Introduction

The excavation equipment manufacturing sector is on the verge of a big change, thanks to the innovative power of Configure, Price, Quote (CPQ) solutions. These tools do more than just streamline the quoting process; they really boost operational efficiency, helping manufacturers respond quickly to complex client needs. But as the industry evolves, a question lingers: how can manufacturers make the most of CPQ to stay competitive and meet growing customer expectations?

In this article, we’ll explore some best practices that can help unlock the full potential of CPQ systems. By doing so, we can ensure success in a landscape that’s changing faster than ever. So, let’s dive in and see how we can navigate this transformation together!

Understand the Role of CPQ in Excavation Equipment Manufacturing

CPQ solutions are a game changer for excavation equipment manufacturers in the manufacturing world. They automate the configuration, pricing, and quoting processes, making life a whole lot easier for manufacturers. Imagine being able to whip up accurate quotes tailored to complex product specs and client needs in no time! For example, a manufacturer can easily set up different excavator models with specific attachments and features, ensuring the quote hits the mark for what the client really wants.

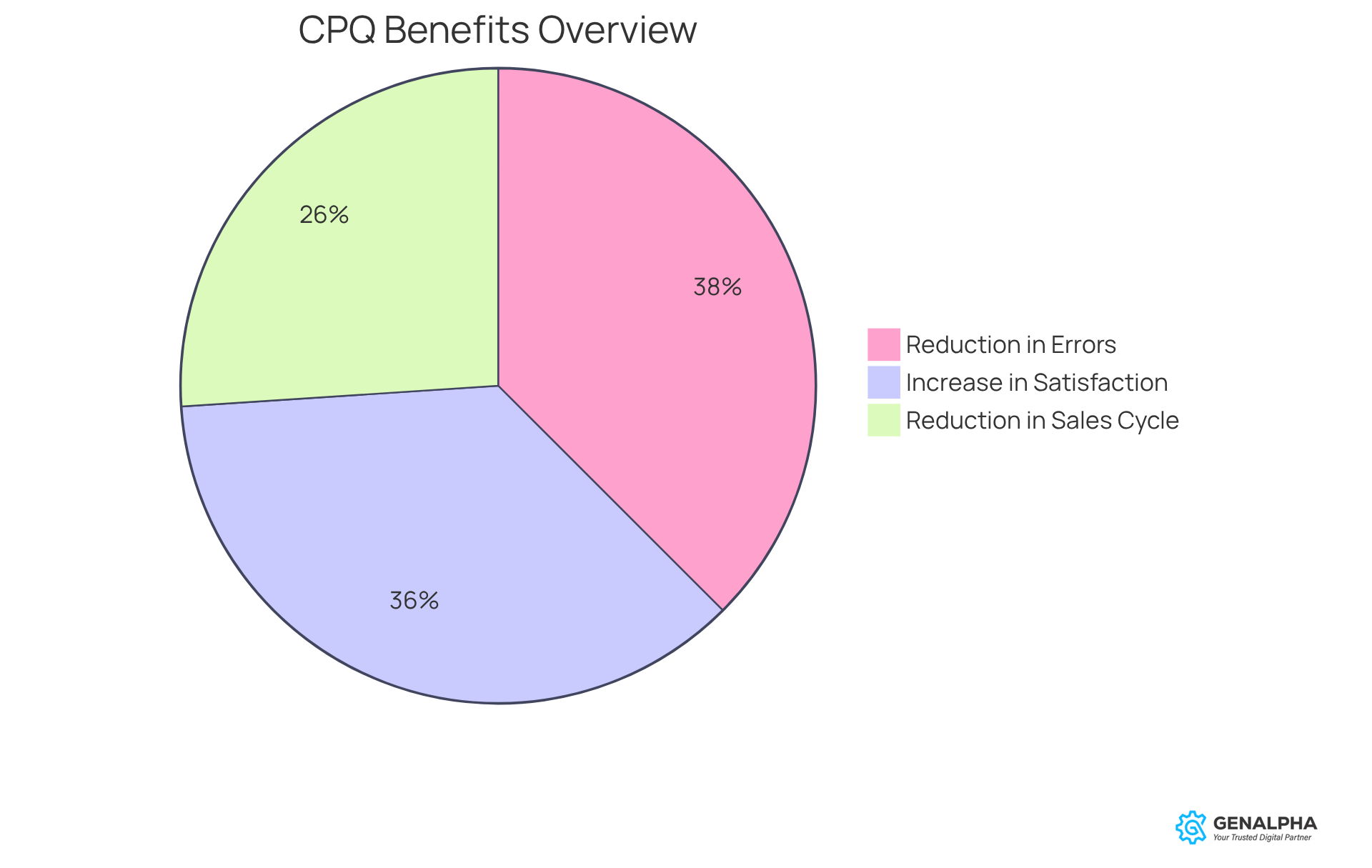

This automation speeds up the transaction cycle dramatically, cutting down the time from weeks to just minutes. Plus, it helps minimize those pesky mistakes that often come with manual quoting. In fact, CPQ solutions can slash the quote process from weeks to mere minutes and lead to a whopping 36% reduction in errors and delays. By embracing CPQ, excavation equipment manufacturers can respond to client inquiries more quickly, enhancing satisfaction and loyalty.

Companies that have jumped on the CPQ bandwagon report a 35% increase in client satisfaction and a 25% reduction in sales cycle times. That really highlights how crucial CPQ is for driving operational efficiency and gaining a competitive edge in the market. To keep reaping these benefits and stay in tune with changing customer expectations, continuous evaluation and optimization of CPQ processes are key. So, why not take a closer look at how CPQ can transform your quoting process?

Evaluate Key Criteria for Selecting a CPQ Solution

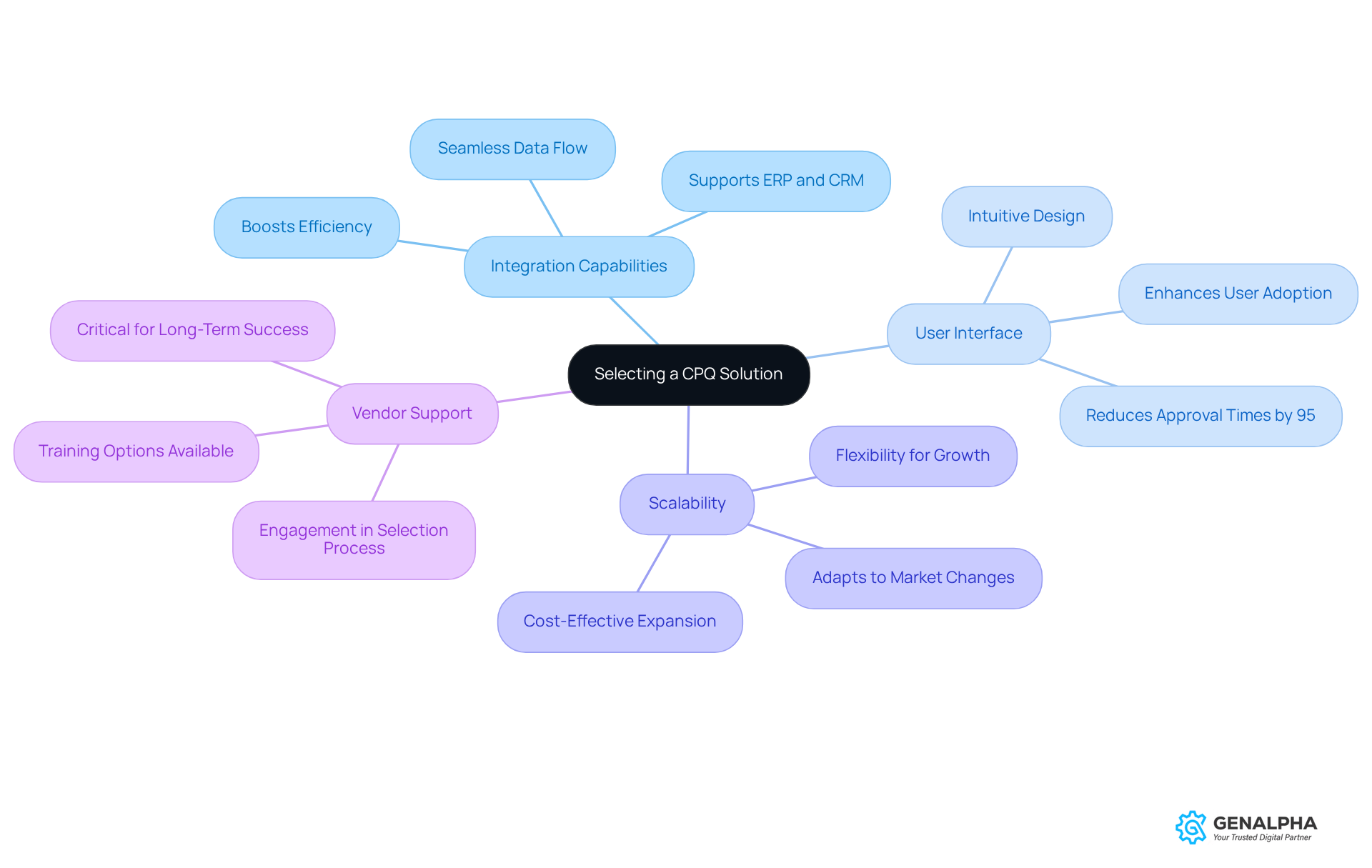

When it comes to selecting a CPQ solution, excavation equipment manufacturers cpq must keep a few key factors in mind to ensure the platform meets their unique operational needs. First off, integration capabilities with existing ERP and CRM systems are a must. Why? Because they help create a smooth data flow and boost overall efficiency. In fact, companies using CPQ tools report a significant productivity boost, with quoting processes speeding up by 27% compared to those without these tools. Plus, there’s a 40% drop in human errors during quoting, which just goes to show how crucial precision and efficiency are in business operations.

Now, let’s talk about the user interface. It should be intuitive, making it easy for sales teams to jump right in and get to work without a steep learning curve. A user-friendly design can cut approval times by up to 95%! That means sales agents can spend more time closing deals instead of wrestling with complicated software.

Scalability is another biggie. As businesses grow, excavation equipment manufacturers cpq need to ensure that their solutions keep up with more product lines and client demands without breaking the bank. This flexibility ensures the system stays effective as market conditions change. And speaking of growth, the CPQ software market is set to soar, projected to hit USD 8917.68 Million by 2033. That’s a clear sign of how relevant these solutions are becoming in the industry.

Lastly, don’t overlook vendor support and training options. Good customer support can make a huge difference in how well the CPQ solution works for you in the long run. Engaging with vendors early in the selection process lets manufacturers gauge the level of support and training available, which is key to getting the most out of their chosen solution. As Jacob Thomas puts it, "For sales groups in 2025 managing intricate products or tailored solutions, CPQ software isn’t merely a luxury-it’s essential." So, what are you waiting for? Let's dive into finding the right CPQ solution for your needs!

Integrate CPQ with ERP and CRM Systems for Enhanced Efficiency

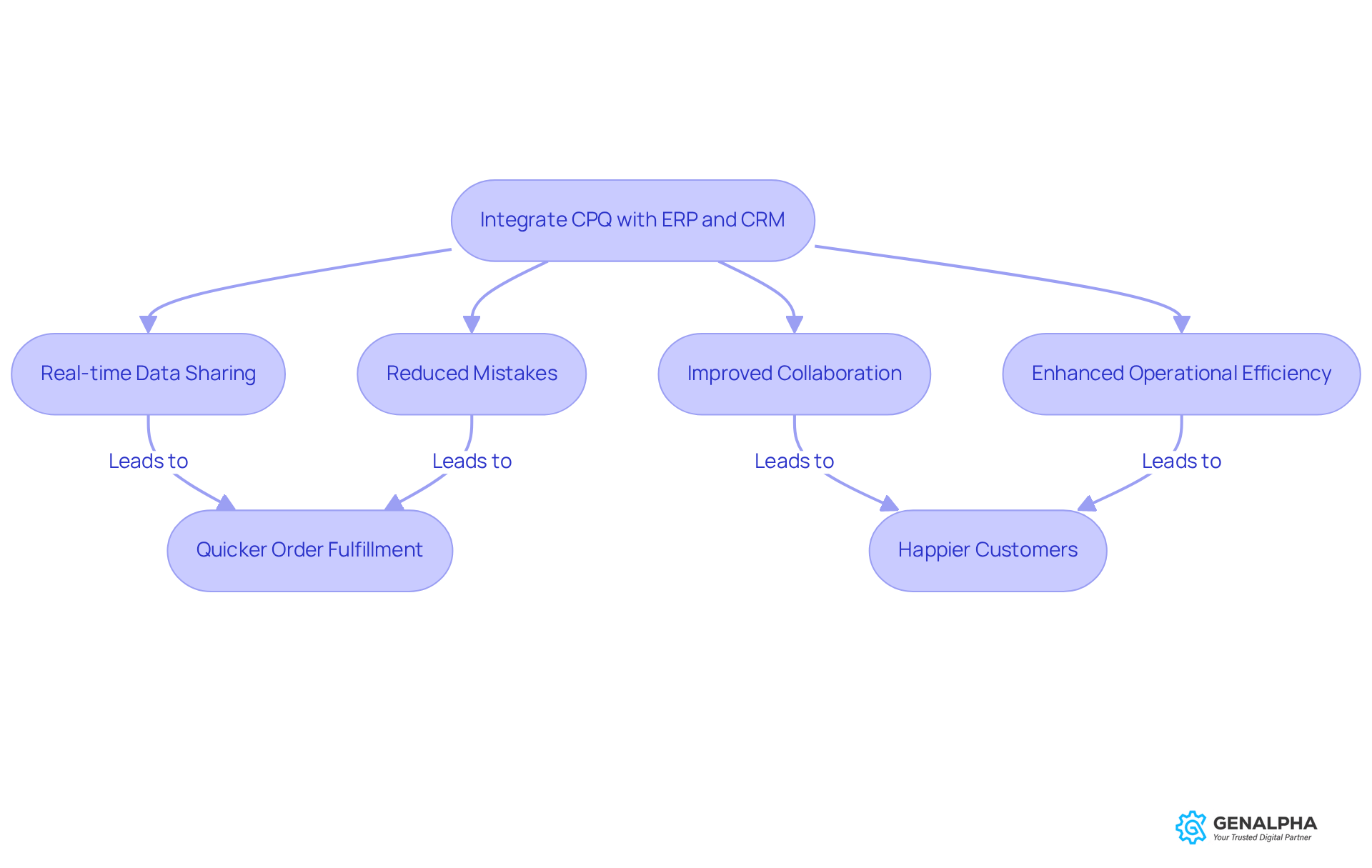

Excavation equipment manufacturers really should focus on integrating CPQ with ERP and CRM platforms. Why? Because this integration allows for real-time data sharing, ensuring that sales teams always have the latest inventory levels, pricing, and customer info at their fingertips. For example, when a sales agent whips up a quote using the CPQ platform, the integration can automatically update the ERP system with the new order details. This not only cuts down on mistakes but also helps avoid any delays.

But that’s not all! This teamwork between systems boosts collaboration across departments. Marketing, sales, and production teams can work together more smoothly, which is a win-win. Plus, automation can lighten the load for the technical department by a whopping 80-90%. Just think about the broader impact of bringing these technologies together on operational efficiency!

In the end, this all leads to quicker order fulfillment and happier customers. Companies have even reported cutting their sales cycle times by up to 60% thanks to the efficiencies gained from real-time data syncing. And let’s not forget about data security - it's super important to keep sensitive information safe during the integration process to maintain trust. So, are you ready to take the plunge into this integration journey?

Provide Training and Support for Effective CPQ Utilization

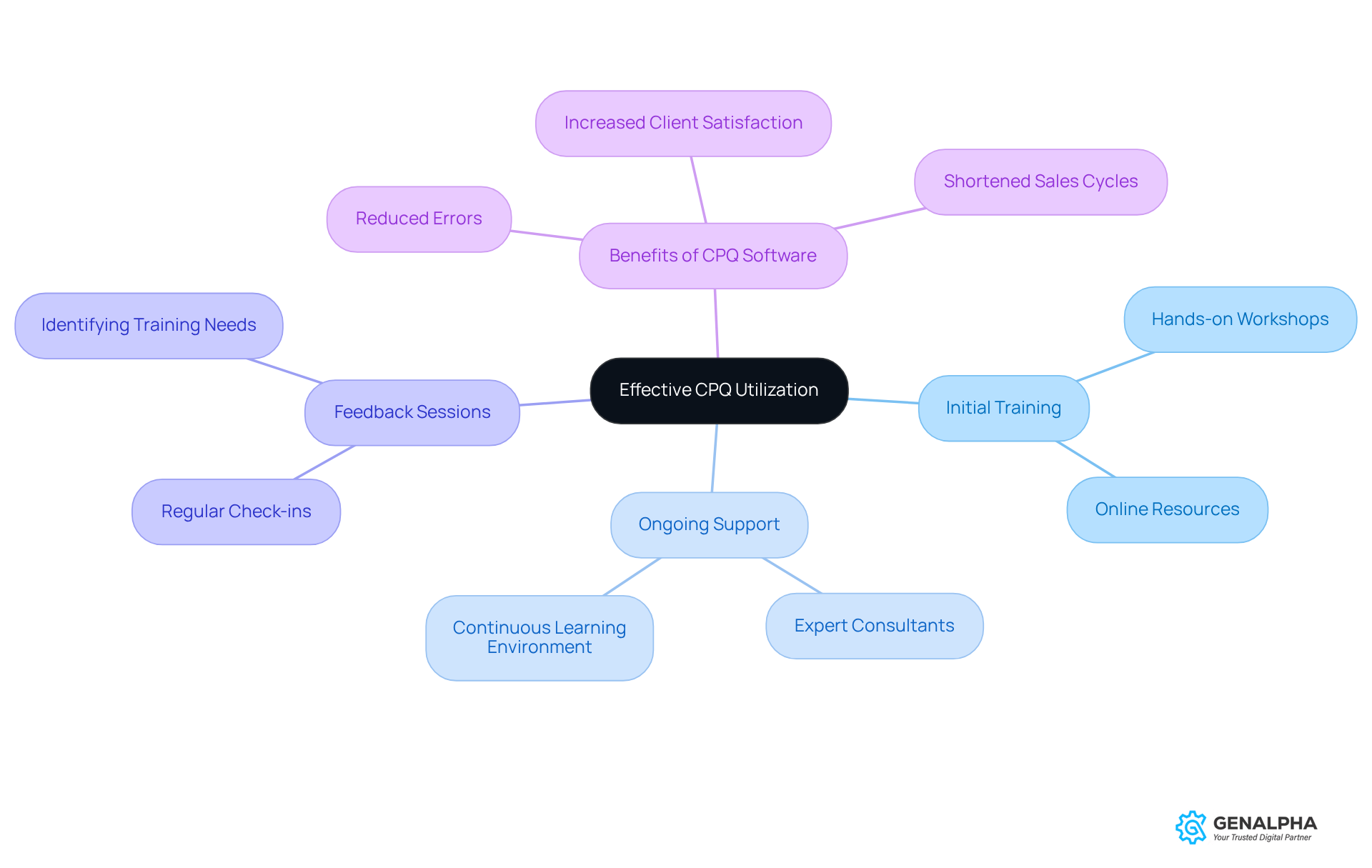

To really get the most out of a CPQ solution, excavation equipment manufacturers CPQ need to focus on solid training and support for their teams. Think about it: initial training sessions can help users grasp the features and functionalities, but ongoing support is just as crucial for tackling any bumps along the way. Establishing a dedicated training program that includes hands-on workshops, online resources, and access to expert consultants is key. Plus, creating an environment of continuous learning encourages users to dive into the advanced features of the CPQ system, which can lead to better revenue performance and happier clients.

Have you ever thought about how regular feedback sessions can pinpoint areas that need more training and support? This ensures that the team stays sharp and effective with the CPQ solution. And here’s a big win: CPQ software can cut down on errors in the quoting process, boosting client satisfaction and trust. Not to mention, sales teams can manage more leads and close deals faster with CPQ software, potentially shortening sales cycles by an impressive 28%!

As Kiana Mostajabian, Senior Director of Product Management, puts it, "As customer demand for personalized products grows, businesses, including excavation equipment manufacturers CPQ, are turning to configure, price, quote (CPQ) software to enhance their custom manufacturing capabilities." So, why not take that step towards better training and support? It could make all the difference!

Conclusion

Embracing CPQ solutions is a game-changer for excavation equipment manufacturers looking to streamline operations and boost customer satisfaction. Imagine automating the configuration, pricing, and quoting processes-this not only cuts down on errors but also speeds up the sales cycle. The result? Stronger client relationships and greater operational efficiency.

So, what does it take to achieve CPQ success? First off, choosing the right solution that fits seamlessly with your existing ERP and CRM systems is key. You’ll want something user-friendly, too, and don’t forget about scalability! Plus, ongoing training and support are vital. They help sales teams tap into the full potential of CPQ software, making it easier to meet the rising demand for customized products.

As the excavation equipment industry continues to evolve, adopting and fine-tuning CPQ strategies will not only enhance productivity but also prepare manufacturers to tackle changing market demands. Investing in these best practices is a smart move toward long-term success and keeping that competitive edge sharp. So, why wait? Let’s get started on this journey together!

Frequently Asked Questions

What is CPQ and how does it benefit excavation equipment manufacturers?

CPQ stands for Configure, Price, Quote. It benefits excavation equipment manufacturers by automating the configuration, pricing, and quoting processes, allowing for the creation of accurate, tailored quotes quickly.

How does CPQ improve the quoting process for manufacturers?

CPQ improves the quoting process by significantly reducing the time required to generate quotes, cutting it from weeks to just minutes, and minimizing errors associated with manual quoting.

What percentage reduction in errors and delays can be achieved with CPQ solutions?

CPQ solutions can lead to a 36% reduction in errors and delays in the quoting process.

What impact does CPQ have on client satisfaction and sales cycle times?

Companies using CPQ report a 35% increase in client satisfaction and a 25% reduction in sales cycle times.

Why is continuous evaluation and optimization of CPQ processes important?

Continuous evaluation and optimization of CPQ processes are important to maintain the benefits of efficiency and to adapt to changing customer expectations.