Introduction

The manufacturing landscape is changing faster than ever, and equipment manufacturers are facing some pretty unique challenges when it comes to efficiency and teamwork. Have you ever thought about how Product Lifecycle Management (PLM) system software could be your secret weapon? It’s not just about streamlining operations; it’s also about boosting team dynamics and speeding up your time-to-market.

But here’s the big question: how can companies like yours really tap into the power of PLM systems? What steps can you take to transform your processes and gain that competitive edge in a market that’s only getting tougher? Let’s dive in and explore how you can make the most of these tools!

GenAlpha Technologies: Streamline Operations with Tailored PLM Solutions

At GenAlpha Technologies, we get it - every equipment producer has unique needs. That’s why we focus on providing tailored PLM system software solutions that fit perfectly. Imagine integrating the PLM system software right into your existing workflows. Sounds great, right? This approach helps streamline operations, cut down on redundancies, and boost data accuracy.

But it’s not just about efficiency; it’s about you. Our customized method enhances productivity while aligning perfectly with your operational needs. This means you can adapt quickly to market changes and customer demands. For example, take a look at our Equip360 platform. It allows manufacturers to manage item data seamlessly, which leads to better decision-making and operational agility.

So, why not explore how GenAlpha can help you navigate the complexities of your industry? Let’s chat about how we can support your journey!

Enhanced Team Collaboration for Quality Control and Efficiency

Have you ever wondered how teams can work together more smoothly? PLM system software is a game changer in that regard! They create a centralized hub for sharing information and managing workflows, which means teams - from design to engineering to production - can collaborate like never before. This integration helps cut down on errors and miscommunication.

For example, when a design change happens, everyone involved gets real-time notifications. This keeps all departments aligned and ensures they stick to quality control measures. As Kerri Doyle puts it, "PLM can assist your business by linking individuals and processes, and offering a..."

This collaborative environment not only boosts operational performance but also enhances quality, leading to happier customers. Companies that use PLM system software have seen a 20% drop in time-to-market and a 30% higher chance of rolling out innovative products. That really shows how crucial PLM is for improving quality control in equipment manufacturing!

A case study on the efficiency gains from implementing PLM system software found that organizations enjoy a 20% boost in collaboration efficiency. Isn’t that impressive? It really highlights the benefits of these systems!

Accelerated Time-to-Market for Competitive Advantage

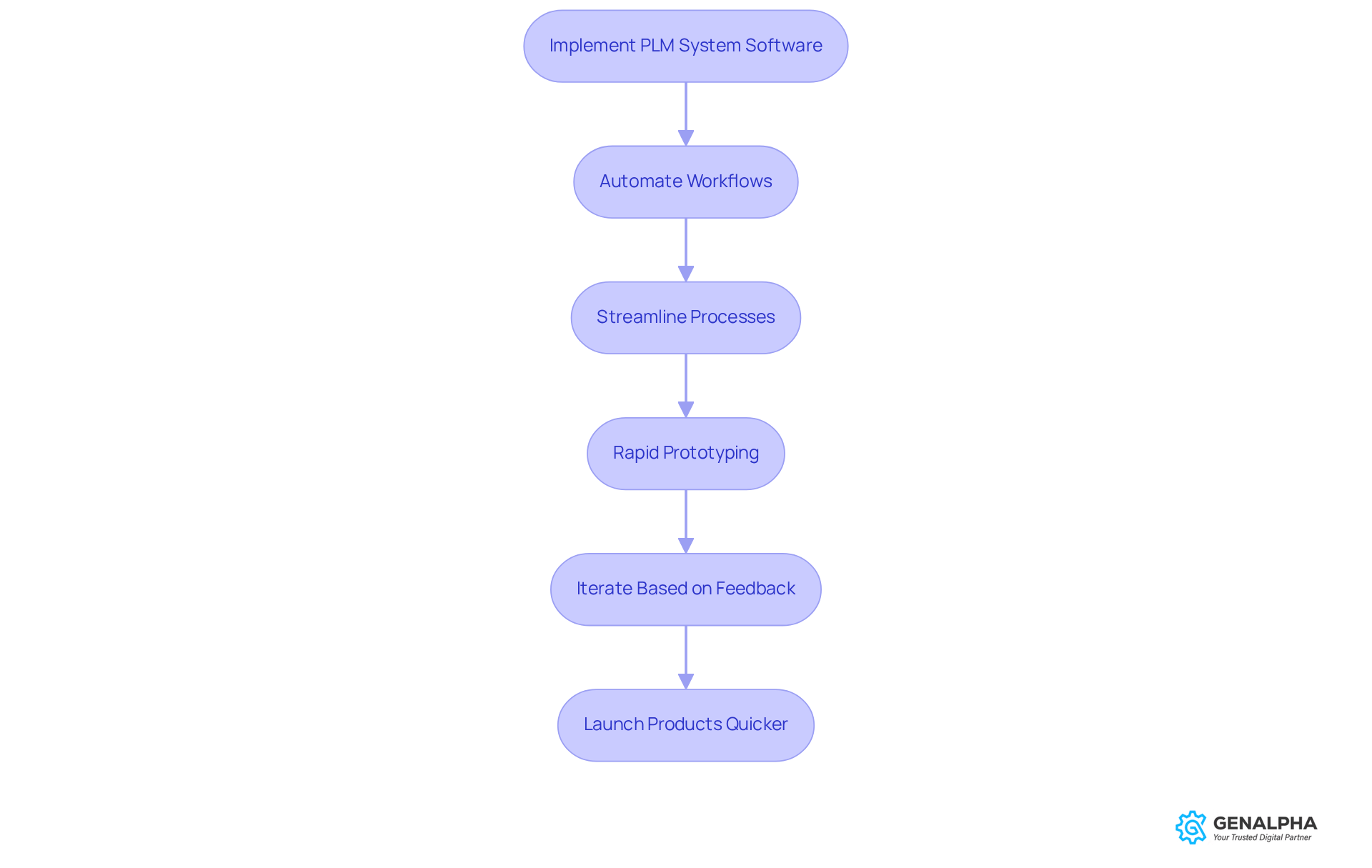

Have you ever wondered how some companies seem to launch new products at lightning speed? Well, implementing solid PLM system software can really make that happen! By automating workflows and streamlining processes, businesses can cut down on the time spent in development and approvals.

For example, consider how PLM system software can aid in rapid prototyping and testing. Teams can quickly iterate based on feedback, which means they can adapt and improve their products faster than ever. This kind of speed not only helps manufacturers meet market demands more effectively but also gives them a leg up on competitors who might be a bit slower to catch on.

So, what does this mean for companies utilizing PLM system software? They can launch products quicker, seize emerging trends, and ultimately boost their revenue growth. Isn’t that something worth considering? If you’re looking to stay ahead in the game, maybe it’s time to explore how PLM system software could work for you!

Conclusion

Implementing a Product Lifecycle Management (PLM) system is a game-changer for equipment manufacturers looking to boost efficiency, collaboration, and speed to market. Imagine streamlining your operations with tailored PLM solutions that integrate workflows and maximize data accuracy. This isn’t just about productivity; it’s about being able to adapt quickly to what the market demands.

So, what are the key benefits? Well, PLM software really shines when it comes to enhancing team collaboration. Think about it: with real-time notifications and a centralized hub for sharing information, teams can work seamlessly across departments. This means fewer errors and faster product development. Plus, the ability to prototype and iterate quickly puts manufacturers in a prime position to seize market trends and stay ahead of the competition.

But here’s the kicker: embracing PLM system software isn’t just about keeping up with industry changes; it’s about transforming how you operate. By leveraging these systems, you can improve your internal processes, boost customer satisfaction, and drive revenue growth. So, why wait? Now’s the time to explore how PLM solutions can revolutionize your manufacturing processes and set your company apart in a competitive landscape. What’s stopping you from taking that leap?

Frequently Asked Questions

What does GenAlpha Technologies offer?

GenAlpha Technologies offers tailored Product Lifecycle Management (PLM) system software solutions designed to fit the unique needs of equipment producers.

How does GenAlpha's PLM system software benefit operations?

The PLM system software helps streamline operations, reduce redundancies, and improve data accuracy, ultimately enhancing productivity and aligning with operational needs.

What is the Equip360 platform?

Equip360 is a platform offered by GenAlpha that allows manufacturers to manage item data seamlessly, leading to improved decision-making and operational agility.

How does GenAlpha's approach help companies adapt to market changes?

By providing customized PLM solutions that integrate into existing workflows, GenAlpha enables companies to adapt quickly to market changes and customer demands.

Why is a tailored PLM solution important for equipment producers?

A tailored PLM solution is important because it addresses the specific operational needs of equipment producers, enhancing efficiency and productivity in their unique workflows.