Introduction

In today’s fast-paced manufacturing world, smart equipment isn’t just a nice-to-have; it’s essential for success. Think about it: from advanced inventory management systems to the latest automation technologies, manufacturers now have a treasure trove of tools at their fingertips, all aimed at boosting efficiency and productivity.

This article dives into ten must-have smart tools that are shaking up modern manufacturing. We’ll highlight their benefits and the vital roles they play in streamlining operations. As industries work hard to stay ahead of the game, it begs the question: which of these innovations will shape the future of manufacturing? And how can businesses tap into them to tackle tomorrow’s challenges? Let’s explore!

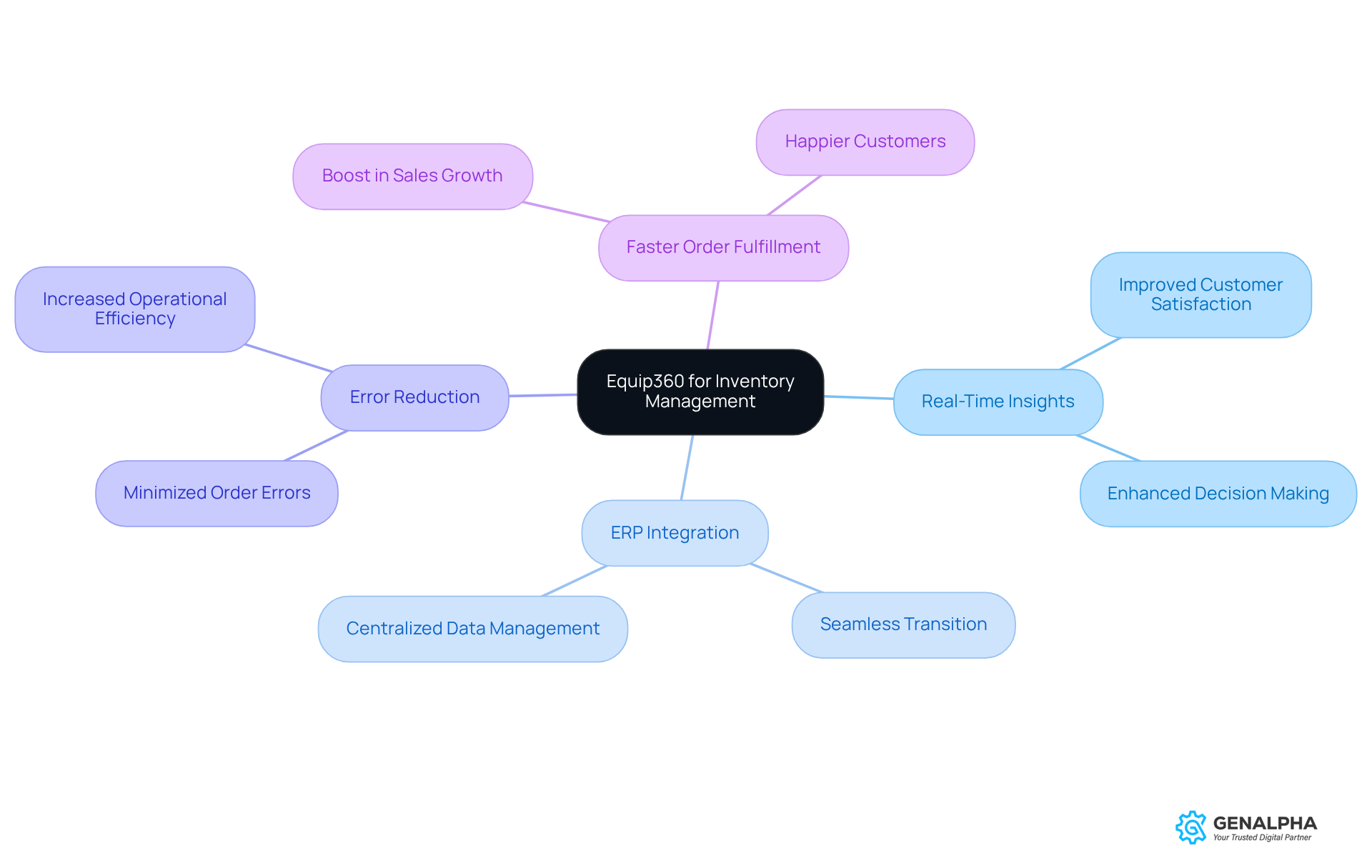

GenAlpha Technologies: Equip360 for Streamlined Inventory Management

Have you ever felt overwhelmed trying to keep track of your inventory? Well, Equip360 is here to change that! This cutting-edge B2B eCommerce platform is tailor-made for manufacturers and distributors, making it easier than ever to manage your stock.

Imagine having real-time insights into your inventory levels, pricing, and order tracking - all at your fingertips. With Equip360, you can do just that! By seamlessly integrating with your existing ERP systems, it helps reduce errors and speeds up order fulfillment times. This means happier customers and a boost in sales growth.

So, why not give Equip360 a try? It’s time to take control of your inventory management and see the difference it can make for your business!

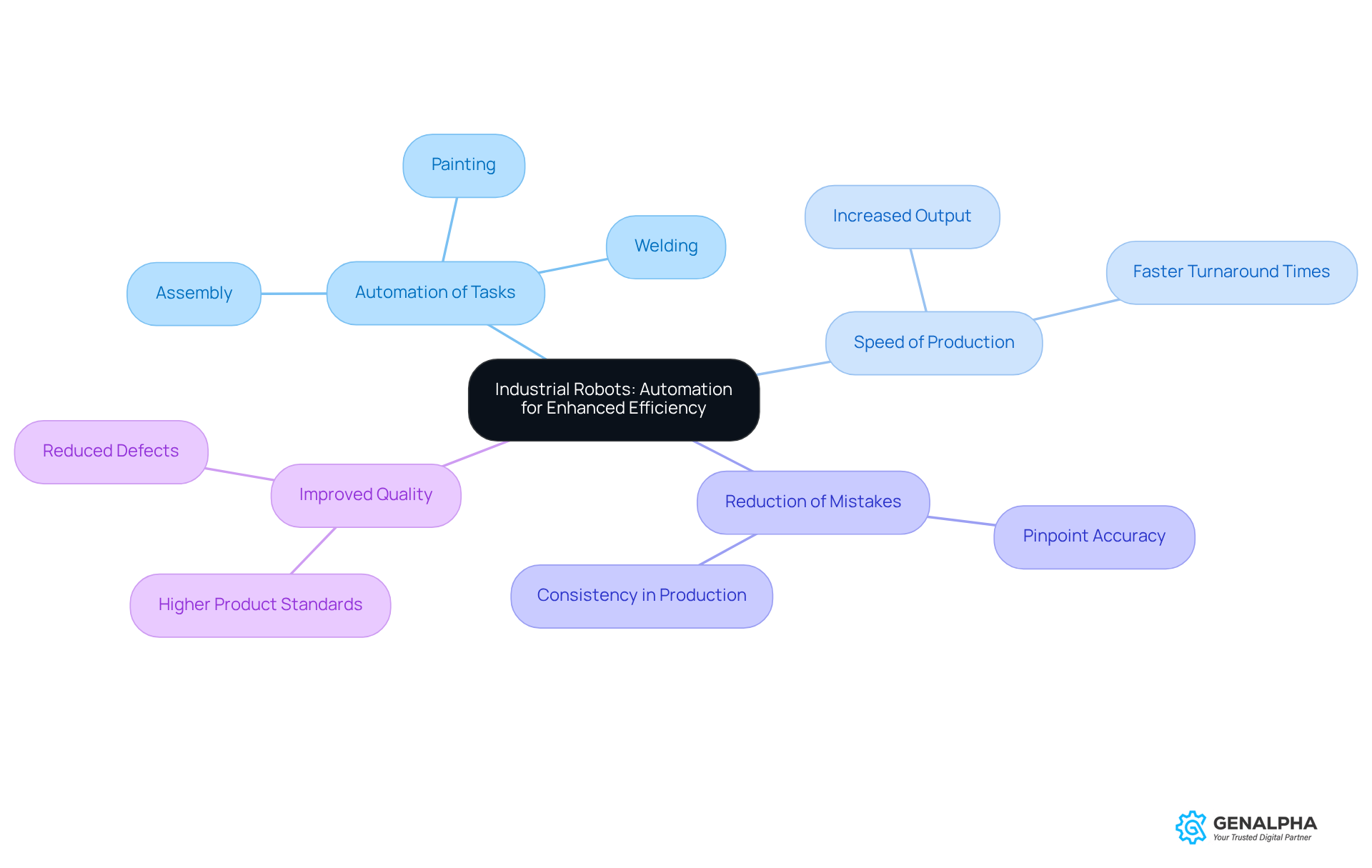

Industrial Robots: Automation for Enhanced Efficiency

Have you ever thought about how industrial robots are shaking things up in production? They’re not just machines; they’re revolutionizing the way we do things by automating tasks like assembly, welding, and painting. Imagine a robot that works tirelessly, never gets tired, and does everything with pinpoint accuracy. Sounds pretty amazing, right?

These robots are game-changers. They can crank out products at a speed that would leave any human worker in the dust. Plus, they help cut down on mistakes, which means the quality of goods is on the rise. Who wouldn’t want that? By improving consistency and reducing operational costs, smart equipment such as industrial robots are becoming must-haves in today’s manufacturing world.

So, what does this mean for us? Well, it’s clear that embracing smart equipment can lead to better products and a more efficient production process. If you’re in the industry, it might be time to consider how these robots can fit into your operations. After all, who wouldn’t want to boost productivity and quality at the same time?

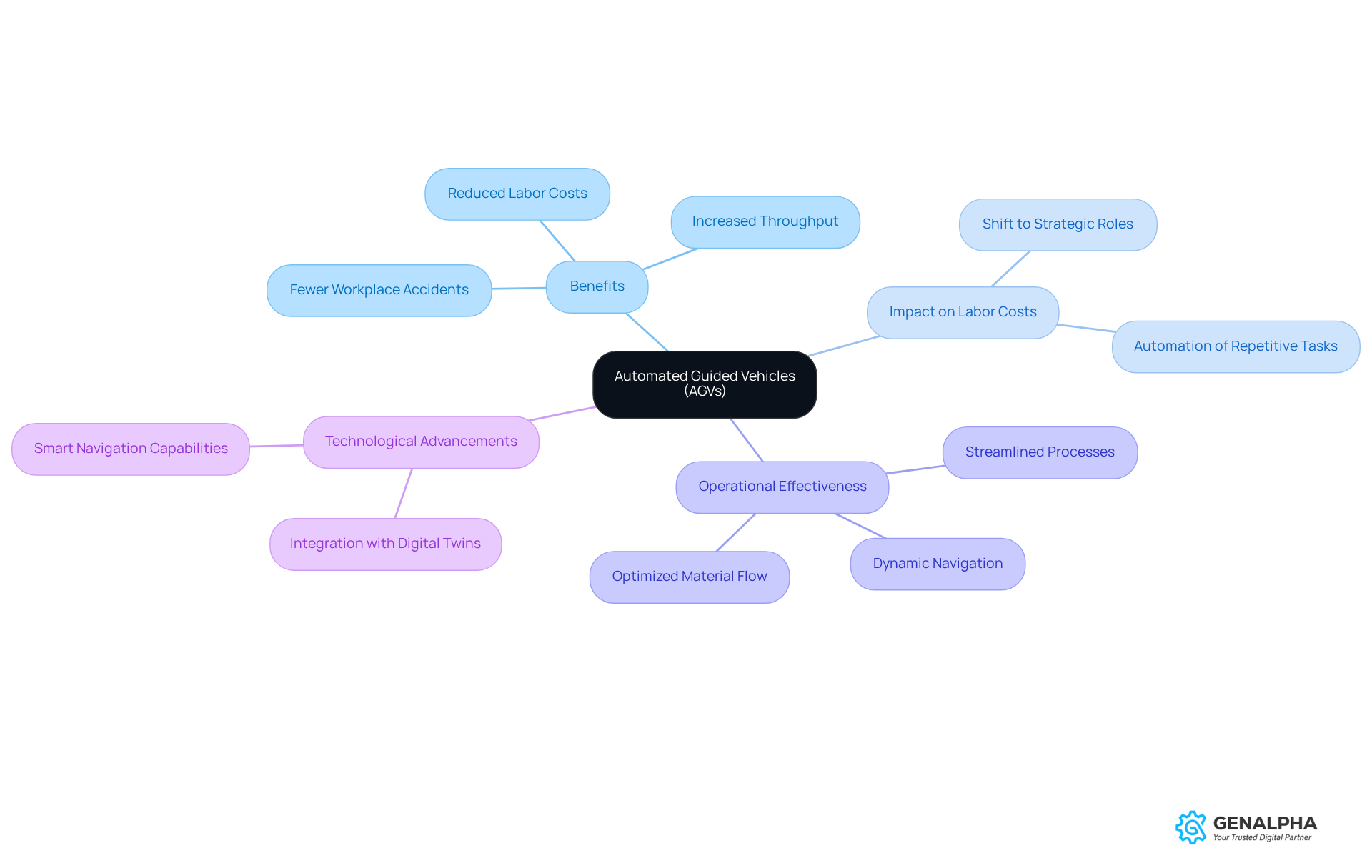

Automated Guided Vehicles (AGVs): Optimizing Material Handling

Automated Guided Vehicles (AGVs) are really shaking things up in manufacturing! Imagine a factory floor where materials glide effortlessly from one spot to another, all thanks to these self-driving wonders. They’re not just cool tech; they’re cutting down on manual labor, which means lower labor costs and fewer workplace accidents. By December 2025, many manufacturers have jumped on the AGV bandwagon, boosting their operational effectiveness and streamlining processes.

So, what’s the latest buzz? AGVs are getting smarter! They can now navigate dynamically and optimize how materials flow through the factory. This flexibility doesn’t just ramp up production; it also makes better use of the available space. As a result, producers are enjoying a noticeable increase in throughput and a drop in those pesky bottlenecks.

Let’s talk about the impact on labor costs. By automating those repetitive tasks, companies can shift their human resources to more strategic roles, which really amps up overall productivity. Plus, studies show that implementing AGVs can cut material handling time by a whopping 30%! That’s a game-changer for manufacturers who want to stay competitive in a fast-paced market where speed and accuracy are everything. And here’s a fun fact: with 29% of global firms now using digital twin applications in production, the partnership between AGVs and digital solutions is set to take operations to the next level.

Isn’t it exciting to think about how AGVs are reshaping the future of manufacturing? What do you think about this tech revolution?

CNC Machines: Precision Manufacturing Solutions

Computer Numerical Control (CNC) machines are pretty much the backbone of precision production these days. They automate the machining process, which means we can create intricate designs and achieve high tolerances that manual machining just can’t match. Imagine being able to run these machines continuously, cranking out complex parts with hardly any human intervention. This not only cuts down lead times but also boosts product quality.

For example, when a 22 mm capacity INDEX CNC multi-spindle automatic machine was installed back in October 2011, productivity skyrocketed five-fold! It turned components in just 24 seconds, compared to a whopping 120 seconds on traditional sliding-head lathes. That’s like having the power of five sliding-head lathes all in one machine! It really highlights how efficient and cost-effective CNC methods can be.

And let’s not forget how quickly these machines can adapt to design changes. This flexibility is crucial in industries that need rapid prototyping and customization. As some industry veterans put it, "In machining, there are no small mistakes. Each error compounds, leading to larger issues down the line." This really drives home the importance of precision in production.

Right now, we’re seeing smart equipment, such as AI-powered CNC systems, stepping onto the scene, transforming production by reducing downtime and enhancing precision through predictive analytics. The commitment to ongoing enhancement and innovation in CNC systems isn’t just a passing trend; it’s vital for manufacturers who want to thrive in a competitive landscape. So, what do you think? Are you ready to embrace the future of CNC technology?

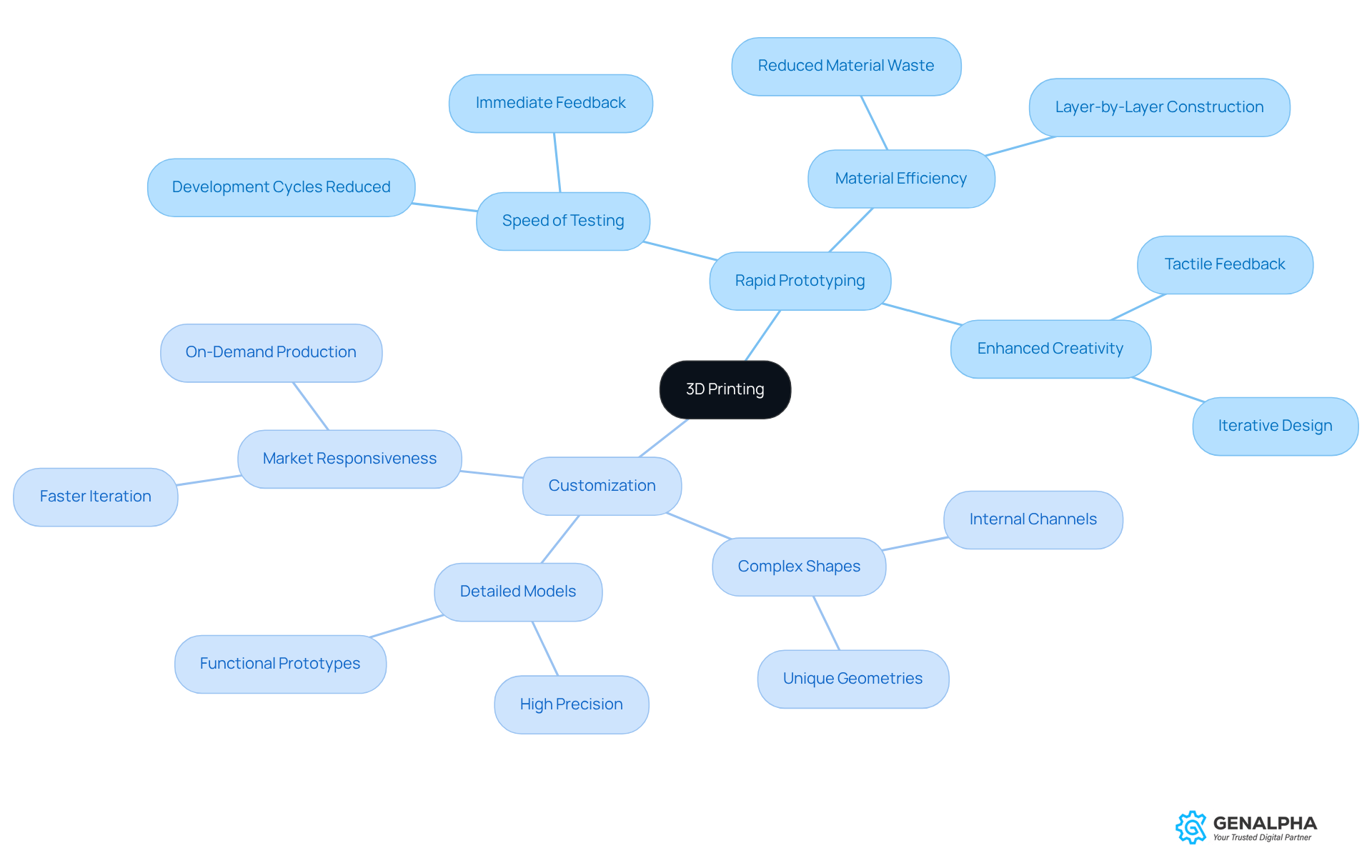

3D Printers: Enabling Rapid Prototyping and Customization

3D printers are really shaking things up in the prototyping world! Imagine being able to whip up prototypes in no time at all. This means designers can quickly test out their ideas before diving into full-scale production. Plus, 3D printing is a game changer when it comes to cutting down on material waste. Traditional manufacturing often leaves a lot of scraps behind, but with 3D printing, parts are built layer by layer, using just what’s needed.

But that’s not all! 3D printing also gives manufacturers the power to customize like never before. They can create complex shapes and detailed models in just a few hours, meeting specific customer needs without the usual delays. How cool is that? This means businesses can respond to market demands faster while keeping their operations running smoothly.

As industry experts put it, 'If speed and innovation are priorities, rapid prototyping with 3D printers is an indispensable advantage.' So, if you’re looking to stay ahead of the game, embracing 3D printing might just be the way to go!

Internet of Things (IoT) Sensors: Real-Time Monitoring Solutions

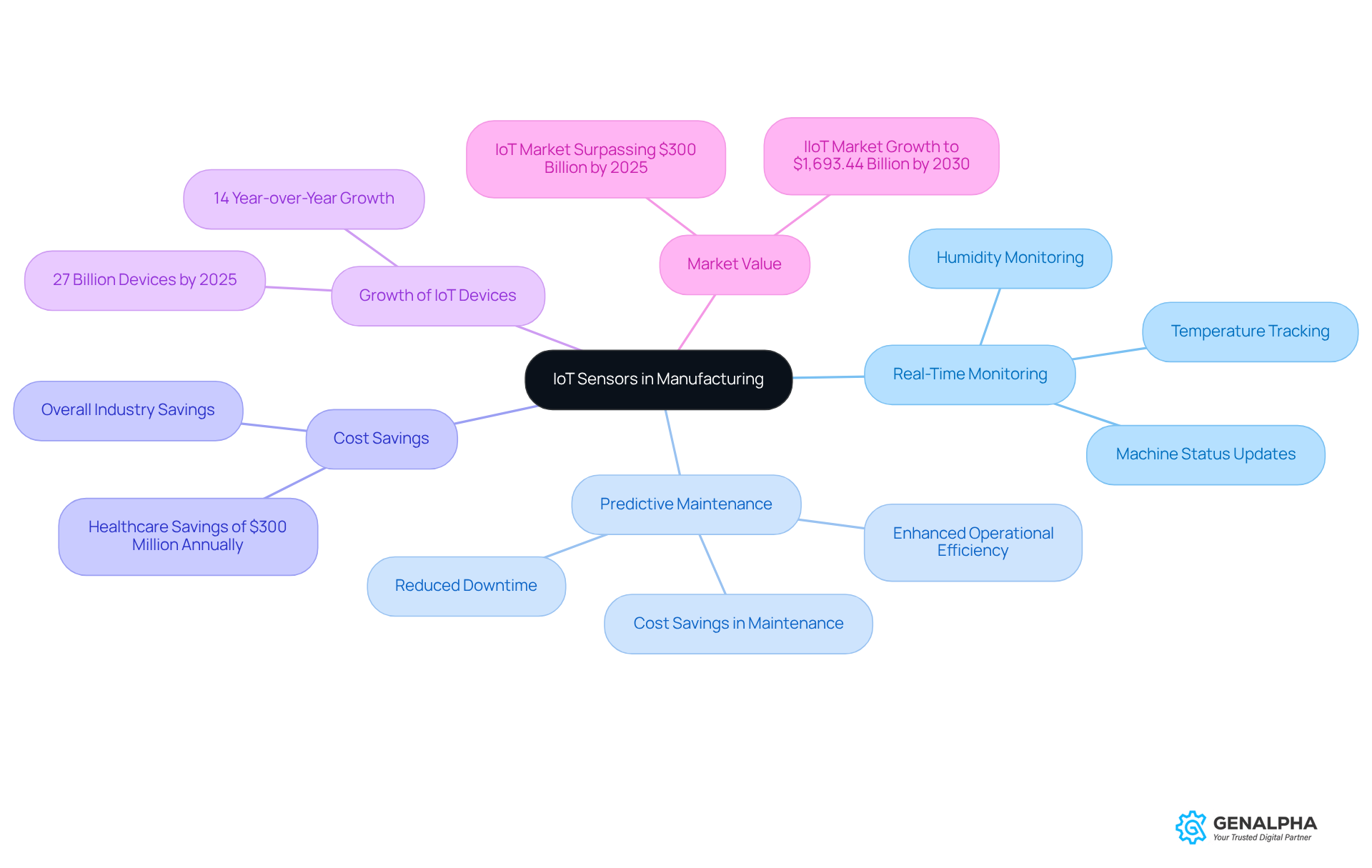

IoT sensors are shaking things up in the manufacturing world, giving us real-time insights into how our equipment is performing and what’s happening in the environment around it. These smart sensors, as part of the smart equipment, keep an eye on important factors like temperature, humidity, and machine status, which means manufacturers can make quick, data-driven decisions.

By tapping into IoT technology, businesses can really boost their predictive maintenance strategies. This is super important for cutting down on downtime and making production processes run smoother. Think about it: this proactive approach not only ramps up operational efficiency but also leads to some serious cost savings. For example, the healthcare industry could save over $300 million annually just by implementing IoT devices!

And here’s something to consider: the number of connected IoT devices is expected to skyrocket to over 27 billion by 2025. That makes integrating these sensors even more crucial for manufacturers who want to keep up in a fast-paced market. Industry leaders are on board, recognizing that adopting IoT solutions can really enhance production efficiency. Many even see this innovation as a key player in driving future growth in the sector.

According to a recent report, the IoT market for production is set to surpass $300 billion by 2025. That really highlights how important these technologies are for pushing the industry forward. So, are you ready to embrace the IoT revolution and take your manufacturing game to the next level?

Production Monitoring Systems: Ensuring Quality Control

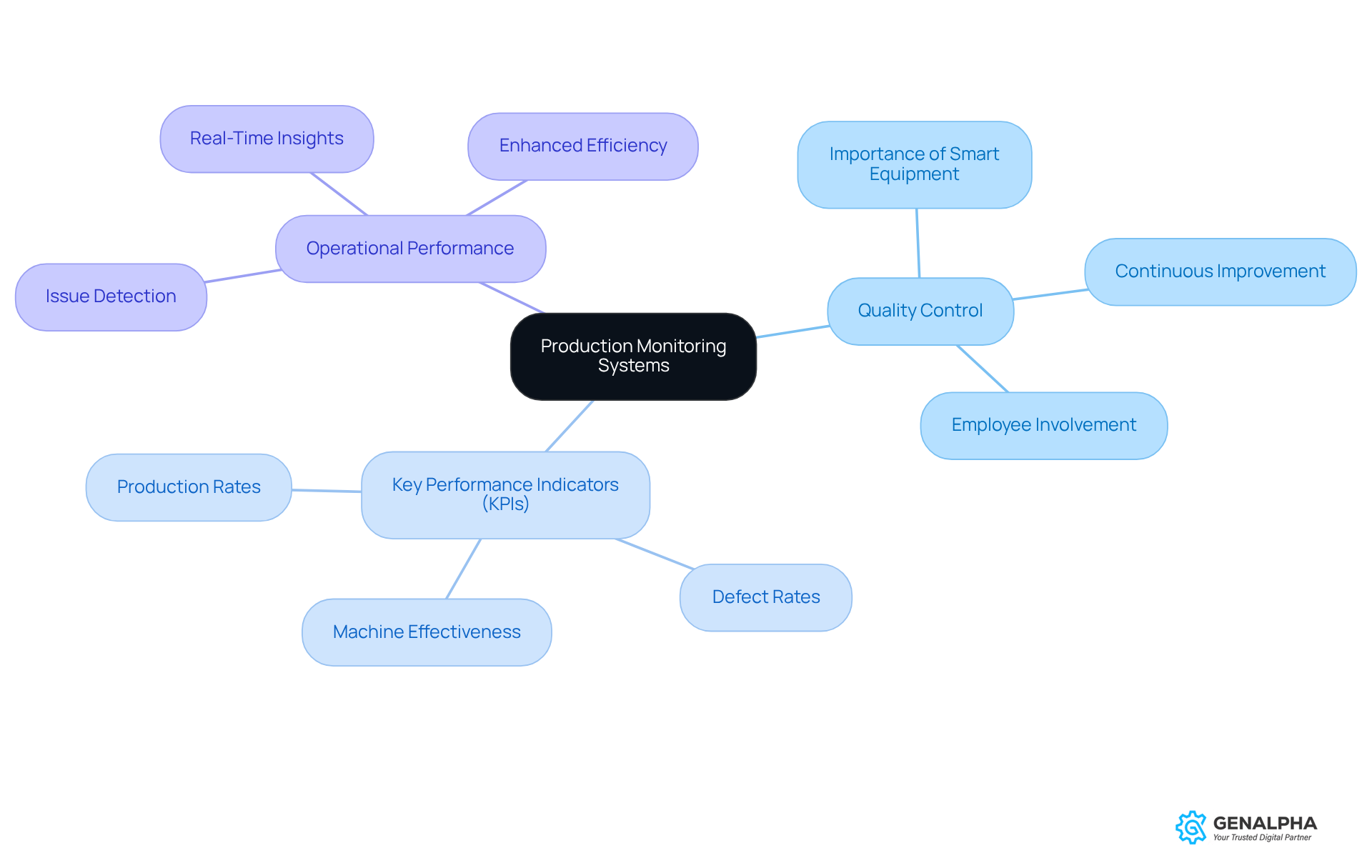

Have you ever wondered how manufacturers keep their products up to par? Well, smart equipment used in production monitoring systems plays a crucial role in ensuring quality control in manufacturing. These systems keep an eye on key performance indicators (KPIs) like production rates, defect rates, and machine effectiveness.

By utilizing smart equipment to provide real-time insights, manufacturers can quickly spot and tackle issues, ensuring that products meet those all-important quality standards. Imagine being able to catch a problem before it escalates - pretty neat, right?

Implementing smart equipment doesn’t just enhance product quality; it also boosts overall operational performance. So, if you’re in the manufacturing game, it might be time to consider how these systems can make a difference for you!

Smart Conveyors: Enhancing Material Flow

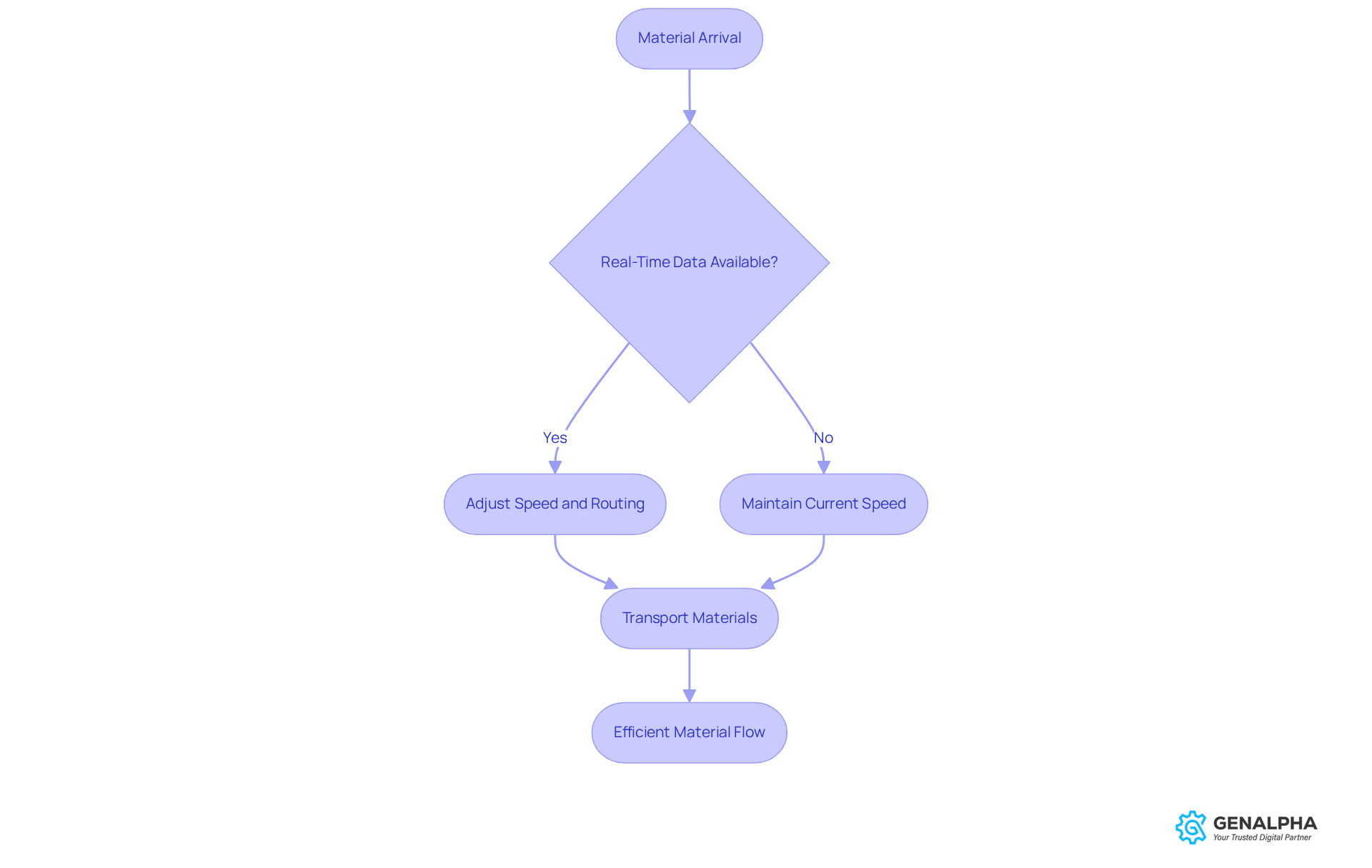

Have you ever thought about how materials move in a production setting? Intelligent conveyors are changing the game! These smart equipment systems are equipped with advanced gadgets like sensors and AI, making material movement smoother and more efficient.

Imagine a conveyor that can automatically adjust its speed and routing based on real-time data. Pretty cool, right? This means that materials can be transported efficiently throughout the production process, reducing those pesky bottlenecks and boosting throughput.

Smart equipment, such as conveyors, enhances operational efficiency and helps create a more agile manufacturing environment. So, if you're looking to streamline your production, it might be time to consider these intelligent systems. What do you think? Could they be the solution you've been searching for?

Predictive Maintenance Tools: Minimizing Downtime

Have you ever thought about how much downtime can cost a facility? Predictive maintenance tools are here to help! By using data analytics and IoT technology, smart equipment can actually foresee equipment failures before they happen. Imagine continuously monitoring machine performance and spotting potential issues before they escalate. This proactive approach enables manufacturers to utilize smart equipment for scheduling maintenance ahead of time, which can significantly cut down on unplanned downtime.

In fact, facilities can save up to $300,000 a year just by reducing downtime by 30 percent! That’s a big deal, especially when you consider that the average annual cost of downtime per facility is a staggering $129 million. It really highlights how crucial it is to avoid those unexpected disruptions. Plus, smart equipment enhances predictive maintenance, which not only saves money but also boosts overall productivity, making it a key player in modern production strategies.

As more industries jump on board with these technologies, the emphasis on data-driven decision-making is only getting stronger. Did you know that 91% of facilities are working to enhance their data collection and analysis capabilities? According to Ryan McClellan, predictive maintenance can cut unplanned downtime by 30-50%, which really underscores its effectiveness.

And here’s something to think about: the compound annual growth rate of predictive maintenance is projected at 29.5%. That’s a clear sign of its growing importance in the industry. So, if you’re not already considering predictive maintenance, now might be the perfect time to start!

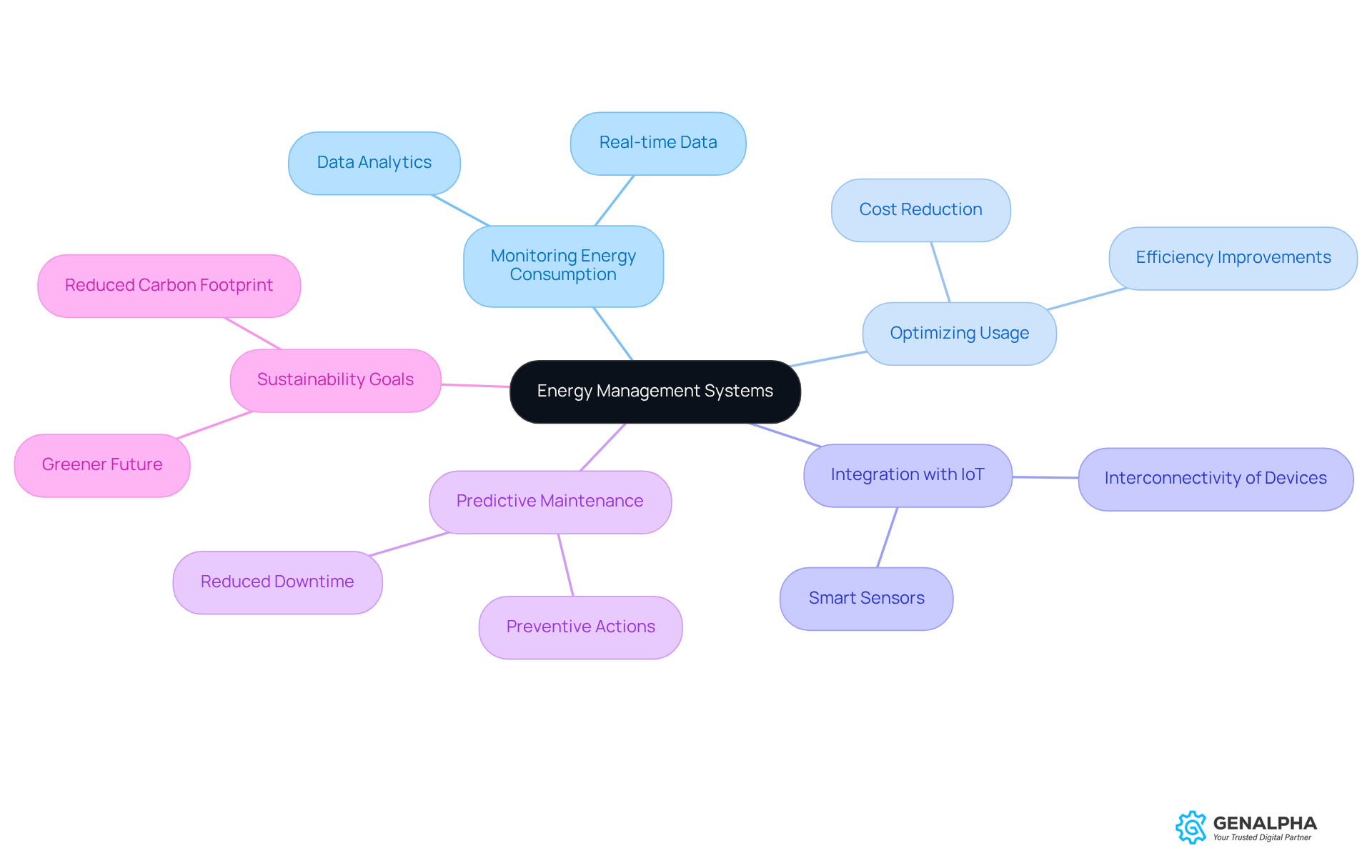

Energy Management Systems: Optimizing Energy Consumption

Have you ever thought about how much energy your manufacturing facility uses? Energy management systems (EMS) are here to help with that! These systems are designed to monitor and optimize energy consumption, giving you real-time data on how energy is being used. This means you can spot inefficiencies and take action to cut costs.

For example, when you integrate EMS with IoT sensors and smart equipment for predictive maintenance tools, you create a powerful approach to energy efficiency. Not only does this support your sustainability goals, but it can also improve your bottom line.

So, why not take a closer look at how EMS can benefit your operations? By embracing these technologies, you’re not just saving money; you’re also contributing to a greener future. Let’s make energy efficiency a priority together!

Conclusion

Integrating smart equipment into modern manufacturing isn’t just a trend; it’s a must if you want to achieve operational excellence and stay competitive in this fast-paced world. Think about it: technologies like Equip360, industrial robots, Automated Guided Vehicles (AGVs), CNC machines, 3D printers, IoT sensors, production monitoring systems, smart conveyors, predictive maintenance tools, and energy management systems can really shake up production processes and lead to big gains in efficiency and quality.

As we dive into this topic, some key insights pop up about what these technologies can do. For instance:

- Equip360 makes inventory management a breeze.

- Industrial robots boost efficiency and precision.

- AGVs are great for optimizing material handling, cutting costs, and improving throughput.

- CNC machines deliver unmatched precision.

- 3D printers allow for rapid prototyping and customization.

- IoT sensors provide real-time monitoring, which helps with proactive decision-making.

- Production monitoring systems ensure top-notch quality control.

- Smart conveyors keep material flowing smoothly.

- Predictive maintenance cuts down on downtime.

- Energy management systems help with sustainability and saving costs.

Looking ahead, the future of manufacturing is clearly linked to these innovations. As more industries jump on the smart equipment bandwagon, the potential for increased productivity, lower operational costs, and better product quality becomes very real. If you’re a manufacturer wanting to thrive, now’s the time to invest in these technologies, embrace digital transformation, and get ahead in the manufacturing revolution. So, are you ready to take that step towards modernization and efficiency?

Frequently Asked Questions

What is Equip360 and how does it help with inventory management?

Equip360 is a B2B eCommerce platform designed for manufacturers and distributors that provides real-time insights into inventory levels, pricing, and order tracking. It integrates with existing ERP systems to reduce errors and speed up order fulfillment.

What benefits does Equip360 offer to businesses?

Equip360 helps businesses manage their inventory more effectively, leading to happier customers and increased sales growth by providing streamlined inventory management.

How are industrial robots transforming production processes?

Industrial robots automate tasks such as assembly, welding, and painting, increasing production speed, reducing mistakes, and improving product quality. They enhance consistency and lower operational costs, making them essential in manufacturing.

What advantages do industrial robots provide?

Industrial robots boost productivity by working tirelessly with precision, resulting in faster production rates and higher quality goods, which are critical for modern manufacturing.

What are Automated Guided Vehicles (AGVs) and their role in manufacturing?

AGVs are self-driving vehicles that automate the transportation of materials within a factory, reducing manual labor, lowering labor costs, and minimizing workplace accidents.

How do AGVs improve operational efficiency?

AGVs optimize material flow and navigation, increasing production throughput, reducing bottlenecks, and allowing companies to allocate human resources to more strategic tasks.

What impact do AGVs have on labor costs and productivity?

By automating repetitive tasks, AGVs help lower labor costs and enhance overall productivity, with studies indicating they can reduce material handling time by up to 30%.

What is the relationship between AGVs and digital twin applications?

The integration of AGVs with digital twin applications is becoming more common, with 29% of global firms using such digital solutions to enhance operational effectiveness in manufacturing.