Overview

Have you ever wondered how equipment manufacturers can streamline their sales processes? The article "10 Key Insights on the CPQ Process for Equipment Manufacturers" dives into the essential elements of the Configure, Price, Quote (CPQ) process tailored specifically for these manufacturers. It reveals how innovative digital solutions, like GenAlpha Technologies' Equip360, can enhance efficiency and accuracy, ultimately boosting customer satisfaction.

Imagine transforming your sales operations to respond swiftly to market demands. That’s exactly what the CPQ process enables. By adopting these advanced tools, manufacturers can not only simplify their workflows but also create a more satisfying experience for their customers.

So, why not explore how these insights can apply to your business? Embracing the CPQ process could be the key to elevating your operations and meeting the ever-changing needs of the market.

Introduction

The manufacturing sector is really going through a transformative shift right now, and it’s all about finding that sweet spot between efficiency and accuracy in sales. At the heart of this evolution is the Configure, Price, Quote (CPQ) process. This nifty tool promises to streamline operations and boost customer satisfaction.

But here’s the thing: as equipment manufacturers navigate the tricky waters of pricing and quoting, getting a handle on the nuances of CPQ can unlock some serious competitive advantages. So, what challenges are manufacturers facing when it comes to implementing these solutions? And how can they harness technology to optimize their processes for better outcomes?

Let’s dive in and explore these questions together!

GenAlpha Technologies: Transforming the CPQ Process for Manufacturers

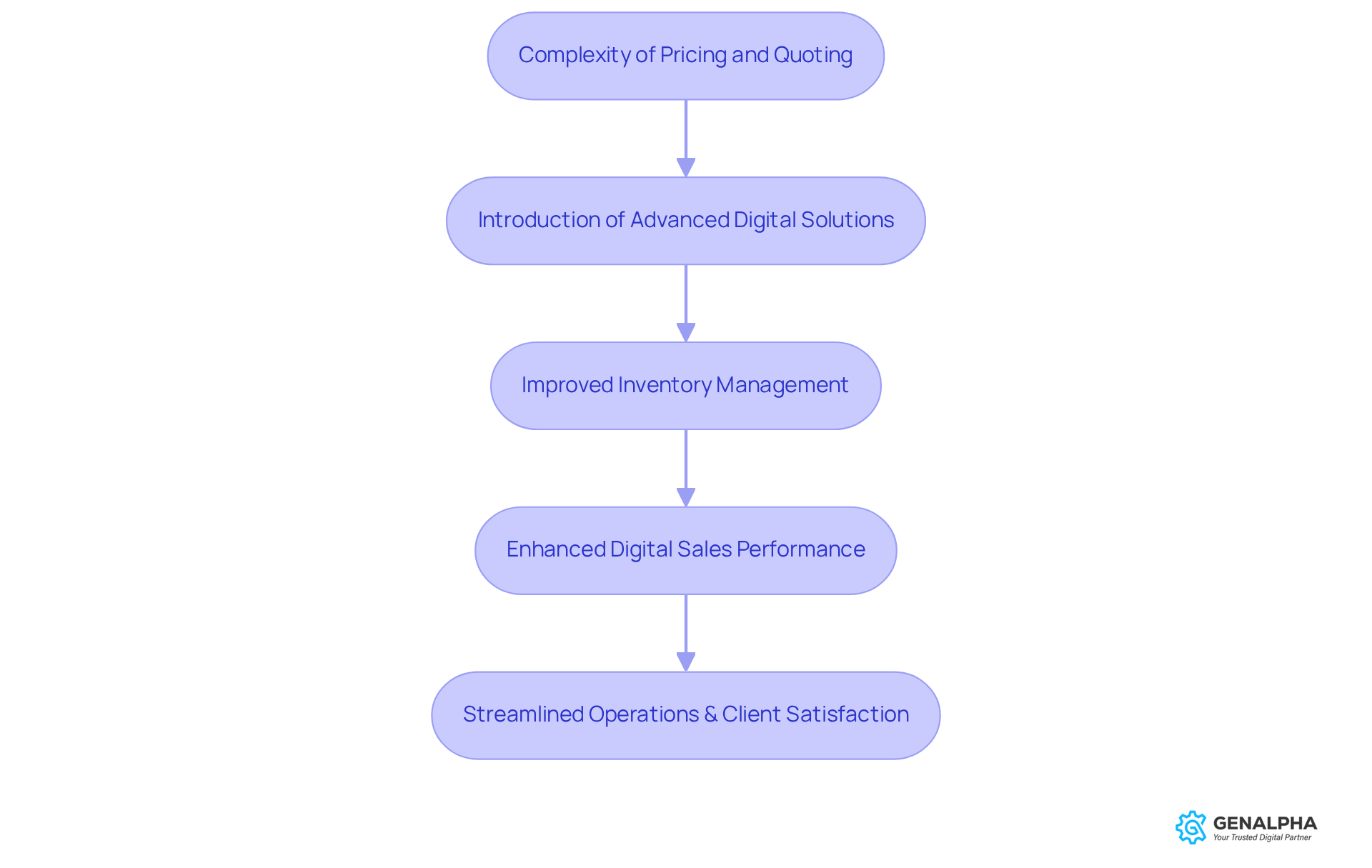

Have you ever felt overwhelmed by the complexity of pricing and quoting? Well, GenAlpha Technologies is here to change that! They’re shaking up the cpq process for producers by bringing in seriously advanced digital solutions that boost both efficiency and precision.

Their standout product, Equip360, is a game-changer. It not only enhances inventory management but also ramps up digital sales performance. Imagine being able to simplify the configuration of complex products and generate accurate quotes in no time! By focusing on the unique needs of equipment producers, GenAlpha ensures that their cpq process not only streamlines operations but also enhances client satisfaction with faster and more reliable service.

So, why not take a closer look? With GenAlpha, you’re not just improving your processes; you’re elevating your entire customer experience!

Understanding the CPQ Process: Key Components and Workflow

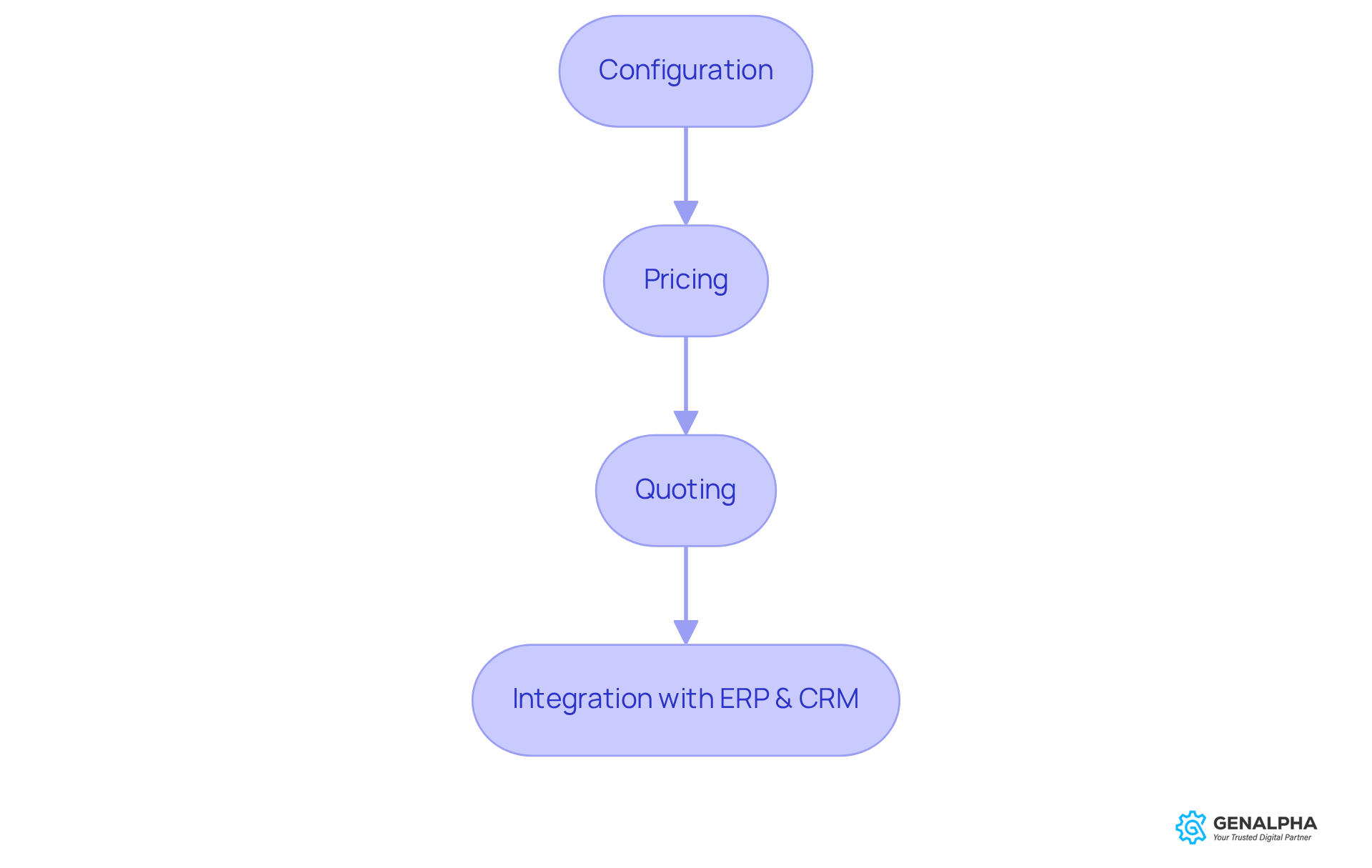

Have you ever wondered how businesses manage to provide accurate quotes so quickly? The process of CPQ is focused on making that happen, and it revolves around three key components: configuration, pricing, and quoting.

- First up, configuration. This step is where the magic begins—choosing product options tailored to client specifications. It’s all about ensuring that the final product meets their needs perfectly.

- Then comes pricing, which calculates the total cost by considering the selected options, any discounts, and established pricing rules.

- Finally, we have quoting, which results in a polished proposal that outlines the product specifications and pricing for the client.

By mastering this workflow, producers can significantly simplify their sales processes. Imagine the boost in client satisfaction when quotes are precise and delivered promptly! And here’s a game-changer: AI can cut the CPQ process implementation time by as much as 50%. This means producers can respond quickly to customer needs and elevate their overall sales performance.

But that’s not all! When you integrate the CPQ process with ERP and CRM frameworks, you’re supporting Industry 4.0 initiatives. This combination enhances workflow efficiency and cross-functional alignment. The result? Fewer errors and a faster sales cycle, allowing producers to seize high-value opportunities.

So, what do you think? Isn’t it exciting to see how these tools can transform the sales landscape?

Benefits of CPQ Systems: Enhancing Efficiency and Accuracy in Manufacturing

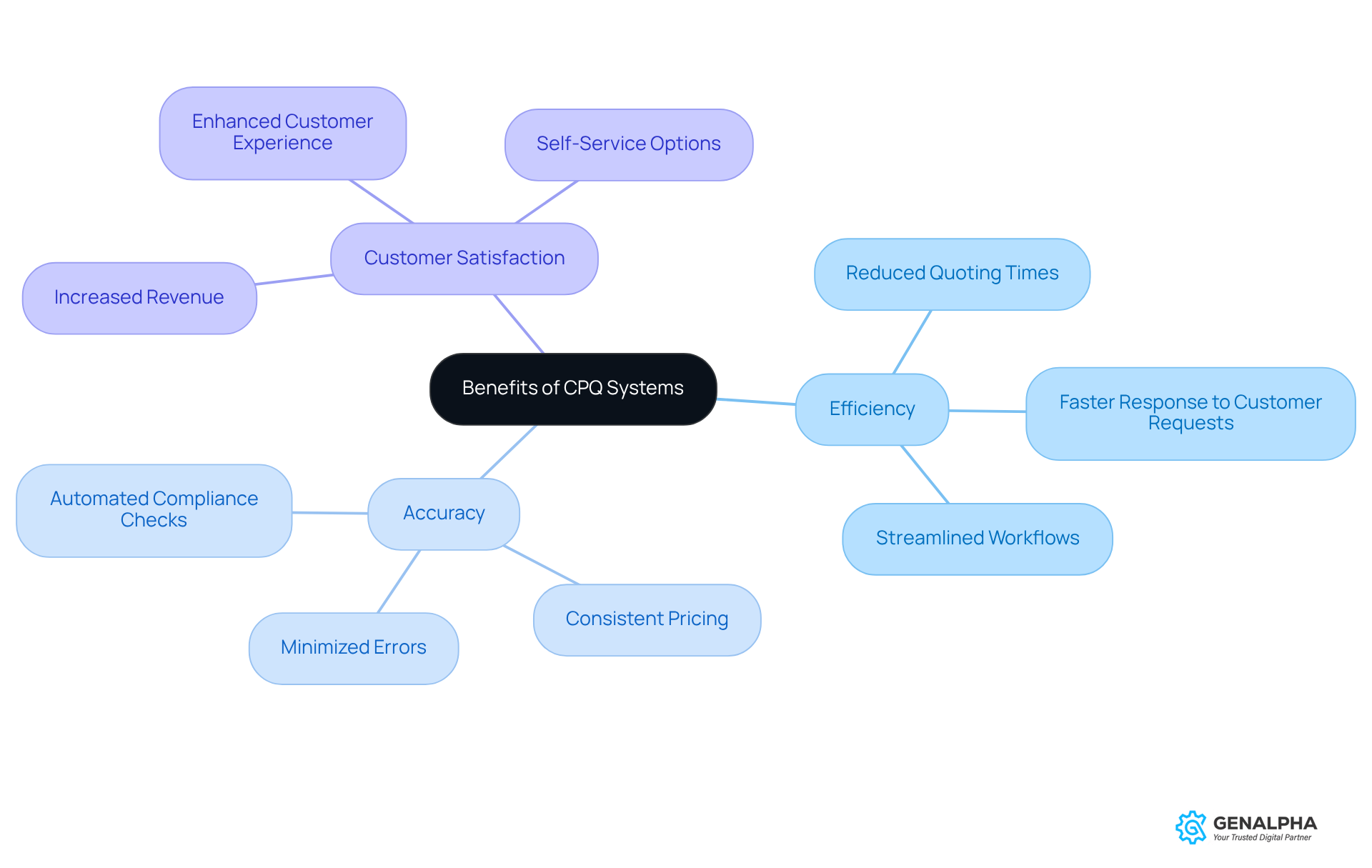

Have you ever wondered how manufacturers can streamline their CPQ process in sales? CPQ solutions are a game changer! They offer fantastic benefits, especially when it comes to boosting efficiency, minimizing errors, and speeding up sales cycles.

By automating configuration and pricing, these systems significantly reduce the time it takes to generate quotes. This means sales teams can focus more on closing deals instead of getting bogged down by administrative tasks. Plus, with CPQ solutions, you can count on pricing accuracy and consistency, which helps prevent mistakes that could lead to unhappy clients.

This streamlined approach not only enhances the CPQ process but also leads to happier customers and increased revenue. For instance, many manufacturers using CPQ software have seen quoting times drop by over 50%, allowing them to respond to customer requests in a flash!

Additionally, integrating CPQ with existing ERP systems keeps product data consistent, which further boosts operational efficiency. So, if you're a manufacturer looking to thrive in a competitive landscape, adopting the CPQ process could be a smart move. Why not explore how these tools can transform your sales process today?

Challenges in CPQ Implementation: What Manufacturers Need to Overcome

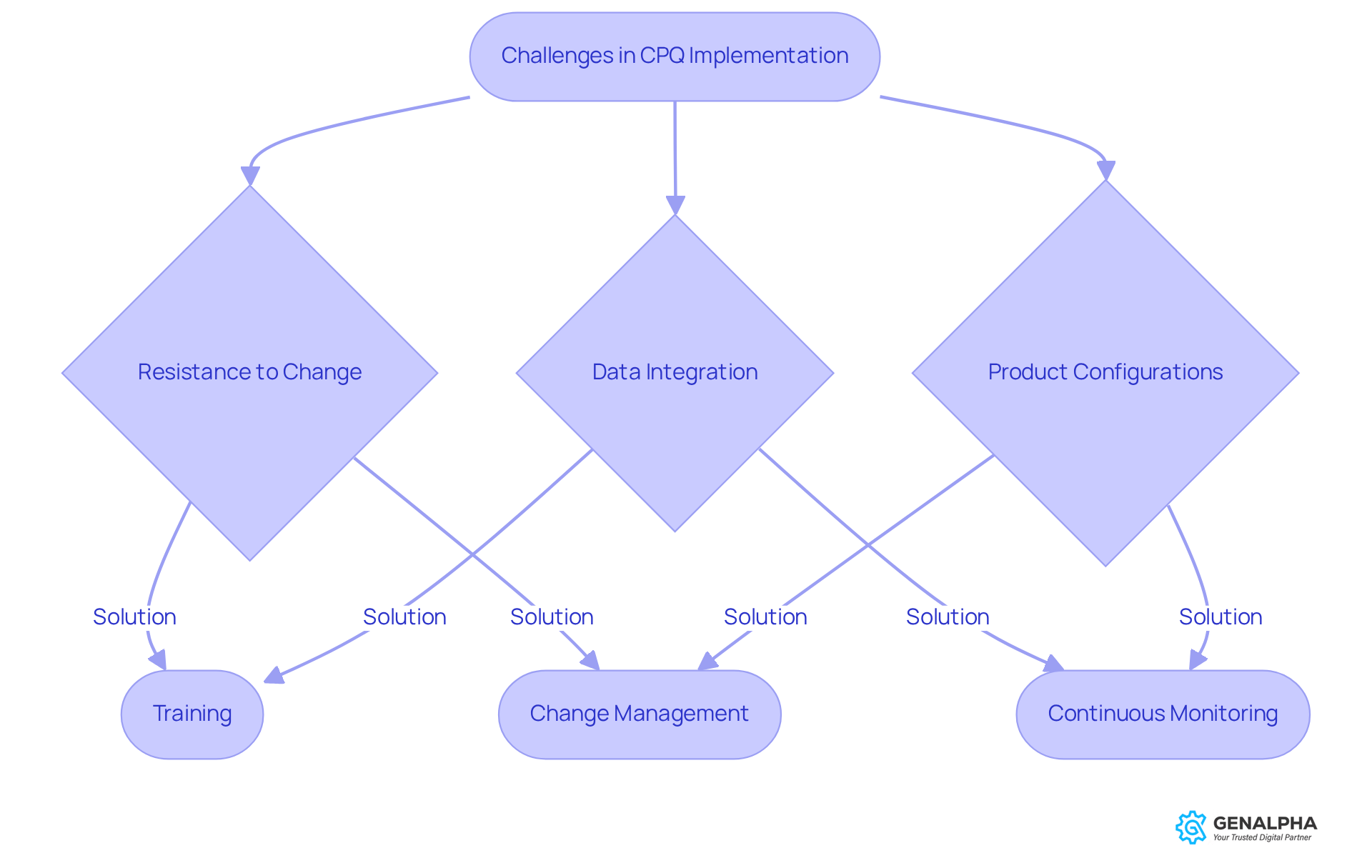

Producers often encounter some bumps in the road when it comes to the CPQ process. You know how it goes—there's resistance to change, data integration headaches, and those tricky product configurations. Employees might hesitate to embrace new tech because they worry it could throw a wrench into their established workflows. This can really slow down the shift towards more efficient processes.

For example, the CPQ process can present quite the challenge when merging with existing ERP and CRM systems. It takes careful planning and execution to avoid any operational hiccups. So, what can producers do to tackle these obstacles? Well, focusing on thorough training and effective change management strategies is key. By keeping everyone in the loop about the benefits of the CPQ process and ensuring they're ready to dive into the platform, organizations can streamline the adoption process and enhance overall efficiency.

Additionally, it is crucial to align the CPQ process with business goals. This way, the platform can meet the unique needs of producers and support their growth ambitions. And don’t forget about the importance of continuous monitoring and feedback after implementation. This helps keep everything aligned with company objectives and addresses any new issues that pop up.

Involving consultants during the CPQ process can also be a game-changer. They bring valuable insights and strategies to help navigate challenges, ensuring a smoother transition and maximizing the benefits of the CPQ solution. So, are you ready to embrace the change and make the most out of CPQ?

Integrating CPQ with ERP and CRM Systems: A Necessity for Manufacturers

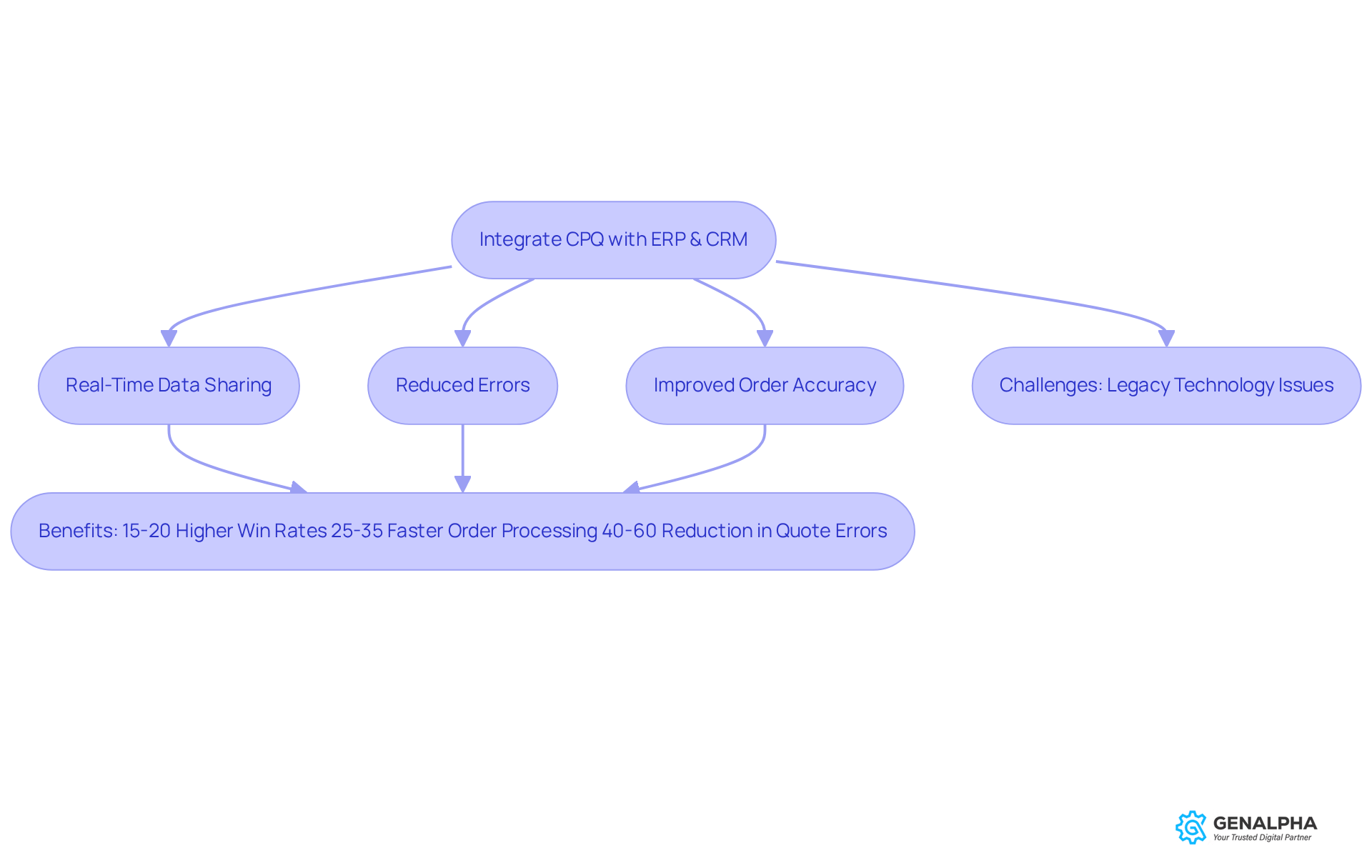

Integrating the cpq process with Enterprise Resource Planning (ERP) and Customer Relationship Management (CRM) platforms is essential for producers looking to optimize their sales processes. Why is this integration so crucial? Well, it allows for real-time data sharing, giving sales teams immediate access to the latest information on inventory levels, pricing structures, and customer details. By aligning these processes, producers can significantly reduce mistakes and improve order accuracy—something that’s vital in today’s competitive market.

Let’s look at a real-world example. ASC Profiles, a producer of steel roofing and wall products, achieved a remarkable 90% reduction in order flow mistakes and an 80% decrease in quote generation time after implementing a phased integration strategy between their Salesforce CPQ and SAP ERP platforms. This not only streamlined their operations but also boosted client satisfaction.

Experts agree that real-time data sharing within the cpq process can be a game changer. Industry leaders note that organizations with integrated CPQ-ERP ecosystems report 15-20% higher win rates and a 25-35% faster order processing time. Plus, companies that utilize real-time data synchronization can expect a 40-60% reduction in quote errors, leading to a more efficient sales cycle and better customer experiences.

However, we can’t overlook the challenges that may arise when merging legacy technologies. This can complicate the synchronization process. Addressing core data synchronization needs is crucial to ensure that product master data, pricing information, and customer-specific agreements are accurately aligned across CPQ and ERP platforms.

In conclusion, the CPQ process's integration with ERP and CRM systems isn’t just a technical upgrade; it’s a strategic necessity. This integration enables producers to respond quickly to market demands, optimize their sales processes, and build stronger relationships with clients. So, are you ready to take that step forward?

Best Practices for Optimizing the CPQ Process in Manufacturing

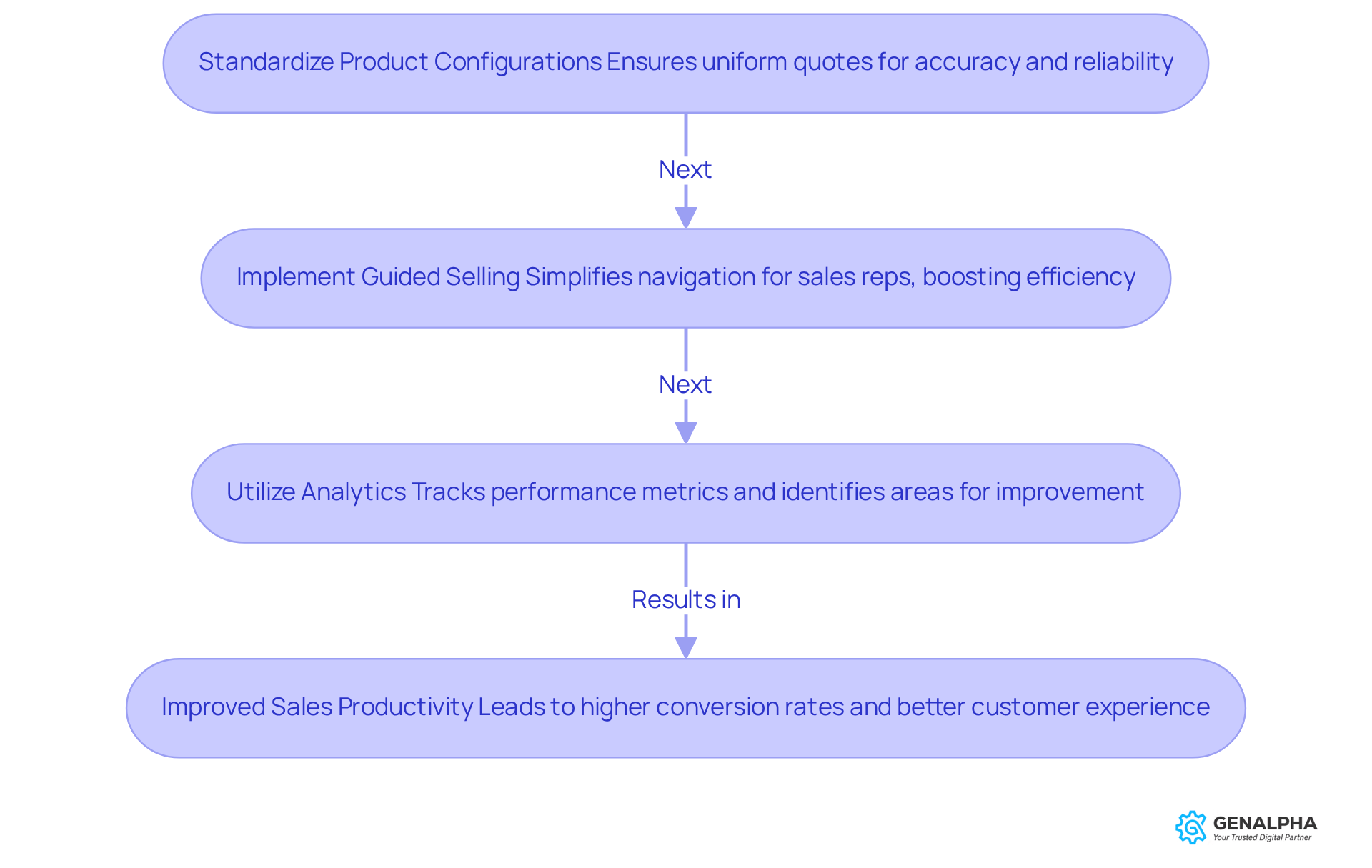

To improve the cpq process for you, let’s discuss some best practices that can be truly beneficial. First off, standardizing product configurations is key. It ensures that all your quotes are uniform, which is super important for keeping everything accurate and reliable when you’re dealing with clients.

Now, have you ever found yourself lost in a sea of complex product options? That’s where guided selling comes in. It simplifies the navigation for your sales reps, boosting their efficiency. For example, companies that have jumped on the guided selling bandwagon have seen some impressive results. Howden Netherlands, for instance, managed to cut their pricing time for orders by a whopping 83% after implementing CPQ!

But wait, there’s more! Using analytics is a game changer too. It allows you to keep an eye on performance metrics, spot bottlenecks, and identify areas that need improvement. This data-driven approach ensures that your cpq process is agile and ready to adapt to changing client needs. In turn, this promotes better sales productivity and higher conversion rates.

So, why not examine these practices and discover how they can improve your own cpq process?

Leveraging Technology: How Digital Solutions Enhance the CPQ Process

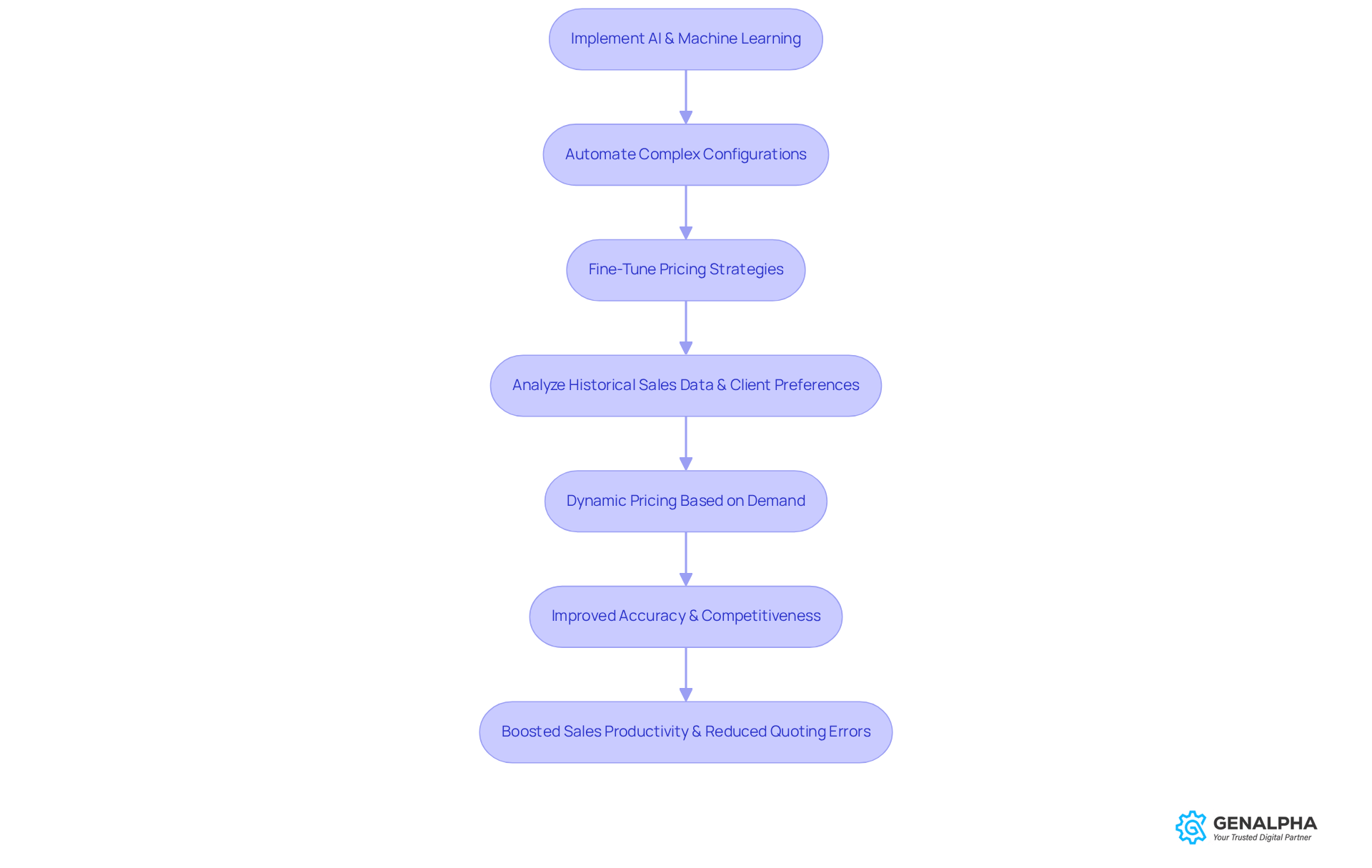

Have you ever thought about how digital solutions, especially AI and machine learning, are shaking things up in the manufacturing world? They’re not just buzzwords; they’re making a significant transformation in the CPQ process. Imagine automating those complex configurations and fine-tuning pricing strategies—sounds pretty cool, right?

With these advanced technologies, manufacturers can analyze historical sales data and client preferences, which means they can whip up more accurate and personalized quotes. For example, the CPQ process can adjust prices on the fly based on demand and customer behavior through AI-driven solutions. This dynamic pricing boosts accuracy and competitiveness, making it easier for businesses to stay ahead of the game.

But it doesn’t stop there. These digital tools also create a seamless interaction between sales teams and clients, leading to a smoother and more enjoyable purchasing experience. By embracing these technologies, manufacturers can ramp up operational efficiency, cut down on errors, and ultimately boost customer satisfaction.

So, what’s the payoff? Organizations that jump on the AI-powered CPQ process are seeing some impressive results—like a 20% bump in sales productivity and a 36% drop in quoting errors. That really highlights how crucial digital transformation is for modern manufacturing. Ready to step into the future?

Impact of CPQ on Customer Satisfaction: Meeting Expectations in Manufacturing

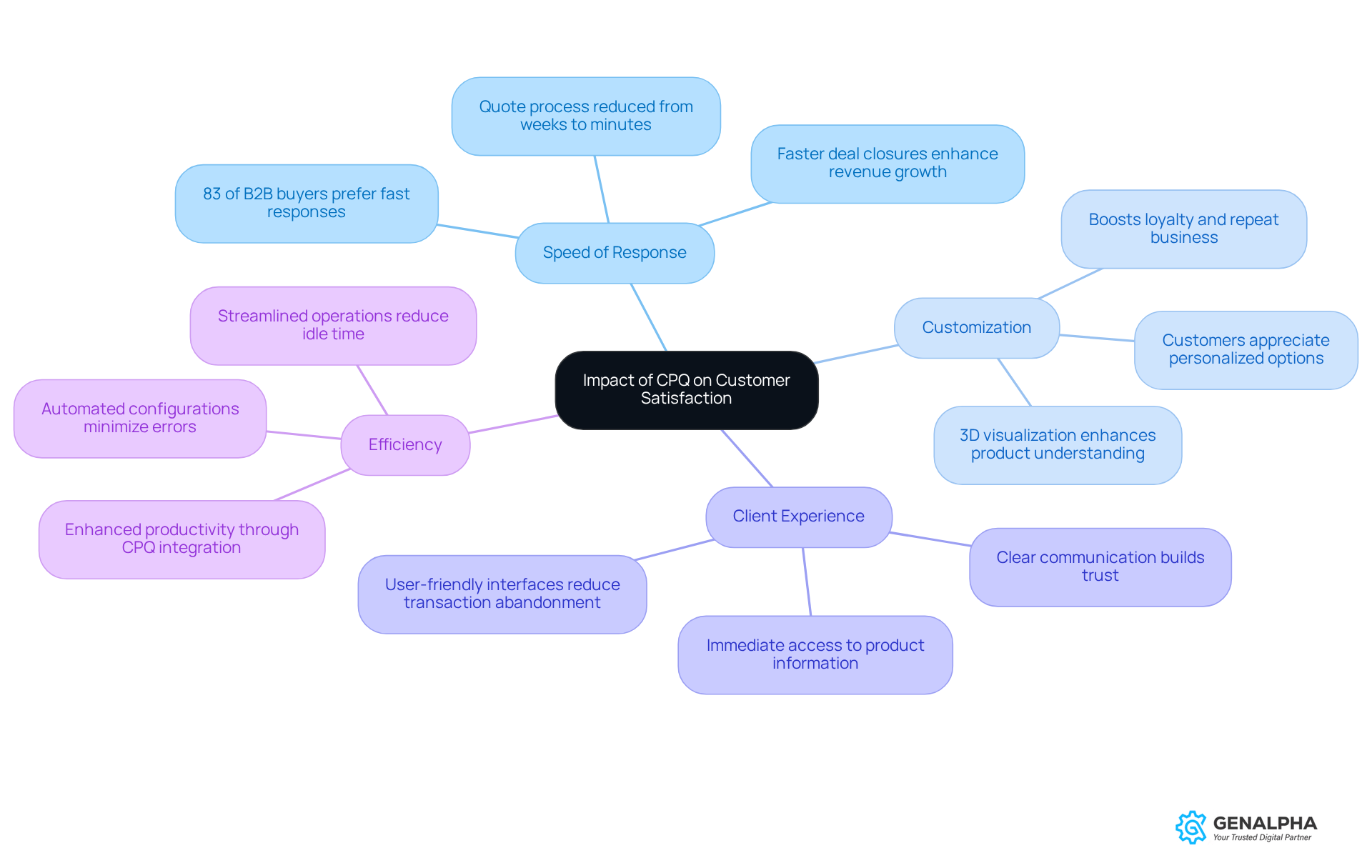

Have you ever wondered how manufacturers can keep their clients happy? Well, the cpq process is a game changer with the adoption of CPQ solutions! By delivering precise and prompt quotes via the cpq process, manufacturers can really hit the mark when it comes to client expectations for speed and reliability. Did you know that 83% of B2B buyers say a fast response positively influences their perception of a vendor? That’s huge!

But it gets even better. The cpq process enables customized configurations, allowing individuals to obtain products tailored to their specific needs. This level of personalization not only boosts the client experience but also builds loyalty and encourages repeat business. With the cpq process, clients have immediate access to all the information necessary to make informed decisions.

And let’s talk about efficiency. The cpq process has been shortened from several weeks to just minutes! That’s a remarkable improvement, showcasing how the cpq process can streamline operations. Ultimately, manufacturers can achieve long-term success by consistently meeting and exceeding client expectations. So, why not consider how effective the cpq process can optimize both traditional and lean manufacturing processes?

Future Trends in CPQ Technology: What Manufacturers Should Anticipate

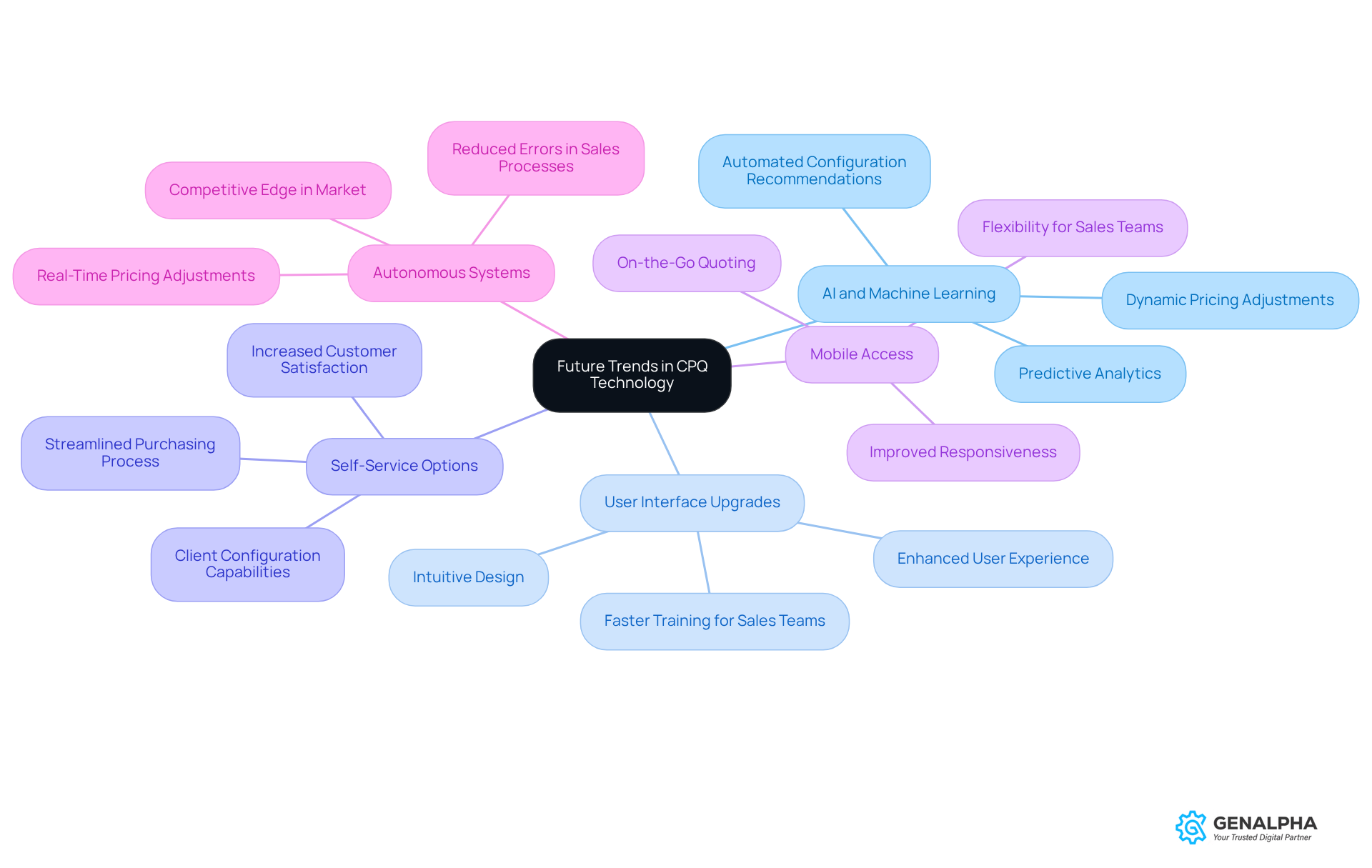

The manufacturing landscape is changing fast, and there are some exciting trends that are set to shape the future of the CPQ process in technology. One of the biggest game-changers is the integration of artificial intelligence (AI) and machine learning. These technologies are not just buzzwords; they’re actually driving predictive analytics and making decision-making a whole lot easier. Imagine a CPQ process that analyzes historical data and market trends to adjust pricing and configurations in real-time, tailored to client needs and inventory availability.

But that’s not all! We can also expect some major upgrades in user interfaces, which means CPQ tools are going to be more intuitive and user-friendly. This is great news for sales teams, as it will make training quicker and boost productivity. Plus, with self-service options, clients can configure products and create quotes on their own, making the purchasing process smoother and increasing satisfaction.

Another trend to watch is mobile access to CPQ tools. This means sales teams can whip up quotes on-the-go, which really ramps up their responsiveness to customer inquiries. As the demand for flexibility grows, manufacturers that adopt the CPQ process will be better equipped to meet the ever-evolving market needs.

Looking ahead to 2025, AI’s role in CPQ systems is set to grow even more. Predictions suggest that these systems will become autonomous, automatically adjusting pricing and configurations. This shift won’t just cut down on mistakes; it will also streamline the sales process, giving producers a competitive edge in a fast-paced marketplace. By monitoring these trends, manufacturers can ensure that their CPQ process remains effective and aligned with client expectations.

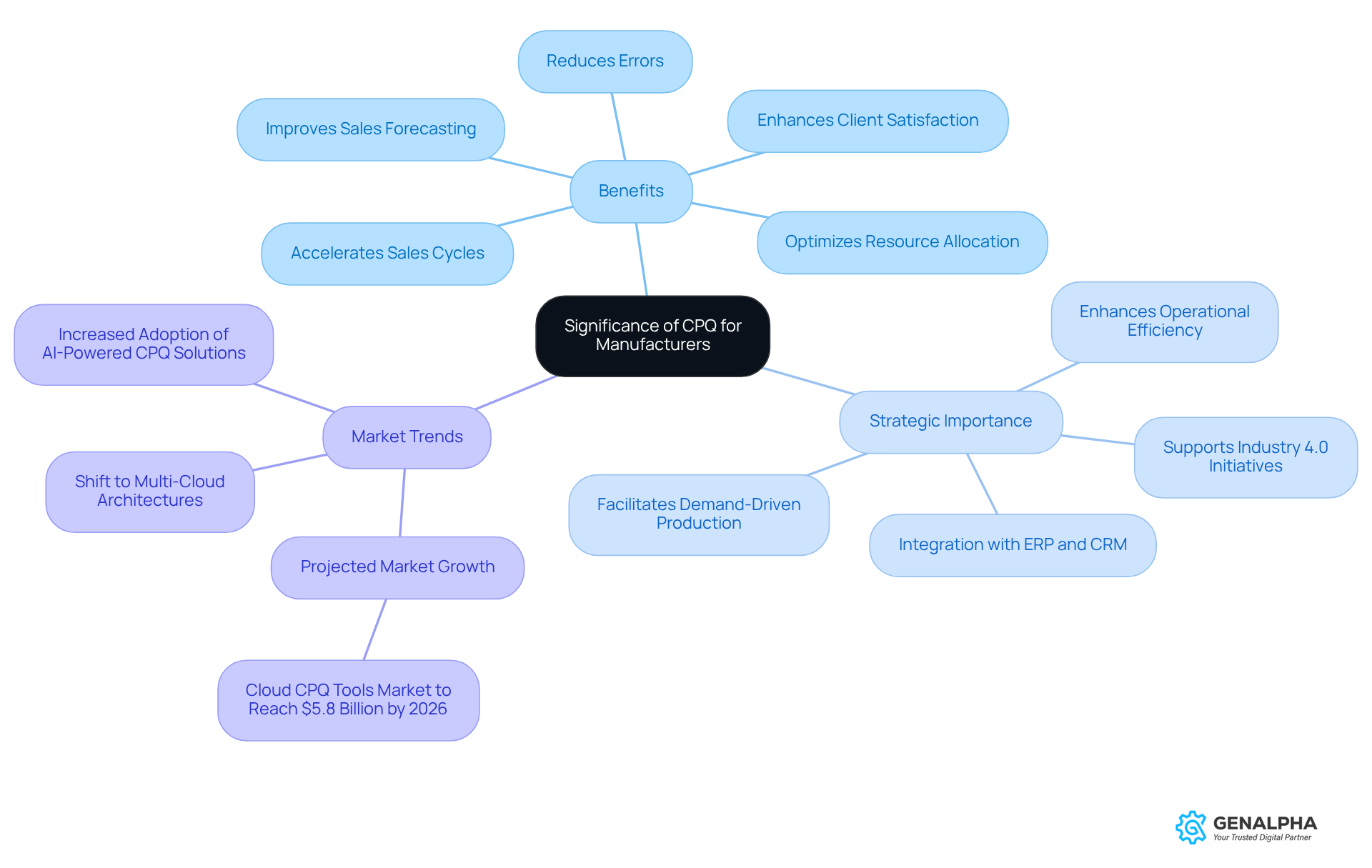

The Significance of CPQ for Manufacturers: Driving Growth and Efficiency

CPQ solutions are a game-changer for manufacturers looking to thrive in today’s competitive world. Imagine automating the cpq process—this not only reduces errors but also accelerates sales cycles and enhances client satisfaction. When you can provide accurate and timely quotes, it doesn’t just make things run smoother; it also strengthens your relationships with clients, leading to higher sales and profitability.

As manufacturers navigate the complexities of the market, investing in the cpq process becomes crucial for achieving sustainable growth and long-term success. Companies using the cpq process can quickly adapt to client demands, optimize resource allocation, and align production with real market needs. This highlights just how strategically significant these solutions are in modern manufacturing.

Did you know that the market for cloud CPQ tools is projected to hit nearly $5.8 billion by 2026? This really underscores the growing recognition of CPQ's value. As Sirocco, the CEO, puts it, "CPQ has evolved from a tool to a strategic partner, transforming how businesses approach complexity, efficiency, and customer satisfaction." This evolution shows how essential it is to integrate the cpq process with ERP and CRM systems, ensuring a smooth and accurate data flow across the enterprise, which further enhances operational efficiency.

Conclusion

The CPQ process is a vital piece for equipment manufacturers looking to boost their operational efficiency and customer satisfaction. Imagine being able to respond quicker and provide more accurate proposals—this is exactly what advanced solutions like those from GenAlpha Technologies can do. By streamlining pricing and quoting processes, manufacturers not only improve their internal workflows but also significantly enhance the customer experience, ensuring that client needs are met with precision and speed.

Throughout our discussion, we uncovered key insights into the essential components of the CPQ process. Think configuration, pricing, and quoting, all while seamlessly integrating with ERP and CRM systems. The benefits of CPQ systems are hard to ignore:

- Increased accuracy

- Reduced sales cycle times

- Enhanced customer loyalty

These showcase their strategic importance in today’s competitive landscape. But let’s not overlook the challenges of implementing CPQ—issues like resistance to change and data integration highlight the necessity for effective training and alignment with business goals.

Looking ahead, manufacturers should really consider embracing the evolving landscape of CPQ technology. By tapping into digital solutions and keeping an eye on future trends like AI and machine learning, companies can set themselves up to not just meet but exceed client expectations. The significance of the CPQ process is huge; it’s not just a tool for efficiency, but a crucial driver of growth and customer satisfaction in the manufacturing sector. By embracing these insights and best practices, manufacturers will be empowered to thrive in a rapidly changing marketplace. So, what are you waiting for? Let’s dive into this exciting journey together!

Frequently Asked Questions

What is GenAlpha Technologies known for?

GenAlpha Technologies is known for transforming the CPQ (Configure, Price, Quote) process for manufacturers by providing advanced digital solutions that enhance efficiency and precision.

What is Equip360 and how does it benefit manufacturers?

Equip360 is GenAlpha's standout product that enhances inventory management and boosts digital sales performance. It simplifies the configuration of complex products and generates accurate quotes quickly, improving operations and client satisfaction.

What are the key components of the CPQ process?

The key components of the CPQ process are configuration, pricing, and quoting. Configuration involves selecting product options based on client specifications, pricing calculates the total cost including discounts, and quoting produces a polished proposal outlining product details and pricing.

How does AI impact the CPQ process?

AI can reduce the implementation time of the CPQ process by as much as 50%, allowing producers to respond quickly to customer needs and enhance overall sales performance.

What are the benefits of integrating the CPQ process with ERP and CRM systems?

Integrating the CPQ process with ERP and CRM systems enhances workflow efficiency and cross-functional alignment, resulting in fewer errors and a faster sales cycle, which helps producers capitalize on high-value opportunities.

How do CPQ systems enhance efficiency and accuracy in manufacturing?

CPQ systems enhance efficiency by automating configuration and pricing, significantly reducing the time to generate quotes. This allows sales teams to focus on closing deals and ensures pricing accuracy, leading to happier customers and increased revenue.

What results have manufacturers experienced by using CPQ software?

Many manufacturers using CPQ software have reported a drop in quoting times by over 50%, enabling them to respond to customer requests more swiftly and effectively.

Why should manufacturers consider adopting the CPQ process?

Manufacturers should consider adopting the CPQ process as it streamlines sales operations, minimizes errors, speeds up sales cycles, and ultimately helps them thrive in a competitive landscape.