Overview

In the world of digital manufacturing transformation, there are four best practices that can really set you up for success:

- Think about adopting integrated data platforms. Why? Because they streamline your operations and make everything run more smoothly.

- There’s the implementation of AI solutions. Imagine the possibilities when you leverage AI to enhance efficiency and decision-making!

- Cultivating a culture of agility and leadership. This means fostering an environment where your team feels empowered to adapt and lead. It’s all about being flexible and responsive in a fast-paced world.

- Building resilience into your manufacturing processes. This is crucial for weathering any storms that come your way.

Each of these practices is backed by compelling examples and statistics. For instance, many companies have seen significant reductions in operational costs and improvements in project delivery speed. These successes highlight just how important it is to strategically implement these practices while engaging your workforce.

So, what do you think? Are you ready to explore how these practices can transform your manufacturing processes? Let’s dive in together!

Introduction

Digital manufacturing transformation is shaking things up in the production world, bringing along some amazing opportunities for efficiency and innovation. Imagine this: by using integrated data platforms and AI solutions, manufacturers can really streamline their operations and make better decisions. Sounds great, right?

But here’s the catch—the journey to successful transformation isn’t always smooth sailing. There are challenges, like resistance to change and the tricky nature of integration. So, how do organizations tackle these hurdles? How can they build a resilient culture that not only embraces agility but also fosters strong leadership?

Let’s dive into this together and explore how we can navigate these challenges while making the most of the exciting opportunities that digital transformation offers.

Adopt Integrated Data Platforms for Seamless Operations

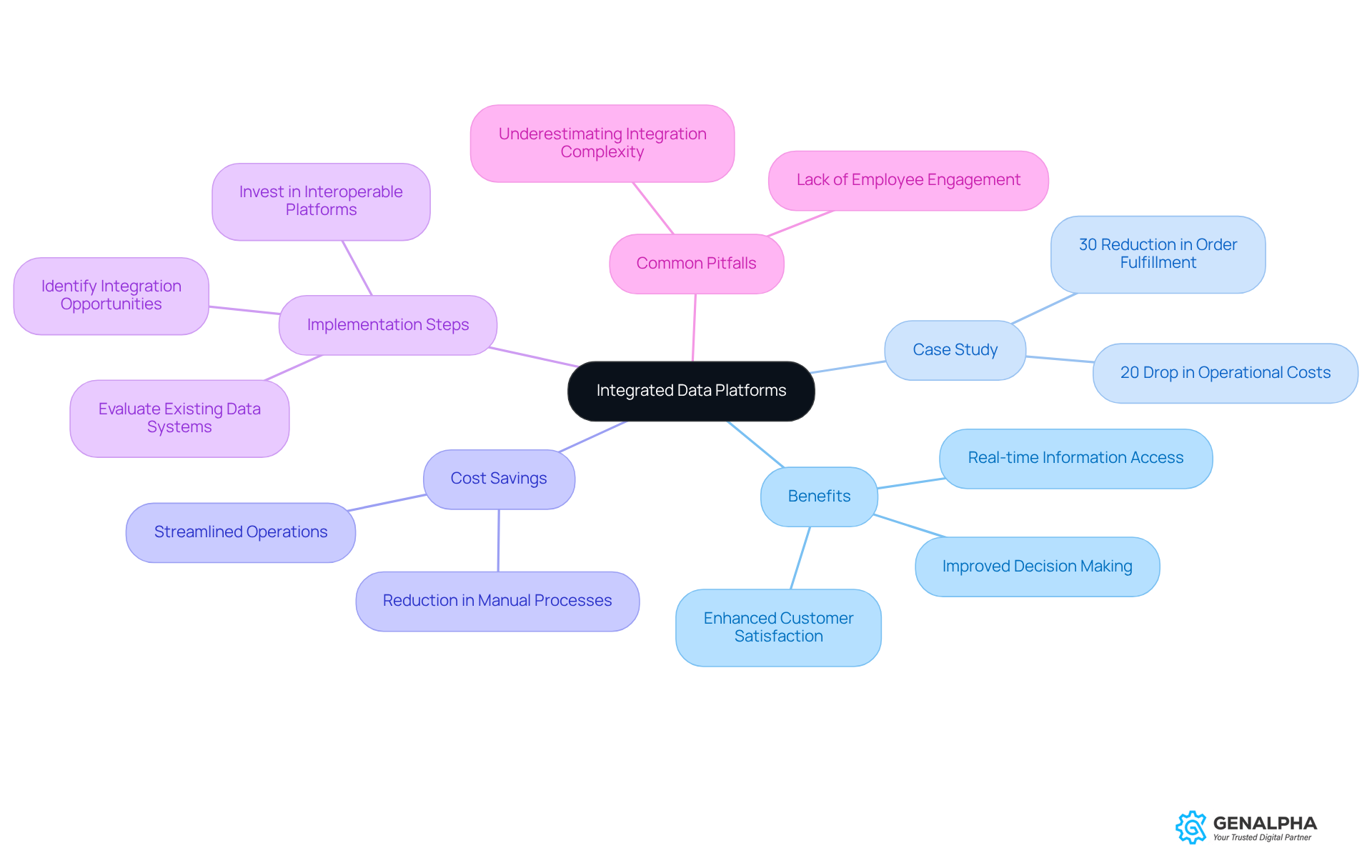

To keep things running smoothly, producers really need to embrace integrated information platforms in their digital manufacturing transformation. These platforms bring together details from all sorts of sources—think inventory, sales, and client interactions—all in one place. This integration supports digital manufacturing transformation by enabling teams to access real-time information, which helps them make quick, informed decisions.

For instance, when you connect ERP systems with eCommerce solutions, it can really streamline order processing and inventory management. A great example comes from a leading equipment producer who saw a 30% reduction in order fulfillment times after implementing an integrated data platform. That’s a huge win for customer satisfaction! Before this change, they struggled with delayed order processing and inaccurate inventory tracking, which really hurt their efficiency.

And it gets better! Companies that have embraced digital manufacturing transformation through end-to-end automation often report a 20% drop in operational costs. That’s some serious financial incentive to consider these platforms! So, how can organizations get on board? It starts with evaluating existing data systems, identifying integration opportunities, and investing in platforms that promote interoperability across departments to facilitate digital manufacturing transformation.

As Dominika Będkowska pointed out, "Digital transformation effectiveness depends on active workforce involvement and buy-in." This highlights the importance of a strategic approach to implementation. But let’s not forget, manufacturers need to be cautious about common pitfalls, like underestimating the complexity of integration and not engaging employees throughout the process.

So, what do you think? Are you ready to explore how integrated platforms can transform your operations?

Implement AI Solutions to Drive Efficiency and Innovation

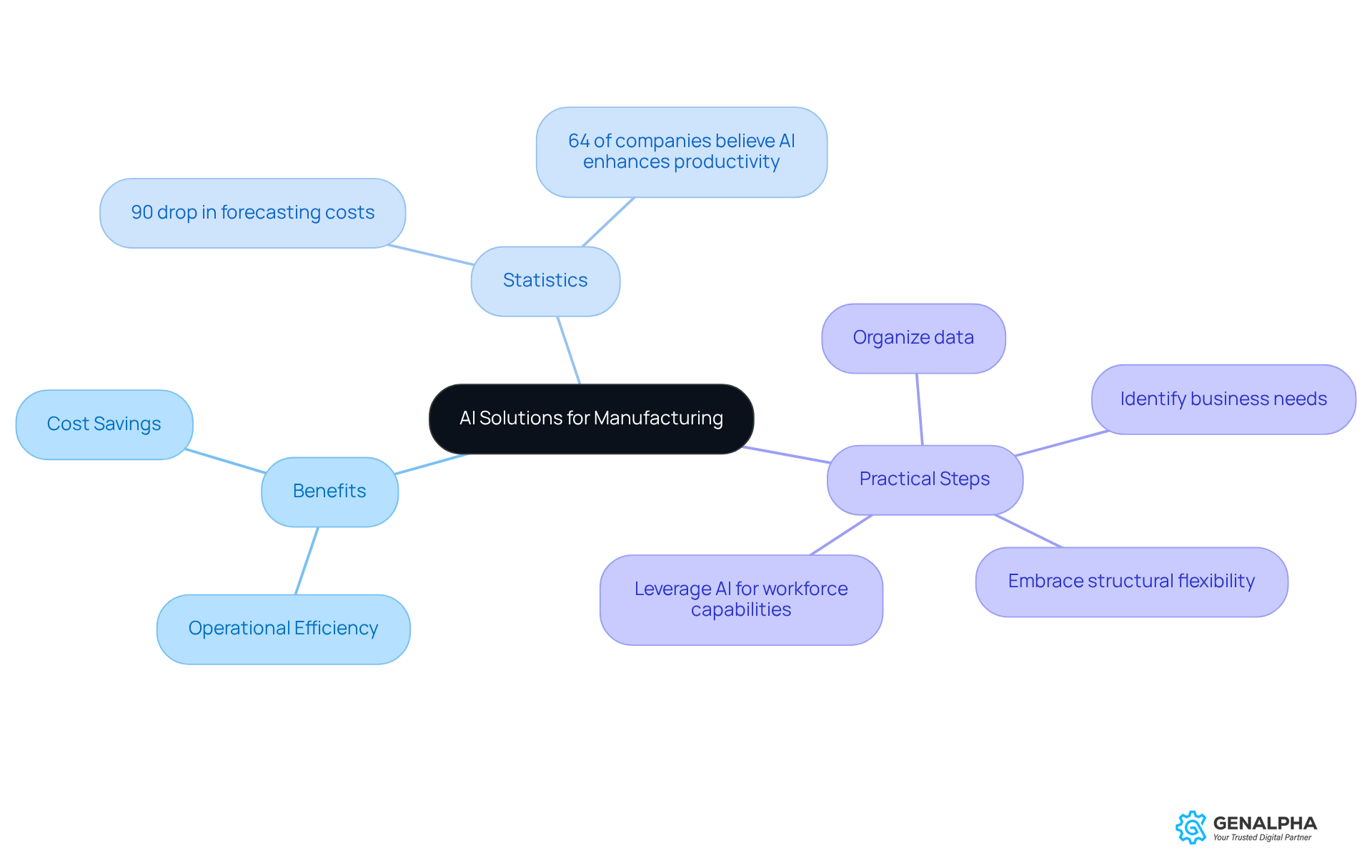

Implementing AI solutions can really boost operational efficiency and spark innovation in manufacturing processes. Have you ever thought about how technologies like machine learning and predictive analytics can take over routine tasks, optimize supply chains, and provide us with valuable insights into customer behavior? For example, one manufacturer that tapped into AI-driven analytics for demand forecasting saw a staggering 90% drop in forecasting costs and a 25% reduction in excess inventory. That’s not just impressive—it translates into significant cost savings and improved cash flow!

Additionally, did you know that 64% of companies believe AI will enhance productivity? This really highlights the potential impact of AI on operational efficiency. So, how can organizations successfully incorporate AI? It all starts with launching pilot projects that tackle specific challenges. By gathering information to refine algorithms, companies can gradually expand AI applications across their operations. This organized approach not only addresses immediate needs but also helps manufacturers harness AI’s full capabilities for long-term growth.

As noted by Deloitte, a whopping 93% of companies see AI as a key technology for driving growth and innovation in the sector. If you’re a manufacturer looking to embark on an AI transformation journey, here are four practical steps to consider:

- Identify your business needs

- Embrace structural flexibility

- Organize your data

- Leverage AI to enhance workforce capabilities

So, are you ready to dive into the world of AI and see how it can revolutionize your manufacturing processes?

Cultivate a Culture of Agility and Leadership for Transformation

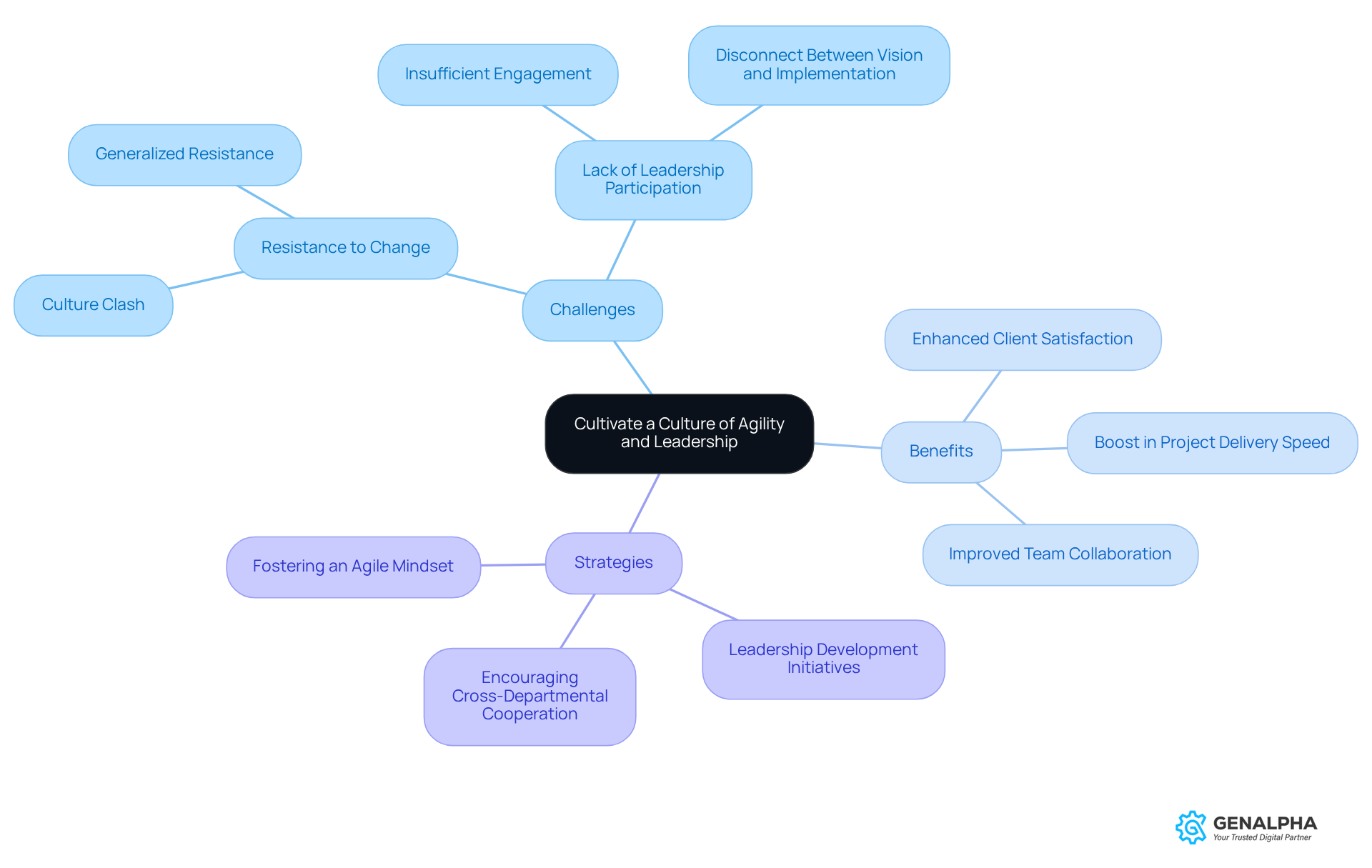

Cultivating a culture of agility alongside strong leadership is crucial for successful digital manufacturing transformation. Have you ever thought about how leaders can truly champion innovation, adaptability, and collaboration? They play a key role in helping teams respond effectively to market dynamics. For example, did you know that nearly half of Agile practitioners (47%) believe that resistance to change or a culture clash are the biggest hurdles to Agile adoption? This really highlights the need for strong leadership to tackle these challenges head-on.

Take a look at a manufacturing company that embraced agile methodologies during their digital manufacturing transformation—they saw an impressive 40% boost in project delivery speed! This allowed them to react faster to client demands, which is a game changer. To nurture this agile culture, organizations should prioritize leadership development initiatives. In fact, 41% of respondents point out that a lack of sufficient leadership participation is a consistent challenge for Agile adoption.

Additionally, encouraging cross-departmental cooperation can create an environment where staff feel empowered to try new things and share their ideas. This approach can significantly enhance operational efficiency, leading to improvements in client satisfaction and overall business performance. As Adam Schanfield, Principal Strategist at TXI, puts it, "To succeed in the AI-driven future, mid-market companies must think big by envisioning transformative possibilities while starting small through targeted, incremental pilots demonstrating quick wins."

So, what steps can your organization take to foster this culture of agility?

Build Resilience into Manufacturing Processes for Long-Term Success

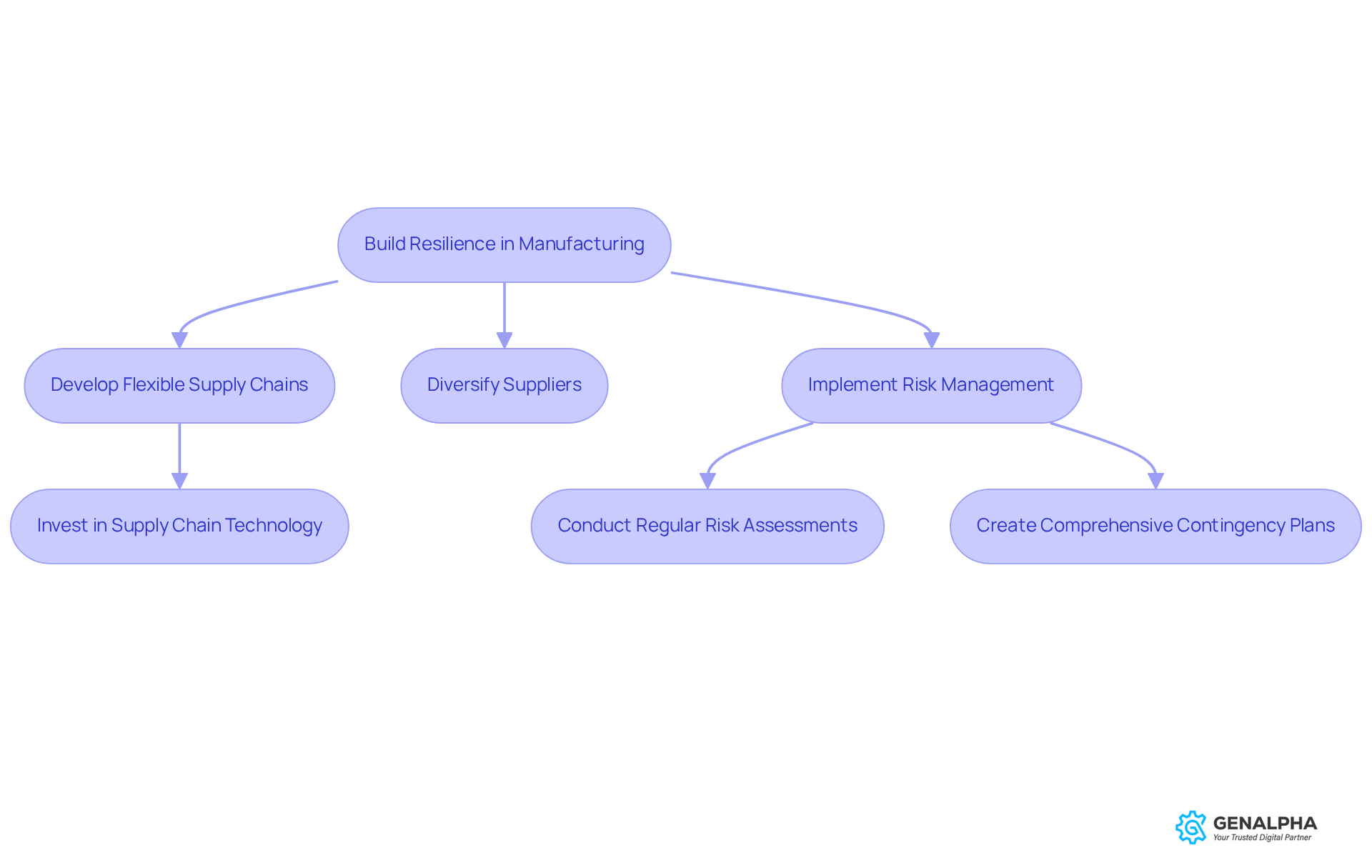

To ensure long-term success, producers really need to weave resilience into their processes. Think about it: developing flexible supply chains, diversifying suppliers, and putting robust risk management strategies in place are all key steps. For example, consider a producer that diversified its supplier base. When a global supply chain disruption hit, they were able to keep production levels steady and maintain their customer service standards.

But how do they do this? Regular risk assessments are a must! They help organizations spot vulnerabilities and adapt accordingly. Investing in technology that boosts supply chain visibility is crucial too. With it, you can track things in real time and make informed decisions.

And let’s not forget about creating comprehensive contingency plans. These plans prepare manufacturers for potential disruptions, ensuring they can respond quickly and keep things running smoothly. So, how prepared are you to handle the unexpected?

Conclusion

Embracing digital manufacturing transformation isn’t just a nice-to-have anymore; it’s a must for organizations looking to thrive in today’s fast-paced world. By integrating data platforms, implementing AI solutions, fostering a culture of agility, and building resilience, manufacturers can streamline operations, boost efficiency, and ultimately spark innovation.

Throughout this article, we’ve highlighted some key practices that can make a real difference. For instance:

- Integrated data platforms are crucial for real-time decision-making.

- AI has the power to transform processes.

- Strong leadership is essential for cultivating an agile work environment.

- Focusing on resilience means manufacturers can weather disruptions and keep things running smoothly.

As the manufacturing sector keeps evolving, it’s vital for organizations to take proactive steps to implement these best practices. The journey toward digital transformation isn’t just about adopting shiny new technologies; it’s about nurturing a mindset that embraces change and innovation. By prioritizing these strategies, manufacturers can set themselves up for long-term success and stay competitive in the face of future challenges. So, what steps will you take to start this journey?

Frequently Asked Questions

What are integrated data platforms, and why are they important for digital manufacturing transformation?

Integrated data platforms bring together information from various sources, such as inventory, sales, and client interactions, into one centralized location. They are important for digital manufacturing transformation because they enable teams to access real-time information, facilitating quick and informed decision-making.

How do integrated data platforms improve order processing and inventory management?

By connecting ERP systems with eCommerce solutions, integrated data platforms streamline order processing and inventory management, leading to improved efficiency. For example, a leading equipment producer experienced a 30% reduction in order fulfillment times after implementing such a platform.

What financial benefits can companies expect from adopting integrated data platforms?

Companies that embrace digital manufacturing transformation through end-to-end automation often report a 20% decrease in operational costs, providing a significant financial incentive to adopt integrated data platforms.

What steps should organizations take to implement integrated data platforms?

Organizations should start by evaluating their existing data systems, identifying opportunities for integration, and investing in platforms that promote interoperability across departments to support digital manufacturing transformation.

What role does employee involvement play in the effectiveness of digital transformation?

Employee involvement and buy-in are crucial for the effectiveness of digital transformation, as highlighted by Dominika Będkowska. A strategic approach to implementation that engages employees can lead to better outcomes.

What common pitfalls should manufacturers be cautious of when integrating data platforms?

Manufacturers should be careful not to underestimate the complexity of integration and should ensure that employees are engaged throughout the process to avoid potential issues.