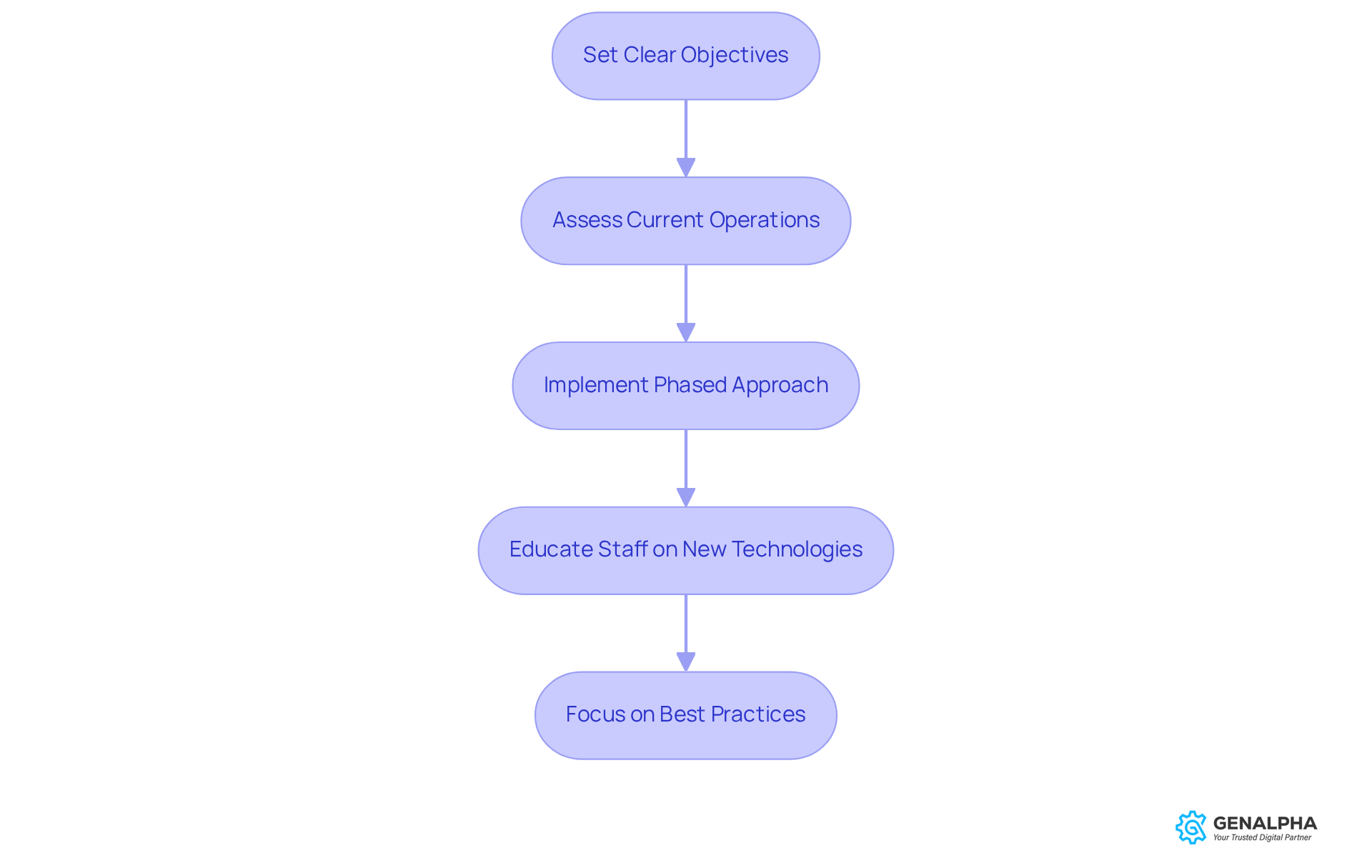

Implement Effective Strategies for Digitizing Manufacturing Processes

To initiate manufacturing digitalization of processes, companies really need to set clear objectives that align with their overall business goals. Think about it: a thorough assessment of current operations can help pinpoint areas that are just begging for improvement. A phased approach works wonders here; for example, producers might start by digitizing their inventory management systems. This can really boost visibility and control over stock levels.

But it doesn’t stop there! Educating staff on these new technologies is super important for ensuring a smooth adoption and maximizing the benefits of electronic tools. Take GenAlpha Technologies, for instance. They’ve been guiding clients through these crucial steps, leading to some impressive improvements in operational efficiency and customer engagement.

By focusing on these best practices, manufacturers can navigate the tricky waters of manufacturing digitalization and position themselves for long-term success. So, are you ready to take the plunge into the digital age?

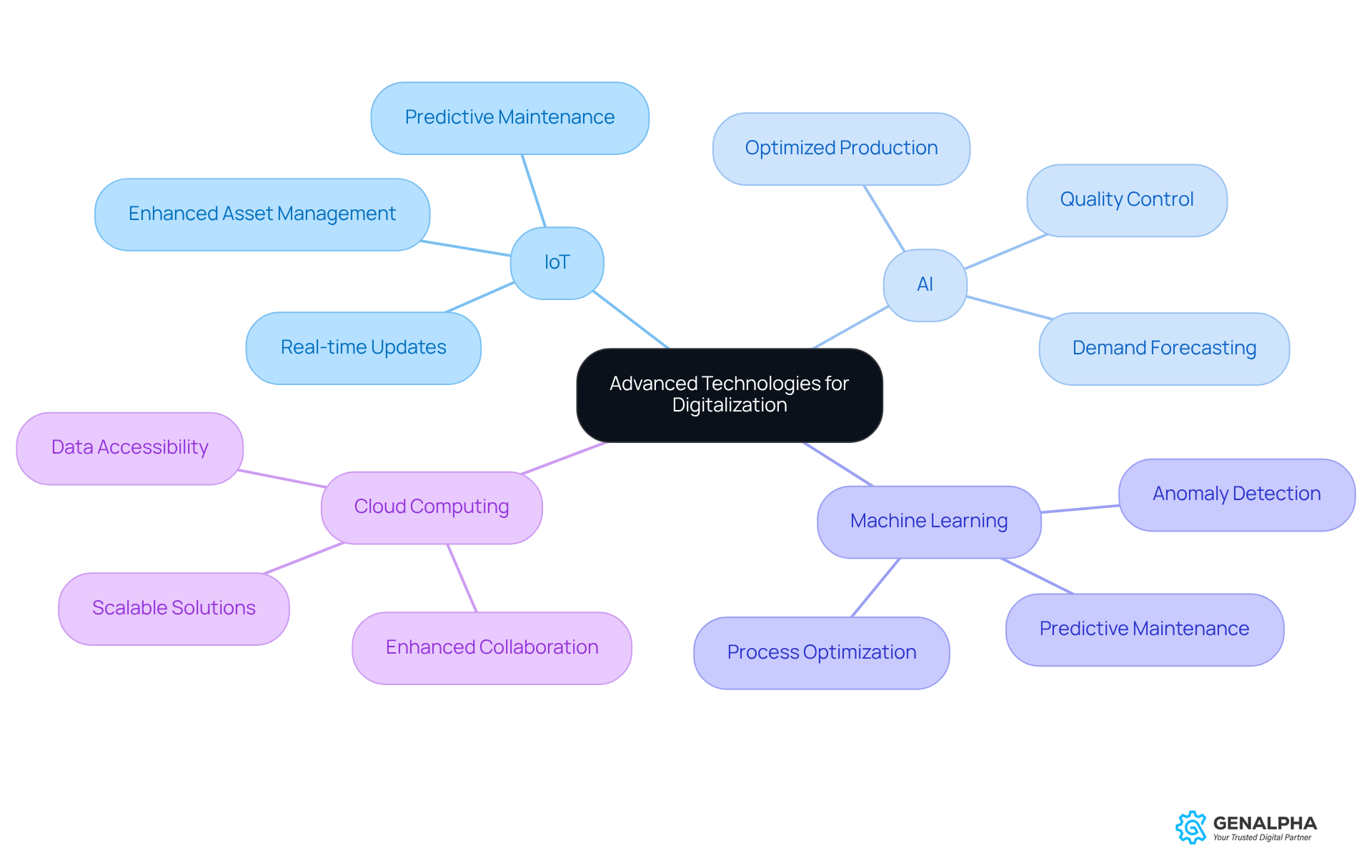

Leverage Advanced Technologies for Enhanced Digitalization

Have you noticed how advanced technologies like IoT, AI, and machine learning are shaking things up in the realm of manufacturing digitalization? It’s pretty exciting! Imagine having IoT devices that give you real-time updates on how your manufacturing digitalization is performing. This means you can do predictive maintenance and keep downtime to a minimum - who wouldn’t want that?

Now, let’s talk about AI. It’s not just a buzzword; manufacturing digitalization can actually sift through tons of data to help you optimize production schedules and improve quality control. Sounds like a game changer, right? And if you’re looking to boost collaboration and make data more accessible, integrating cloud computing solutions is definitely worth considering.

For instance, take a look at GenAlpha Technologies' Equip360 platform. It’s a fantastic example of how these technologies can streamline operations and enhance customer interactions. By leveraging these tools for manufacturing digitalization, you’re not only improving efficiency but also driving growth.

So, what do you think? Are you ready to embrace these technologies and see how manufacturing digitalization can transform your manufacturing processes?

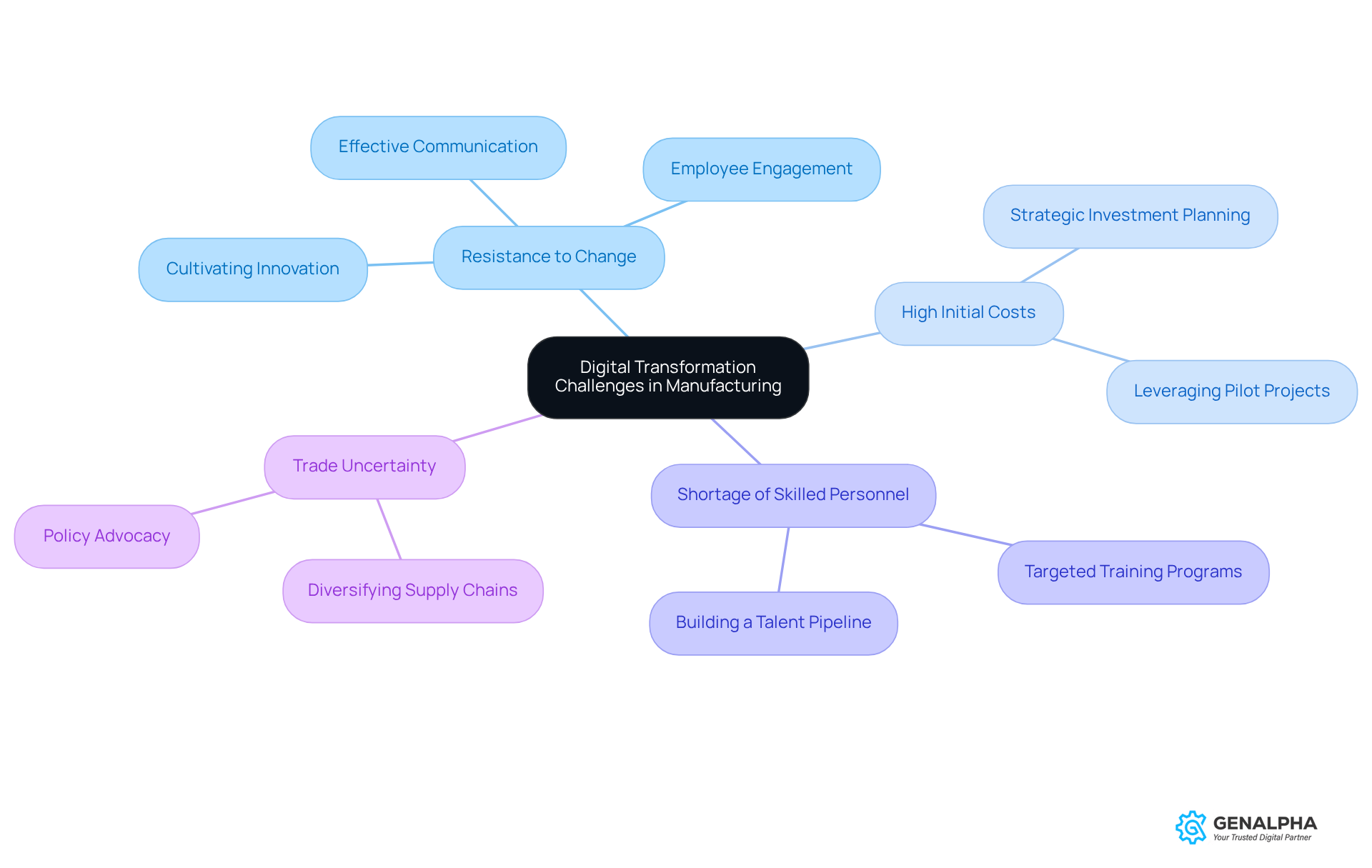

Address Challenges and Considerations in Digital Transformation

Digital transformation in manufacturing can feel like a daunting journey, right? With challenges like resistance to change, high initial costs, and a shortage of skilled personnel, it’s no wonder many producers are hesitant. In fact, in 2025, a whopping 78% of producers pointed to trade uncertainty as their biggest worry. This really highlights the need for a solid strategy for manufacturing digitalization.

So, how can manufacturers tackle these hurdles? It all starts with cultivating a culture of innovation and adaptability. Engaging employees from the get-go and providing thorough training can make a world of difference in reducing resistance. For example, organizations that roll out targeted pilot projects create a safe space for teams to adapt and learn. This not only fosters a sense of ownership but also encourages collaboration.

Now, let’s talk about communication. It’s crucial to clearly convey the benefits of manufacturing digitalization. This helps align the workforce with the company’s vision and demystifies new technologies, making it easier for everyone to get on board. Dean Clark emphasizes that having a robust online infrastructure and organized data is key to successful change initiatives.

Take a look at companies like GenAlpha Technologies. They’re a great example of how tailored solutions can meet specific client needs, like integrating agentic AI in aftermarket services. This approach leads to smoother transitions and boosts operational efficiencies.

By prioritizing employee engagement and fostering a culture of continuous learning, manufacturers can not only overcome resistance but also drive successful manufacturing digitalization efforts. So, what steps can you take today to start this journey?

Conclusion

Manufacturing digitalization is really shaking things up in the industry, isn’t it? It’s not just about keeping up; it’s about boosting operational efficiency, cutting costs, and enhancing product quality. As more manufacturers realize that diving into digital technologies isn’t just a nice-to-have but a must-have, the push for digital transformation becomes crucial for sustainable growth and staying competitive.

So, what are some best practices for making this digital leap? First off, it’s all about:

- Setting clear goals that sync up with your business objectives.

- Leveraging cutting-edge tech like IoT and AI for real-time data analysis.

- Fostering a culture of innovation to tackle challenges like resistance to change.

Companies like GenAlpha Technologies are great examples of how tailored solutions can meet specific industry needs, leading to better operational efficiencies and stronger customer engagement.

In this fast-paced manufacturing world, the message is loud and clear: manufacturers need to actively chase digitalization to thrive. By focusing on:

- Employee engagement,

- Investing in advanced technologies,

- Rolling out strategic frameworks,

businesses can tackle the complexities of digital transformation head-on. Embracing these changes not only gears manufacturers up for future challenges but also helps them tap into the full potential of digitalization, ensuring they’re set for long-term success and resilience in a competitive market. So, are you ready to take the plunge into digitalization?

Frequently Asked Questions

Why is digitalization important in manufacturing?

Digitalization is crucial in manufacturing as it boosts operational efficiency, reduces costs, and improves product quality. It has become a necessity for manufacturers to stay competitive.

What benefits do manufacturers experience by embracing digitalization?

Manufacturers that adopt digitalization experience increased productivity and agility, as well as enhanced customer experiences through smoother purchasing processes and better service via digital channels.

How does digitalization facilitate decision-making in manufacturing?

Digitalization enables real-time data analysis, allowing manufacturers to make quick and informed decisions based on accurate and timely information.

Can you provide an example of a company leading in manufacturing digitalization?

GenAlpha Technologies is an example of a company that is leading the charge in manufacturing digitalization by offering tailored solutions to address the unique challenges faced by producers and distributors.

What should manufacturers consider regarding digitalization?

Manufacturers should consider how digitalization can work for them and explore the steps they can take to start their digital transformation journey.