Introduction

The engineer to order (ETO) manufacturing sector is booming like never before, with a jaw-dropping 100% growth over the last 15 years! As manufacturers hustle to keep up with this rapid change, the need for specialized engineer to order ERP software has never been more crucial.

So, what’s the deal with ETO ERP systems? This article dives into their essential features, showing how they can streamline operations, boost customer engagement, and ultimately ramp up profitability.

But here’s a question for you: what specific functionalities should manufacturers focus on to stay ahead in this ever-evolving landscape?

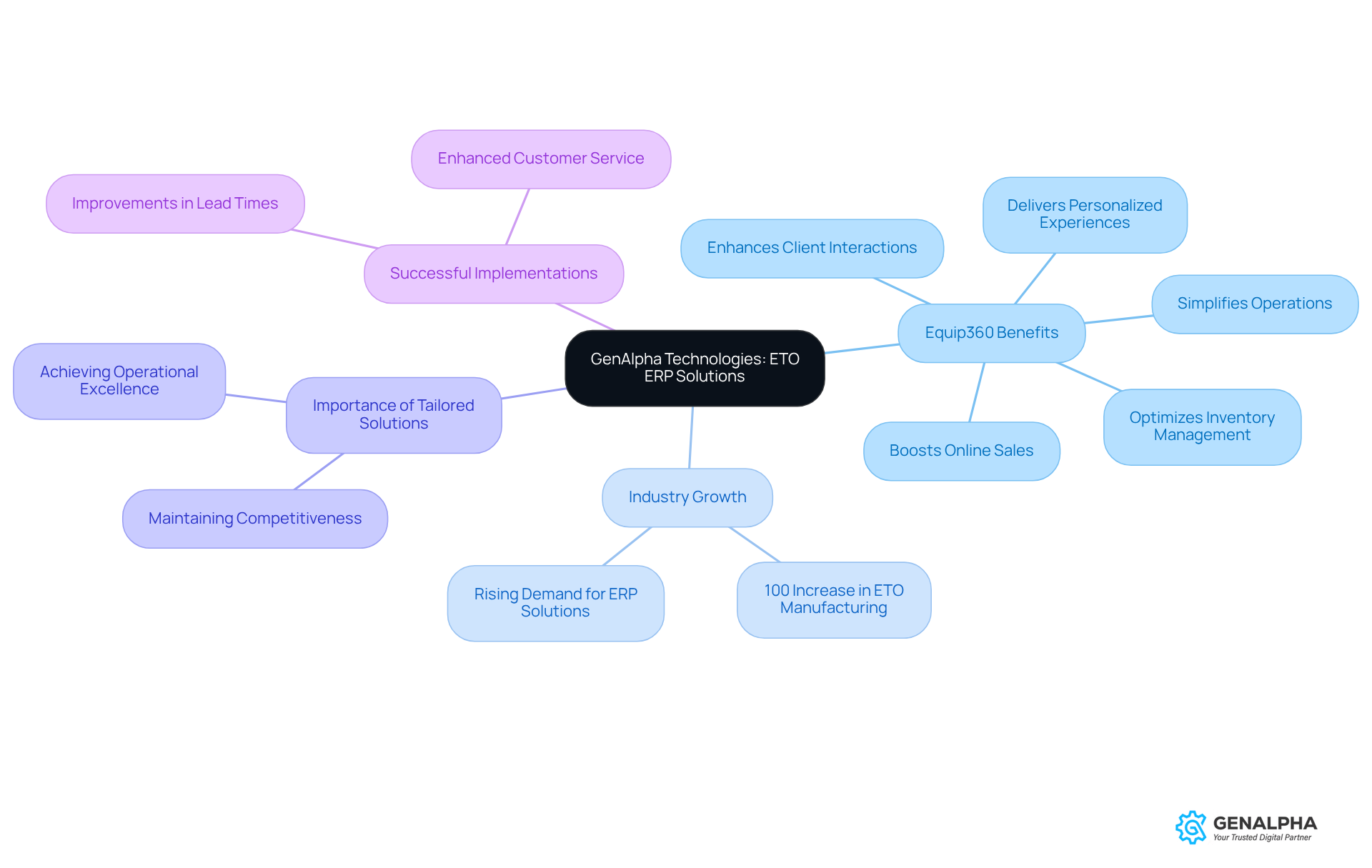

GenAlpha Technologies: Comprehensive ETO ERP Solutions for Manufacturers

GenAlpha Technologies really shines when it comes to providing tailored engineer to order ERP software that addresses the unique challenges faced by manufacturers. Their flagship product, Equip360, connects seamlessly with existing systems, offering a robust set of tools designed to simplify operations, enhance client interactions, and optimize inventory management.

Did you know that the ETO manufacturing sector has seen a whopping 100% rise over the last 15 years? That’s right! With such growth, the demand for engineer to order ERP software solutions has become increasingly critical. Equip360 helps businesses boost their online sales capabilities and customer satisfaction by delivering personalized experiences and efficient order management.

Industry leaders emphasize that choosing engineer to order ERP software specifically designed for manufacturing processes is crucial for maintaining competitiveness and achieving operational excellence. As Thomas R. Cutler, President and CEO of TR Cutler, Inc., puts it, "Selecting the right ERP is one of the most crucial choices a producer will make."

Successful implementations of engineer to order ERP software have demonstrated significant improvements in lead times and customer service. This really highlights the importance of adopting solutions like Equip360 that meet the unique needs of ETO producers. So, are you ready to take your manufacturing operations to the next level?

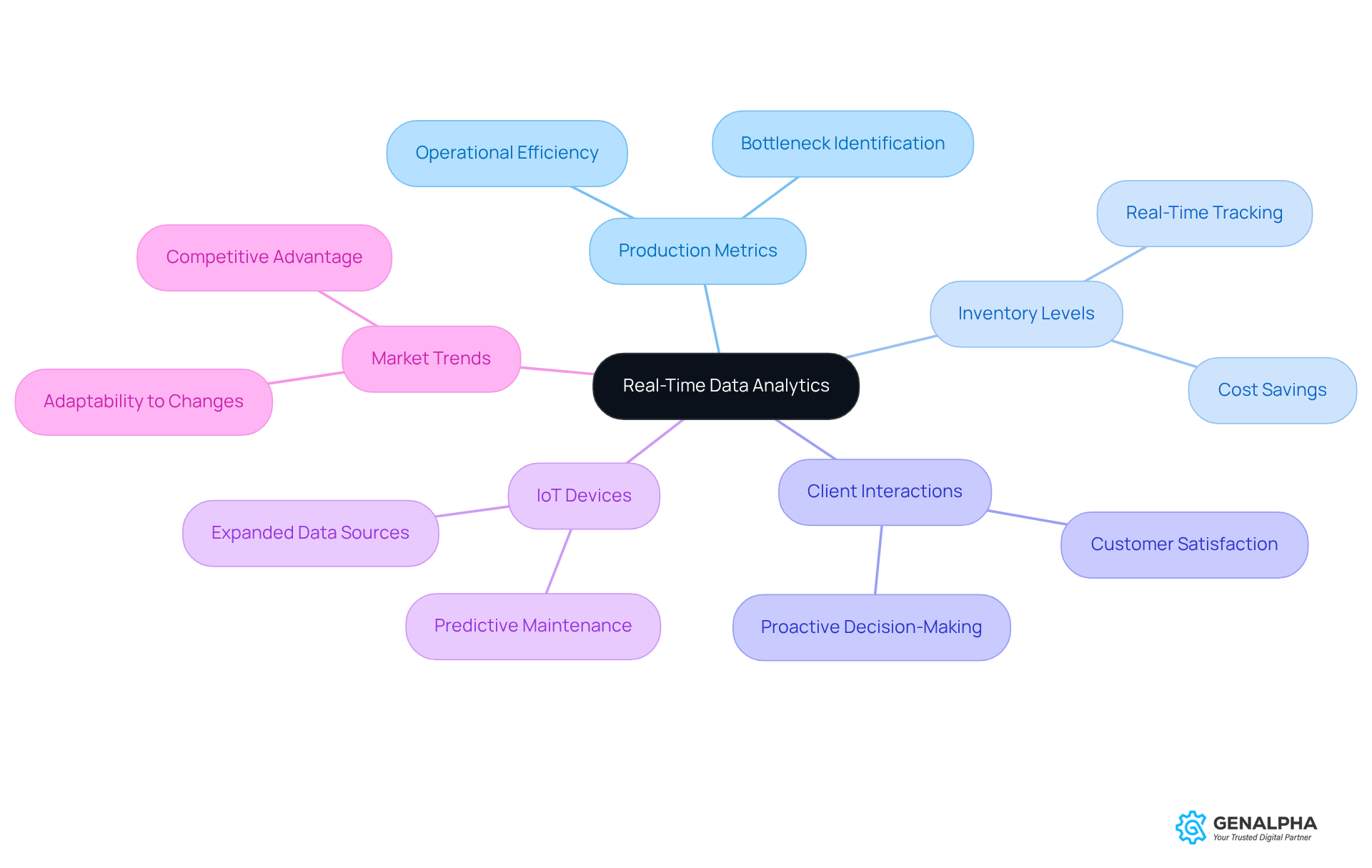

Real-Time Data Analytics for Informed Decision-Making

Have you ever thought about how real-time data analytics can change the game for businesses? When integrated into engineer to order ERP software, it enables producers to monitor production metrics, inventory levels, and client interactions in real-time. This means businesses can quickly adapt to market changes, optimize how they use their resources, and really boost their operational efficiency.

Imagine being able to make decisions based on real-time insights! It’s not just about enhancing profitability; it’s also about making customers happier. Industry experts point out that having access to timely data encourages a proactive approach to decision-making. This way, producers can spot trends, minimize risks, and grab opportunities as they pop up.

And let’s not forget about the role of IoT devices. They expand the sources of data, giving a fuller picture of what’s happening on the factory floor. With the global big data analytics market expected to soar to over $68 billion by 2025, it’s clear that embracing real-time data analytics is more important than ever.

Plus, with the increasing focus on security in data analytics platforms, sensitive information is better protected. This not only enhances operational efficiency but also sharpens decision-making capabilities. So, why not take the leap and explore how real-time data analytics can transform your business?

Customizable Workflows to Fit Unique Manufacturing Needs

Have you ever felt overwhelmed by the unique demands of a project? That’s where engineer to order ERP software plays a crucial role! They offer customizable workflows that let producers tailor their processes to fit specific operational needs. This flexibility is a game-changer, especially when managing complex projects with unique specifications and customer requests.

Imagine being able to create workflows that align perfectly with your production processes. By doing so, you can boost efficiency, reduce mistakes, and improve overall project management. It’s all about making your life easier and your projects more successful.

So, why not explore how engineer to order ERP software can transform your workflow? You might just find the solution you’ve been looking for!

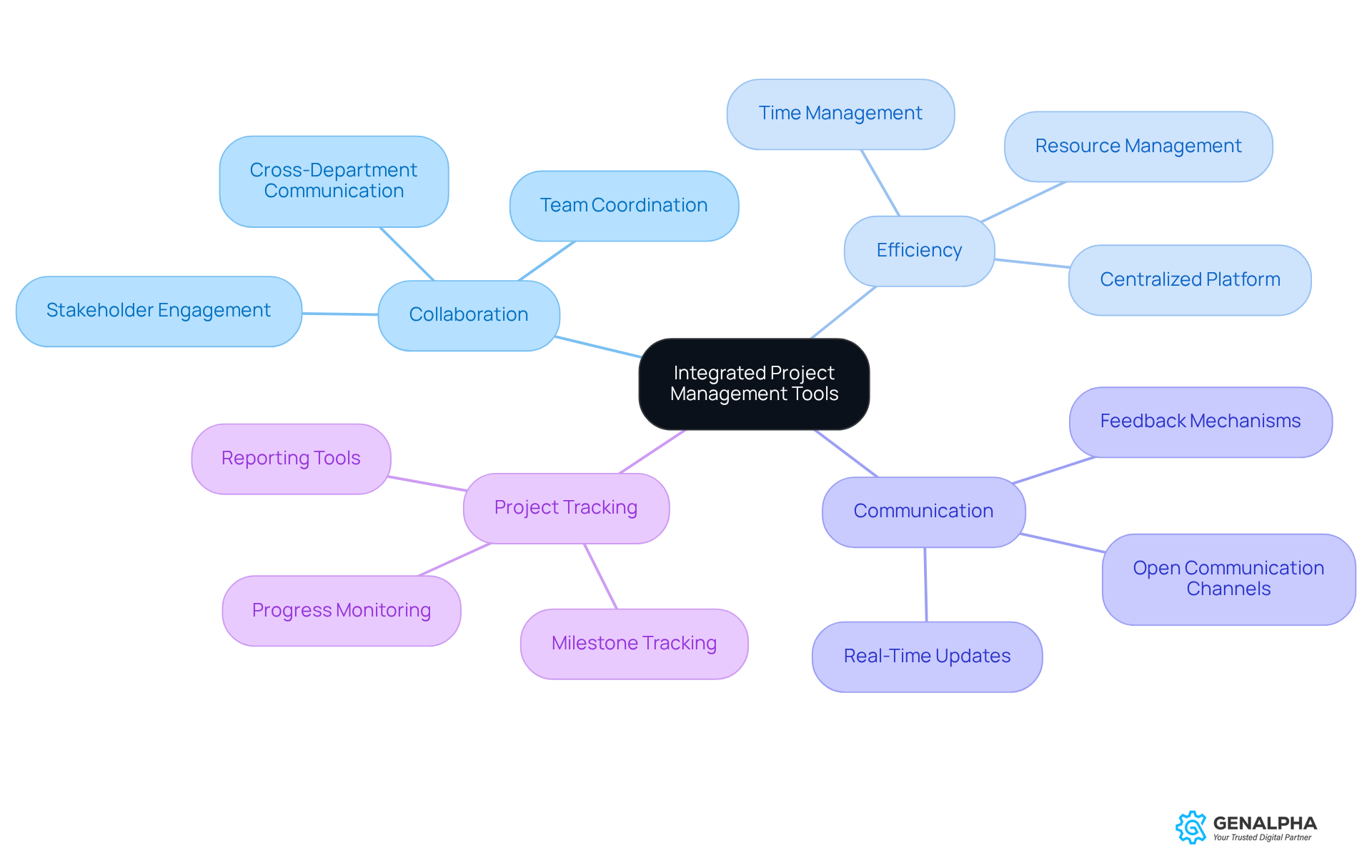

Integrated Project Management Tools for Complex Projects

Have you ever felt overwhelmed managing a project from start to finish? The integration of project management tools within engineer to order ERP software can really make a difference. They help producers keep track of complex projects, ensuring everything runs smoothly from inception to completion.

These tools are fantastic for fostering collaboration across departments. Imagine everyone - stakeholders, team members, and managers - being on the same page throughout the project lifecycle. It’s all about keeping communication open and clear.

By offering a centralized platform for tracking progress, managing resources, and sharing updates, producers can utilize engineer to order ERP software to boost project efficiency. Plus, meeting customer deadlines becomes a whole lot easier! So, why not explore how these tools can transform your project management experience?

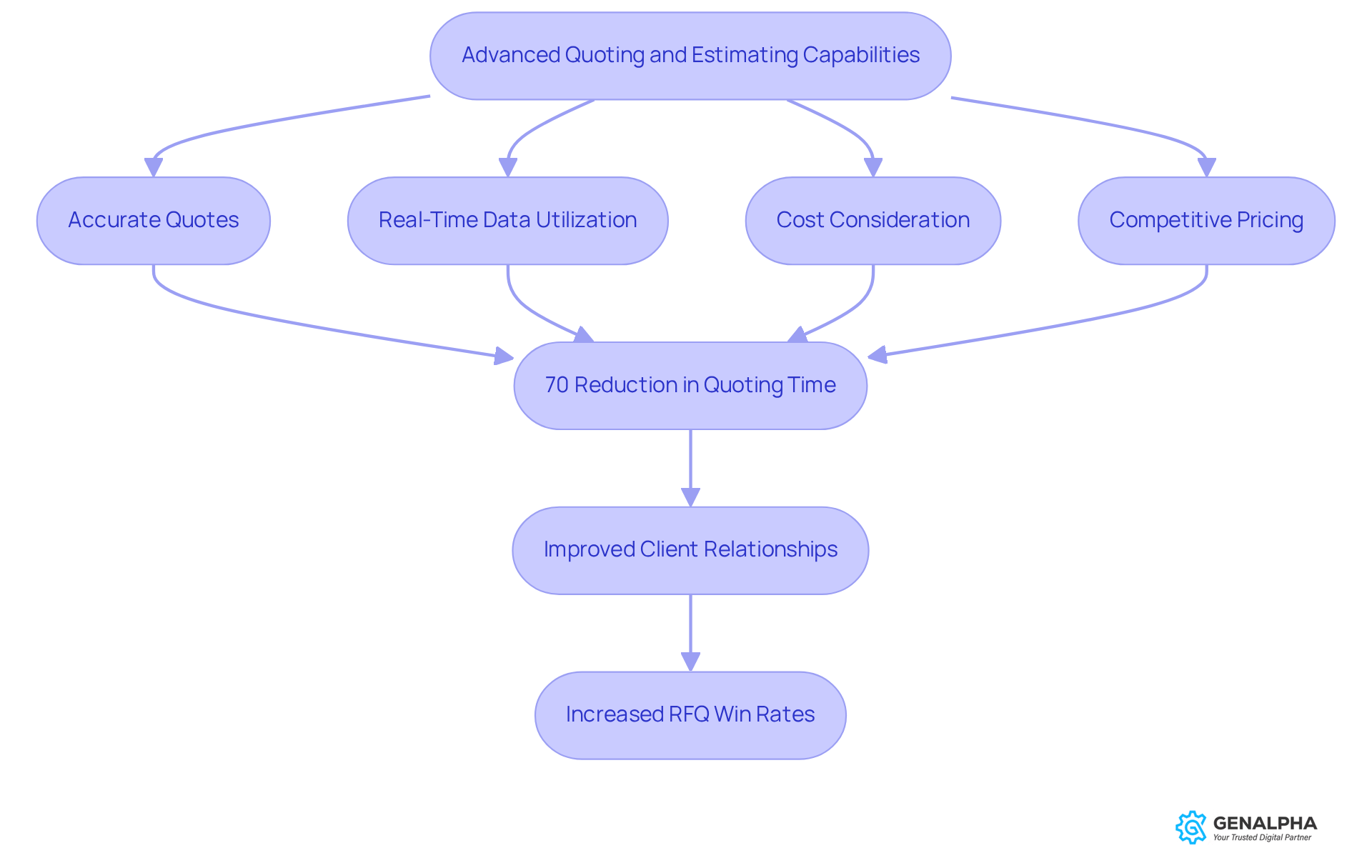

Advanced Quoting and Estimating Capabilities for Accurate Pricing

Have you ever wondered how some manufacturers seem to nail their quotes every time? Well, the advanced quoting and estimating features in engineer to order ERP software are the secret sauce! These tools help producers whip up accurate quotes by tapping into real-time data and detailed project specs. They take into account all costs - materials, labor, and overhead - so manufacturers can set competitive prices that really boost their profit margins.

And get this: businesses using AI-driven quoting systems have seen a jaw-dropping 70% reduction in quoting time! That’s right - AI is not just a buzzword; it’s a game changer for efficiency in the quoting process. This speed-up doesn’t just help sales teams work faster; it also strengthens client relationships by delivering timely and precise quotes.

Take Flex, for example. They revamped their quoting process and skyrocketed their RFQ win rates from 15% to 68% by using advanced quoting tools. This really highlights how crucial accurate pricing is for profitability and building trust with customers. After all, nobody wants to risk underpricing their products!

Industry leaders are echoing this sentiment, emphasizing that precise pricing strategies and engineer to order ERP software with CPQ solutions are essential for producers to remain competitive. So, if you want to seize market opportunities and boost your sales performance, it’s time to consider how you can enhance your quoting process!

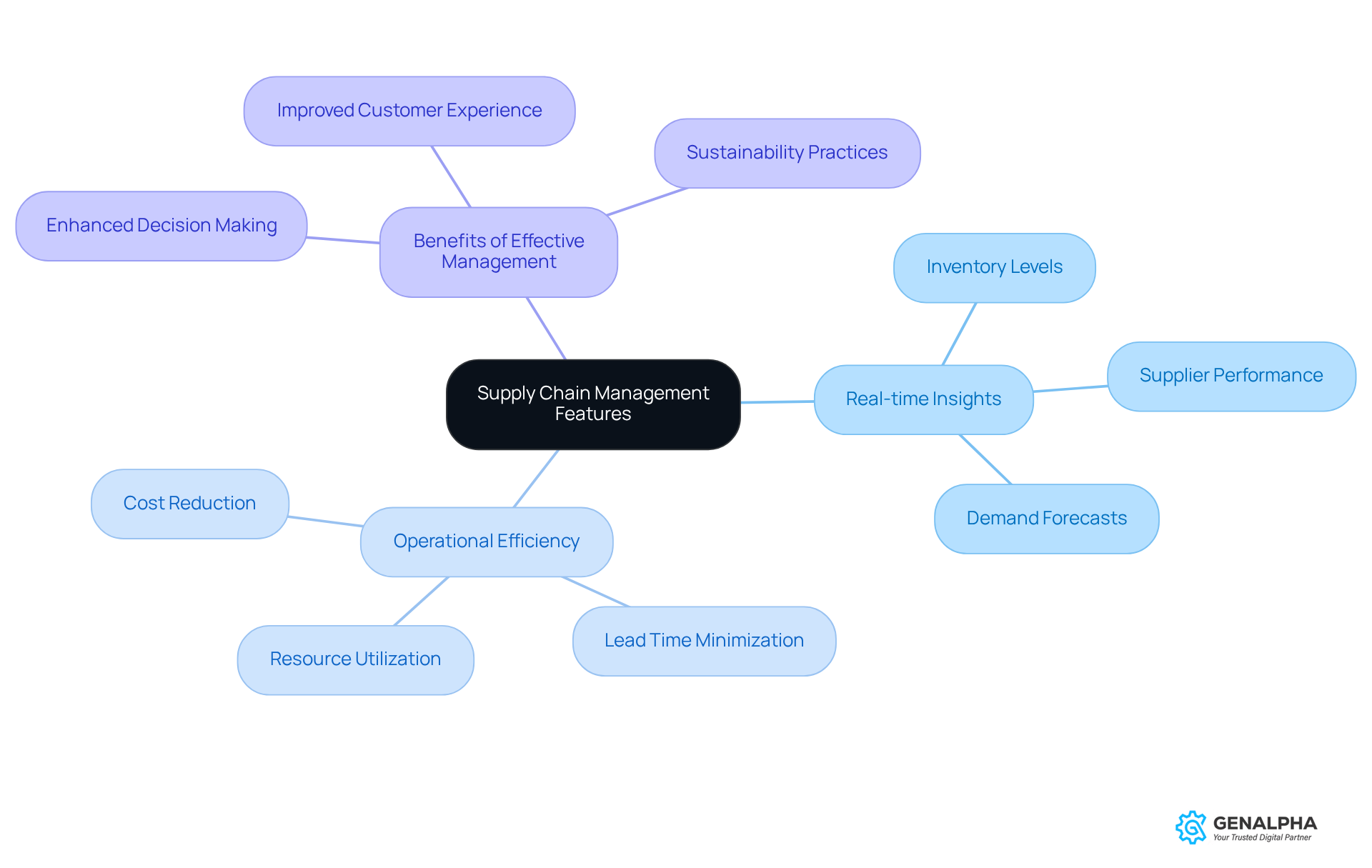

Supply Chain Management Features for Efficient Resource Allocation

Have you ever wondered how some producers seem to have their supply chains running like a well-oiled machine? Well, that’s where engineer to order ERP software solutions come into play! These tools are designed to help producers enhance resource distribution and simplify procurement procedures.

Imagine having real-time insights into your inventory levels, supplier performance, and demand forecasts. Sounds helpful, right? That’s exactly what these solutions offer! They assist producers in making informed choices that boost operational efficiency.

When supply chain management is effective, it can really make a difference. It reduces lead times, minimizes costs, and ensures that resources are utilized effectively to meet production demands. So, why not consider how engineer to order ERP software could transform your operations? Let's explore the possibilities together!

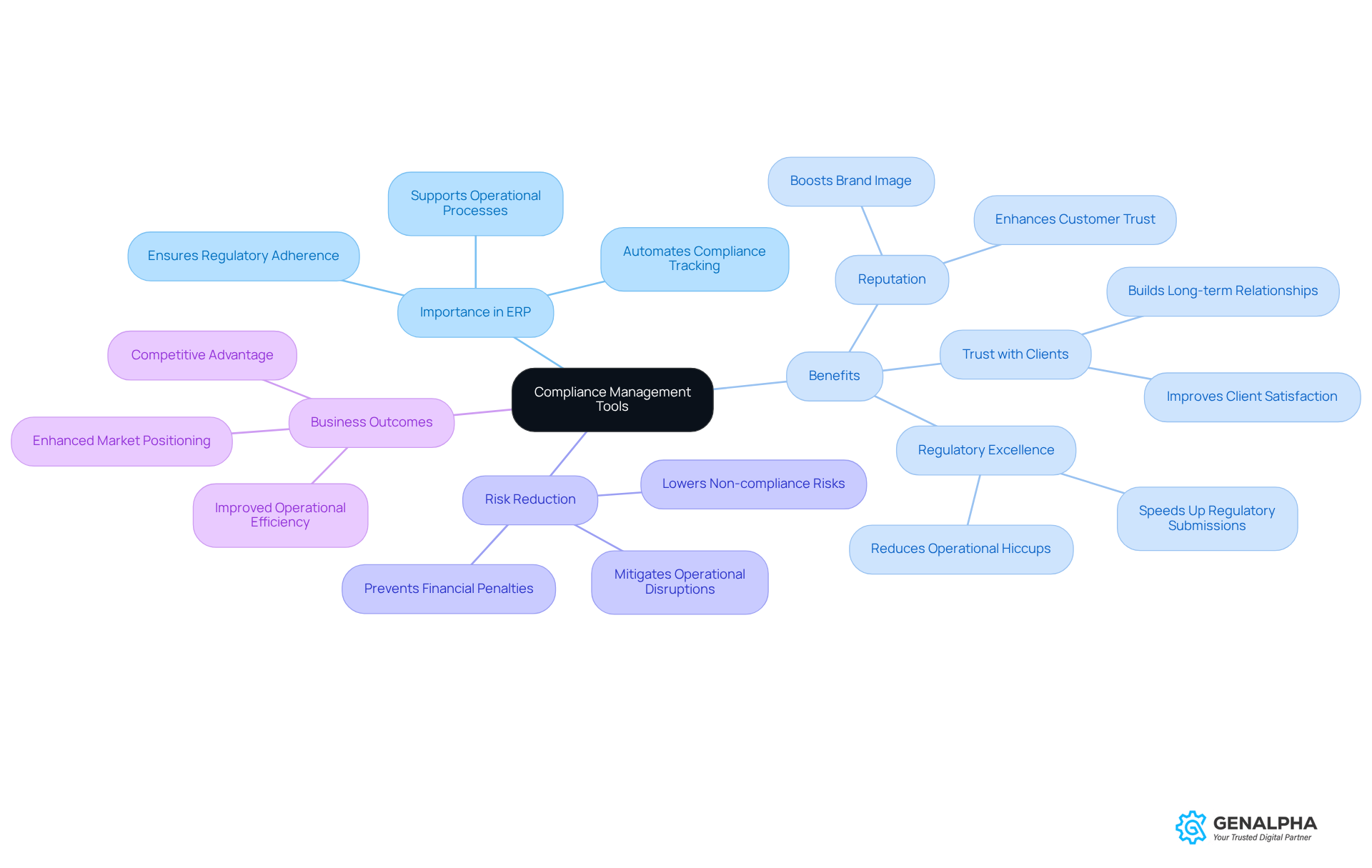

Compliance Management Tools to Ensure Regulatory Adherence

Have you ever thought about how compliance management tools can make a difference in engineer to order ERP software systems? For producers trying to navigate the tricky waters of regulations, these tools are absolutely essential. They automate compliance tracking and reporting, making sure that every operational process meets industry standards and regulations.

By managing compliance effectively, producers can significantly lower the risk of non-compliance and the nasty penalties that come with it - penalties that can really hurt their operations. Plus, when companies uphold strong compliance practices, they not only boost their reputation but also build trust with clients. And who doesn’t want better business outcomes?

For example, organizations that embrace comprehensive ERP-supported compliance capabilities often find that they can speed up regulatory submissions and cut down on operational hiccups. This proactive approach doesn’t just shield them from potential violations; it also gives them a leg up in a competitive market, showcasing their commitment to quality and regulatory excellence.

So, why not take a closer look at how these tools can work for you? It might just be the game-changer your business needs!

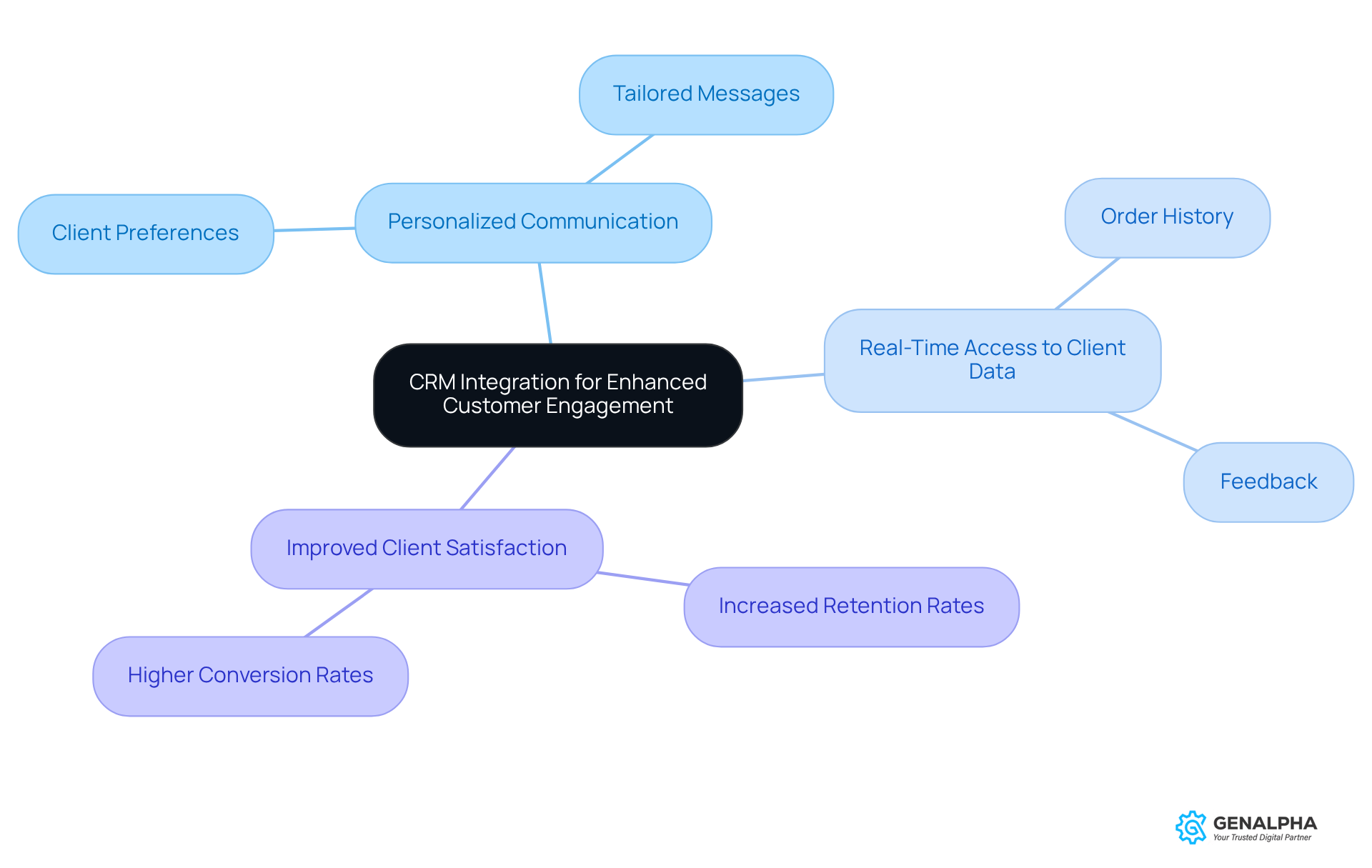

CRM Integration for Enhanced Customer Engagement

Have you ever wondered how some companies seem to know exactly what you want? Integrating CRM systems with engineer to order ERP software can help producers achieve just that! This integration gives sales teams a complete view of client interactions, making it easier to connect on a personal level.

Imagine having real-time access to client preferences, order history, and feedback right at your fingertips. This means personalized communication and service delivery become second nature. By tapping into CRM insights, producers can use engineer to order ERP software to boost client satisfaction and build long-lasting relationships.

So, why not take the leap? Embrace this integration and watch how it transforms your client engagement strategy!

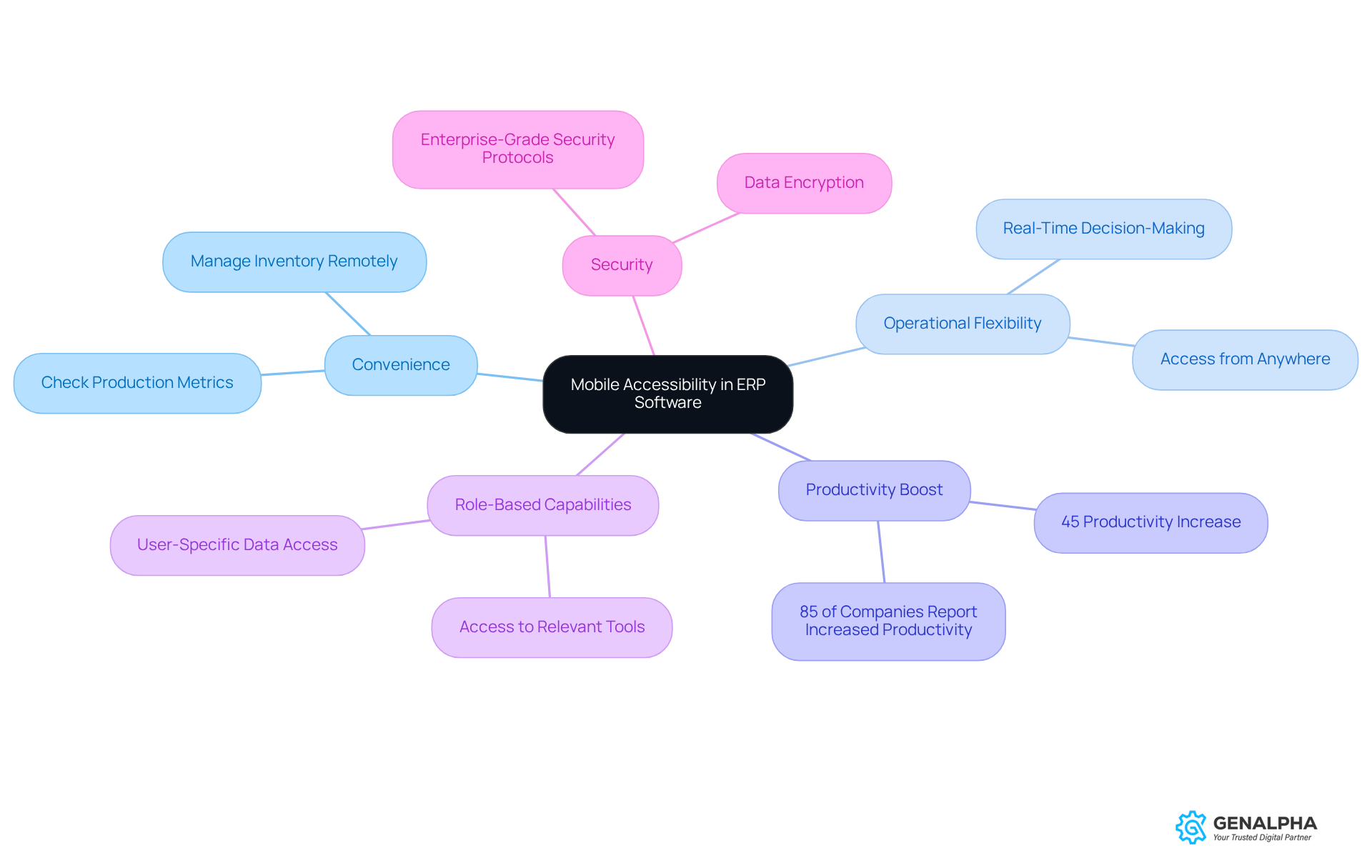

Mobile Accessibility for On-the-Go Information Access

Imagine being able to check on your production metrics or manage inventory right from your phone, no matter where you are. Sounds convenient, right? That’s exactly what mobile accessibility in engineer to order ERP software provides. It allows employees to stay connected and informed while on the go, making it easier to communicate with team members and respond to customer needs quickly.

By embracing mobile access, producers can really boost their operational flexibility. Think about it: real-time decision-making can lead to faster responses and better service. In fact, research from IQMS Manufacturing Software shows that companies that have jumped on the mobile tech bandwagon have seen productivity soar by up to 45% and operational efficiency jump by as much as 44%!

As Liz, a well-respected enterprise technology writer, puts it, "Mobile ERP not only streamlines processes but also fosters a culture of agility and responsiveness, which is essential for thriving in today's competitive landscape." This means that having up-to-date information at your fingertips can enhance reporting accuracy and support informed decision-making, ultimately driving business success.

Plus, mobile ERP solutions come with role-based capabilities, ensuring that users only access the tools and data they need for their specific job functions. And let’s not forget about security-enterprise-grade protocols keep sensitive information safe. So, if you’re a producer looking to stay ahead, engineer to order ERP software is definitely a resource worth considering. Why not explore how it could work for you?

Robust Reporting and Analytics for Strategic Planning

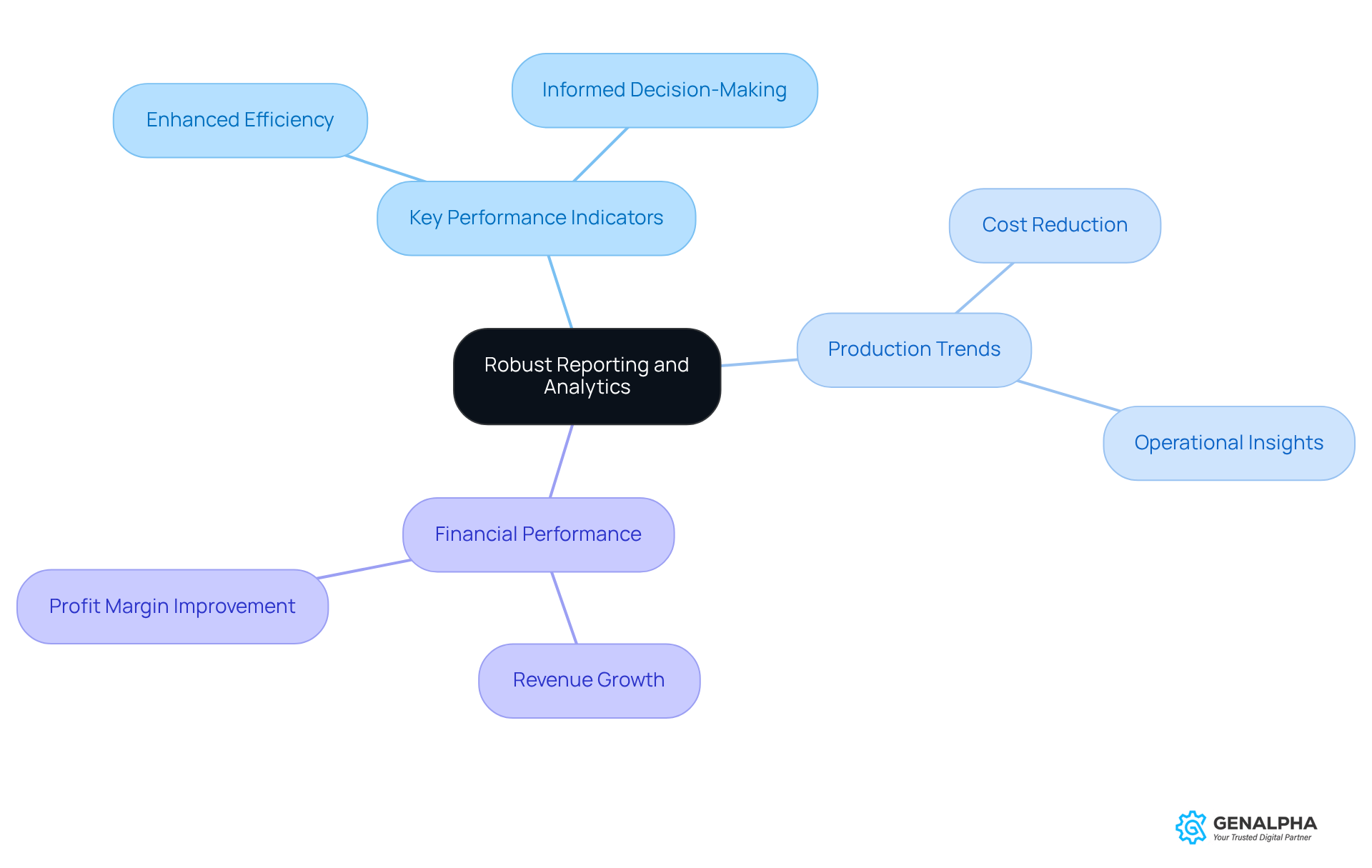

Have you ever wondered how some manufacturers seem to have a pulse on their operations? Well, that’s where robust reporting and analytics capabilities in ETO ERP systems come into play! These tools are like a treasure map, guiding producers to valuable insights about their businesses.

With these systems, businesses can easily track key performance indicators, analyze production trends, and evaluate their financial performance. Imagine being able to see exactly where you stand and what’s working - it’s a game changer! By tapping into these data-driven insights, manufacturers can make smart, informed decisions that not only enhance efficiency but also cut costs and drive growth in today’s competitive marketplace.

So, why not take advantage of these powerful tools? They can truly transform the way you operate, helping you stay ahead of the curve. Let’s embrace the data and see how it can work for us!

Conclusion

You know, the importance of engineer to order (ETO) ERP software for manufacturers really can’t be overstated. With the ETO sector booming, picking the right ERP solution - like GenAlpha Technologies' Equip360 - becomes crucial for manufacturers who want to boost operational efficiency, keep customers happy, and stay ahead of the competition.

Let’s take a closer look at some key features of ETO ERP software. Think about:

- Real-time data analytics

- Customizable workflows

- Integrated project management tools

- Advanced quoting capabilities

- Effective supply chain management

Each of these features plays a vital role in streamlining processes, helping you make informed decisions, and enhancing customer engagement. By tapping into these tools, manufacturers can not only fine-tune their operations but also tackle the unique challenges that come with their projects.

So, why should manufacturers embrace engineer to order ERP software? Well, it’s a smart move for those looking to thrive in today’s fast-paced market. Integrating these advanced features means greater flexibility, efficiency, and compliance, which ultimately drives business success. Now’s the time for manufacturers to explore how these powerful solutions can reshape their operations and lead them toward sustained growth and innovation. What do you think? Ready to take the leap?

Frequently Asked Questions

What is GenAlpha Technologies known for?

GenAlpha Technologies specializes in providing tailored engineer to order (ETO) ERP software solutions for manufacturers, with their flagship product being Equip360.

How does Equip360 benefit manufacturers?

Equip360 connects seamlessly with existing systems and offers tools that simplify operations, enhance client interactions, and optimize inventory management, ultimately boosting online sales capabilities and customer satisfaction.

What trend has been observed in the ETO manufacturing sector?

The ETO manufacturing sector has experienced a 100% rise over the last 15 years, increasing the demand for engineer to order ERP software solutions.

Why is selecting the right engineer to order ERP software important?

Choosing the right ERP software designed for manufacturing processes is crucial for maintaining competitiveness and achieving operational excellence, as emphasized by industry leaders.

What improvements can be expected from successful implementations of engineer to order ERP software?

Successful implementations can lead to significant improvements in lead times and customer service for ETO producers.

How does real-time data analytics enhance business operations?

Real-time data analytics integrated into engineer to order ERP software allows producers to monitor production metrics, inventory levels, and client interactions in real-time, enabling quick adaptations to market changes and optimizing resource usage.

What advantages does real-time data analytics provide?

It encourages proactive decision-making, helps spot trends, minimizes risks, and allows businesses to seize opportunities, ultimately enhancing profitability and customer satisfaction.

What role do IoT devices play in data analytics?

IoT devices expand the sources of data, providing a comprehensive view of factory floor activities and contributing to better decision-making capabilities.

Why is data security important in analytics platforms?

Increased focus on security in data analytics platforms protects sensitive information, enhancing operational efficiency and decision-making capabilities.

How does customizable workflow in engineer to order ERP software benefit manufacturers?

Customizable workflows allow producers to tailor their processes to meet specific operational needs, boosting efficiency, reducing mistakes, and improving overall project management.