Introduction

Digital transformation is shaking things up in industrial manufacturing, bringing in a fresh wave of efficiency and innovation. As manufacturers look to boost their operations, integrating advanced technologies offers a fantastic chance to streamline processes, cut costs, and ramp up productivity. But here’s the big question: how can companies navigate this digital shift to not just survive but truly thrive in such a competitive market?

Let’s dive into the key benefits of digital transformation. By exploring these insights, manufacturers can feel empowered to embrace change and tap into their full potential. So, are you ready to see how this transformation can make a real difference?

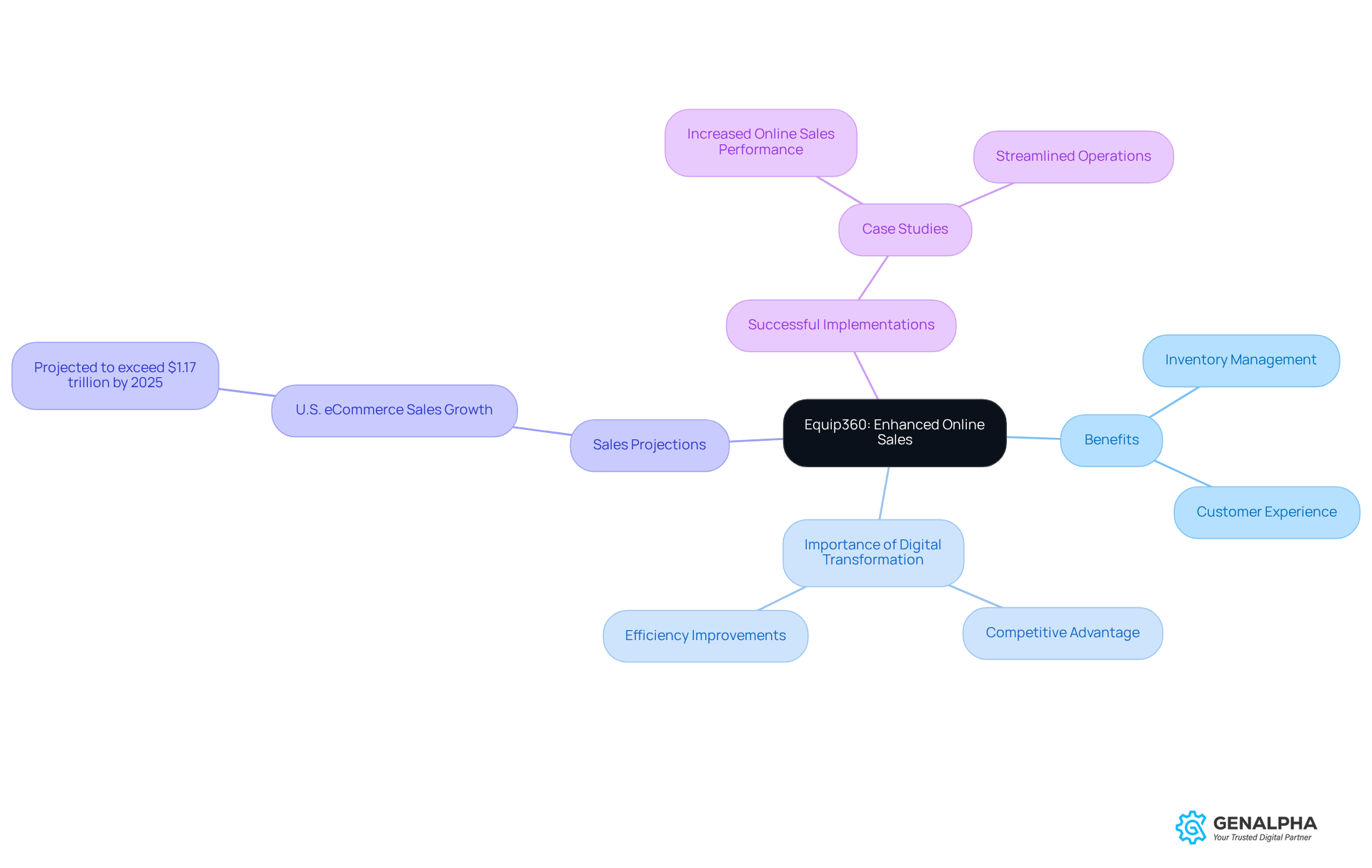

GenAlpha Technologies: Enhanced Online Sales Capabilities

GenAlpha Technologies is here to help producers and distributors step up their online sales game with a wide range of eCommerce solutions. Their standout product, Equip360, really takes inventory management to the next level and boosts digital sales performance, making it easier for businesses to provide a smooth purchasing experience. By integrating these solutions with existing ERP systems, companies can streamline their operations and keep customers happy.

Now, why is digital transformation in industrial manufacturing so important? Well, producers who embrace advanced eCommerce tools are set to see some serious growth. In fact, U.S. eCommerce sales are expected to soar past $1.17 trillion by the end of 2025! Industry leaders are stressing that adopting these innovative solutions is key to staying competitive in today’s fast-paced marketplace.

Successful implementations of Equip360 have shown real improvements in online sales performance, proving just how effective it can be in driving growth and efficiency as part of the digital transformation in industrial manufacturing. So, if you’re looking to enhance your business, why not consider Equip360? It might just be the game-changer you need!

Increased Manufacturing Efficiency: Streamlining Operations

Producers looking to boost their operational efficiency are finding that digital transformation in industrial manufacturing is a game changer. Imagine having the power to automate processes and access real-time data at your fingertips! By tapping into technologies like the Internet of Things (IoT) and artificial intelligence (AI), companies can keep a close eye on production, quickly spot any bottlenecks, and fine-tune their workflows. This proactive approach can really cut down on downtime, letting producers respond to market demands faster and ramp up productivity.

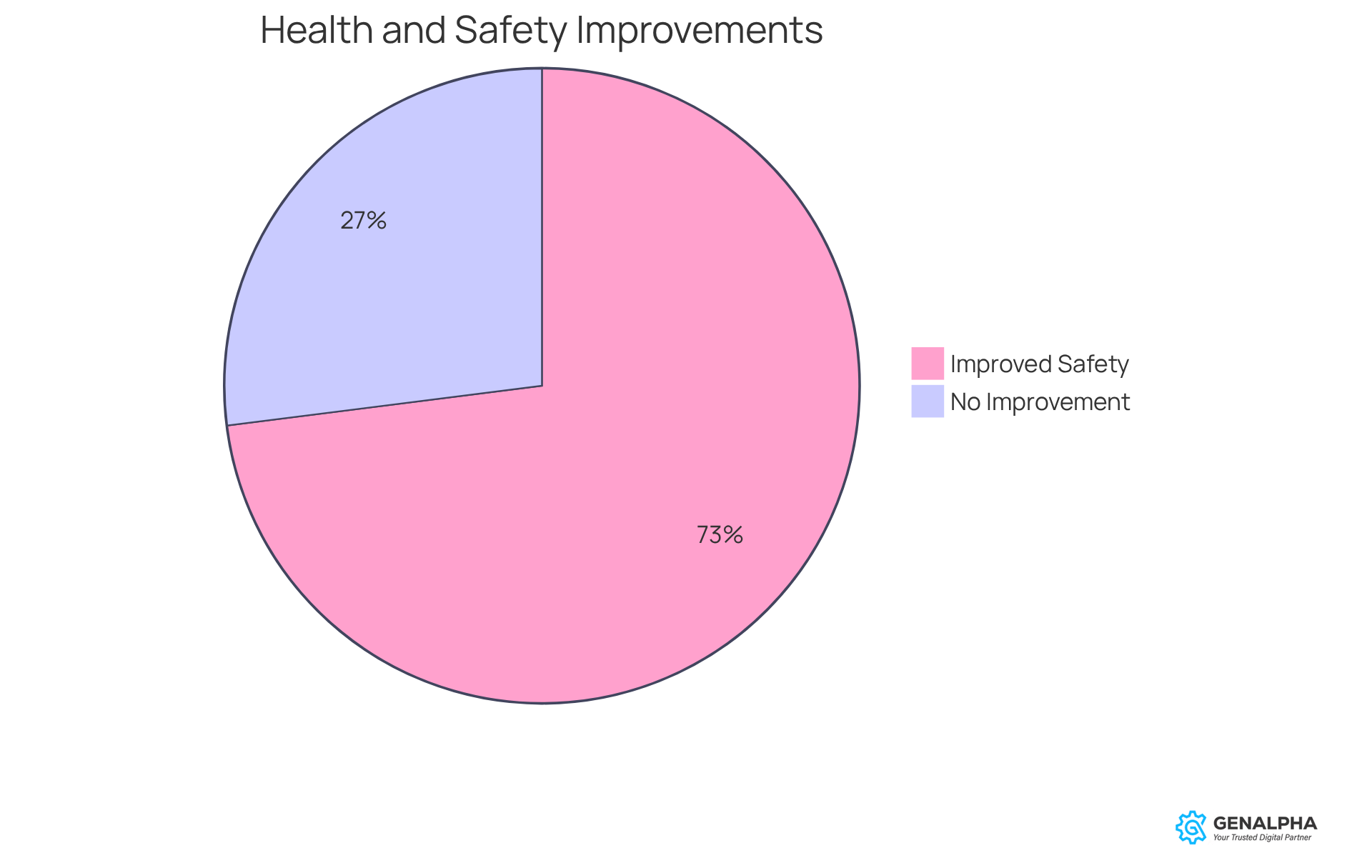

For example, a recent case study showed that:

- 73% of companies in the energy sector saw improvements in health and safety.

- Companies experienced reduced downtime after they rolled out IoT solutions.

Pretty impressive, right? Plus, with smart robots powered by AI, data analysis and decision-making on the assembly line can happen autonomously, making operations even smoother.

As Jeff Bezos puts it, agility is the only lasting advantage in today’s unpredictable world. This really underscores why it’s crucial for producers to embrace digital transformation in industrial manufacturing if they want to stay competitive. So, what do you think? Are you ready to take the leap into the digital age?

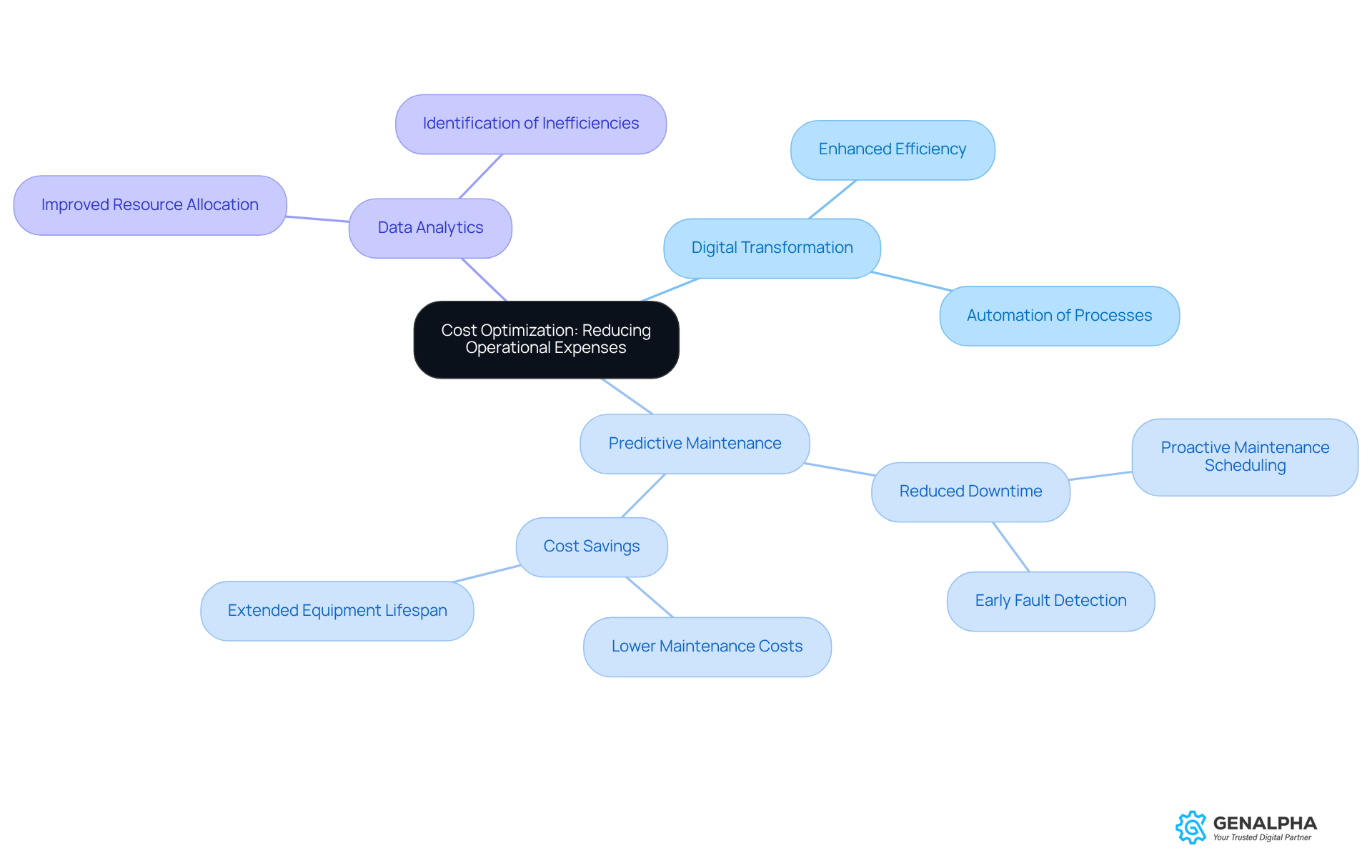

Cost Optimization: Reducing Operational Expenses

Have you ever thought about how digital transformation can really help businesses save money? It’s all about automating those tedious manual processes and cutting down on waste. For instance, technologies like predictive maintenance can help producers spot potential equipment failures before they happen, which means less costly downtime.

Additionally, data analytics can shine a light on inefficiencies in supply chains. This insight allows for better resource allocation and, ultimately, lower costs. Imagine being able to reduce expenses while still keeping those high-quality standards intact!

By embracing these technologies, producers can achieve significant cost reductions. So, why not take the plunge and explore how digital transformation can work for you?

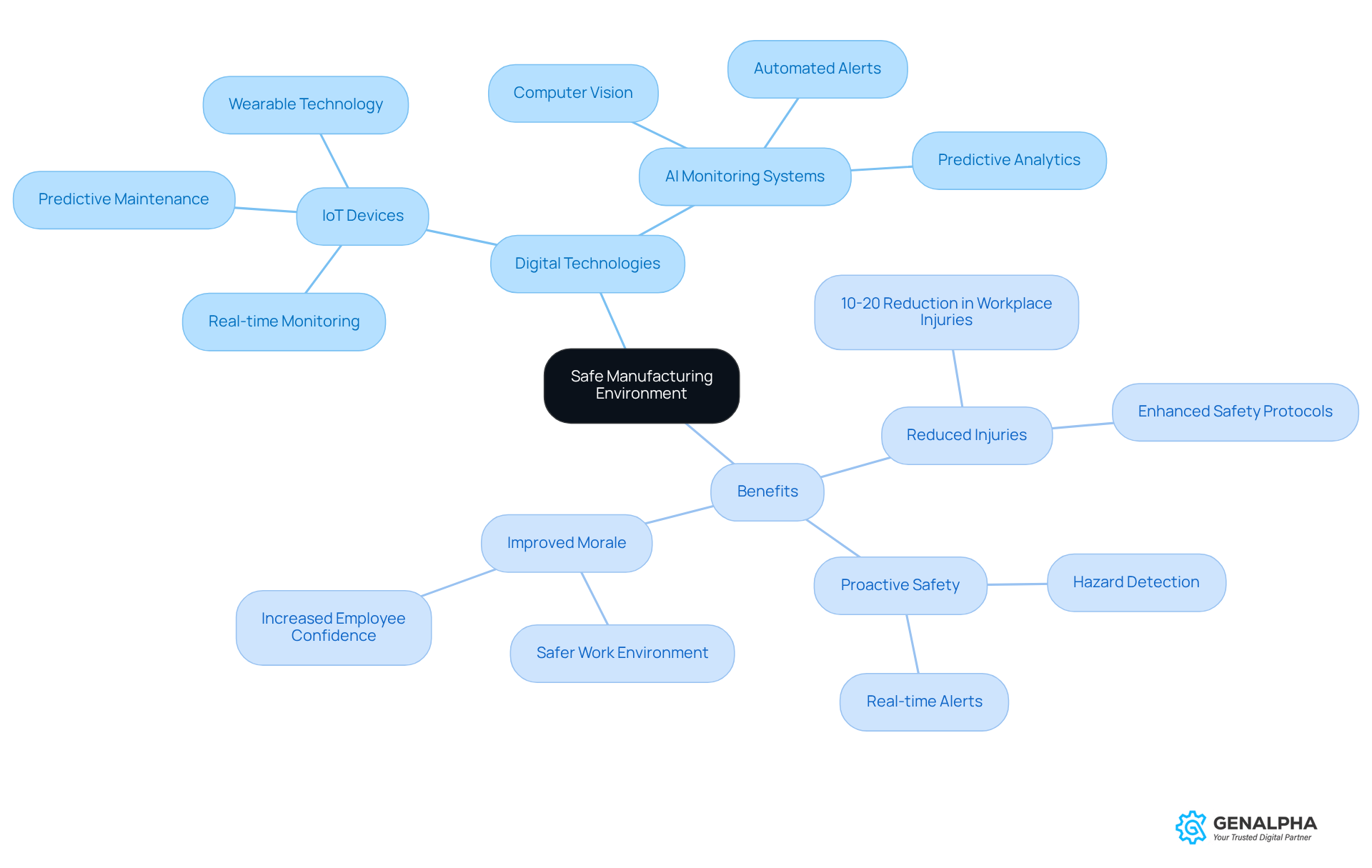

Safe Manufacturing Environment: Enhancing Worker Safety

Digital technologies play a crucial role in boosting worker safety in manufacturing settings. Have you ever thought about how IoT devices and AI monitoring systems can change the game? They allow for real-time tracking of safety protocols and help spot hazards before they become a problem. For example, IoT-connected sensors can keep an eye on air quality and machine performance, alerting workers to potential risks and promoting a proactive safety approach.

According to a Deloitte report, companies that have embraced IoT for worker safety have seen a 10-20% drop in workplace injuries. That really highlights how effective these technologies can be! Plus, AI-powered predictive analytics can pinpoint leading indicators for safety decisions, which boosts overall operational efficiency.

By fostering a culture of safety through these digital solutions, manufacturers can drive digital transformation in industrial manufacturing, which not only cuts down on accidents but also lifts employee morale. It’s all about creating a safer and more productive work environment. So, how can we start implementing these technologies in our own workplaces?

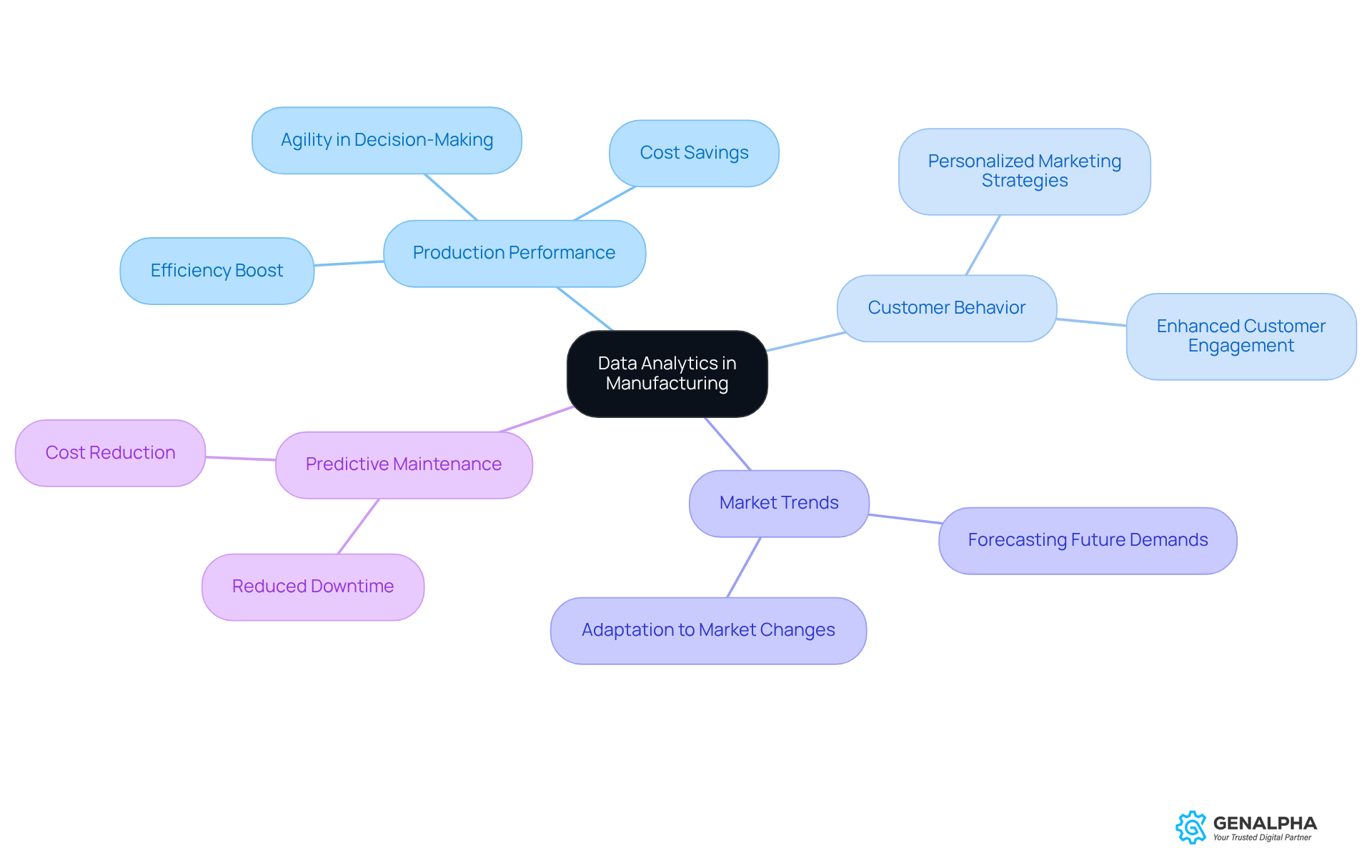

Enhanced Decision-Making Processes: Leveraging Data Analytics

Data analytics is shaking things up in the manufacturing world! It’s all about making smart decisions based on insights into production performance, customer behavior, and market trends. With advanced analytics tools, manufacturers can dig through huge datasets to find patterns that help with strategic planning and flexibility. For instance, did you know that predictive maintenance analytics can cut service costs by up to 23%? That’s a clear example of how data-driven insights can lead to significant savings and boost efficiency, ultimately enhancing overall performance.

Industry analysts are buzzing about how organizations that tap into data insights are in a better spot to handle market changes. Doug Tull, a technical writer, puts it nicely: "By leveraging and understanding accurate and relevant data, organizations can make agile, responsive, optimal, and informed decisions, reduce risks and losses, and enhance operational efficiency." Plus, the integration of analytics with IoT devices is expected to generate a whopping 79.4 zettabytes of data by 2025! This opens up incredible opportunities for producers to refine their strategic planning processes. Just think about it - this data explosion will let producers harness insights that drive innovation and boost operational performance.

By embracing advanced analytics tools, producers can not only forecast future demands but also adapt swiftly to changing customer needs. This agility is crucial for staying ahead in a fast-paced marketplace. It’s all about fostering innovation and enhancing production performance, which ultimately leads to sustainable growth. So, are you ready to dive into the world of data analytics and see how it can transform your operations?

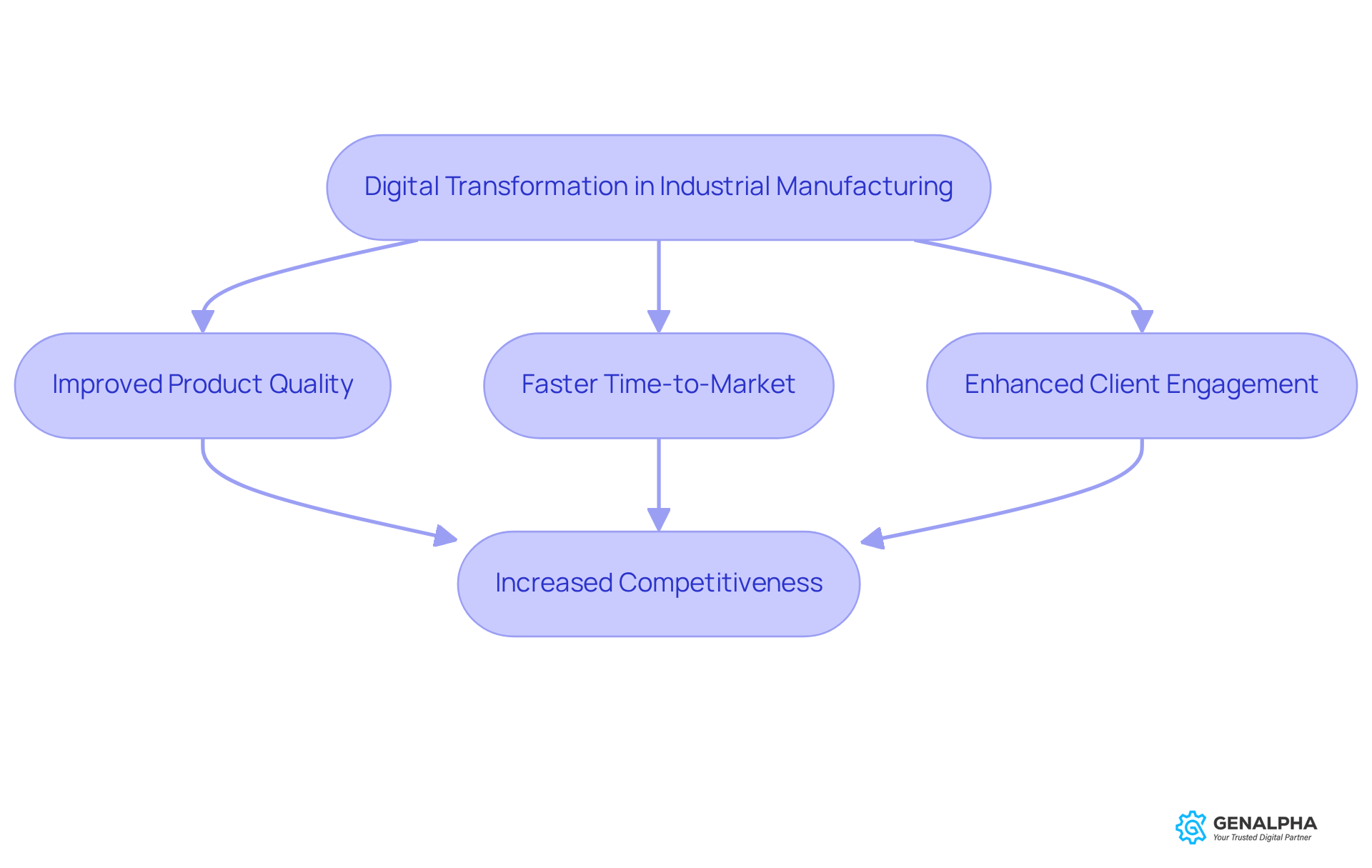

Competitiveness: Staying Ahead in the Market

Digital transformation in industrial manufacturing is a game changer for producers looking to stay competitive in a fast-paced market. Have you ever thought about how adopting innovative technologies can really make a difference? Companies that embrace these tools can see a big boost in product quality, speed up their time-to-market, and enhance client engagement.

For example, producers using automated assembly tools have reported impressive gains in efficiency and product reliability. In fact, some have seen a 20% increase in their optimal batch production daily volume! This isn’t just about numbers; these advancements attract new clients and build loyalty among existing ones, solidifying producers' positions as leaders in their fields.

As industry experts emphasize, the digital transformation in industrial manufacturing requires integrating digital solutions, which is essential for achieving operational excellence and meeting evolving client expectations. So, what are you waiting for? It’s time to consider how the digital transformation in industrial manufacturing can elevate your business!

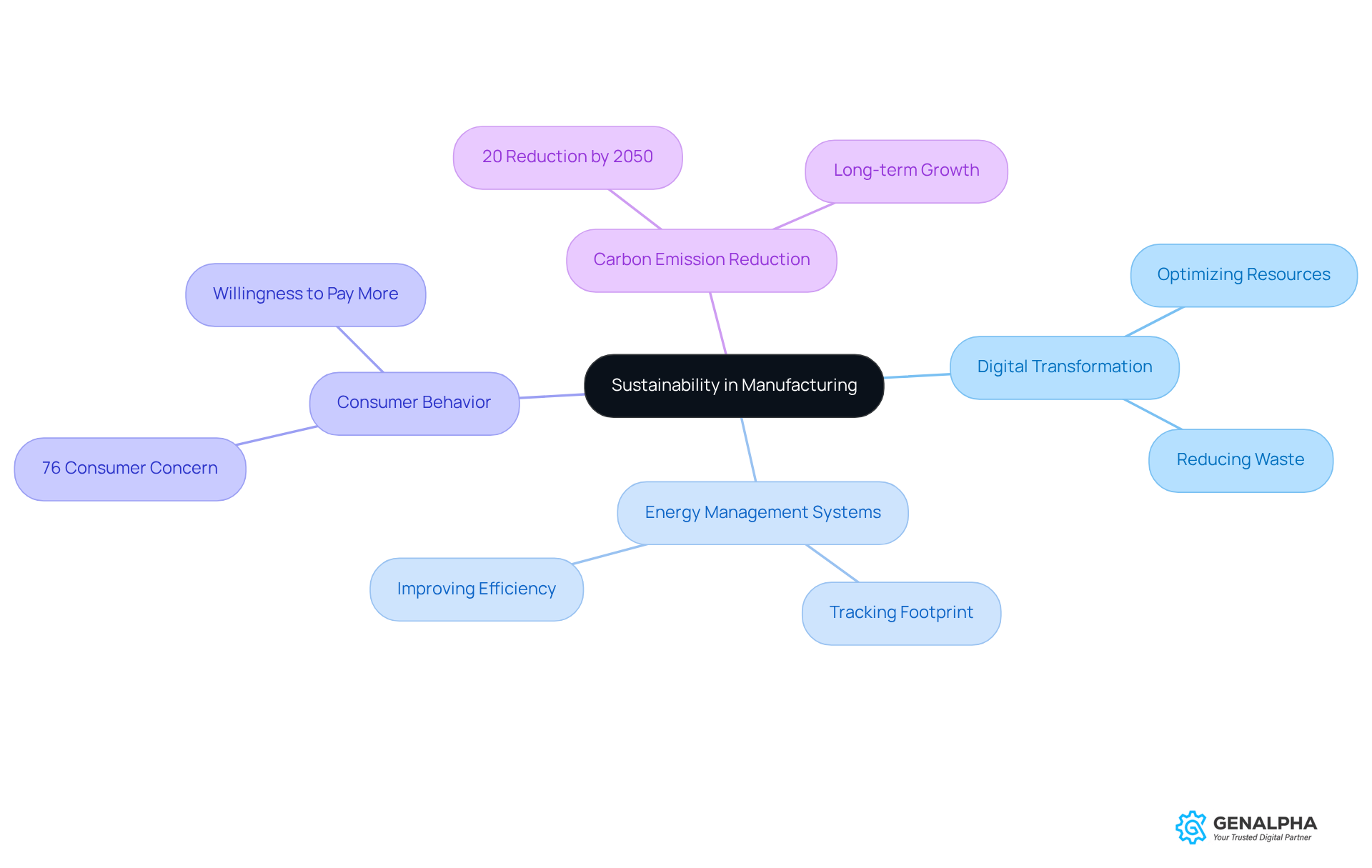

Sustainability: Adopting Greener Manufacturing Practices

Sustainability is becoming a big deal in manufacturing these days, right? Companies are really stepping up to reduce their environmental impact. And guess what? The shift is a game changer due to the digital transformation in industrial manufacturing! It helps producers optimize how they use resources and cut down on waste.

Take energy management systems, for example. These nifty tools let businesses keep an eye on their energy consumption and spot areas where they can do better. Not only do they track the environmental footprint, but they also help in adopting sustainable supply chain solutions that fit into broader sustainability goals.

So, what’s in it for producers? Well, improving their brand image and building customer loyalty is a huge perk. Research shows that a whopping 76% of consumers would stop buying from companies that ignore environmental practices crucial for digital transformation in industrial manufacturing. Plus, American shoppers are willing to spend about 12% more on sustainably made products. How cool is that?

And here’s something to think about: industry experts believe that the digital transformation in industrial manufacturing could lead to a significant drop in carbon emissions - up to 20% by 2050! As Greta Thunberg puts it, "Everyone needs to take their moral responsibility… to make a change."

This commitment to greener practices not only meets what consumers want but also positions producers as leaders in sustainability. It’s a win-win that drives long-term growth and resilience in a competitive marketplace. So, what steps can we take today to be part of this positive change?

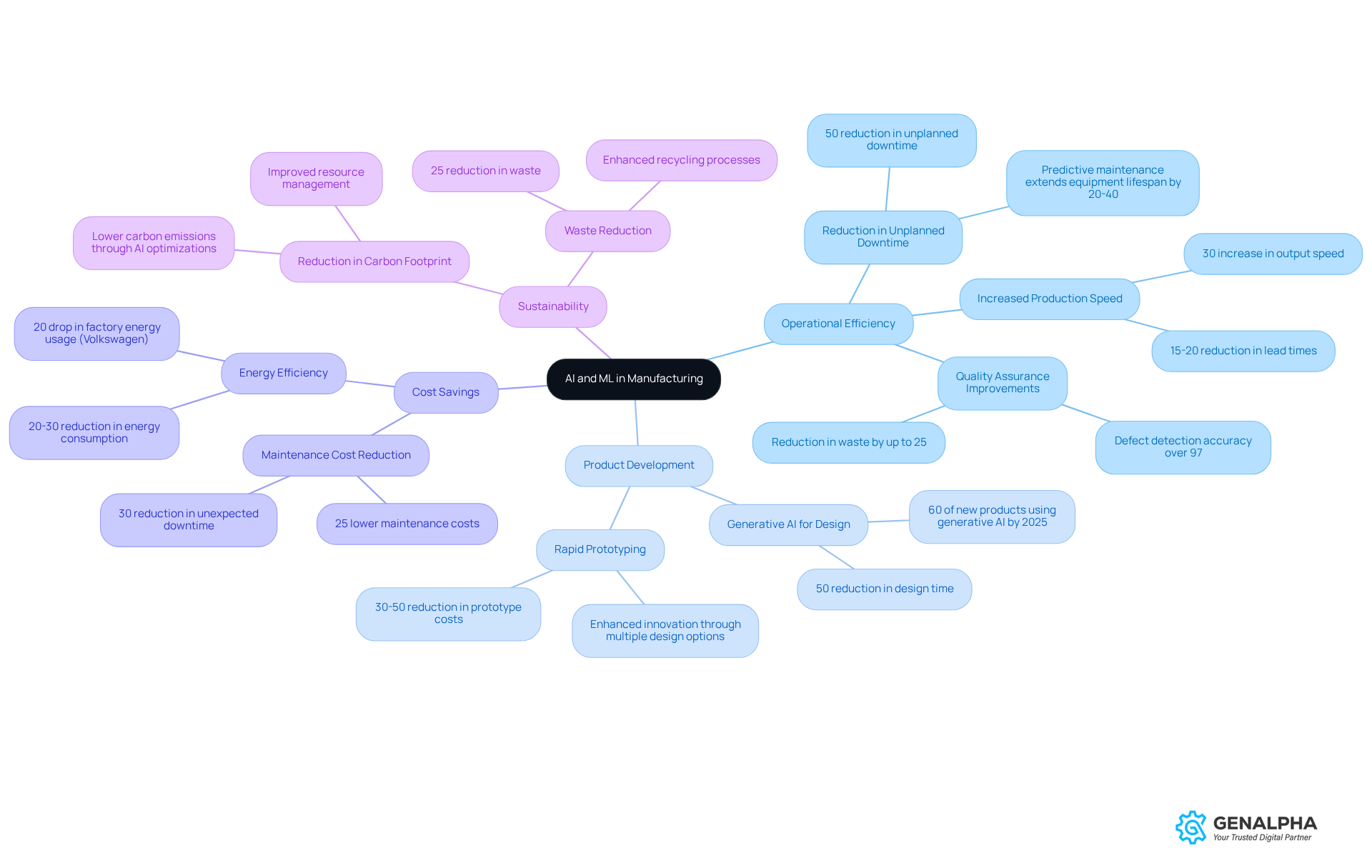

Artificial Intelligence and Machine Learning: Driving Innovation

Artificial intelligence (AI) and machine learning (ML) are shaking things up in the manufacturing world, making operations smarter and sparking innovative product development. Imagine being able to analyze data in real-time-this is what these technologies bring to the table, significantly improving processes and boosting quality assurance. For example, AI-driven predictive maintenance can cut unplanned downtime by up to 50%, extend equipment lifespan by 20-40%, and save a ton on maintenance costs.

Leading companies are already tapping into AI for production optimization. Take Volkswagen, for instance; they’ve seen over a 20% drop in factory energy usage thanks to AI enhancements. This shows just how much potential there is for efficiency and sustainability. Plus, AI is making waves in supply chain management, with 41% of manufacturers using it to handle supply chain data effectively. And let’s not forget-AI can slash forecasting errors by 50%, which really amps up operational efficiency.

The impact of AI on operational efficiency is nothing short of remarkable. Machine learning algorithms can ramp up output speed by as much as 30%, while AI-driven quality assurance systems can boost defect detection precision to over 97%. That’s a big leap from the 60-70% accuracy we see with manual inspections. This kind of precision not only cuts down on waste but also ensures that products meet top-notch quality standards, ultimately leading to happier customers.

As the manufacturing landscape continues to evolve, real-time data analysis will be crucial for optimizing processes. By 2025, it’s expected that over 60% of new product launches will use generative AI for design and concept creation. This trend highlights how reliant the industry is becoming on AI technologies. The global AI market in manufacturing is projected to hit $20.8 billion by 2028, which really underscores the importance of adopting AI. The future of manufacturing is clearly linked with AI and ML, paving the way for innovation and growth in a competitive marketplace. So, how are you planning to embrace these changes?

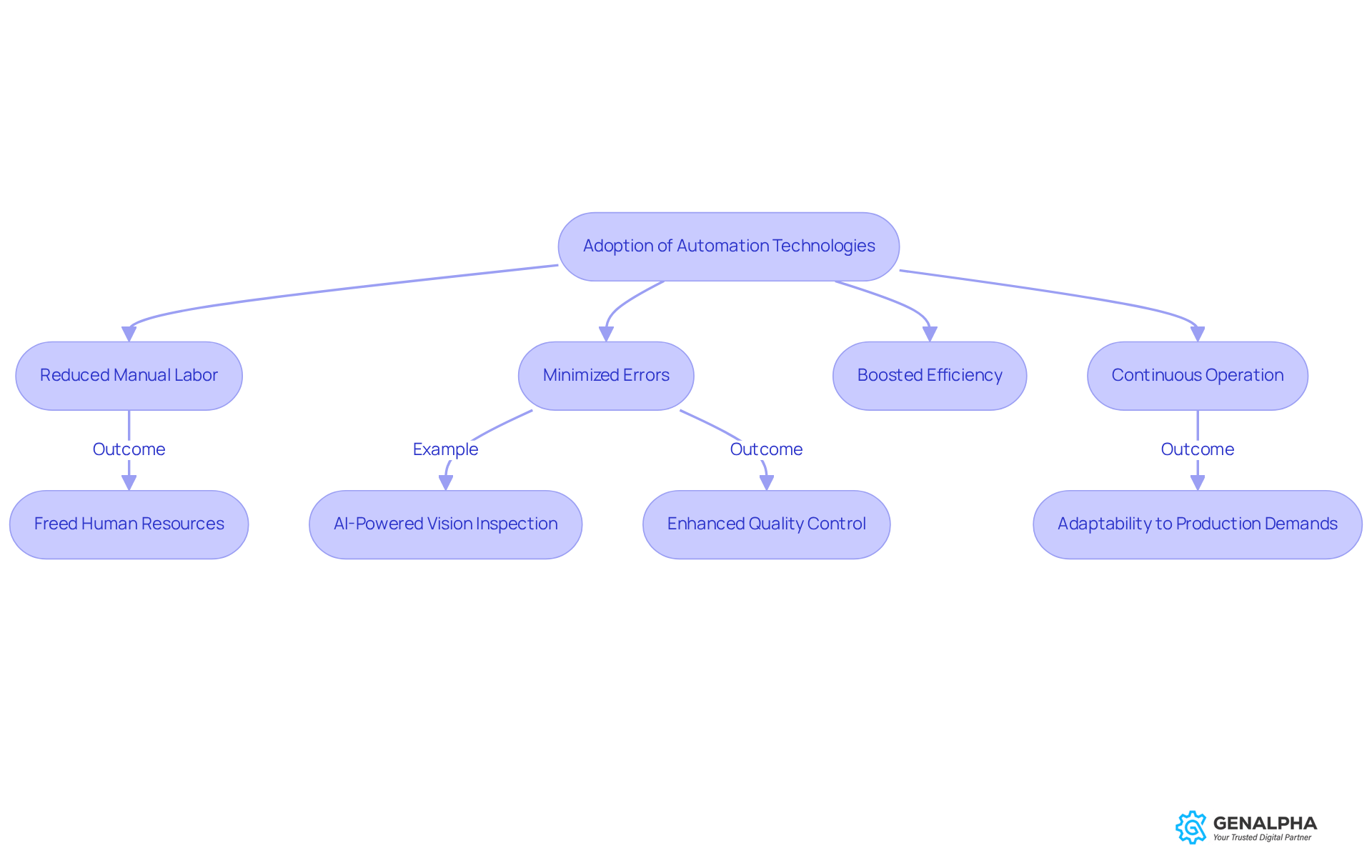

Automation Technologies: Streamlining Production Processes

Automation technologies are super important for facilitating digital transformation in industrial manufacturing. Have you ever thought about how adopting robotics and automated systems can really cut down on manual labor? Not only that, but they also help minimize errors and boost efficiency. These advanced technologies allow for continuous operation and can quickly adapt to shifting production demands, making sure manufacturers meet client expectations every time.

For example, AI-powered vision inspection systems can analyze products with incredible accuracy in just milliseconds. This drastically improves quality control and reduces the need for manual inspections. Plus, integrating automation doesn’t just ramp up productivity; it frees up human resources too! This means employees can focus on more strategic and value-added tasks.

As industry experts point out, the digital transformation in industrial manufacturing through effectively applying automation really magnifies operational efficiency. This positions companies to thrive in a competitive landscape. So, what do you think? Isn’t it exciting to see how automation can reshape the future of manufacturing?

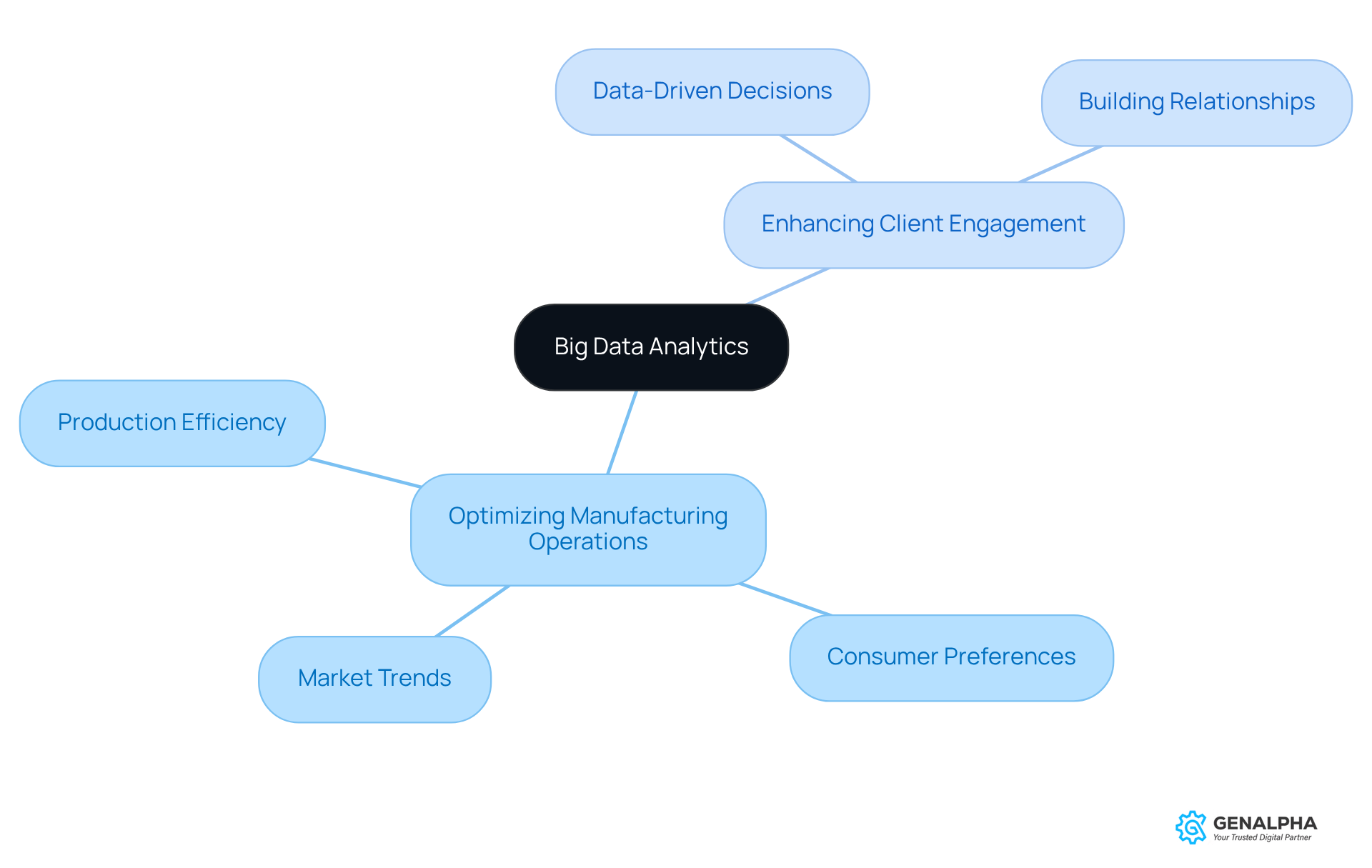

Big Data and Analytics: Optimizing Operations and Engagement

Big data analytics is a game changer when it comes to optimizing manufacturing operations and connecting with clients. Have you ever wondered how manufacturers figure out what works best? By diving into large datasets, they uncover insights about production efficiency, consumer preferences, and market trends. This kind of information empowers companies to make smart, data-driven decisions that not only boost their operational performance but also tailor their offerings to meet client needs.

Imagine being able to enhance efficiency while building stronger relationships with customers. That’s the power of leveraging big data! It’s not just about crunching numbers; it’s about driving long-term success through meaningful connections. So, how can your business tap into this potential? Let's explore the possibilities together!

Conclusion

Digital transformation is a game changer for industrial manufacturing, isn’t it? It’s not just about keeping up; it’s about fundamentally reshaping how businesses operate and compete. By embracing advanced technologies, manufacturers can boost their efficiency, cut costs, and enhance safety - all while driving innovation and sustainability. Think about it: integrating digital tools streamlines operations and helps companies respond quickly to changing market demands, keeping them competitive in a fast-paced world.

As we dive into digital transformation, some key benefits really stand out. We’re talking about:

- Improved online sales capabilities

- Enhanced manufacturing efficiency through automation and data analytics

- Cost savings

- A strong commitment to sustainability

Companies that harness technologies like AI, IoT, and big data analytics are seeing real improvements in productivity and decision-making. Plus, focusing on worker safety and environmental responsibility is crucial for maintaining a positive brand image and customer loyalty.

Looking ahead, the importance of digital transformation is crystal clear. It’s not just a passing trend; it’s a vital strategy for long-term growth and resilience. Organizations need to actively implement these transformative practices if they want to thrive in the future. So, what’s the takeaway? Let’s embrace digital transformation today and unlock the potential for innovation, efficiency, and sustainability in industrial manufacturing!

Frequently Asked Questions

What is GenAlpha Technologies and what do they offer?

GenAlpha Technologies provides a range of eCommerce solutions aimed at enhancing online sales capabilities for producers and distributors. Their key product, Equip360, focuses on improving inventory management and boosting digital sales performance.

How does Equip360 benefit businesses?

Equip360 enhances inventory management and streamlines operations by integrating with existing ERP systems, which helps businesses provide a smoother purchasing experience and improve customer satisfaction.

Why is digital transformation important in industrial manufacturing?

Digital transformation is crucial as it enables producers to adopt advanced eCommerce tools, leading to significant growth. U.S. eCommerce sales are projected to exceed $1.17 trillion by 2025, making it essential for companies to stay competitive in a fast-paced marketplace.

What results have been observed from implementing Equip360?

Successful implementations of Equip360 have shown real improvements in online sales performance, driving growth and efficiency as part of the digital transformation in industrial manufacturing.

How can digital transformation increase manufacturing efficiency?

Digital transformation allows for the automation of processes and access to real-time data, which helps producers monitor production, identify bottlenecks, and optimize workflows, ultimately reducing downtime and increasing productivity.

What technologies contribute to increased manufacturing efficiency?

Technologies such as the Internet of Things (IoT) and artificial intelligence (AI) are key contributors, enabling companies to enhance operational monitoring and automate decision-making processes on the assembly line.

What are the benefits of predictive maintenance in cost optimization?

Predictive maintenance helps producers identify potential equipment failures before they occur, reducing costly downtime and enabling better resource allocation, which leads to significant cost savings.

How can data analytics assist in cost optimization?

Data analytics can identify inefficiencies in supply chains, allowing businesses to improve resource allocation and reduce operational expenses while maintaining high-quality standards.