Introduction

In the fast-paced world of B2B manufacturing, automation is really shaking things up. It’s not just a buzzword; it’s a game changer that’s transforming how companies operate and connect with their clients. Imagine being able to streamline processes, boost efficiency, and cut down on costs - all while keeping your customers happy. Sounds great, right?

But here’s the catch: as companies dive into these advanced technologies, they often hit some bumps along the way. What are the best practices that can help ensure a smooth transition to automation? And how can businesses use these strategies not just to get by, but to truly thrive in a competitive market? Let’s explore this together!

Understand the Role of B2B Automation in Manufacturing

Have you ever thought about how technology can make our work lives easier? In the world of B2B manufacturing, mechanization is doing just that! By implementing b2b automation to streamline business processes, companies are cutting down on manual tasks and making everything run smoother. Imagine using b2b automation to automate order processing, manage inventory, and even handle client communications - all without the usual hassle.

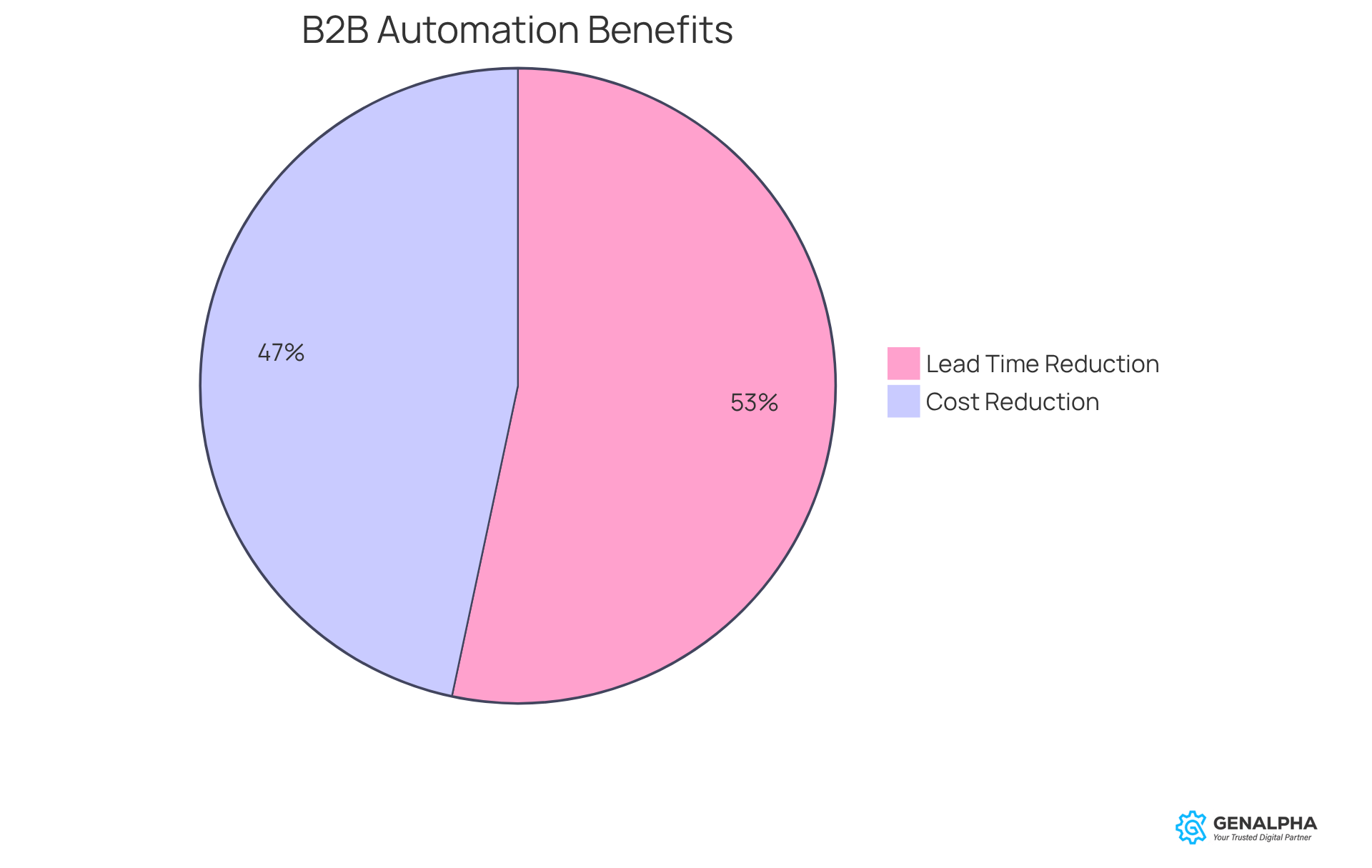

The benefits of b2b automation systems are quite impressive. For example, when companies streamline their order handling, they can cut lead times by up to 48%! That’s a huge win for customer satisfaction, right? Plus, with b2b automation allowing less time spent on routine tasks, teams can focus on what really matters - strategic initiatives that drive growth.

And it gets better! Firms that have jumped on the mechanization bandwagon are seeing operational cost reductions of up to 42%. That’s not just a number; it’s a game changer for service delivery. As more manufacturers embrace b2b automation, we can expect to see some serious efficiency improvements that could reshape the industry landscape.

So, what does this mean for the future? By 2025, mechanization is set to become a key player in gaining a competitive edge. Are you ready to explore how these advancements can benefit your business?

Integrate Automation with Existing ERP Systems

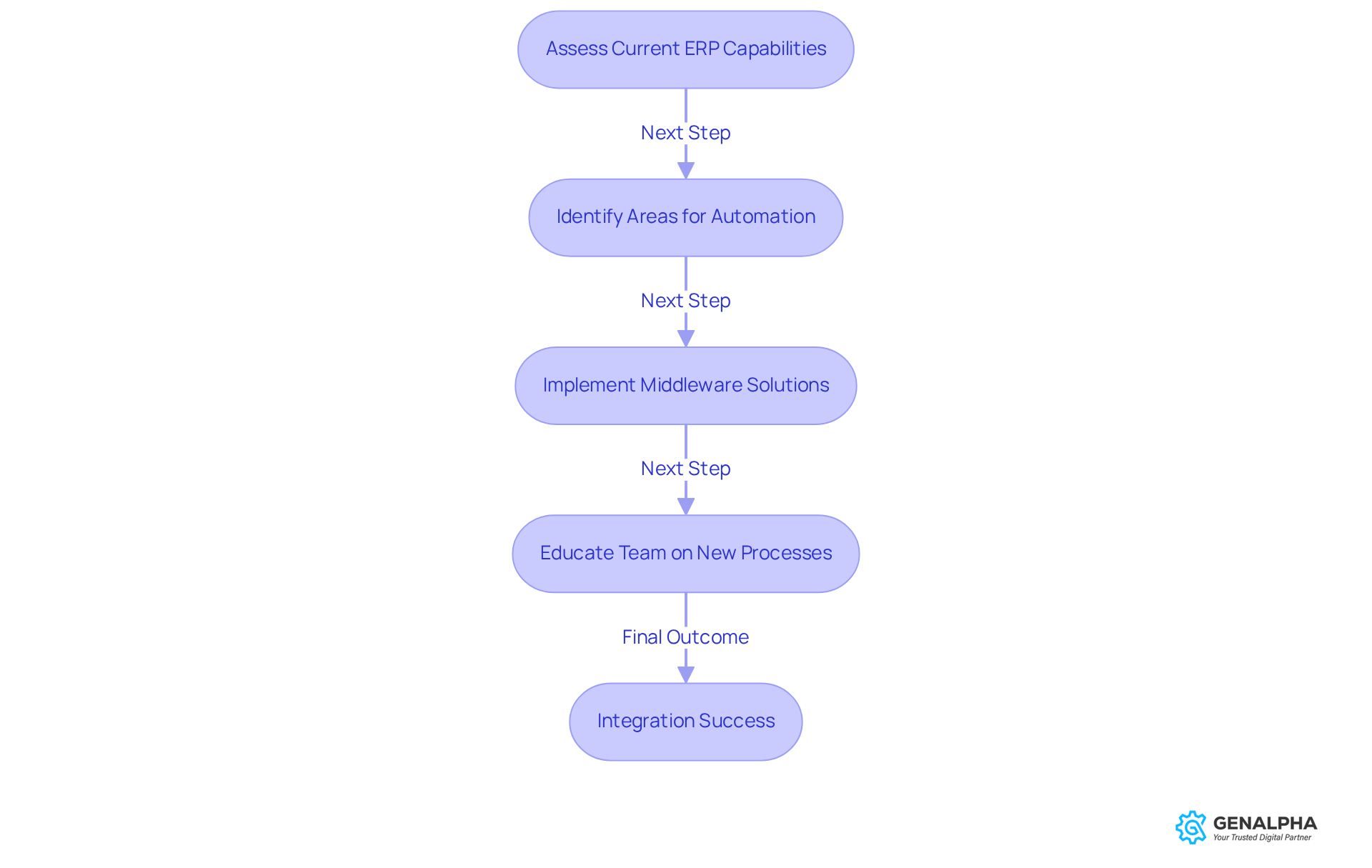

Integrating mechanization with your current ERP systems is super important if you want to get the most out of both technologies. Have you taken a good look at what your existing ERP can do? It’s worth pinpointing where mechanization can step in and make things even better. For instance, think about automating those tedious data entry tasks. Not only can this cut down on errors, but it also frees up your team to focus on more strategic stuff.

To make this integration a success, consider using middleware solutions. These handy tools help your ERP and control systems communicate smoothly. And let’s not forget about your team! Educating them on the new processes is key to ensuring everything transitions seamlessly.

Companies that have successfully integrated b2b automation with their ERP systems often see benefits like improved data visibility and quicker response times. This can lead to better customer service, which is something we all want, right? So, why not take the plunge and explore how mechanization can elevate your ERP experience?

Leverage Data Analytics for Operational Optimization

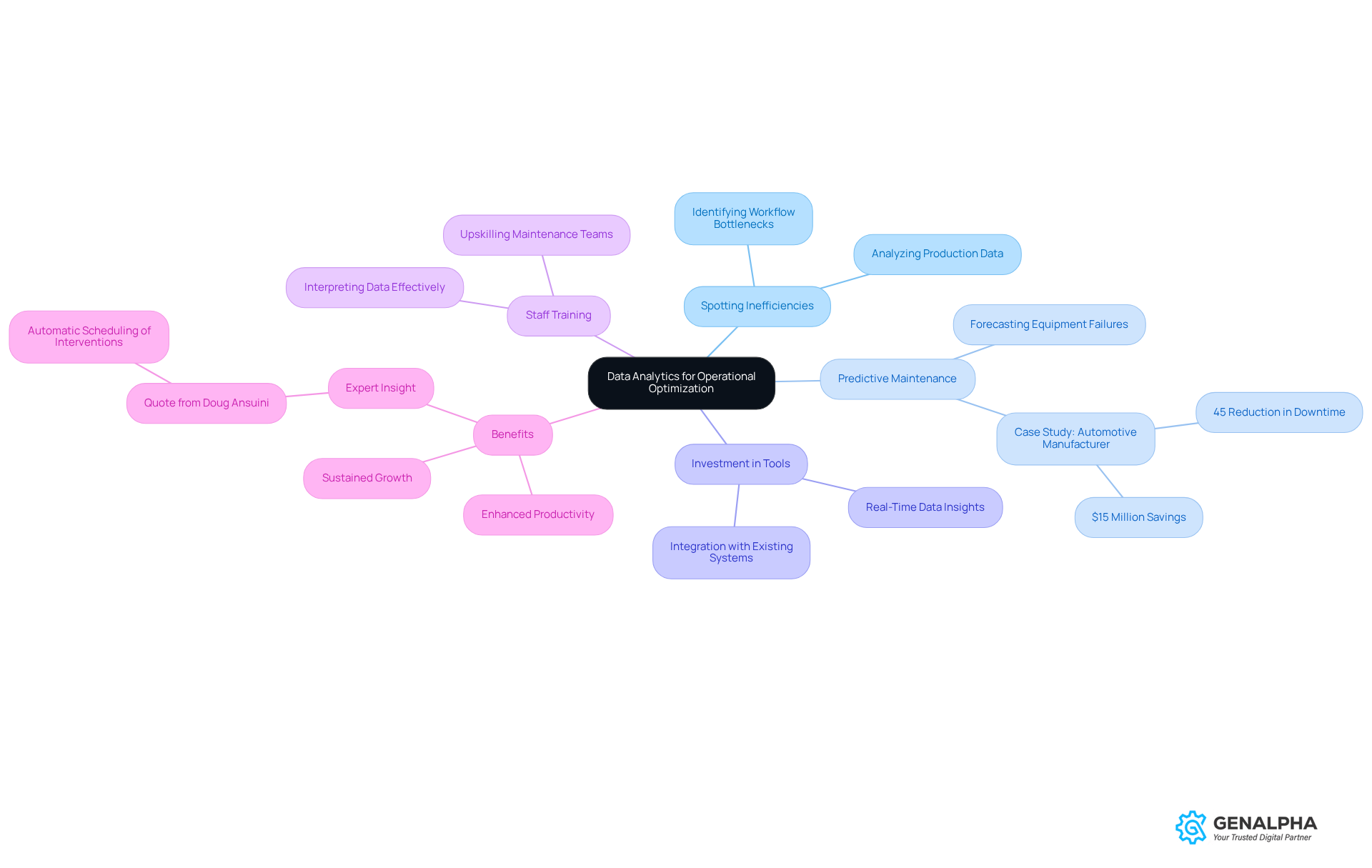

Data analytics is super important for optimizing manufacturing processes. It helps producers spot inefficiencies and boost productivity. Have you ever thought about how predictive analytics plays a key role here? By forecasting equipment failures, it allows for proactive maintenance strategies that can really cut down on downtime. For instance, a global automotive manufacturer managed to reduce downtime by 45%, saving a whopping $15 million! That’s a clear win for predictive maintenance.

Investing in analytics tools that easily connect with existing frameworks is essential for getting real-time insights into production processes. Plus, it’s crucial to equip staff with the skills to interpret data effectively. This way, they can make informed decisions. As Doug Ansuini, VP and Senior Software Architect, puts it, "One of the greatest advantages of maintenance predictive analytics lies in the automatic scheduling of interventions."

So, why should companies embrace data-driven strategies? Not only do they enhance productivity, but they also set themselves up for sustained growth in a competitive landscape. It’s clear that analytics can truly transform manufacturing. What steps can your company take to leverage this powerful tool?

Enhance Customer Engagement through Automation

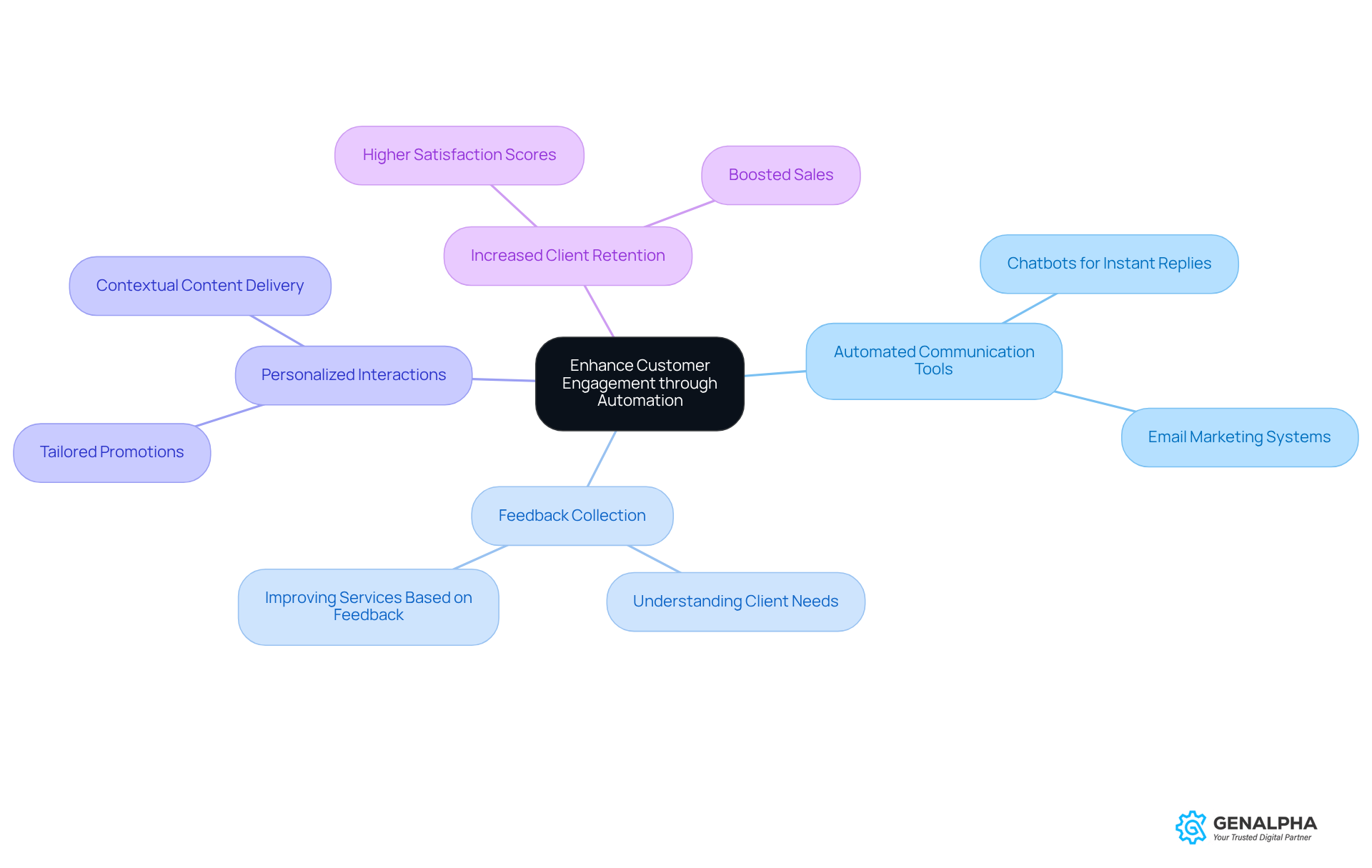

Have you ever thought about how b2b automation can really boost client engagement? It’s all about providing timely and personalized interactions that make your clients feel valued. Imagine using automated communication tools like chatbots and email marketing systems to handle client inquiries and follow-ups effortlessly. For example, a chatbot can give instant replies to common questions, which not only speeds up response times but also makes users happier.

Additionally, automating feedback collection can help you understand your clients’ needs and preferences better. Companies that have embraced b2b automation often see higher retention rates and increased sales. Isn’t that a win-win? These strategies can truly help you build strong relationships with your customers.

So, why not consider integrating some of these tools into your business? It could make a world of difference!

Conclusion

B2B automation is shaking things up in the manufacturing sector! It’s all about streamlining processes, boosting efficiency, and driving growth. When manufacturers embrace automation technologies, they can cut down on manual tasks, shorten lead times, and lower operational costs. This not only helps them stand out in a competitive landscape but also sets the stage for success.

So, what’s the scoop? Successful B2B automation isn’t just about integrating advanced technologies; it’s also about harnessing data analytics for operational optimization. For example, predictive analytics can help minimize downtime and encourage proactive maintenance. Plus, automated customer engagement tools can strengthen relationships and enhance client satisfaction. Each of these strategies contributes to a comprehensive approach that positions manufacturers for long-term success.

As the manufacturing industry evolves, embracing B2B automation has become essential. Companies should actively look to weave these technologies into their operations, invest in data analytics capabilities, and focus on customer engagement strategies. By doing this, manufacturers can boost their operational efficiency and stay competitive in a rapidly changing market. The future of manufacturing is all about automation - are you ready to take the leap?

Frequently Asked Questions

What is B2B automation in manufacturing?

B2B automation in manufacturing refers to the use of technology to streamline business processes, reducing manual tasks and improving overall efficiency.

How does B2B automation benefit companies?

B2B automation helps companies cut down on manual tasks, streamline order processing, manage inventory, and handle client communications, leading to smoother operations.

What impact can B2B automation have on order handling times?

Companies that implement B2B automation can reduce lead times by up to 48%, significantly enhancing customer satisfaction.

How does B2B automation affect team focus and strategic initiatives?

With less time spent on routine tasks due to B2B automation, teams can concentrate on strategic initiatives that drive growth.

What are the potential cost savings from implementing B2B automation?

Firms that adopt B2B automation can see operational cost reductions of up to 42%, improving service delivery.

What is the expected future impact of mechanization in manufacturing?

By 2025, mechanization is anticipated to play a crucial role in helping companies gain a competitive edge in the manufacturing industry.

Why should manufacturers consider adopting B2B automation?

Manufacturers should consider B2B automation to improve efficiency, reduce costs, and enhance customer satisfaction, which can reshape the industry landscape.