Introduction

Effective service and parts management is super important for organizations looking to boost their operational efficiency and keep customers happy. Imagine this: by focusing on what clients really need, optimizing stock, and integrating the latest tech, businesses can really streamline their processes and enhance service delivery. But here’s the big question: how can organizations not just meet but actually exceed customer expectations while juggling inventory?

In this article, we’ll dive into four essential practices that can transform service and parts management. These strategies can lead to sustained growth and loyalty, especially in today’s competitive landscape. So, let’s get started!

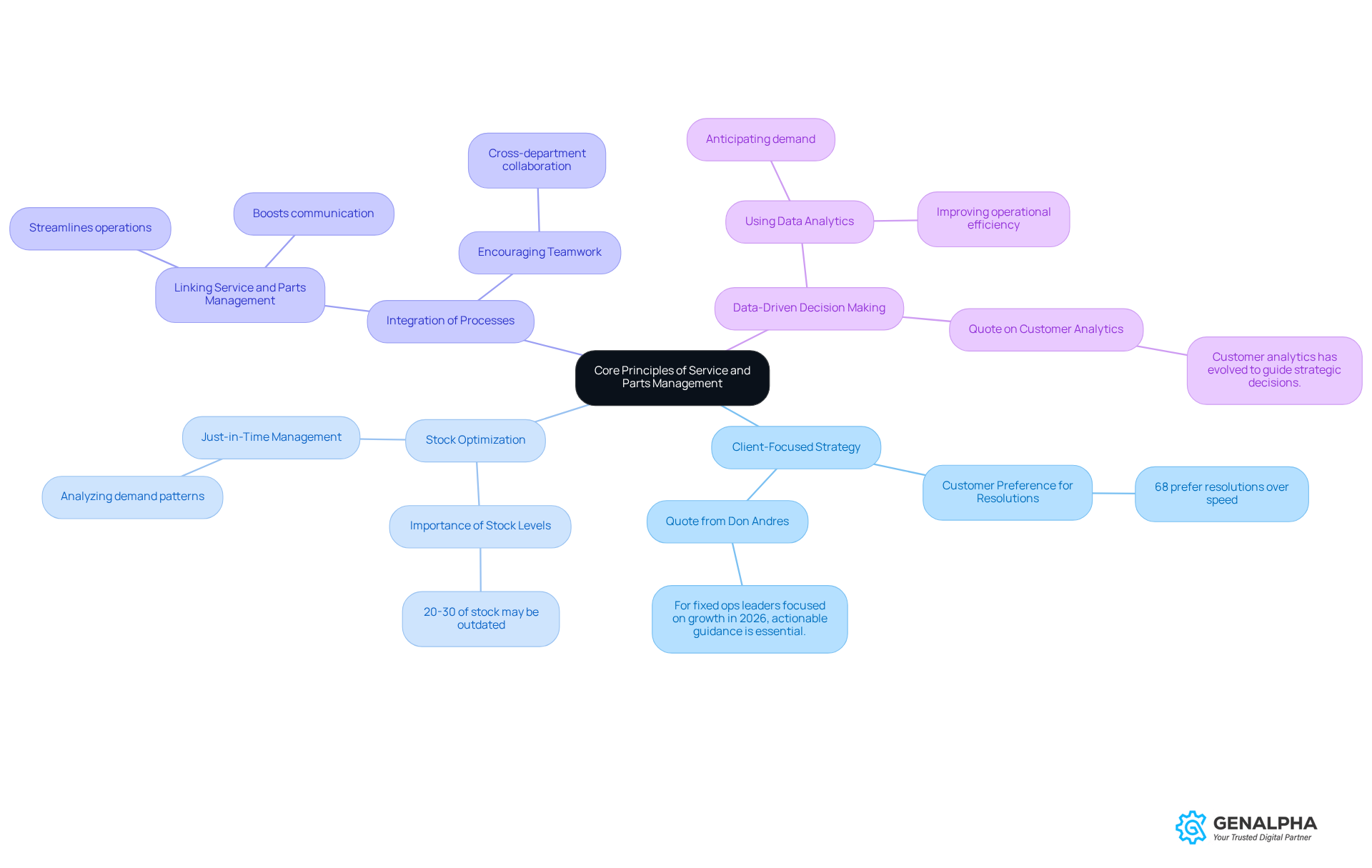

Understand Core Principles of Service and Parts Management

To effectively manage service and parts management, organizations need to grasp the core principles that drive these processes. Let’s break down some key principles:

-

Client-Focused Strategy: It’s all about putting client needs and expectations front and center. When you understand the client experience and the challenges they face, you can tailor your offerings to hit the mark. Did you know that 68% of customers prefer resolutions over speed? This really underscores the importance of a thoughtful approach to service interactions. As Don Andres puts it, "For fixed ops leaders focused on growth in 2026, Why Auto Service Departments Fail to Grow offers actionable guidance grounded in real-world experience."

-

Stock Optimization: Keeping stock levels just right is crucial for balancing availability and cost. This means analyzing demand patterns and using just-in-time stock management practices. Here’s a stat for you: outdated components can make up 20-30% of total stock in a typical dealership. That’s why effective stock oversight is key. Remember, "You’re not just managing inventory anymore."

-

Integration of Processes: It’s important to ensure that service and parts management processes are linked with other business functions, like sales and logistics. This not only streamlines operations but also boosts communication. A comprehensive approach encourages teamwork across departments, leading to better assistance delivery.

-

Data-Driven Decision Making: Using data analytics to guide decisions about inventory management, client preferences, and operational efficiency is vital. By anticipating demand and cutting down on excess stock, organizations can ramp up operational efficiency and client satisfaction. Those who make good use of customer information often see significant improvements in outcome quality and loyalty. As noted, "Customer analytics has evolved from descriptive reporting to predictive and prescriptive intelligence that guides strategic decisions."

By understanding and applying these principles, organizations can lay a solid foundation for effective service and parts management strategies. So, what do you think? Are you ready to put these ideas into action?

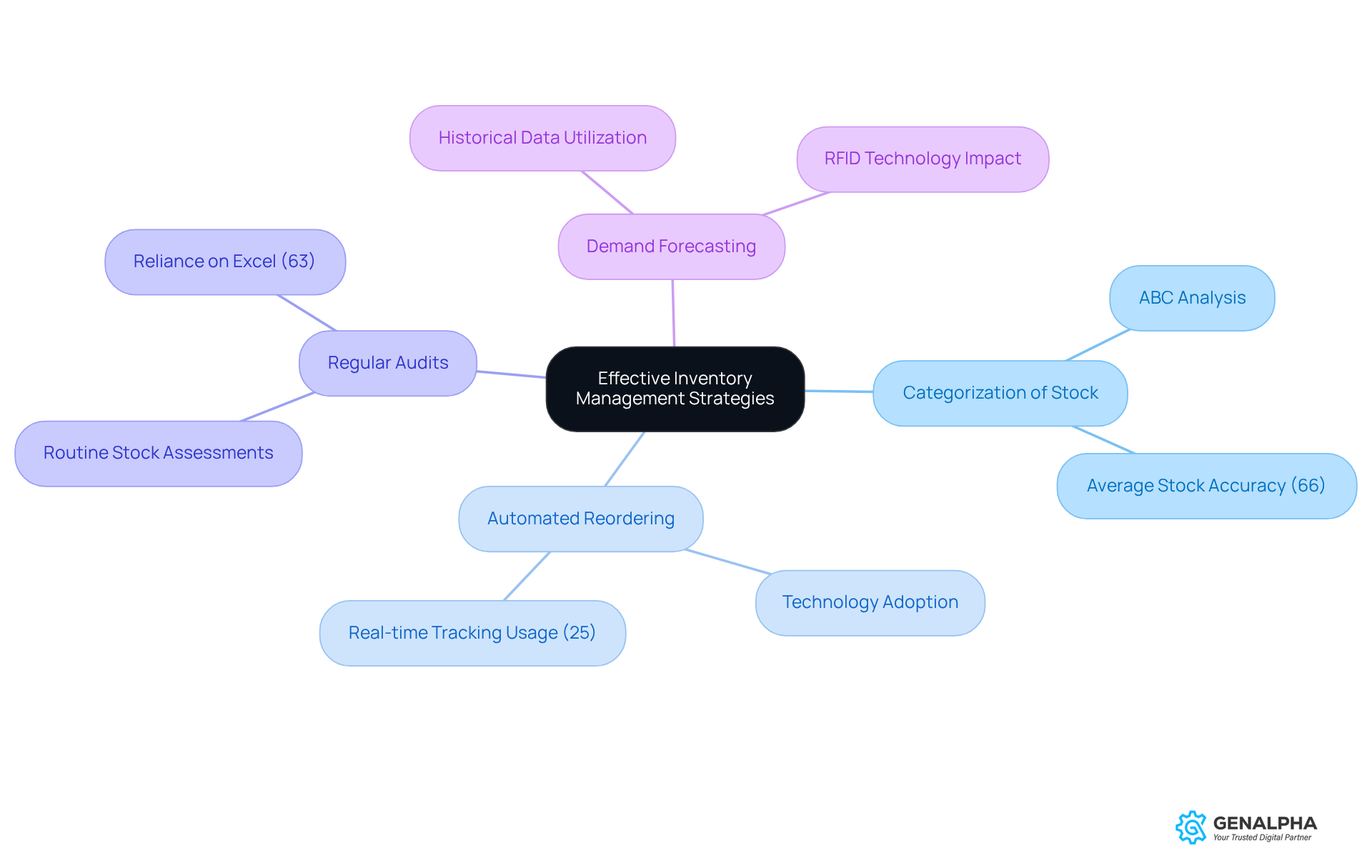

Implement Effective Inventory Management Strategies

Efficient stock control is super important for making sure you have the components you need when you need them, all while keeping those pesky surplus items at bay. So, how can you get this right? Here are some key strategies to consider:

-

Categorization of Stock: Think about classifying your stock based on how often items are used - this is often called ABC analysis. It’s a smart way to prioritize your management efforts and optimize stock levels. Did you know that the average stock accuracy in U.S. retail businesses is only 66%? That really shows how crucial effective categorization is for improving availability and cutting down on stockouts.

-

Automated Reordering: Why not let technology do some of the heavy lifting? Automating your reordering processes based on set thresholds can really help reduce the risk of running out of stock and ensure you’re replenishing items on time. As Oliver Munro points out, "Real-time visibility is commonly cited as an important solution, but only a quarter of supply chain and logistics leaders are using real-time tracking for their shipments." This highlights just how vital it is to adopt automated systems.

-

Regular Audits: It’s a good idea to conduct routine stock assessments to spot any discrepancies and adjust levels as needed. This practice helps keep your stock control precise and accountable. With 63% of supply chain managers still relying on Excel spreadsheets for stock oversight, regular audits can really help mitigate the risks that come with manual processes.

-

Demand Forecasting: Using historical data and analytics tools can help you forecast demand accurately. This way, you can proactively adjust stock levels, which means less surplus and lower costs. For instance, a case study on RFID technology adoption shows that integrating such tech can boost tracking accuracy and reduce errors, ultimately enhancing your demand forecasting capabilities.

By putting these strategies into action, you can really improve your stock handling procedures. This leads to better performance and lower operational expenses. So, what are you waiting for? Let’s get started!

Leverage Technology for Enhanced Service and Parts Management

Technology is a game-changer for enhancing service and parts management. So, how can we make the most of it? Let’s dive into some effective strategies:

-

Implement an Integrated Software Solution: Think about using comprehensive software platforms that bring together stock control, customer relationship management (CRM), and service coordination. This setup not only ensures a smooth flow of data but also sharpens decision-making. Did you know that companies embracing integrated software solutions can see up to a 30% boost in operational productivity? That’s pretty impressive!

-

Utilize IoT for Real-Time Monitoring: Have you heard about Internet of Things (IoT) devices? They’re fantastic for real-time tracking of stock levels and equipment status. This kind of visibility helps you manage proactively and cuts down on downtime. As stock expert Antoinette Turkie puts it, "IoT gives organizations the power to keep an eye on stock levels, avoid shortages, and react swiftly to market shifts."

-

Adopt Predictive Analytics: Imagine being able to predict demand and optimize your inventory levels! With predictive analytics, you can analyze past data and market trends to forecast future needs accurately. This means you’ll be ready to meet client demands head-on.

-

Enhance Client Interaction with Digital Tools: Why not improve client interactions with digital tools like chatbots and self-service portals? These tools can make the purchasing process smoother and boost client satisfaction. Linda Piercy highlights that effective parts oversight ensures maintenance teams have quick, reliable access to essential components, which helps prevent costly equipment downtime.

By embracing these technologies, organizations can significantly enhance their service and parts management processes, which leads to greater efficiency and client loyalty. But remember, it’s crucial to tackle challenges like data security and compatibility issues when integrating AI and IoT into supply chains. Only then can we fully reap the benefits of these amazing technologies!

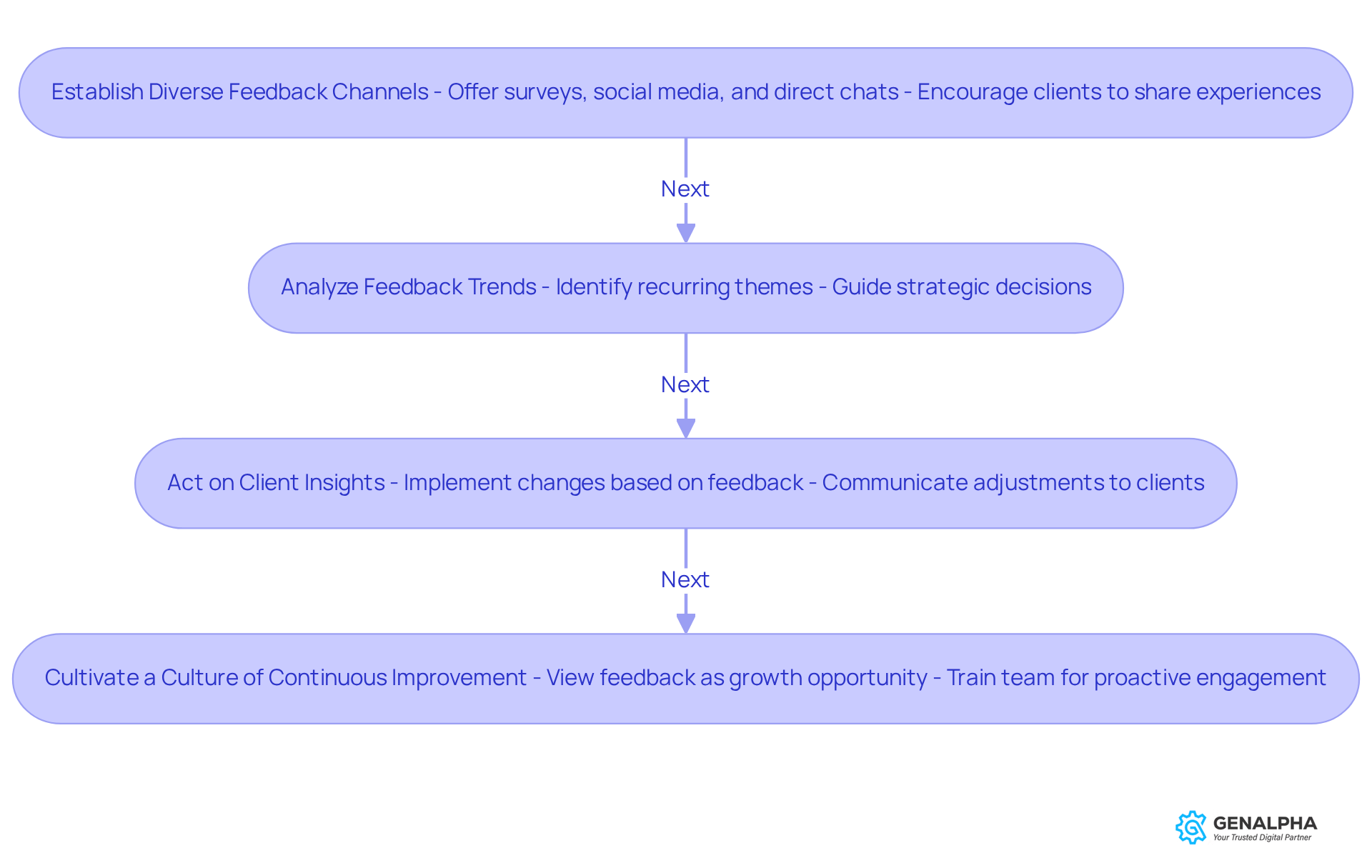

Incorporate Customer Feedback for Continuous Improvement

Customer feedback is a game changer for enhancing service and parts management. So, how can we make the most of it? Here are some effective strategies to consider:

-

Establish Diverse Feedback Channels: Let’s make it easy for people to share their thoughts! By offering various ways to provide feedback - like surveys, social media, and direct chats - we can encourage clients to share their experiences and suggestions. This not only boosts engagement but also helps us learn. Remember what Bill Gates said: "Your most dissatisfied clients are your greatest source of learning."

-

Analyze Feedback Trends: It’s crucial to regularly check in on client feedback. By looking for recurring themes, we can identify areas that need a little TLC. This data-driven approach can guide our strategic decisions and enhance our offerings. Did you know that 93% of clients are likely to return to companies that provide exceptional service? That’s a strong reason to pay attention to feedback!

-

Act on Client Insights: Show your clients that you value their input by taking real steps based on their feedback. Implement changes that reflect their suggestions and let them know about these adjustments. This shows that their opinions matter. After all, poor service can put a whopping $3.7 trillion in potential revenue at risk globally. We can’t afford to ignore client insights!

-

Cultivate a Culture of Continuous Improvement: Let’s create an environment where client feedback is seen as a stepping stone for growth. Train your team to view feedback as an opportunity for improvement rather than criticism. This mindset encourages proactive engagement with client insights.

By integrating customer feedback into our service and parts management processes, we can continuously enhance what we offer. This leads to happier customers and stronger loyalty. So, what steps will you take to integrate feedback today?

Conclusion

Effective service and parts management really comes down to understanding some core principles and putting best practices into action. When we prioritize what clients need, optimize our stock levels, and integrate processes across departments, we set ourselves up for success. Plus, by leveraging data analytics, we can create a solid framework that boosts service delivery and operational efficiency. A client-focused strategy, paired with the right technology, opens the door to sustained growth and happier customers.

Think about it: strategies like efficient inventory management, automated reordering, and listening to customer feedback are crucial for continuous improvement. These practices not only streamline operations but also foster a culture that values client insights. This leads to greater loyalty and lower operational costs. And let’s not forget about modern technologies like IoT and predictive analytics - they empower us to anticipate demand and respond quickly to market changes.

In today’s fast-paced world, we can’t underestimate the importance of effective service and parts management. It’s essential for organizations to embrace these best practices and stay adaptable to change. After all, meeting the ever-evolving expectations of our clients is key. By committing to these principles and strategies, we can position ourselves for success and build lasting relationships with our customers. So, are you ready to take the next step?

Frequently Asked Questions

What are the core principles of service and parts management?

The core principles include a client-focused strategy, stock optimization, integration of processes, and data-driven decision making.

How does a client-focused strategy benefit service management?

A client-focused strategy prioritizes client needs and expectations, allowing organizations to tailor their offerings effectively. Research shows that 68% of customers prefer resolutions over speed, highlighting the importance of thoughtful service interactions.

What is stock optimization and why is it important?

Stock optimization involves maintaining the right levels of inventory to balance availability and cost. Analyzing demand patterns and implementing just-in-time stock management can help prevent outdated components, which can represent 20-30% of total stock in a dealership.

Why is the integration of processes important in service and parts management?

Integrating service and parts management with other business functions, such as sales and logistics, streamlines operations and enhances communication, leading to improved teamwork and better service delivery.

How does data-driven decision making impact service and parts management?

Data-driven decision making utilizes analytics to inform inventory management, client preferences, and operational efficiency. This approach can help organizations anticipate demand, reduce excess stock, and improve client satisfaction and loyalty.

What benefits can organizations expect from applying these core principles?

By understanding and applying these principles, organizations can establish a solid foundation for effective service and parts management strategies, leading to enhanced operational efficiency and improved customer outcomes.