Introduction

In the fast-paced world of manufacturing, have you ever felt like you're navigating a labyrinth when it comes to the quoting process? It can be overwhelming! But here’s the good news: with the right strategies and tools - like Equip360 - you can streamline this critical workflow, boosting both efficiency and accuracy.

This article dives into ten essential tips that not only simplify quoting but also elevate your overall performance. So, what happens when traditional methods clash with the need for speed and precision? Exploring these insights could be the key to unlocking a new era of quoting success in manufacturing. Ready to find out more?

GenAlpha Technologies: Streamline Your Quoting Process with Equip360

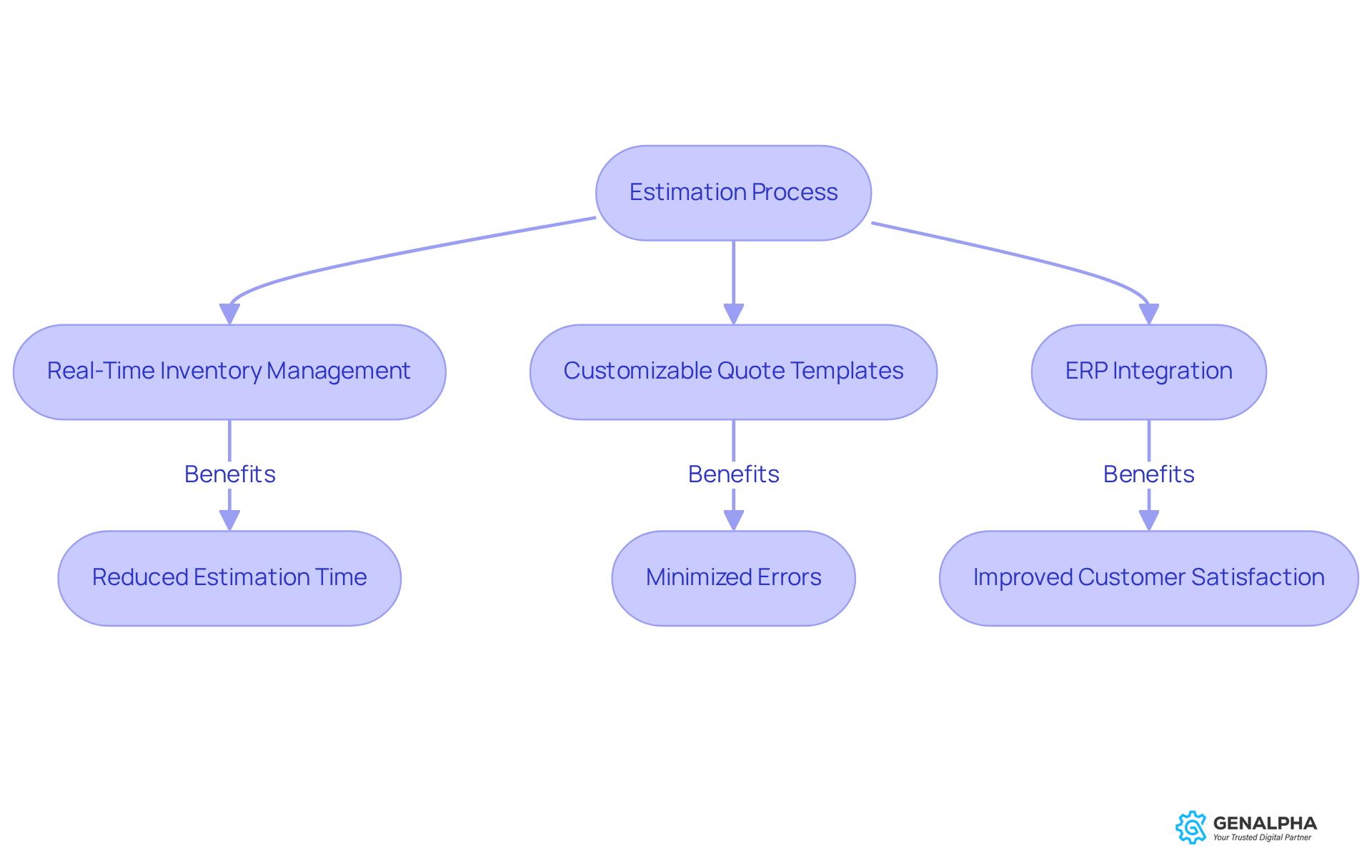

Have you ever felt overwhelmed by the estimation process? Well, Equip360 is here to change that! This platform is designed for quoting cpq to simplify the estimation workflow for manufacturers and distributors by automating essential tasks. Imagine having real-time inventory management, customizable quote templates, and seamless integration with your existing ERP systems - all in one place.

By quoting cpq with Equip360, businesses can cut down on estimation time significantly. Who wouldn’t want to minimize errors and boost customer satisfaction with quicker response times? This platform not only streamlines the estimation procedure but also enhances quoting cpq by providing analytics to monitor performance and identify areas for improvement.

So, why not give Equip360 a try? It’s time to make your estimation process smoother and more efficient!

Understand the CPQ Process: Key Steps for Effective Quoting

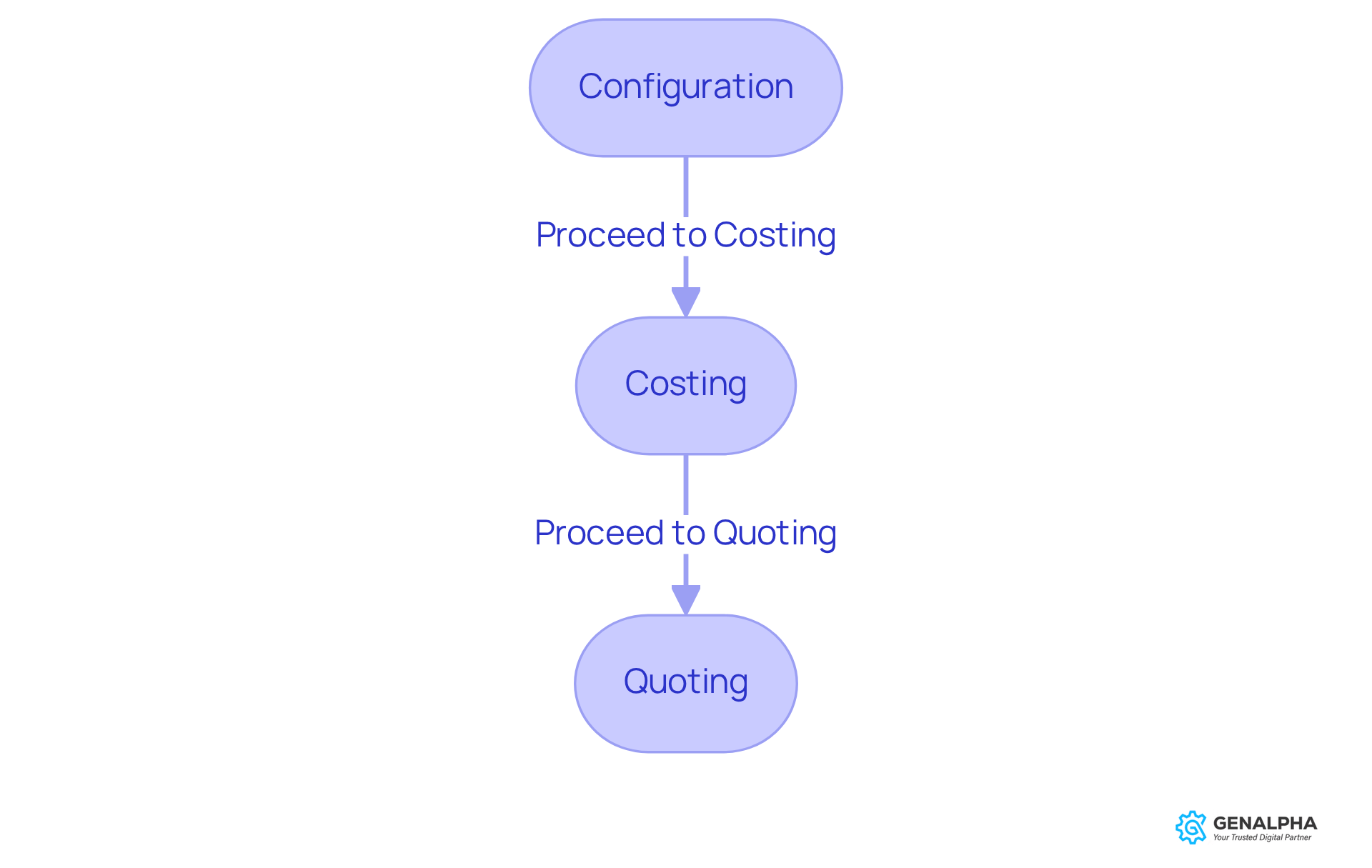

The Configure Price Quote (CPQ) procedure is a game changer for manufacturers, and it boils down to three key steps: configuration, pricing, and quoting CPQ.

-

Configuration: Think of this as the starting line. Here, you select the right products and options that fit your customer’s needs. With CPQ software in your corner, you can make this process a breeze, ensuring the right configurations are picked quickly and accurately.

-

Costing: Now that you’ve got your configurations set, it’s time to tackle costs. This step is all about applying the right cost regulations and discounts to stay competitive. The cool part? CPQ solutions can automate this, cutting down the time spent on cost determination by up to 73% compared to traditional methods. That’s some serious operational savings!

-

Quoting: Finally, we get to the fun part-generating a formal quote that wraps up all those configurations and pricing details. With CPQ software, quoting CPQ can reduce the time for quote generation from weeks to just minutes, boosting productivity and keeping your clients happy. In fact, organizations using CPQ solutions have seen a 28% reduction in sales cycle length and a whopping 49% increase in proposal volume.

Understanding these steps is crucial for manufacturers looking to level up their pricing processes. The best strategies focus on ensuring data accuracy while keeping customer needs front and center during the configuration and pricing phases. Industry leaders agree that effective pricing strategies not only enhance accuracy but also supercharge overall sales performance. So, if you’re in the manufacturing game, embracing CPQ is a must to stay ahead in this competitive landscape.

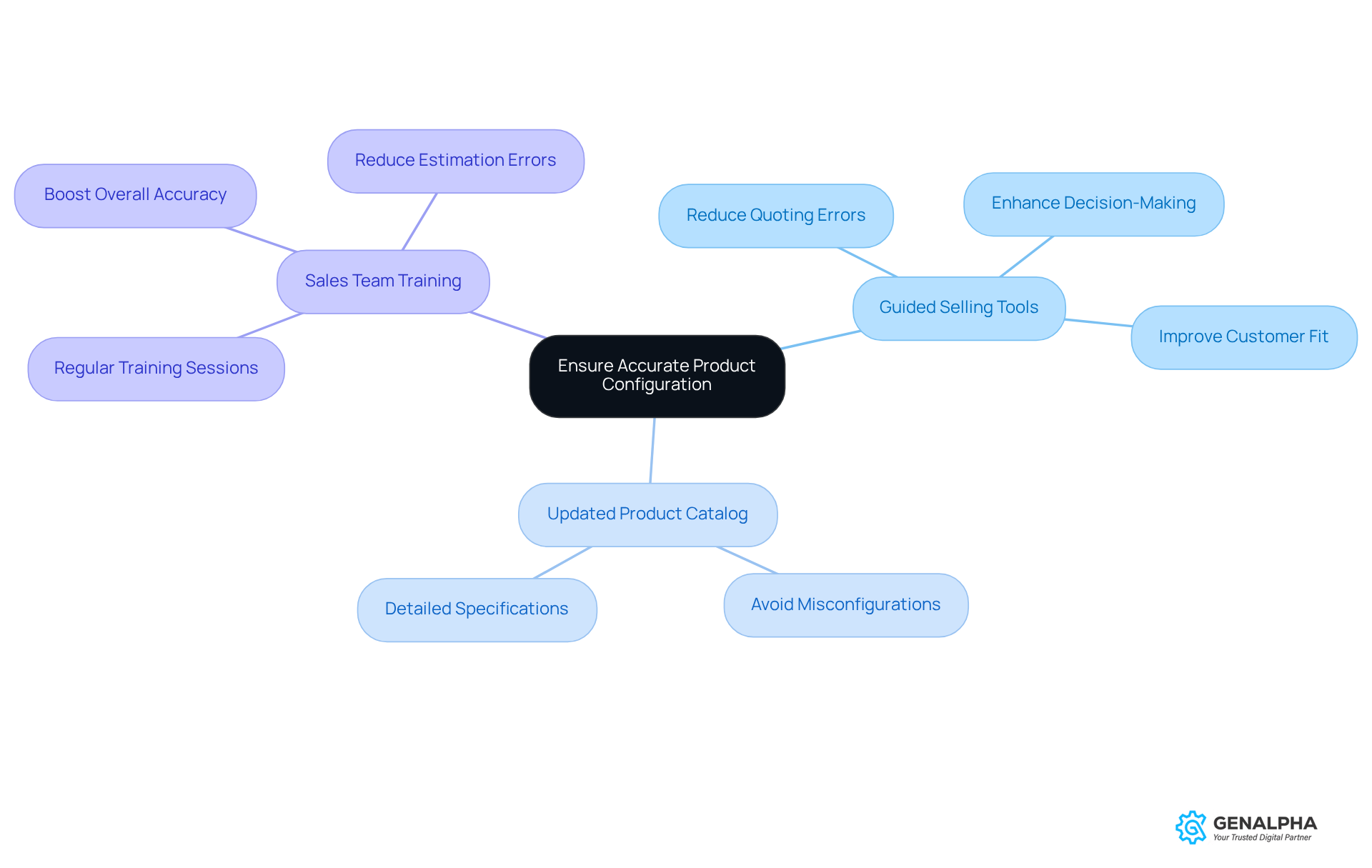

Ensure Accurate Product Configuration: Avoid Common Quoting Errors

Want to nail your product configuration? Manufacturers should really consider quoting cpq by using guided selling tools. These tools help sales teams in quoting cpq to choose the best options that perfectly fit customer needs. Did you know that a recent survey found that 88% of participants lost deals due to slow estimate generation and approval? That’s a big deal! It shows just how important quoting cpq is for improving estimation methods.

These tools make decision-making a breeze by quoting cpq, which helps in cutting down on mistakes. Plus, keeping your product catalog updated with detailed specs is key to avoiding misconfigurations. And let’s not forget about training! Regular sessions for sales teams on product features and configurations can really make a difference. They not only help reduce estimation errors but also boost overall accuracy.

As Derek Knudsen wisely said, "In enterprise sales, value isn’t realized through features - it’s realized through outcomes." By focusing on these strategies, manufacturers can seriously up their estimation game and keep customers happy. So, what are you waiting for? Let’s get started!

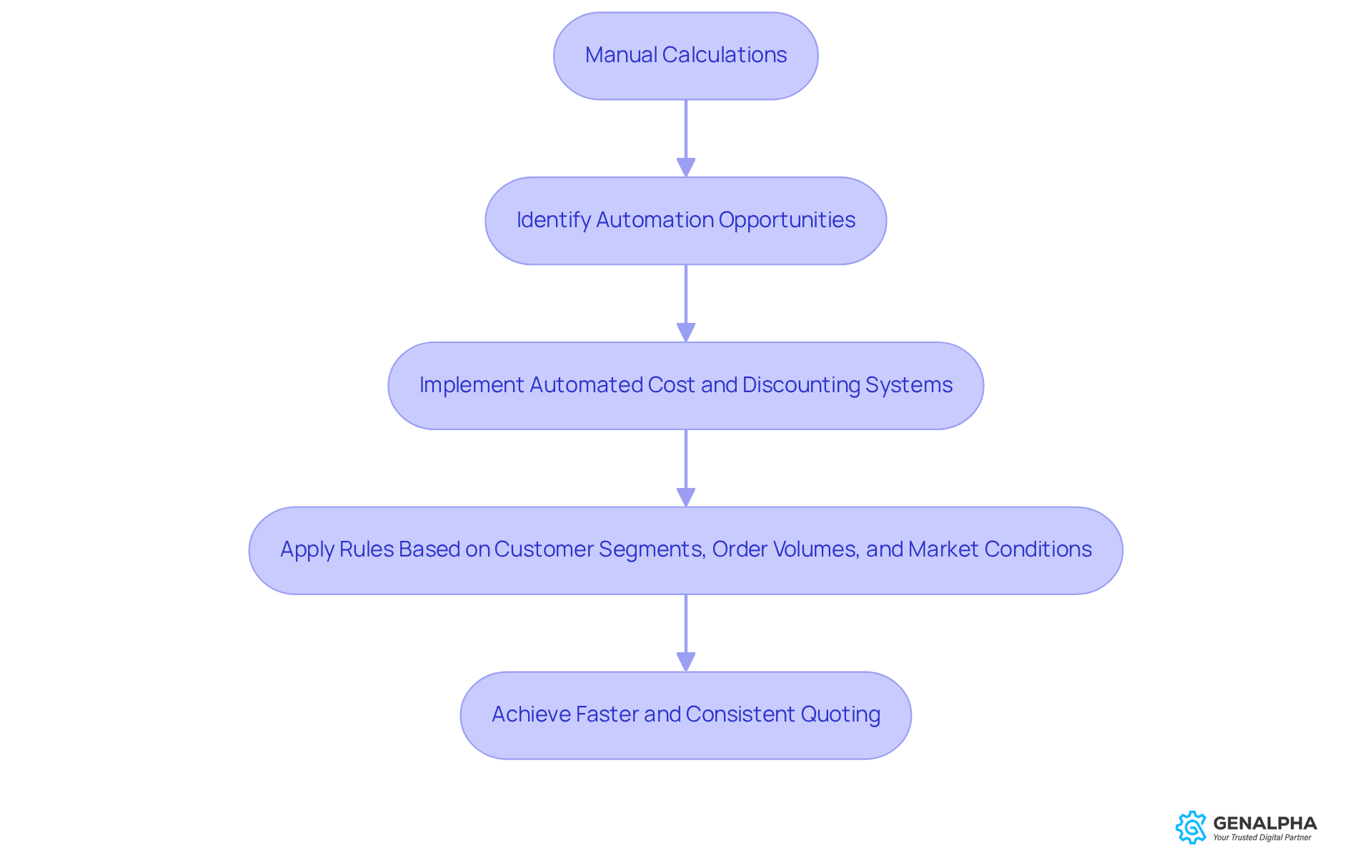

Leverage Automated Pricing and Discounting: Enhance Quoting Efficiency

Have you ever thought about how much time manual calculations can eat up in a manufacturing setting? Quoting cpq by implementing automated cost and discounting systems can really change the game. Manufacturers can quickly apply rules based on customer segments, order volumes, and market conditions. This not only speeds up the quoting cpq process but also ensures that costs remain consistent and competitive.

By using software that connects with existing systems, companies can automate those complex cost structures. Imagine cutting down the hours spent on manual calculations! It’s all about working smarter, not harder. So, why not take the leap and explore how automation can streamline your operations?

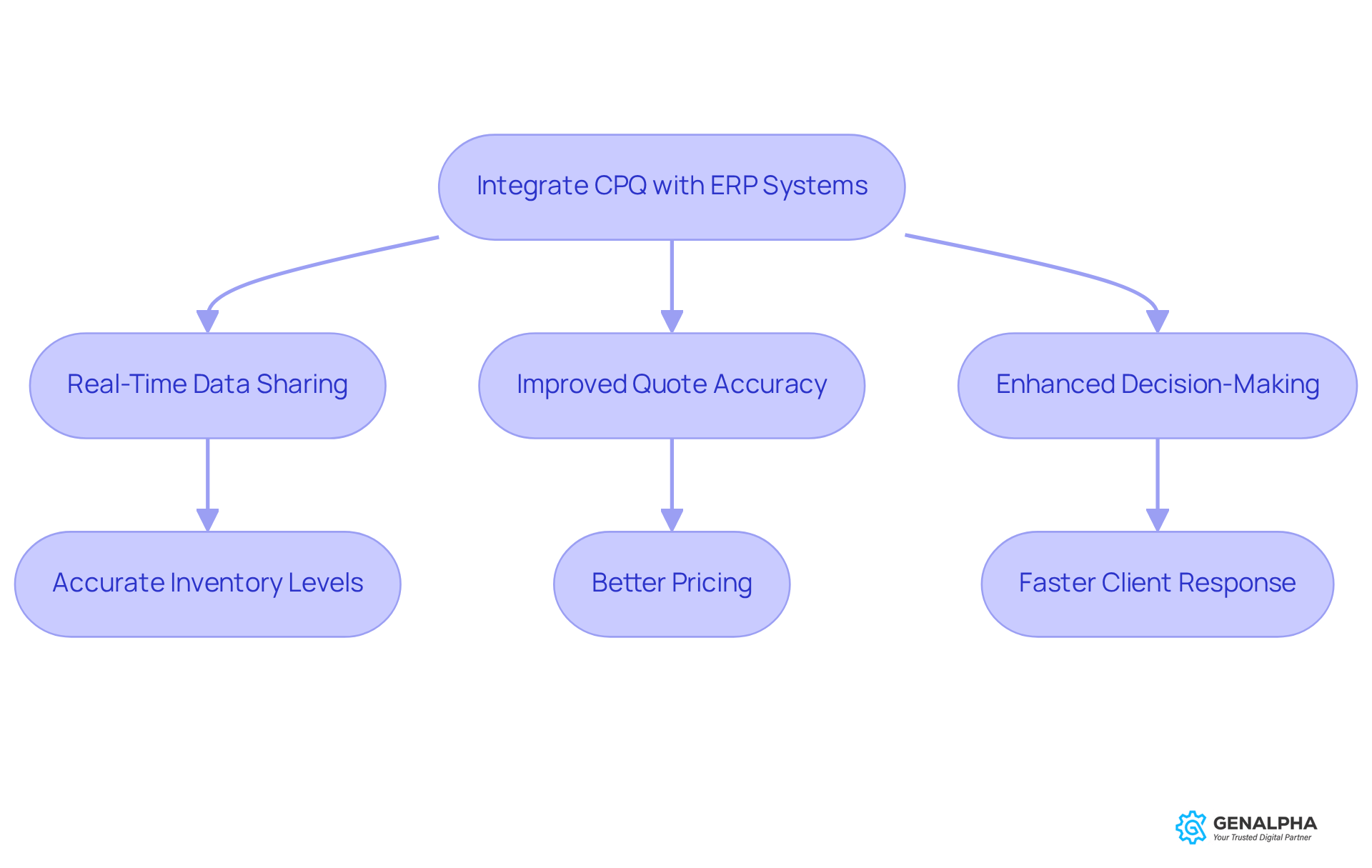

Integrate CPQ with ERP Systems: Maintain Seamless Operations

Have you ever thought about how quoting CPQ with ERP systems can significantly change the game? It’s all about sharing data in real-time across departments, which helps keep sales, inventory, and finance teams on the same page. This kind of integration is key for quoting CPQ, which helps maintain accurate inventory levels, pricing, and client information-essential elements for generating precise quotes.

For example, a mid-sized manufacturing company saw a whopping 90% improvement in quote accuracy after they implemented CPQ-ERP integration. That’s a clear win! Plus, did you know that 66% of organizations report better operational efficiency thanks to their ERP systems? This really highlights how important robust integration capabilities are.

As the experts at MobileForce.ai point out, quoting CPQ, integrated CPQ-ERP systems provide insights and efficiency boosts that can enhance decision-making. By focusing on quoting CPQ solutions with strong integration capabilities, manufacturers can streamline their operations and respond more quickly to client needs. But let’s not forget the challenges-about 50% of ERP implementations fail on the first try.

Efficient real-time data exchange not only cuts down on mistakes but also fosters a more agile and informed decision-making process. This ultimately leads to happier clients and improved sales performance. So, what do you think? Are you ready to explore how CPQ-ERP integration can benefit your business?

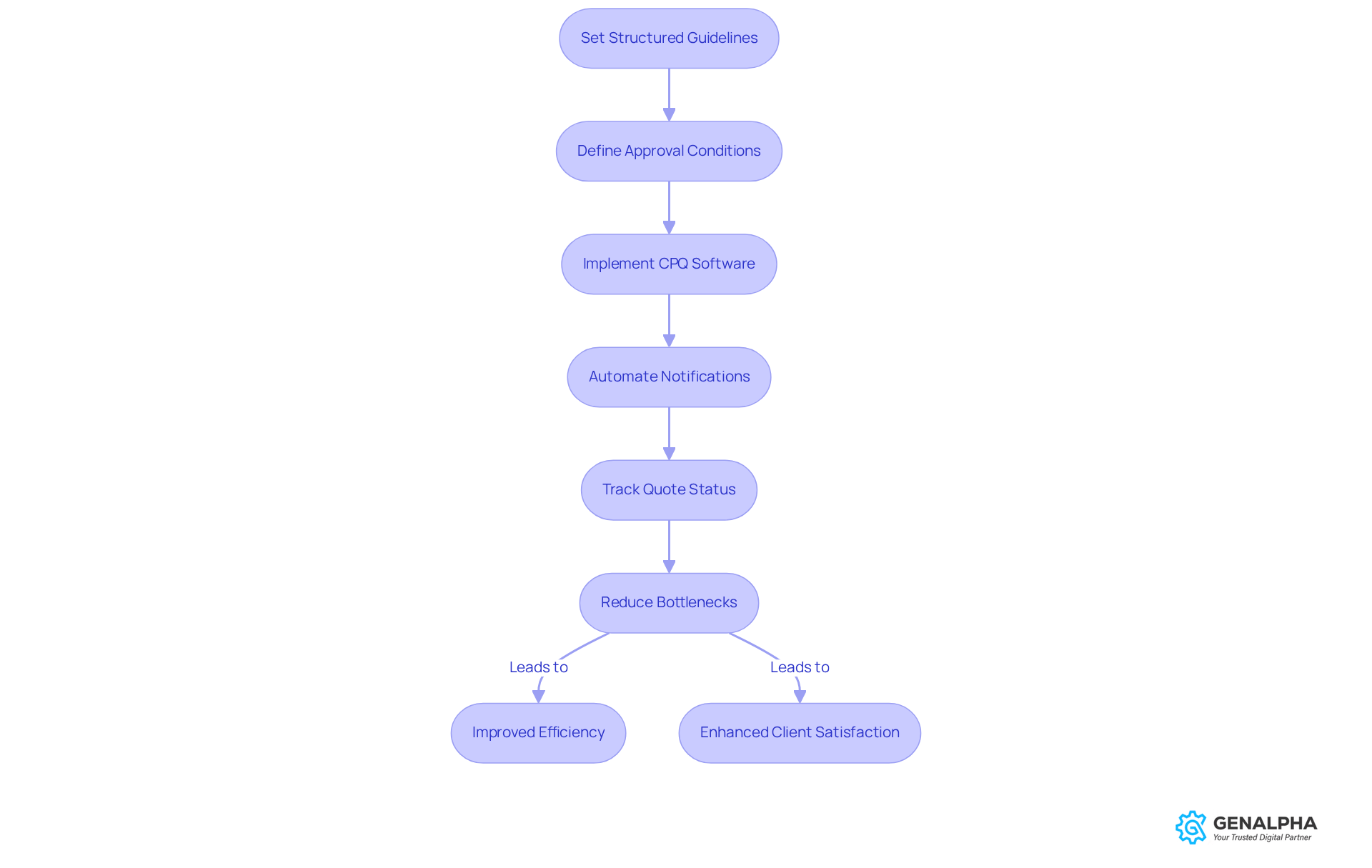

Implement Effective Quote Approvals: Streamline Your Quoting Workflow

Want to speed up your quote approvals? Manufacturers can really boost efficiency by putting structured guidelines and workflows in place. These should clearly outline who approves what and under what conditions. And here’s where quoting cpq software comes in handy! It automates the whole process, sending notifications to approvers and tracking each quote's status in real-time. This means fewer bottlenecks, so quotes get reviewed and sent to clients without any holdups.

Take Groupe DEYA, for example. They’ve successfully utilized quoting cpq solutions to get quick responses for client requests, which has really optimized their approval processes and sped up their sales cycle. The impact of automating workflows is huge - some companies have cut quote turnaround times by up to 95%! That’s more time for sales teams to focus on closing deals instead of getting stuck in admin tasks.

As Ajda Hafner, CMO, points out, automation transforms the pricing process into something quick, precise, and professional. This not only boosts client satisfaction but also drives sales success. So, if manufacturers want to enhance their pricing workflows and improve the overall client experience, implementing these practices is a smart move. What do you think? Ready to give it a try?

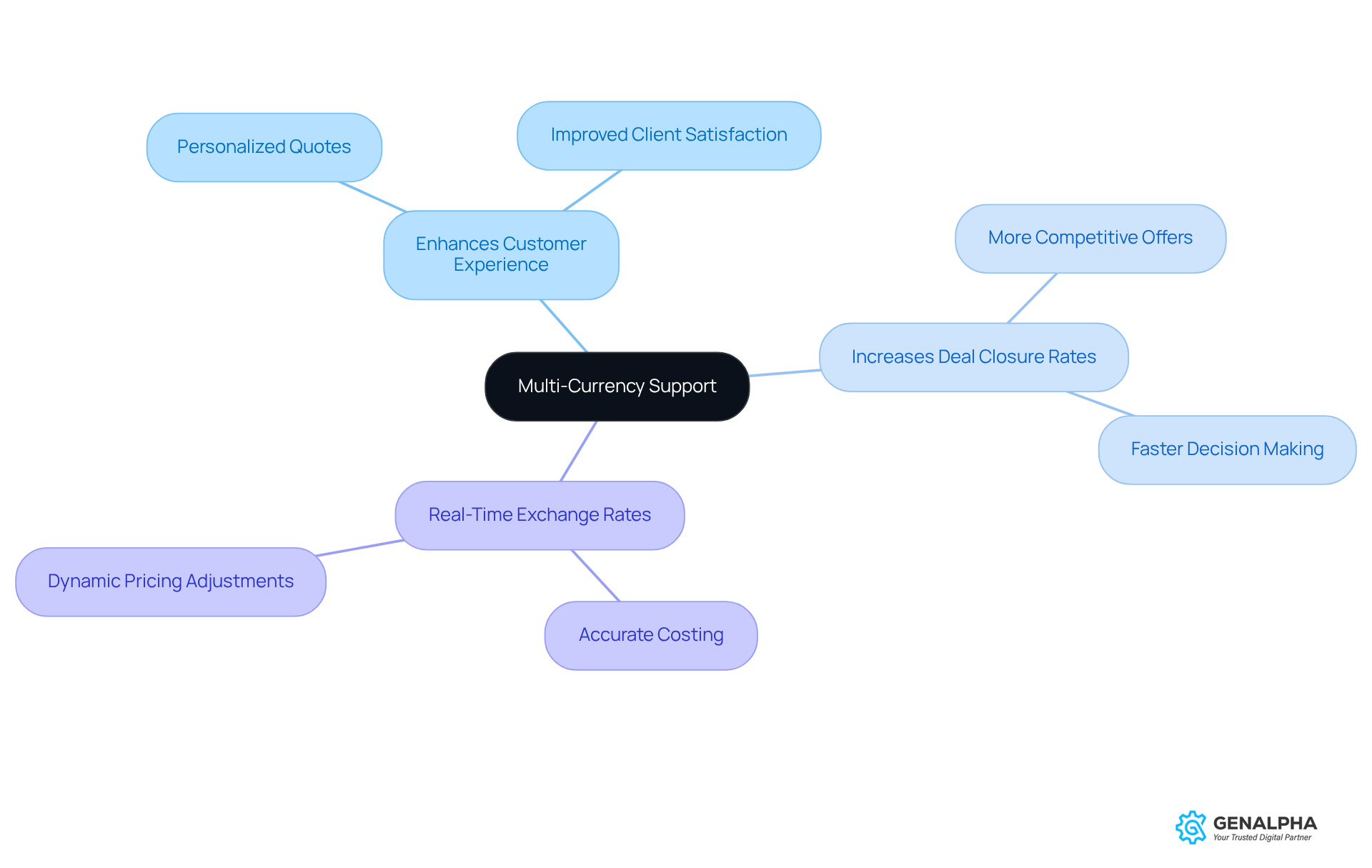

Utilize Multi-Currency Support: Expand Your Market Reach

Have you ever thought about how important it is for manufacturers to connect with international clients? Implementing multi-currency support in quoting CPQ systems can truly make a difference! By providing quotes in local currencies, businesses not only enhance the customer experience but also boost their chances of closing deals.

Imagine a customer receiving a quote in their own currency - it feels more personal, right? That’s why it’s crucial for businesses to ensure their CPQ solutions can handle quoting CPQ for multiple currencies and offer real-time exchange rates. This way, they can maintain precise costs and keep their clients happy.

So, if you’re in the manufacturing game, consider how multi-currency support could transform your quoting process. It’s all about making things easier for your customers and, in turn, driving your success!

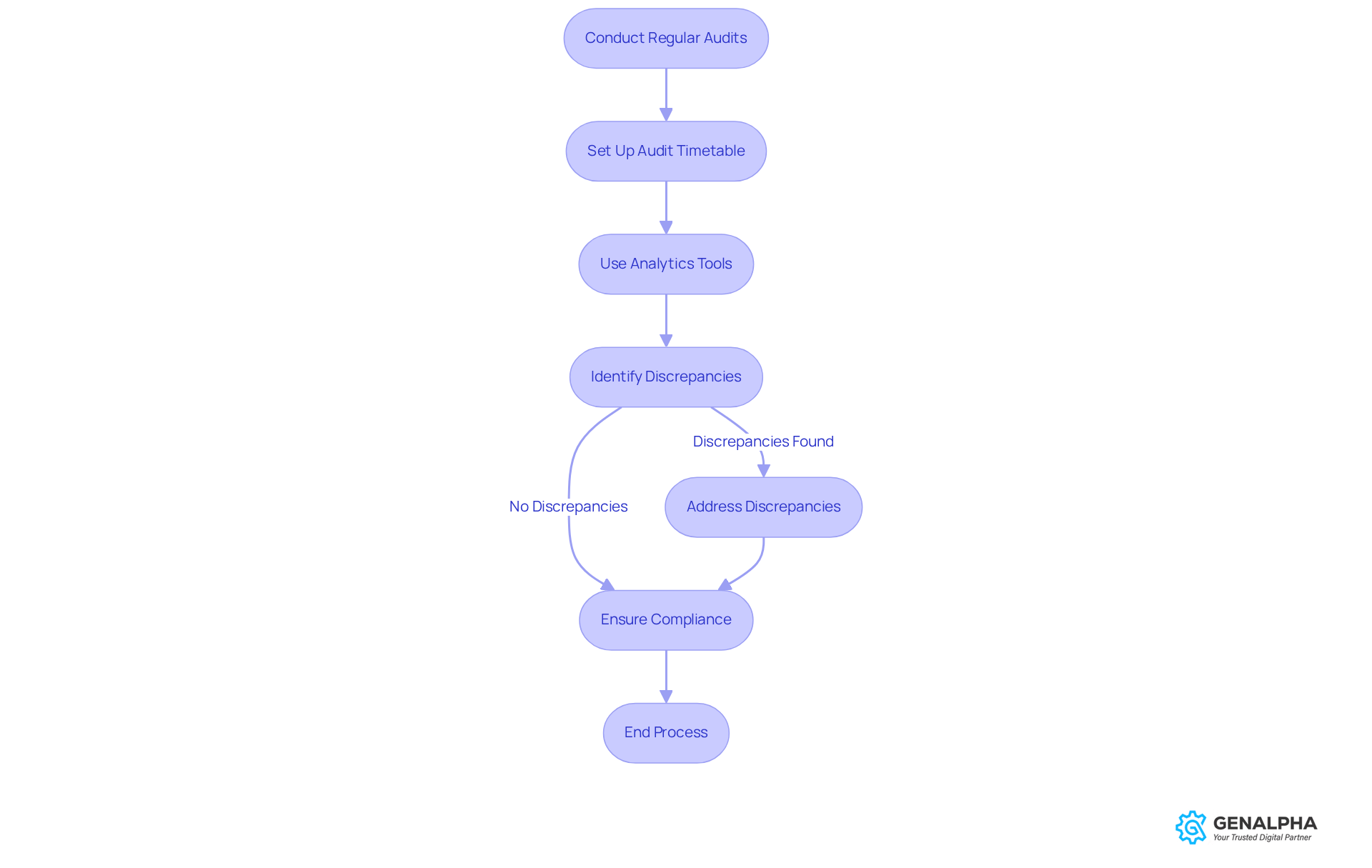

Conduct Regular Audits: Ensure Compliance and Accuracy in Quoting

Have you ever thought about how regular audits of your pricing process can really make a difference? They’re not just a box to check; they help spot areas that need a little boost and ensure you’re sticking to your pricing policies and regulations. It’s like having a safety net!

Manufacturers should definitely think about setting up a timetable for these audits. And hey, using analytics tools to keep an eye on pricing performance can be a game changer. This proactive approach means you can tackle any discrepancies before they start to impact your relationships with clients or your bottom line.

So, why not take that step? It’s all about staying ahead of the game!

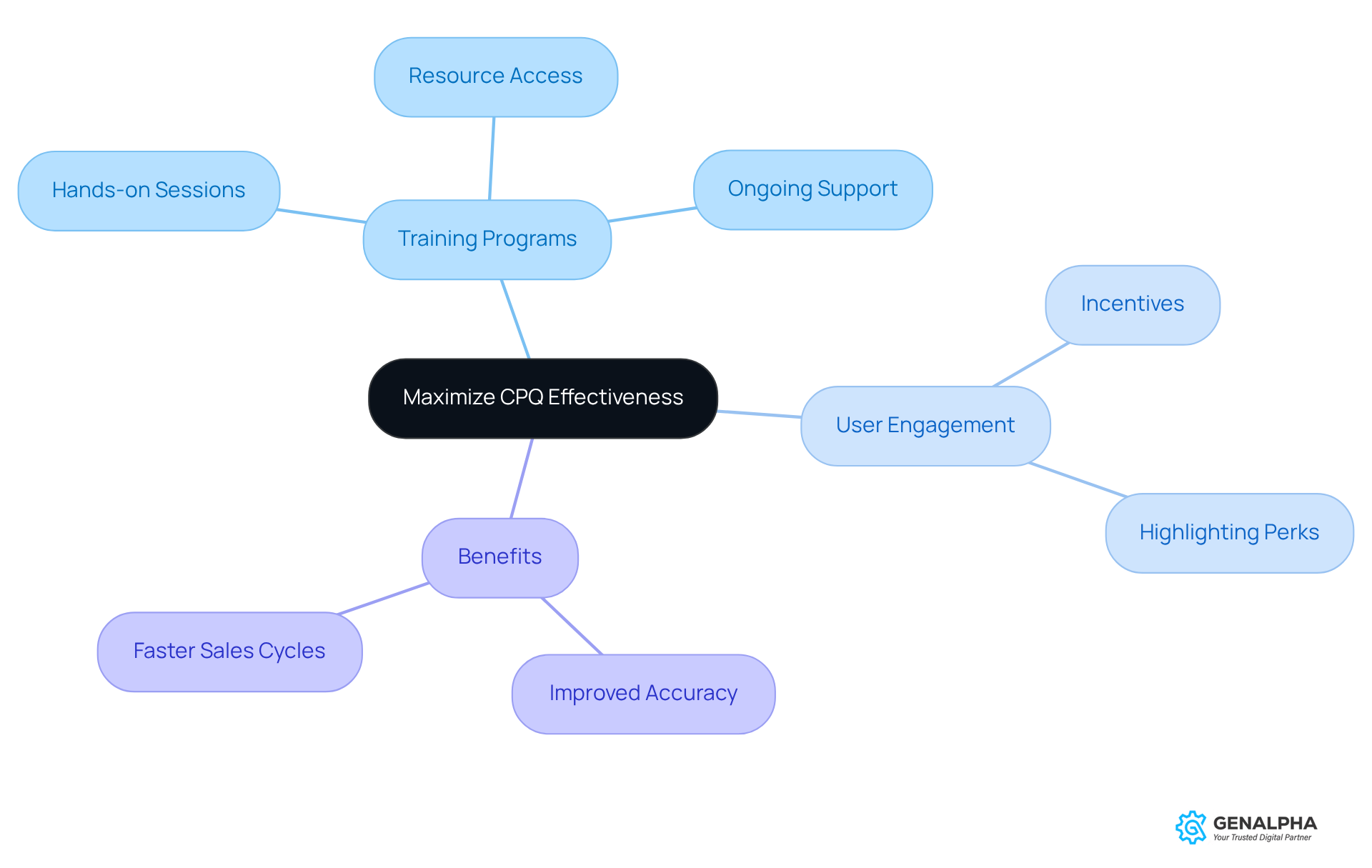

Focus on User Training and Adoption: Maximize CPQ Effectiveness

To really get the most out of CPQ systems, manufacturers should think about investing in solid training programs for their sales teams. Imagine hands-on training sessions where team members can dive right in, along with easy access to resources and ongoing support to tackle any bumps in the road. Plus, when you promote user engagement with some fun incentives and highlight the perks of CPQ tools, you can see a boost in accuracy for estimates and speedier sales cycles.

So, why not take that step? By focusing on training, you’re not just improving skills; you’re also creating a more confident and capable sales team. And who wouldn’t want that? Let’s make sure everyone’s on board and ready to embrace the advantages that come with effective CPQ systems!

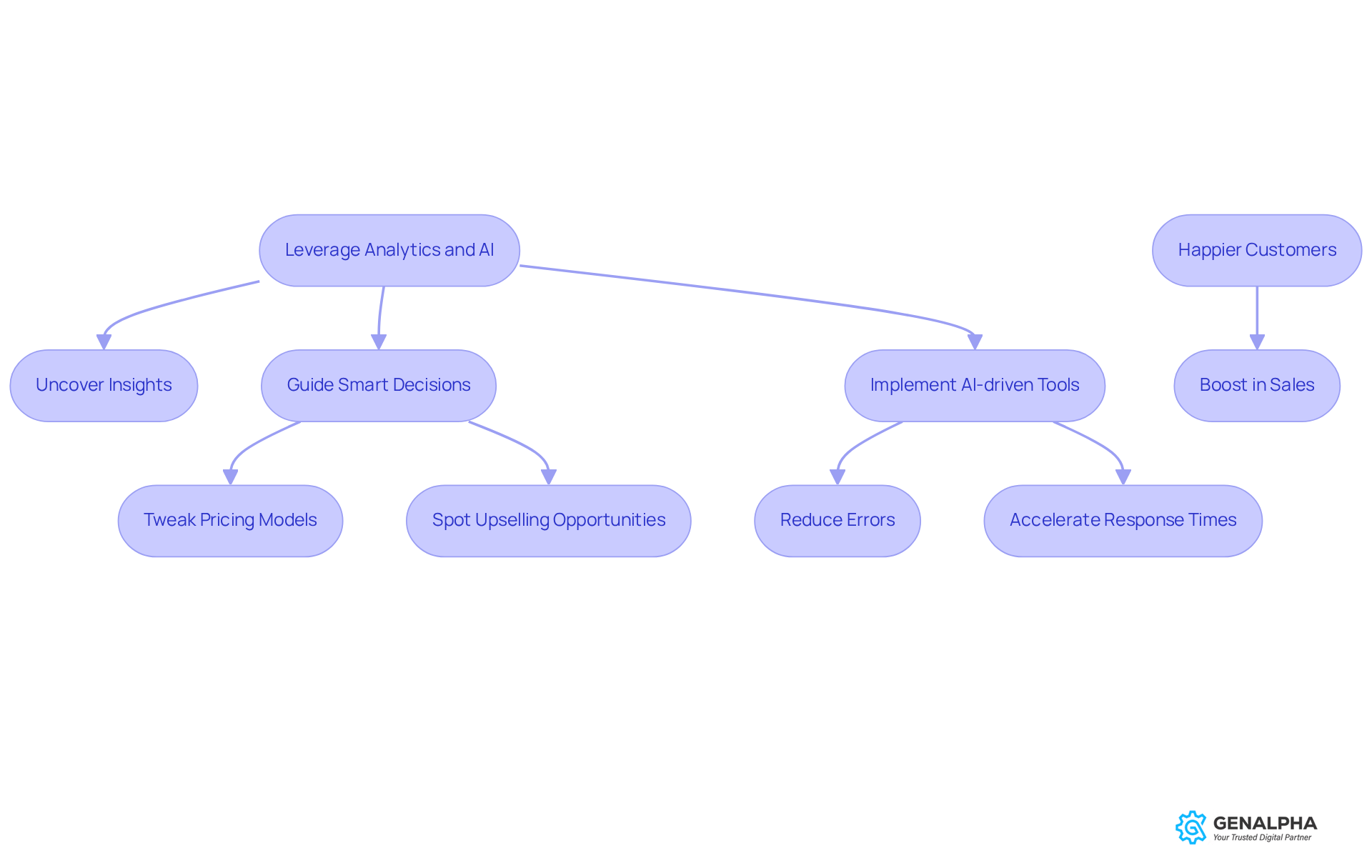

Leverage Analytics and AI: Optimize Your Quoting Strategies

Have you ever wondered how manufacturers can really get to know what their customers want? By tapping into analytics and AI, they can uncover insights about consumer preferences, cost trends, and even how well their bids are performing. This kind of data isn’t just numbers on a page; it can actually guide smart decisions, like tweaking pricing models or spotting chances for upselling.

Imagine this: implementing AI-driven tools can streamline the quoting cpq process, reducing errors and accelerating response times. Who wouldn’t want that? The result? Happier customers and a boost in sales. So, why not consider how these tools could work for you? Let’s explore the possibilities together!

Conclusion

Wrapping up, success in manufacturing really comes down to how well you implement Configure Price Quote (CPQ) strategies. Imagine streamlining your quoting processes with advanced tools like Equip360 - sounds great, right? Not only does it enhance accuracy, but it also boosts customer satisfaction. In this article, we’ve shared some essential tips for optimizing your quoting practices. Automation, integration with ERP systems, and solid training for your sales teams are key!

So, what are the key takeaways? First off, understanding the CPQ process is crucial, and it boils down to three critical steps:

- Configuration

- Pricing

- Quoting

Plus, using automated pricing and discounting, ensuring accurate product configurations, and integrating CPQ with ERP systems can really ramp up your operational efficiency. Don’t forget about regular audits and user training - they’re vital for compliance and maximizing the effectiveness of your CPQ systems. This all leads to a more agile and responsive quoting process.

Manufacturers, it’s time to embrace these strategies! Explore the potential of analytics and AI to refine your quoting approaches. By taking these steps, you’re not just improving your internal workflows; you’re also positioning yourself favorably in a competitive market. This could pave the way for increased sales and customer loyalty. So, let’s enhance quoting efficiency and drive overall business success together!

Frequently Asked Questions

What is Equip360 and how does it help with the quoting process?

Equip360 is a platform designed to streamline the quoting process for manufacturers and distributors by automating essential tasks, providing real-time inventory management, customizable quote templates, and seamless integration with existing ERP systems.

How does Equip360 improve the estimation workflow?

Equip360 significantly reduces estimation time, minimizes errors, and boosts customer satisfaction by providing quicker response times. It also offers analytics to monitor performance and identify areas for improvement.

What are the key steps in the Configure Price Quote (CPQ) process?

The CPQ process consists of three key steps: configuration (selecting the right products and options), costing (applying cost regulations and discounts), and quoting (generating a formal quote with configurations and pricing details).

How does CPQ software enhance the costing step?

CPQ software automates the costing process, reducing the time spent on cost determination by up to 73% compared to traditional methods, leading to significant operational savings.

What benefits do organizations experience when using CPQ solutions?

Organizations using CPQ solutions have seen a 28% reduction in sales cycle length and a 49% increase in proposal volume, boosting productivity and client satisfaction.

How can manufacturers avoid common quoting errors?

Manufacturers can avoid quoting errors by using guided selling tools to help sales teams choose the best options for customer needs, keeping product catalogs updated, and providing regular training sessions on product features and configurations.

Why is it important to focus on accurate product configuration?

Accurate product configuration is crucial because slow estimate generation and approval can lead to lost deals. Ensuring data accuracy and keeping customer needs front and center during the configuration and pricing phases enhances overall sales performance.