Overview

Have you ever wondered how to make your manufacturing processes smoother? The article "10 Key Insights for Effective BOM Manufacturing in Equipment Production" dives into just that! It highlights essential strategies that can really amp up how we manage our Bill of Materials (BOM).

Imagine integrating digital tools into your workflow. Sounds great, right? This article emphasizes how these tools can enhance accuracy through regular reviews. Plus, understanding the different types of BOMs can help us optimize our workflows, which means fewer errors and a boost in operational efficiency.

So, if you're looking to improve your manufacturing game, this article is a must-read! It’s packed with insights that not only inform but also inspire action. Why not take a moment to explore these strategies further? You might just find the key to transforming your approach!

Introduction

Understanding the intricacies of Bill of Materials (BOM) management is crucial for manufacturers like us striving for efficiency and accuracy in production. As technology evolves, so do the strategies and tools available to streamline BOM processes. This evolution offers us the chance to enhance productivity and reduce costs. But let’s be real—these advancements can also bring challenges that might trip us up on our path to operational success.

So, how can we effectively navigate these complexities to ensure our BOMs are not only accurate but also aligned with our manufacturing goals? This article dives into ten key insights that can transform our BOM manufacturing practices, paving the way for improved operations in equipment production. Let’s explore these ideas together!

GenAlpha Technologies Equip360: Streamline Your BOM Management and Boost Sales

Have you ever felt overwhelmed by managing your BOMs? Well, GenAlpha Technologies' Equip360 is here to change that! This comprehensive B2B eCommerce platform is specially crafted for manufacturers and distributors, making BOM manufacturing oversight a breeze. Imagine flipping through interactive 2D/3D catalogs that help you quickly find parts and access all the necessary documentation. Not only does this enhance the accuracy of your BOMs, but it also boosts sales by improving BOM manufacturing, which creates a better customer experience.

Equip360 doesn’t just stop there; it seamlessly integrates with your current ERP systems. This means that your data related to BOM manufacturing is always up-to-date and readily available—essential for efficient planning and inventory management. So, why not take a closer look at Equip360? It could be the game-changer you’ve been waiting for!

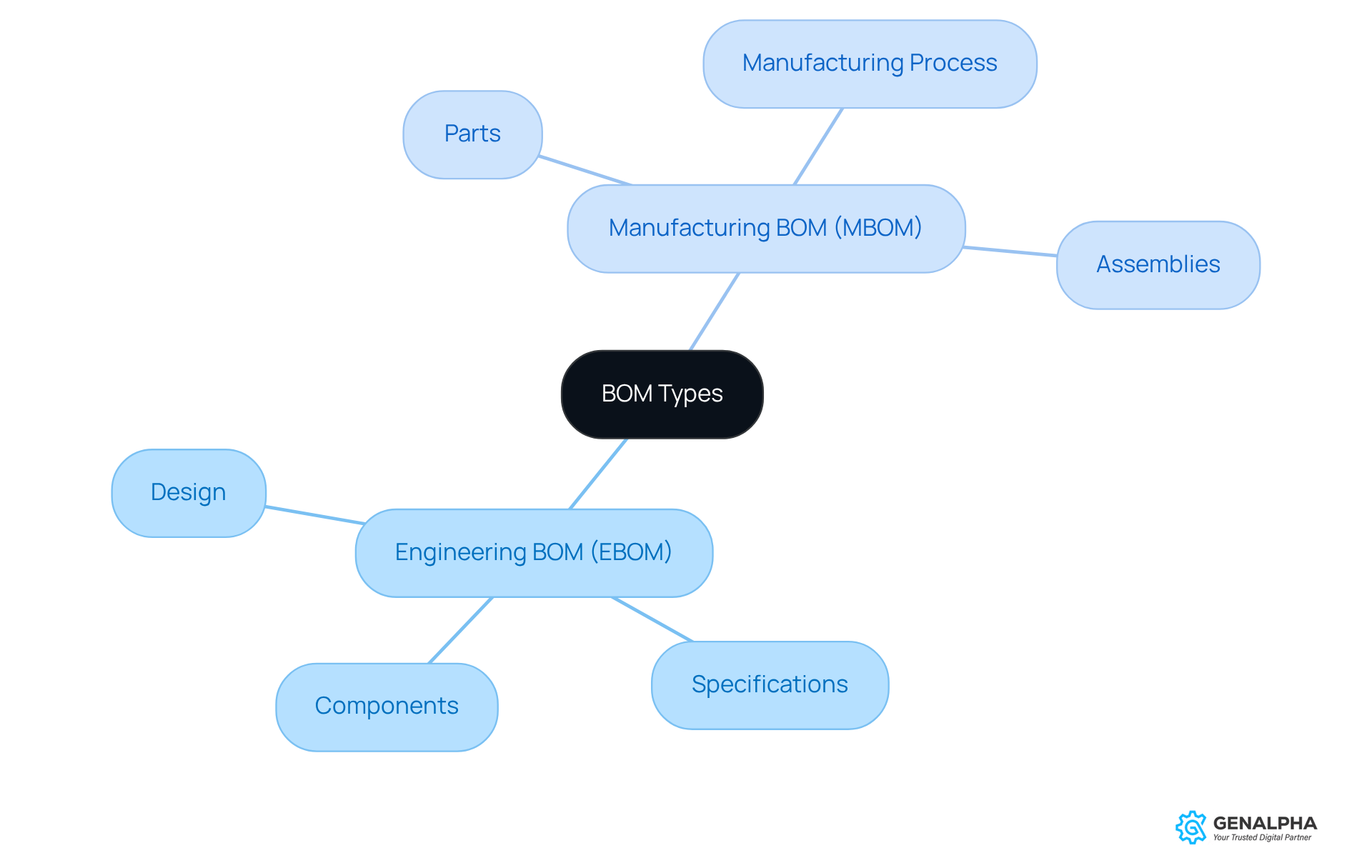

Engineering BOM vs. Manufacturing BOM: Key Differences for Effective Production

Have you ever thought about how products come to life? Well, that’s where the Engineering BOM (EBOM) steps in! It’s all about the design and specifications, detailing the components and materials we need for development.

Now, on the other hand, we have the BOM manufacturing (MBOM). This one is tailored for BOM manufacturing, outlining the parts and assemblies necessary for the manufacturing process.

Understanding these differences can really help manufacturers optimize their workflows in BOM manufacturing. Imagine having the right information at your fingertips exactly when you need it—sounds great, right? This is crucial for minimizing errors and boosting productivity.

So, next time you think about product development, remember how these two BOMs play a vital role in making everything run smoothly!

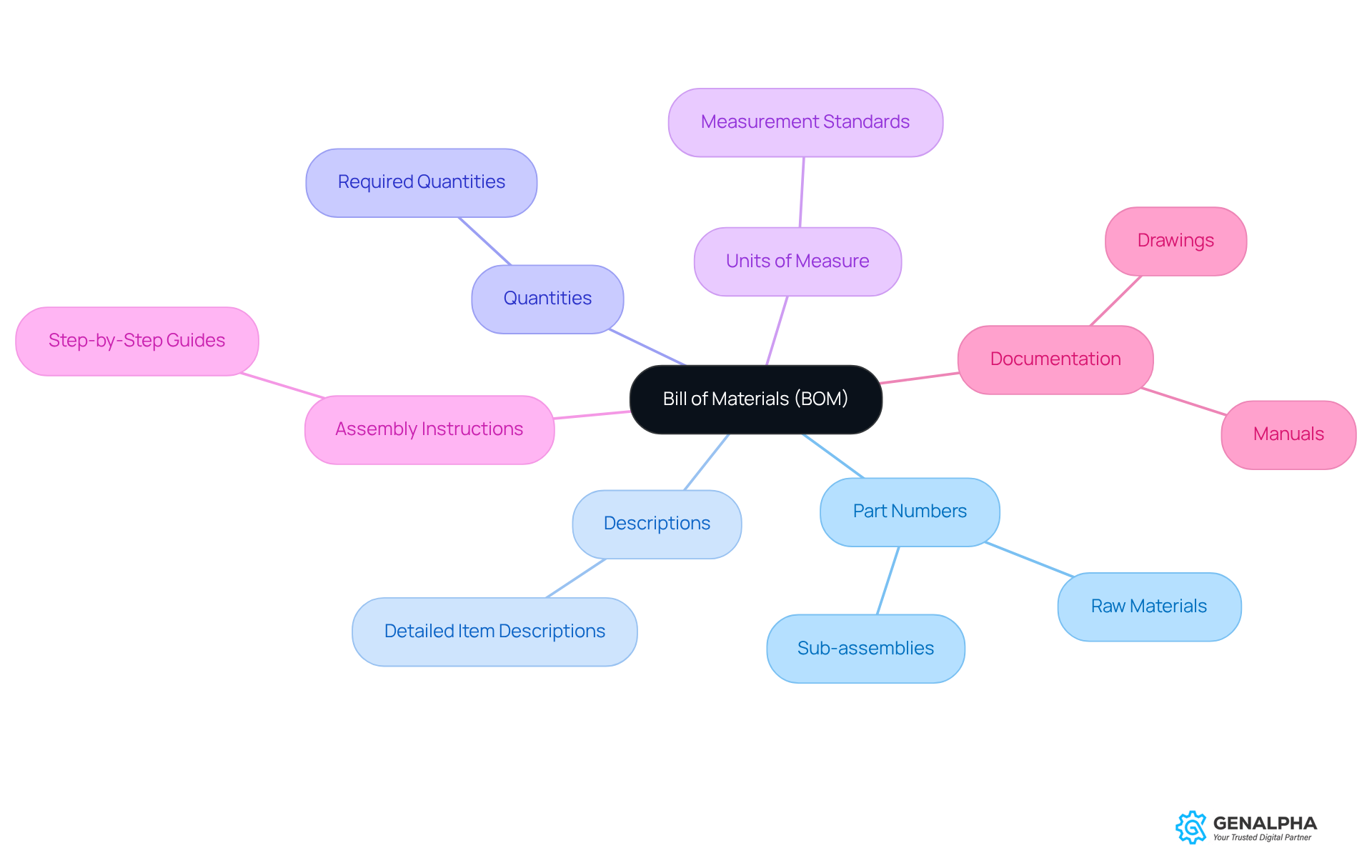

Essential Components of a Bill of Materials: What Every Manufacturer Must Include

Have you ever thought about how crucial BOM manufacturing is for successful manufacturing? It’s like the backbone of the whole process! A solid BOM should include several key components that make everything run smoothly. Think about it: part numbers, detailed descriptions, quantities, units of measure, and specific specs for each item are all essential.

But wait, there’s more! It’s also super important to include comprehensive assembly instructions and any relevant documentation, like drawings or manuals. This thorough approach ensures that everyone involved has access to the vital information they need, which ultimately optimizes workflow processes.

Did you know that incomplete BOMs can lead to significant production errors? Studies have shown that a well-structured BOM can cut waste by up to 30% and boost efficiency. That’s a big win for smoother BOM manufacturing operations! As one expert put it, 'A bill of materials or product structure is a list of the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts, and the quantities of each needed to manufacture an end product.' This really underscores the importance of meticulous documentation in BOM manufacturing management. So, how can you ensure your BOM is up to par?

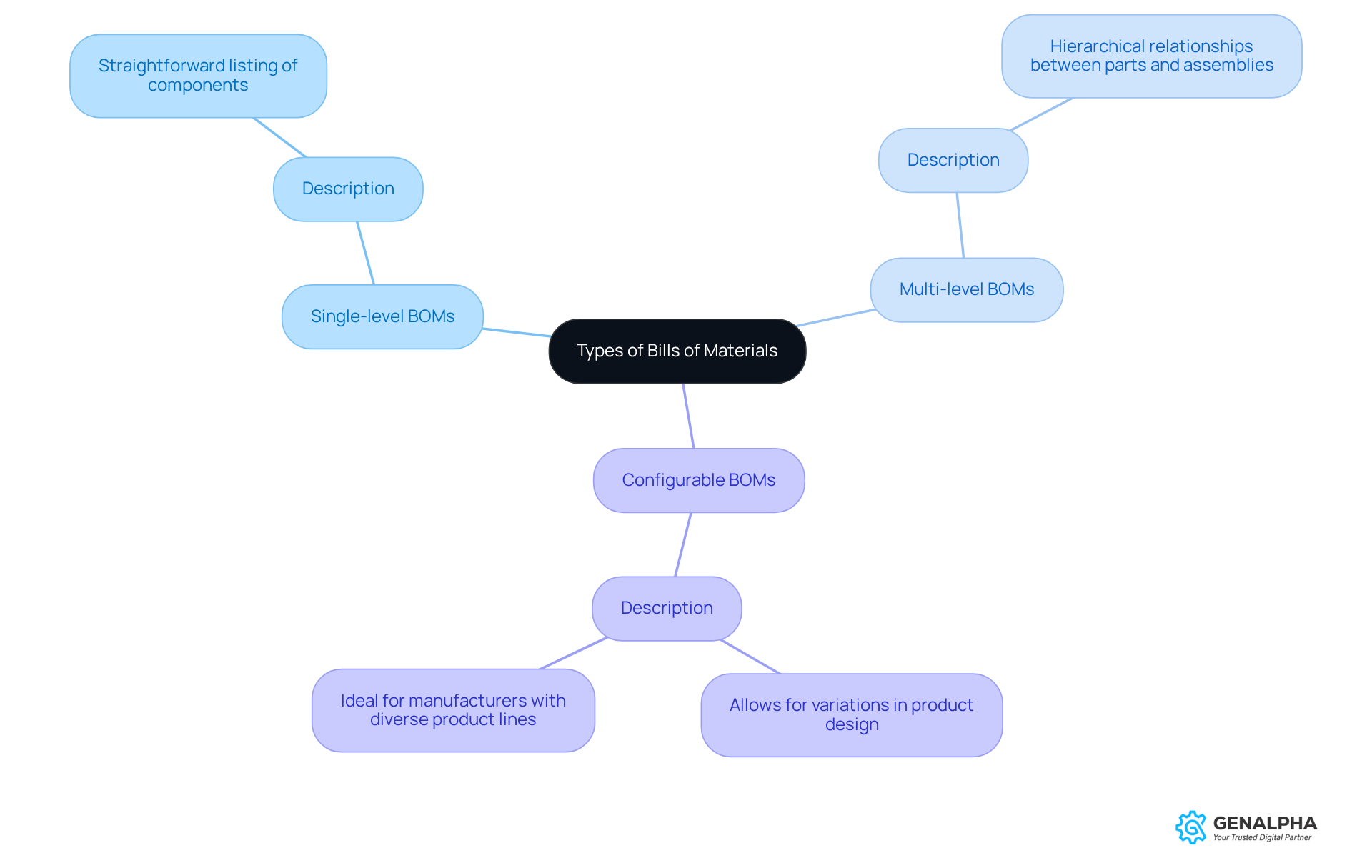

Types of Bills of Materials: Choosing the Right Format for Your Manufacturing Needs

Have you ever wondered about the different types of Bills of Materials (BOMs)? Well, let’s dive into it! There are several kinds, including:

- Single-level BOMs

- Multi-level BOMs

- Configurable BOMs

Single-level BOMs are pretty straightforward—they simply list the components you need. On the other hand, multi-level BOMs go a step further by detailing the hierarchical relationships between parts and assemblies. This can really help you understand how everything fits together!

Now, if you’re in a business that offers various product designs, configurable BOMs are your best friend. They allow for variations in product design, making them perfect for manufacturers with diverse product lines.

So, why does it matter which BOM type you choose? Well, selecting the right one is crucial for aligning with your BOM manufacturing strategies and ensuring that resources are allocated efficiently. Think about it—what type of BOM do you think would work best for your needs?

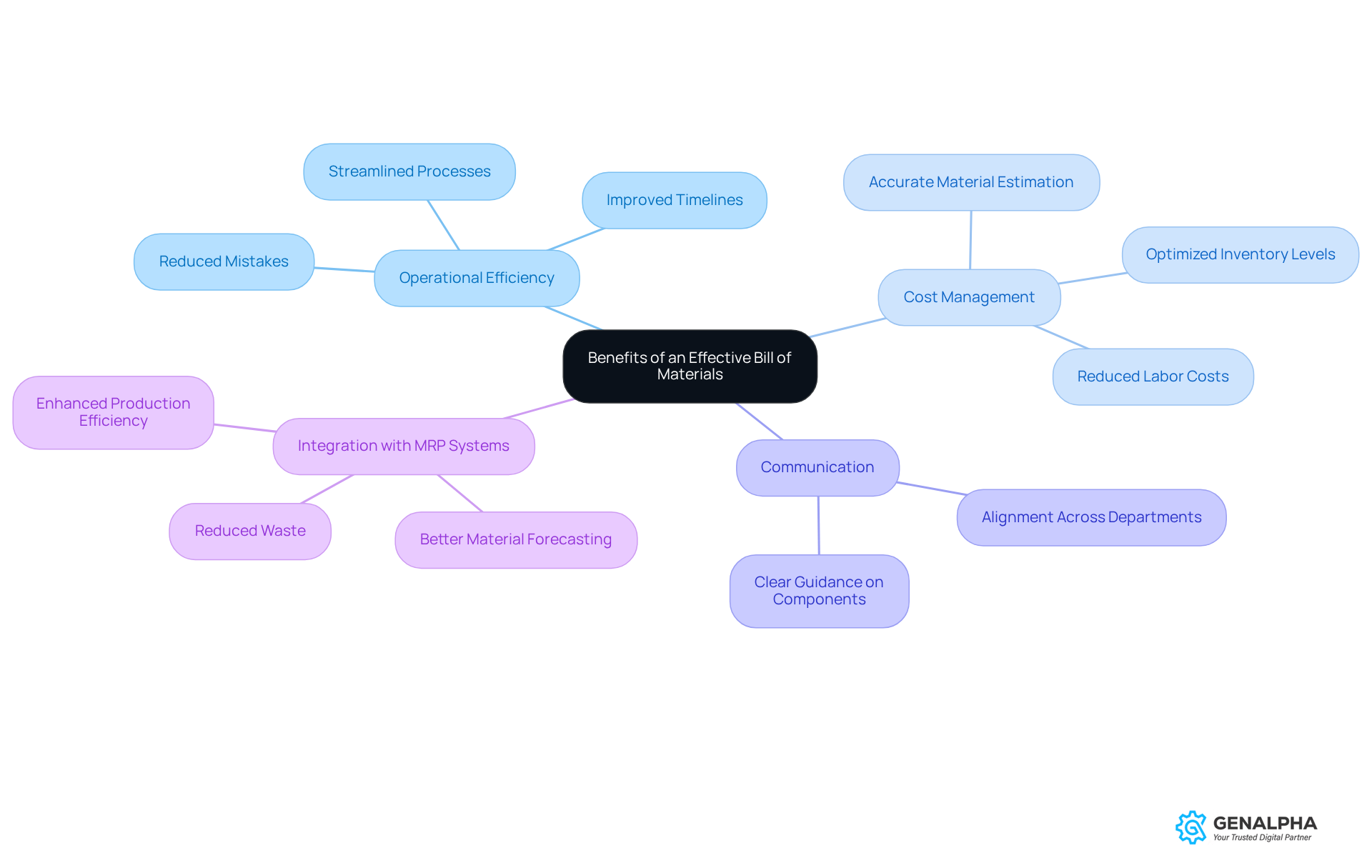

Benefits of an Effective Bill of Materials: Enhancing Efficiency and Cost Management

An effective BOM manufacturing process can significantly enhance your operational efficiency! It gives you clear guidance on the components needed for BOM manufacturing, which helps to cut down on mistakes and delays—something we all know can be costly, whether it’s missed deadlines or increased labor costs. Plus, BOM manufacturing relies on a well-structured BOM, which is key for managing costs and allows manufacturers to accurately estimate material expenses and optimize inventory levels. By detailing every necessary part, BOM manufacturing helps streamline processes, ensuring all materials are on hand when needed and avoiding those frustrating interruptions caused by missing parts.

But that’s not all! A detailed BOM manufacturing also fosters better communication across different departments, aligning everyone involved in the manufacturing process. This alignment is essential for keeping the workflow smooth in BOM manufacturing and ensuring that everyone knows what materials and components are required at each stage. For example, companies that have embraced organized BOM manufacturing alongside Material Requirements Planning (MRP) systems have seen significant reductions in waste and improved timelines for production. In fact, industry studies show that companies leveraging BOM manufacturing effectively have managed to cut inventory levels by up to 20% and enhance production efficiency by 15%.

So, how can you make the most out of BOMs? Consider integrating them with MRP systems to ensure that your material requirements are accurately forecasted and managed. This strategic move not only boosts your operational success but also helps you thrive in a competitive marketplace. Ready to take your manufacturing process to the next level?

Best Practices for Maintaining Your Bill of Materials: Ensuring Accuracy and Consistency

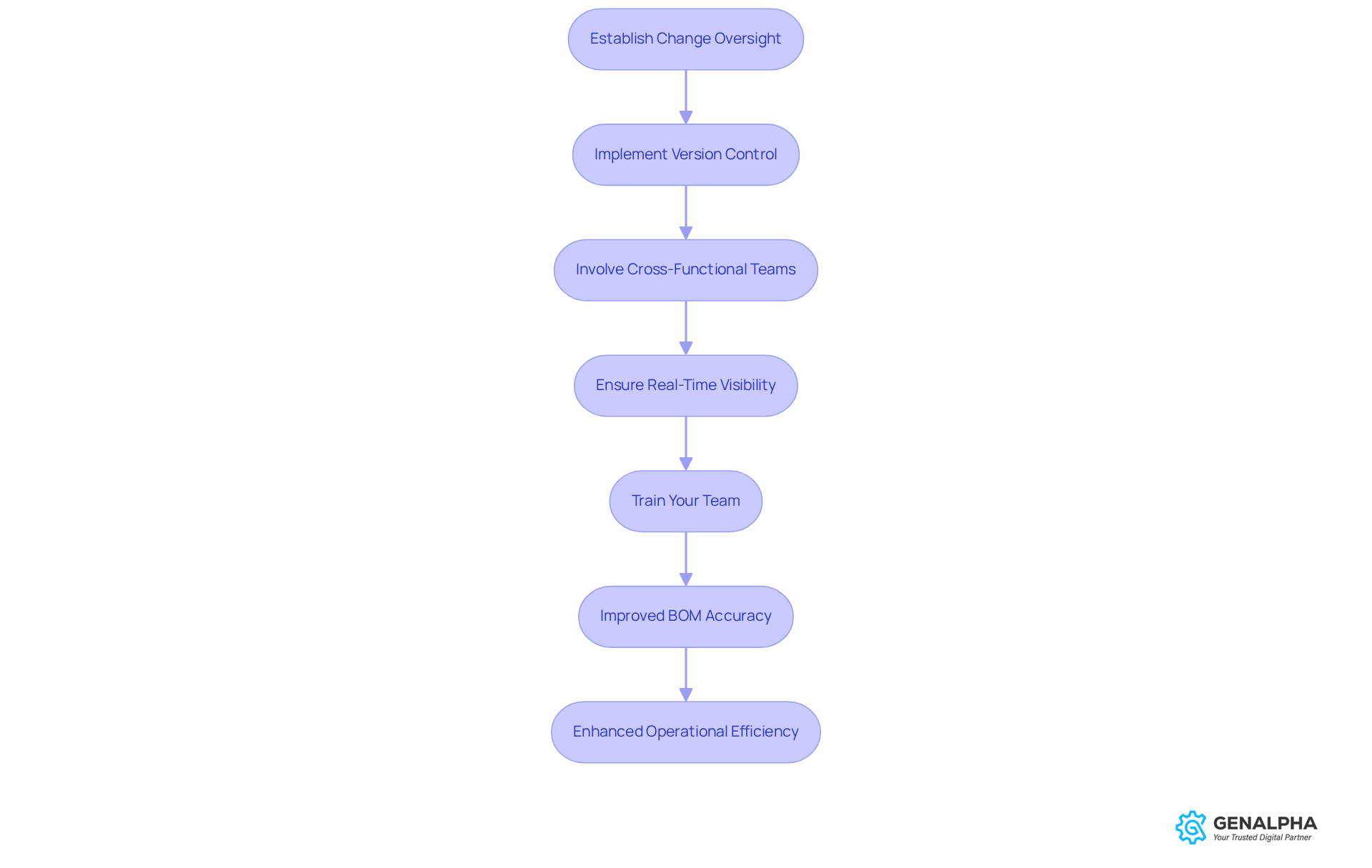

To keep your Bill of Materials (BOM) precise and consistent, it’s crucial for manufacturers to focus on a solid change oversight process in BOM manufacturing, along with regular reviews and updates. Have you ever thought about how managing changes can directly impact the accuracy of quotes and operational efficiency? Establishing clear protocols for this is essential. Version control systems are key players here, helping teams track revisions and maintain a single source of truth for product data. Plus, a digital BOM records historical changes, which means you’ll always have the latest data at your fingertips.

Involving cross-functional teams—like sales, engineering, and finance—in the BOM creation and maintenance process really enhances collaboration. This way, you ensure that all necessary information is captured. Isn’t it great how a collaborative approach can streamline communication and reduce the risk of errors that often come from siloed information? Real-time visibility into production processes is vital too, as it allows producers to oversee progress and make quick adjustments to the BOM when needed.

Training your team on BOM handling tools and practices is also essential for maintaining accuracy over time. For instance, producers like Resani have seen significant advancements in project oversight and document regulation after implementing organized systems that support version control and compliance. By optimizing profits through efficient inventory oversight and cutting down on non-value-added tasks with automated tracking, producers can boost their efficiency in BOM manufacturing oversight. This ultimately leads to better supplier relationships and more accurate quotes. So, what steps can you take today to improve your BOM processes?

Digital Tools for BOM Management: Leveraging Technology for Enhanced Efficiency

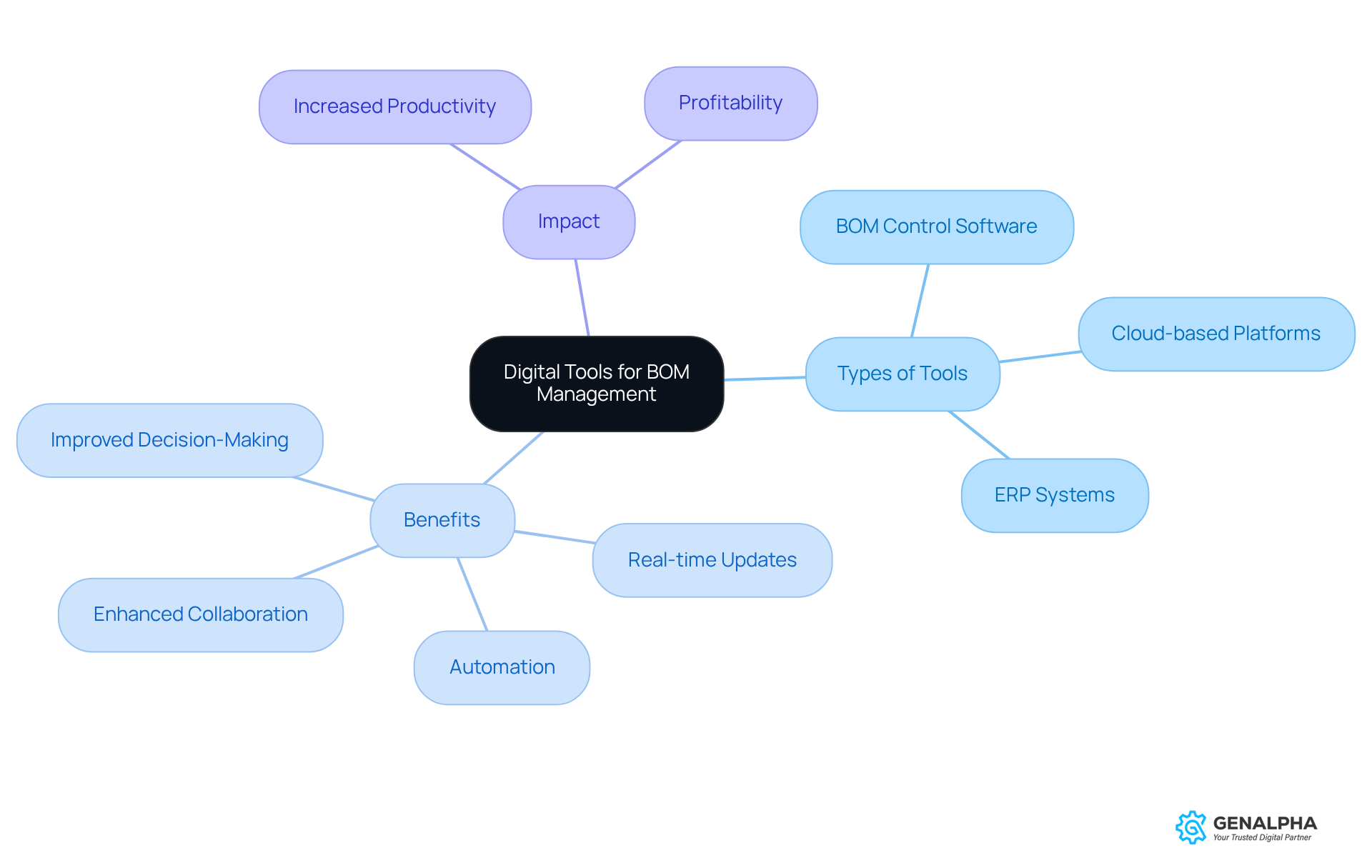

Digital tools like BOM manufacturing control software, cloud-based platforms, and ERP systems are game-changers for managing Bills of Materials (BOM) in manufacturing. Have you ever wished for real-time updates that cut down on errors? Well, these technologies do just that! They automate data entry, which means less manual input and more consistent accuracy.

But that’s not all—enhanced collaboration is another fantastic perk! Imagine seamless communication and data sharing across departments. By integrating BOM manufacturing oversight with current ERP systems, manufacturers can ensure that all relevant data remains in sync. This leads to smoother operations and a lower risk of discrepancies.

For example, using a cloud-based BOM oversight platform means your team can access the latest information from anywhere. This not only streamlines decision-making but also improves inventory management. Think about it: better decision-making translates to increased productivity and profitability in equipment manufacturing. So, are you ready to embrace these technological advancements?

Regular Reviews and Updates: Keeping Your BOM Relevant and Accurate

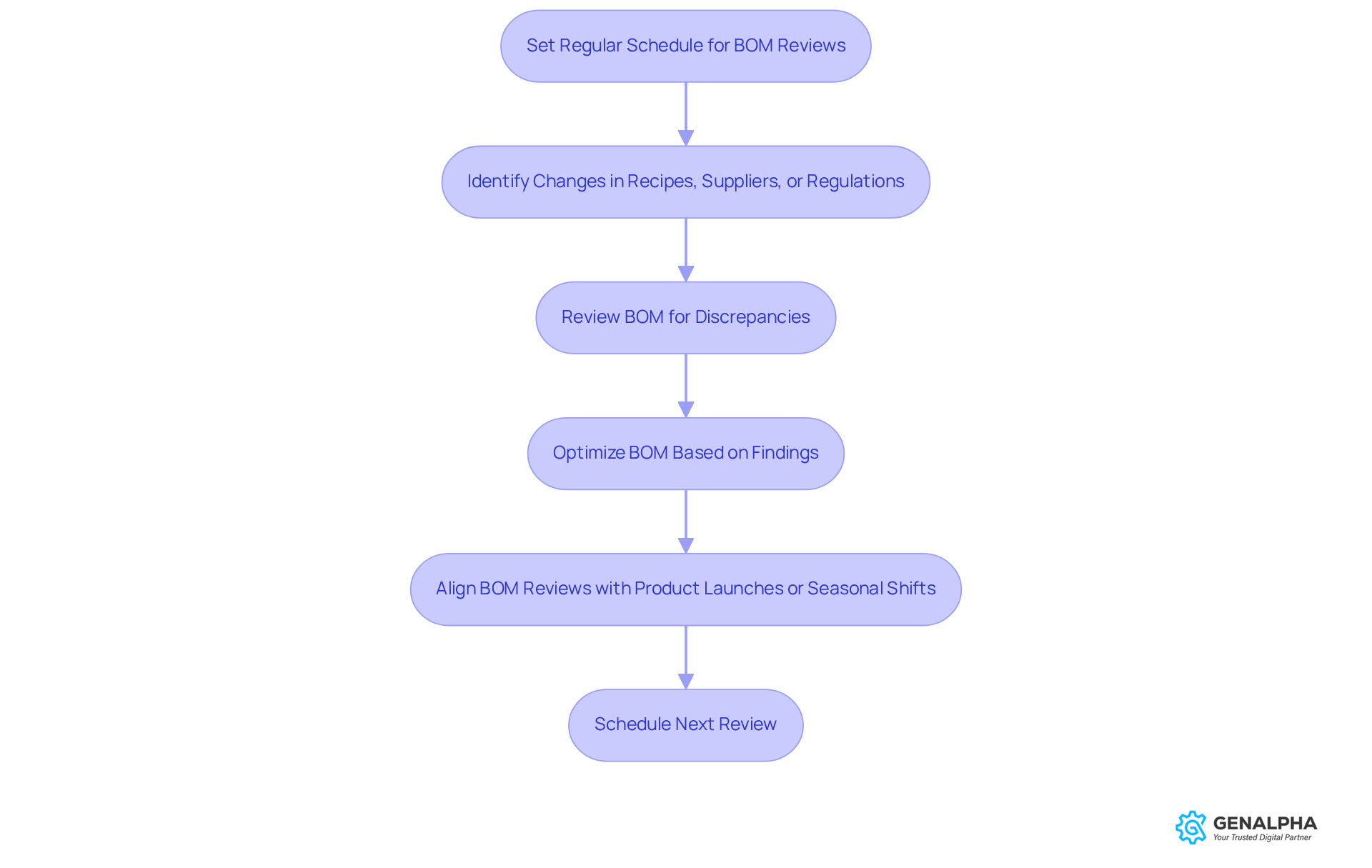

Keeping your Bill of Materials (BOM) up to date is crucial for effective bom manufacturing and staying in sync with your inventory environment. Have you thought about how often you review your BOM? It’s a good idea to set up a regular schedule for these reviews, especially when there are changes in your product lifecycle or during inventory audits.

For instance, if your recipes, suppliers, or regulations change, it’s time to take a closer look at your BOM. This proactive approach not only helps catch discrepancies and outdated information but also paves the way for optimization in bom manufacturing. When your bom manufacturing is accurate and relevant, you can really boost efficiency and cut down on operational costs.

Think about aligning your BOM reviews with product launches or seasonal shifts. This way, you can quickly adapt to market demands, keeping your production processes agile and cost-effective. As Rob Terry pointed out, "In an industry where a single mislabeled ingredient can trigger a nationwide recall, precision isn’t just important, it’s non-negotiable."

Additionally, understanding the different types of BOMs—like single-level, multi-level, indented, and recipe-based—can give you more context for managing them effectively. Remember, neglecting to keep your BOM accurate can lead to compliance issues and operational hiccups. So, why not start scheduling those reviews today?

Integrating BOMs with ERP Systems: Streamlining Operations for Better Resource Planning

Have you ever wondered how BOM manufacturing integration with ERP systems can elevate a producer's game? Well, it turns out that this integration can significantly boost operational efficiency and resource planning. Imagine all departments having access to BOM data—it fosters better decision-making and coordination across the board.

By tapping into ERP capabilities, producers can automate essential processes like inventory control, procurement, and production scheduling. This not only streamlines operations but also slashes operational costs. For example, organizations that have embraced ERP systems report an impressive 83% success rate in meeting their ROI expectations. Many have seen optimized inventory levels and a noticeable increase in productivity. Additionally, 66% of these organizations noted a direct improvement in operational efficiency thanks to their ERP integration.

So, what does this mean for producers? The strategic alignment of BOM manufacturing processes and ERP systems allows them to swiftly respond to market demands, fostering growth and competitiveness in the industry. However, it’s crucial to keep in mind that 50% of ERP implementations face initial hurdles. This highlights the importance of careful planning and execution.

As industry analyst Robert Poe puts it, "Mastering your value chain is more than cost discipline — it’s a competitive edge." This really emphasizes the critical role effective ERP integration plays in achieving operational excellence. Have you considered how this could apply to your operations?

Common Challenges in BOM Management: Strategies for Overcoming Implementation Hurdles

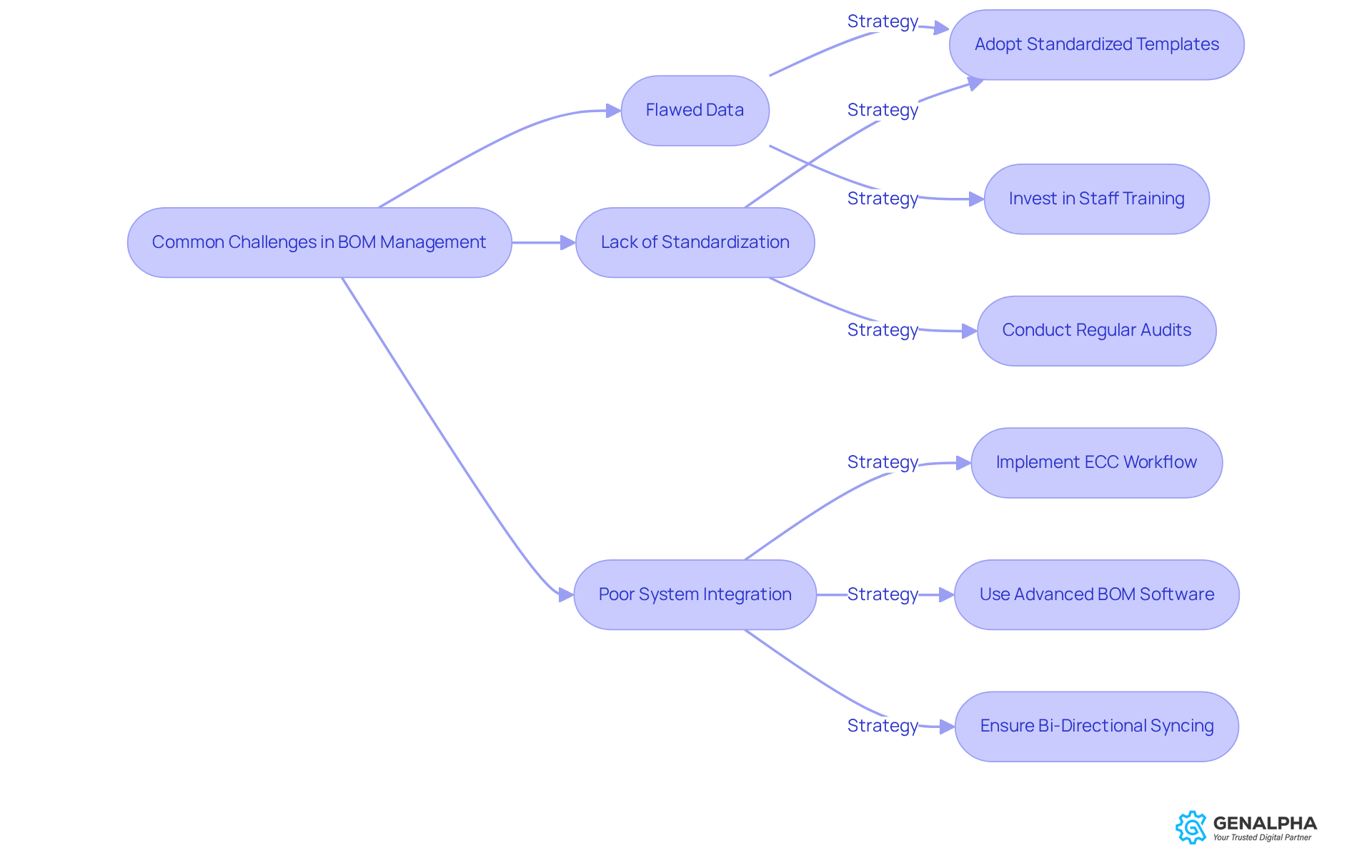

BOM oversight can be a bit of a headache, right? You know, dealing with flawed data, lack of standardization, and systems that just don’t play nice together. So, what can manufacturers do to tackle these challenges? One effective approach is to adopt standardized templates for BOM manufacturing. This not only streamlines data entry but also boosts accuracy across different departments. Plus, regular audits are a must! They help ensure that BOMs stay current and reflect any changes in materials or processes. And let's not forget about training—investing in staff education on BOM best practices fosters a culture of precision and responsibility.

Now, let’s talk about the importance of a formal engineering change control (ECC) workflow. It’s essential for tracking and approving changes before they go live. This way, all modifications are documented and authorized, keeping everything above board. And when it comes to cloud-based BOM systems, role-based access is key. It upholds data integrity and prevents unauthorized changes, which is crucial for accurate BOM oversight.

Have you heard about advanced BOM management software? It’s a game-changer for automating processes and enhancing data integrity. For example, cloud-based systems allow real-time collaboration among engineering, procurement, and manufacturing teams. This means everyone has access to the latest information, which minimizes errors and boosts operational efficiency. Plus, with bi-directional syncing to ERP and PLM systems, changes in one platform are reflected across all relevant systems.

Manufacturers who have standardized their processes for BOM manufacturing often see a significant uptick in data accuracy and operational efficiency. By implementing strategies like built-in validation in BOM software to prevent incorrect data entry and utilizing Super BOMs for configurable products, organizations can overcome common BOM hurdles. This leads to smoother production operations and cuts down on costs associated with errors and delays.

So, what steps will you take to enhance your BOM oversight?

Conclusion

Understanding the ins and outs of Bill of Materials (BOM) manufacturing is crucial for any manufacturer looking to optimize their production processes. Think about it—effective BOM management can really make a difference. Tools like GenAlpha Technologies' Equip360 can streamline operations significantly. By leveraging technology and embracing best practices, manufacturers can ensure their BOMs are not just accurate but also boost overall efficiency and cost management.

Throughout this discussion, we’ve touched on some key points. We explored the differences between Engineering BOMs and Manufacturing BOMs, what essential components every BOM should include, and the various types of BOMs available. Remember, keeping accuracy through regular reviews and updates is vital, as is integrating BOMs with ERP systems. These strategies can help minimize errors, enhance communication, and ultimately elevate productivity in manufacturing environments.

So, what’s the takeaway? The importance of a well-managed BOM cannot be overstated. By embracing these insights and putting the recommended strategies into action, manufacturers can navigate the complexities of production more effectively. The goal should be fostering an agile and responsive manufacturing process that meets market demands while positioning companies for long-term success in a competitive landscape. Taking proactive steps towards optimizing BOM management today can lead to substantial improvements in operational efficiency and overall profitability down the line.

Frequently Asked Questions

What is Equip360 and what does it offer?

Equip360 is a comprehensive B2B eCommerce platform developed by GenAlpha Technologies for manufacturers and distributors. It streamlines BOM (Bill of Materials) management by providing interactive 2D/3D catalogs, enhancing accuracy, and improving sales through better BOM manufacturing.

How does Equip360 integrate with existing systems?

Equip360 seamlessly integrates with current ERP (Enterprise Resource Planning) systems, ensuring that data related to BOM manufacturing is always up-to-date and readily available for efficient planning and inventory management.

What are the key differences between Engineering BOM (EBOM) and Manufacturing BOM (MBOM)?

The Engineering BOM (EBOM) focuses on the design and specifications of a product, detailing the components and materials needed for development. In contrast, the Manufacturing BOM (MBOM) is tailored for the manufacturing process, outlining the parts and assemblies necessary for production.

Why is it important to understand the differences between EBOM and MBOM?

Understanding the differences between EBOM and MBOM helps manufacturers optimize their workflows in BOM manufacturing, minimizing errors and boosting productivity by having the right information readily available.

What essential components should be included in a Bill of Materials (BOM)?

A solid BOM should include part numbers, detailed descriptions, quantities, units of measure, specific specifications for each item, comprehensive assembly instructions, and relevant documentation like drawings or manuals.

What are the consequences of having an incomplete BOM?

Incomplete BOMs can lead to significant production errors. A well-structured BOM can reduce waste by up to 30% and boost efficiency, emphasizing the importance of meticulous documentation in BOM management.

What is the significance of meticulous documentation in BOM manufacturing?

Meticulous documentation in BOM manufacturing ensures that all parties involved have access to vital information, which optimizes workflow processes and minimizes production errors.