Introduction

In the fast-paced world of manufacturing, managing orders efficiently can really make or break a business. Think about it: an effective order management system (OMS) isn’t just a nice-to-have; it’s a game changer. These systems help streamline operations, boost customer satisfaction, and drive growth. But here’s the catch - implementing and integrating these solutions can be a bit tricky. So, what are some best practices that can help businesses navigate this complex landscape and truly harness the power of OMS? Let's dive in!

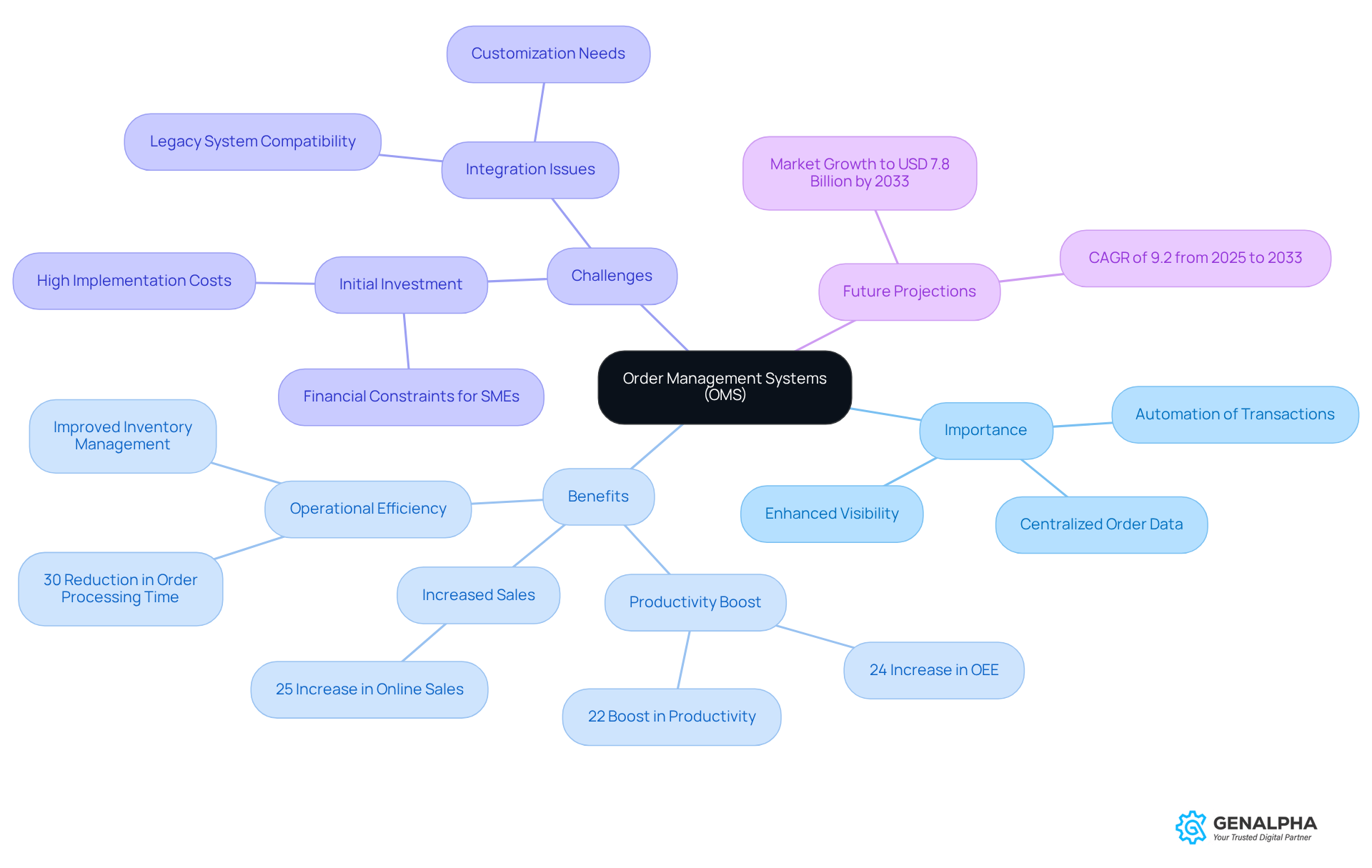

Define Order Management Systems and Their Importance in Manufacturing

An order management solution is a game-changer for businesses, automating and managing the entire lifecycle of transactions-from creation to fulfillment and delivery. Think about it: in the manufacturing world, an order management solution is crucial for tying together various processes, ensuring that requests are handled efficiently and accurately. It doesn’t just keep an eye on requests; it also manages inventory levels, aligns production schedules, and boosts communication across departments.

By centralizing order data with an order management solution, producers can really enhance visibility, cut down on errors, and ramp up overall operational efficiency. For example, a furniture producer in Southeast Asia saw a whopping 25% increase in online sales after implementing an OMS. That’s a clear win for customer satisfaction and loyalty! And it doesn’t stop there-another producer experienced a 24% jump in Overall Equipment Effectiveness (OEE) and a 22% boost in productivity. These numbers really show how effective an OMS can be in driving operational improvements.

As Aditi Nischal puts it, "The implementation of an OMS is not just the adoption of new technology-it is driving business growth." With the order management solution market projected to grow to USD 7.8 billion by 2033, it’s clear that these order management solutions are becoming essential for manufacturers looking to thrive in a competitive landscape.

But let’s not overlook the challenges. Integrating legacy systems can be tricky, and the initial investment can be steep, which might throw a wrench in successful implementation. So, what do you think? Is your business ready to embrace the benefits of an OMS?

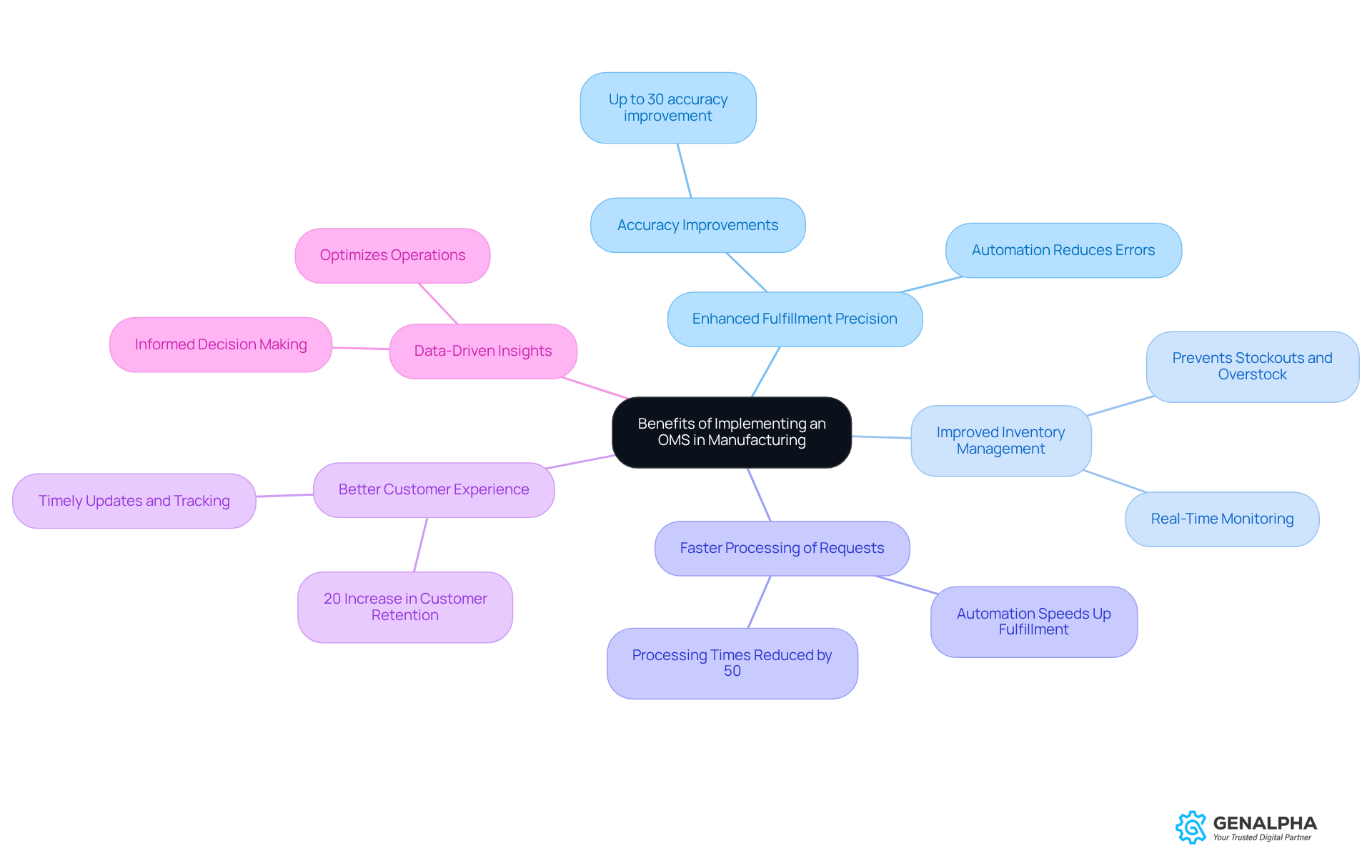

Identify Key Benefits of Implementing an OMS in Manufacturing

Implementing an order management solution in manufacturing comes with some pretty significant perks.

-

Enhanced Fulfillment Precision: Think about it-when you automate entry and processing, you cut down on human errors. This means requests get completed correctly, every time. Research shows that manufacturers using OMS have seen accuracy improvements of up to 30%. That’s a game changer for operational reliability! As Bill Gates wisely said, "The first rule of any technology used in a business is that automation applied to an efficient operation will magnify the efficiency."

-

Improved Inventory Management: Real-time inventory monitoring is a lifesaver. It helps producers keep optimal stock levels, reducing excess inventory and avoiding those dreaded stockouts. In today’s world, where customers expect lightning-fast delivery, this capability is crucial. With tools like AutoStore, you can track data in real-time, ensuring your inventory records are spot on and preventing both stockouts and overstock situations.

-

Faster Processing of Requests: Who doesn’t want speed? Automation speeds up the fulfillment process, allowing manufacturers to respond quickly to customer needs. Businesses that have embraced advanced order management solutions report that processing times have dropped by as much as 50%. That’s efficiency at its best! The AutoStore system, with its advanced automation and real-time data tracking, really boosts processing efficiency.

-

Better Customer Experience: Let’s face it-customers love precise tracking and timely updates. It makes for a seamless buying experience, which in turn boosts satisfaction and loyalty. Research indicates that businesses with an effective order management solution see a 20% increase in customer retention rates. That’s something to strive for!

-

Data-Driven Insights: An order management solution isn’t just about managing orders; it’s about making smart decisions. The analytics it provides can help producers make informed choices about production planning and inventory management. By leveraging these data insights, companies can optimize operations, leading to better profitability and efficiency. Real-time information enhances precision and decision-making in managing requests.

Looking ahead to 2025, we can expect advanced technologies like AI and IoT to further revolutionize order management. This will help producers stay competitive in a rapidly changing market.

Common Pitfalls: But hey, it’s not all smooth sailing. While implementing an OMS can bring huge benefits, manufacturers need to watch out for common pitfalls. Issues like inadequate training, lack of integration with existing systems, and not adapting processes to fully utilize the OMS can derail success. Tackling these challenges early on can pave the way for a successful implementation.

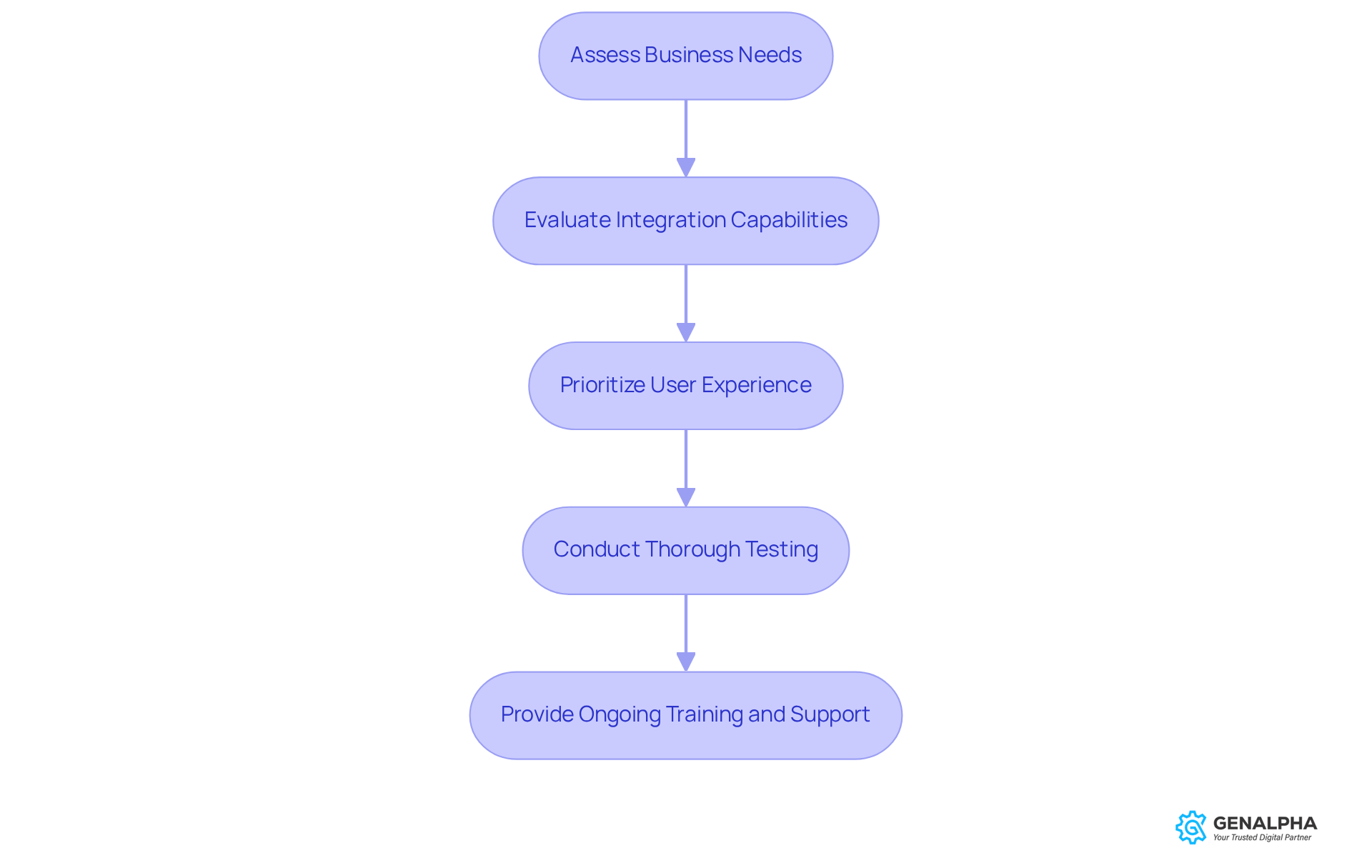

Outline Best Practices for Selecting and Implementing an OMS

When you're on the hunt for the right Order Management System (OMS), there are some best practices you definitely want to keep in mind:

-

Assess Business Needs: Start by pinpointing the specific challenges and requirements in your manufacturing processes. This way, you can ensure that the OMS aligns perfectly with your operational goals and tackles those pesky pain points.

-

Evaluate Integration Capabilities: Look for an OMS that can easily connect with your existing ERP platforms. This is super important - 67% of purchasing firms say that inventory and distribution functions are critical ERP capabilities. A well-integrated system not only enhances data flow but also boosts operational efficiency, which can lead to happier customers and a stronger competitive edge.

-

Prioritize User Experience: Opt for a platform that offers a user-friendly interface. An intuitive design cuts down on training time and helps staff adopt the system more readily. Did you know that the top three areas where ERP solutions often fall short are data accuracy, user experience, and analytics? That’s why focusing on user-friendly options is a must.

-

Conduct Thorough Testing: Before you go all in, make sure to run some pilot tests to catch any potential hiccups. This step is crucial - 51% of companies face operational disruptions during go-live phases. Common issues during ERP implementation, like not testing enough or skipping process reengineering, can lead to major operational headaches. So, thorough testing is key!

-

Provide Ongoing Training and Support: Don’t forget to give your staff comprehensive training and ensure support is available for any post-implementation challenges. Continuous education keeps the system running smoothly and boosts user confidence. Plus, 77% of companies say that strong leadership support is the most critical factor for successful ERP implementation. That just shows how important leadership is for a smooth OMS adoption.

By adhering to these best practices, manufacturers can implement an order management solution that not only addresses their current needs but also adapts to the challenges of the future.

Establish Continuous Improvement Strategies for OMS Effectiveness

To really make the most of your Order Management System (OMS), let’s chat about some continuous improvement strategies that can work wonders:

-

Regularly Review Performance Metrics: Keep an eye on those key performance indicators (KPIs) like request accuracy, processing time, and customer satisfaction. This isn’t just busywork; it helps you spot areas that need a little TLC and ensures your order management solution aligns with your business goals. As ABJ Cloud Solutions puts it, "Effective order management KPI are grounded in clear, objective, and measurable metrics."

-

Solicit Feedback from Users: Don’t shy away from gathering insights from your team and customers. What are their pain points? What could be better? This feedback loop is essential for understanding user experiences and making smart adjustments. Ruth Hadari reminds us that gathering input from staff and customers is essential to understand pain points and areas where the order management solution can be improved.

-

Stay Updated with Technology Trends: Technology moves fast, and so should you! Stay updated with the latest advancements in order management solution technology. Regularly check out potential upgrades or new features that could boost functionality and efficiency. This proactive approach acts as an order management solution that helps prevent your infrastructure from becoming outdated and ensures it meets your evolving business needs.

-

Foster a Culture of Continuous Improvement: Encourage your teams to regularly assess processes and suggest improvements. When you create an environment that values innovation and proactive problem-solving, you’re setting the stage for significant operational enhancements. Just look at the case study on "Chasing Perfection" - it shows how striving for excellence can cultivate a culture of high standards and continuous improvement.

-

Conduct Periodic Training: Ongoing training sessions for your staff are a must. Ensure they are fully utilizing the order management solution and are up to speed on any new features or updates. Investing in employee development can really amp up system effectiveness and user satisfaction. Remember, as ABJ Cloud Solutions notes, 'A satisfactory purchasing experience can solidify customer loyalty, while a poor one can lead to lost future sales and even immediate returns.'

-

Address Common Pitfalls: Be on the lookout for common pitfalls when rolling out these strategies. For instance, don’t forget to track specific KPIs like Order Fill Rate or On-time Shipping Rate - they’re crucial for gauging your OMS's efficiency. Spotting and dodging these pitfalls can streamline your order management solution and boost overall performance.

Conclusion

Order management solutions are a must-have for manufacturers looking to boost operational efficiency and keep customers happy. By automating the entire transaction lifecycle, these systems make processes smoother, improve accuracy, and enhance communication across departments. The benefits are clear: better inventory management, quicker processing times, and data-driven insights highlight just how powerful a solid order management system can be.

So, how do you choose and implement the right order management solution? Here are some key practices to consider:

- Start by assessing your business needs

- Ensure the system can integrate well with your existing tools

- Prioritize user experience

- Conduct thorough testing

- Don’t forget about ongoing training and support

Sticking to these best practices can help you dodge common pitfalls and truly harness the power of your OMS, driving growth and operational excellence.

As the manufacturing world keeps changing, embracing new technologies and fostering a culture of continuous improvement is essential. Staying updated on industry trends and encouraging feedback from users will help ensure your order management systems stay effective and aligned with your business goals. Remember, optimizing order management is an ongoing journey, and engaging with these strategies will set you up for lasting success in a competitive market.

Frequently Asked Questions

What is an order management system (OMS)?

An order management system (OMS) is a solution that automates and manages the entire lifecycle of transactions in a business, from creation to fulfillment and delivery.

Why are order management systems important in manufacturing?

OMS are crucial in manufacturing as they tie together various processes, ensuring efficient and accurate handling of requests, managing inventory levels, aligning production schedules, and boosting communication across departments.

How does an OMS enhance operational efficiency?

By centralizing order data, an OMS enhances visibility, reduces errors, and improves overall operational efficiency, leading to better business performance.

Can you provide examples of the benefits experienced by manufacturers using an OMS?

Yes, a furniture producer in Southeast Asia saw a 25% increase in online sales after implementing an OMS. Another producer experienced a 24% increase in Overall Equipment Effectiveness (OEE) and a 22% boost in productivity.

What does Aditi Nischal say about the implementation of an OMS?

Aditi Nischal states that "The implementation of an OMS is not just the adoption of new technology-it is driving business growth."

What is the projected growth of the order management solution market?

The order management solution market is projected to grow to USD 7.8 billion by 2033.

What challenges might businesses face when implementing an OMS?

Businesses may face challenges such as integrating legacy systems and the initial investment costs, which can complicate successful implementation.